Académique Documents

Professionnel Documents

Culture Documents

Alignment Coupling Operation Manual Tyre-Flex

Transféré par

er_sanjaypatelTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Alignment Coupling Operation Manual Tyre-Flex

Transféré par

er_sanjaypatelDroits d'auteur :

Formats disponibles

TYRE-FLEX COUPLINGS

OPERATING

INSTRUCTIONS

Rathi Transpower Pvt. Ltd.

Rathi Chamers, 7, Deccan College Road, PUNE 411 006 (INDIA)

Phone : 91-20-2669 6820, Fax: 91-20-2669 5655

E-mail : info@rathigroup.com

R-OI/T-01/00-12/05

GENERAL

I) Standard features of Tyre-Flex Couplings (Pg. 1)

II) Detail knowledge of this Operating Instructions will ensure trouble free

operation of the Tyre-Flex Coupling. Persons responsible for handling,

installation & use of the coupling shall required & understand these

Operating Instructions.

This coupling is suitable for applications in stationery/mobile use in

engineering industry.

The copyright of these Operating Instructions remains the property of

Rathi Transpower Pvt. Ltd.

For all technical queries please contact

Rathi Transpower Pvt. Ltd.

Rathi Chambers, 7, Deccan College Road, PUNE 411 006 (INDIA)

Phone : 91-20-669 6820, Fax: 91-20-2669 5655

E-mail : info@rathigroup.com

Website : www.rathitranspower.com

TYRE-FLEX COUPLING

INDEX

CONTENTS PAGE

Standard Features 1

TYRE-FLEX Family - At a Glance 2

Elastomer Information 3

Standard Material of Construction 4

Torsional Stiffness for Standard TYRE-FLEX coupling 5

Special features & Constructional details 6-8

of various types of TYRE-FLEX coupling

Ratings for Standard TYRE-FLEX coupling 9

Weight & M.I. of TYRE-FLEX coupling 10

Applications of TYRE-FLEX couplings 11

Selection procedure 12-14

Fit tolerance guide lines for bores with parallel keys 15

Finish bore and keyway procedure 16-17

Standard tolerances for finish bore & keyway 18

Installation & Assembly Instructions 19-30

TYRE-FLEX COUPLING

STANDARD FEATURES

Torsionally soft coupling

Protects against heavy shock due to sudden change in

load

Absorbs vibrations & impact loads

Simple in construction

No lubrication needed

Less down time for alignment or replacement of tyre

Low inventory by utilising same coupling for different

shaft sizes with the help of taper bushes

Permits angular, axial, parallel or combination of

misalignments

All metal parts are coated with anti-corrosive agents

Can be modified as per customers specific

requirement

1

TYRE-FLEX COUPLING

TYRE-FLEX FAMILY AT A GLANCE

Sizes : 15 (T-4 to TO-25)

Power Rating : 3.75 kW to 2310 kW 1500 rpm

(5.02 HP to 3097 HP )@1500 rpm

Bore Range : 32 mm to 190 mm.

Misalignment :

a) Parallel - 1.1 mm. to 6.6 mm.

b) Angular - upto 4 Depends on

sizes

c) Axial - 1.3 mm. to 8.2 mm.

T B With inside

clamping ring

and parallel bore

(T-4 to

T-12)

T - F/H With inside

clamping ring

and taper bore

to suit taper

bush

(T-4 to

T-6)

TO - B With outside

clamping ring

and parallel bore

(TO-14 to

TO-25)

TO - F/H With outside

clamping ring

and taper bore

to suit taper

bush

(TO-7 to

TO-22)

TOFH To permit any

position like FF,

HH, FH in same

flange

(TFH7 to

TFH12)

Application wise

For DBSE, Spacer type RST - 12 to 35

TS - B - 5 to 12

TS - F/H - 5 to 12

For Engine Driven, TF/TOF - 6 to 12

flange type

2

TYRE-FLEX COUPLING

ELASTOMER INFORMATION

Rathi is the only manufacturer, which produces its own

rubber elements in a whole range of compounds, by

conducting specific research and development into rubber

engineering technology.

By combining the benefits of this technology with

mechanical expertise we can optimise power transmission

solutions.

Full laboratory control and a wide range of specialised

equipment ensure high quality and consistency in product

performance.

Specialised compounds can be developed in our

laboratories to meet specific requirements.

Recommended Elastomers for Tyre-flex Coupling

Type Shore hardness Max. operating

temp. (C)

Natural 75 5 70

Synthetic 75 5 100

Fras 75 5 100

3

TYRE-FLEX COUPLING

STD. MATERIAL OF CONSTRUCTION

Component Used in Material

Flange / Adapter/ Hub

B type

F/H type

TFH type

C.I. BS 1452-61 Gr. 12

C.I. BS 1452-61 Gr. 17

C.I. BS 1452-61 Gr. 17

Taper Bush All type C.I. BS 1452-61 Gr. 14

Clamping Ring All type BS 970

Tyre All type Natural ASTM D-2000-720

Optional - Synthetic, Fras

Spacer RST BS 970

Socket head cap screw TS-5 to TS-12

(For Spacer Side

only)

High Tensile BS 4168 Gr. 12.9

Hex. Head screw All type High Tensile BS 4168 Gr. 10.9

Spring washer All type Steel BS 4464

4

TYRE-FLEX COUPLING

TORSIONAL STIFFNESS FOR

STANDARD TYRE-FLEX COUPLING

# TORSIONAL

COUPLING STIFFNESS

SIZE Nm/Deg. ()

4 5

5 13

6 26

7 41

8 63

9 91

10 126

11 178

12 296

14 470

16 778

18 1371

20 1959

22 2760

25 3562

# At Rated Torque

5

TYRE-FLEX COUPLING

SPECIAL FEATURES OF VARIOUS TYPES OF TYRE-FLEX

COUPLING

A. T-B TYPE (Fig. 1)

Simple in construction.

Less down time for replacement of tyre. Alignment quickly checked by

placing straight edge.

Clamping force on tyre is applied from inside through inside clamping

ring by tightening of hex. head screw.

Finish bore & keyway to be done directly in flanges.

B. T-F/H TYPE (Fig. 2)

Flanges are taper bored to suit standard taper bush.

Use of taper bushes of different bore helps to use same coupling for

different shaft diameters.

Easy removal of flanges by loosening of taper bushes.

C. TO (B OR F/H) TYPE (Fig. 3a & 3b)

Easy for installation and alignment.

Clamping force on tyre is applied from outside through outside

clamping ring tightening of hex. head bolts.

Straight bores and taper bores can be done in either or flanges.

D. TFH TYPE (Fig. 4)

Clamping force on tyre is applied through inside clamping ring and

external flange by tightening of hex. head bolts.

Hubs of this type are reversible which permits arranging them in any

position like F/H, F/F, H/H. Hence low inventory is the important

feature of this type.

G. RST TYPE (Fig. 5a & 5b)

Use of shaft ended flanges with adapter helps to use std. tyre-flex

coupling as spacer type for given DBSE .

This type special designed for motor pump installation where drive or

driven equipment are not to disturb while servicing impeller packing

glands, etc.

Reduces maintenance cost.

H. TS TYPE (Fig. 6)

Spacer type coupling to accommodate given DBSE.

Can be provided with straight bore or taper bore to suit standard taper

bushes.

Easy removal of spacer for maintenance purpose.

I. TF TYPE (Fig. 7)

Suitable for engine driven equipment.

Std. coupling can be bolted to flange mounting.

Easy for assembly & disassembly.

6

Available with SAE flanges.

TYRE-FLEX COUPLING

CONSTRUCTIONAL DETAILS OF VARIOUS TYPES OF TYRE-FLEX

Type TO (B) Assly

TYPE B TYPE B

T-4 To T-12 TO-14 To TO-25

Fig. 1 Fig. 3a

TYPE F/H TYPE F/H

T-4 To T-6 TO-7 To TO-22

Fig. 2 Fig. 3b

TYPE T-F/H

TFH-7 To TFH-12

Fig. 4

7 7

TYRE-FLEX COUPLING

CONSTRUCTIONAL DETAILS OF VARIOUS TYPES OF TYRE-FLEX

Type RST(T) Type RST(TO)

Fig. 5a Fig. 5b

Type TS Type TF

Fig. 6 Fig. 7

Nomenclature:-

1) Hub 6) RST Adapter 11) Adapter

2) Tyre 7) RST Spacer 12) Socket Head Cap Screw

3) Clamping Ring 8) Taper Bush 13) Bolted Flange

4) Hex. Head Bolt 9) Flange

5) Spring Washer 10) Spacer Flange

TYRE-FLEX COUPLING

RATINGS FOR STANDARD TYRE-FLEX COUPLING

Sr. Coupling Rated Torque Rated Power

No. Size

Nm kg-m lbs-in. @100 rpm @1500 rpm @ Speed

kW HP kW HP rpm

1 4 24 2.4 212 0.25 0.34 3.75 5.03 1500

2 5 66 6.7 584 0.69 0.92 10.35 13.9 1500

3 6 127 12.9 1123 1.33 1.8 19.95 26.7 1500

4 7 250 25.5 2211 2.62 3.5 39.3 52.7 1500

5 8 375 38.2 3317 3.93 5.3 58.95 79.0 1500

6 9 500 51.0 4422 5.24 7.0 78.6 105 1500

7 10 675 68.8 5970 7.07 9.5 106.05 142 1500

8 11 875 89.2 7739 9.16 12.3 137.4 184 1500

9 12 1330 135.6 11763 13.9 18.6 208.5 279 1500

10 14 2325 237.0 20562 24.3 32.6 364.5 489 1500

11 16 3730 380.2 32988 39.5 52.9 592.5 794 1500

12 18 6270 639.1 55452 65.7 88.1 986.5 1322 1500

13 20 9319 950 82400 97.6 130.8 1464 1962 1200

14 22 11553 1178 102253 121 162.2 1815 2433 1000

15 25 14704 1499 130141 154 206.5 2310 3097.5 1000

9

8

TYRE-FLEX COUPLING

WEIGHT & MI OF TYRE-FLEX COUPLING

Size Type Wt. MI. GD

2

kg kg-m

2

kg-m

2

T-4 B 1.9 0.00161 0.00644

F/H 1.7 0.00148 0.00592

T-5 B 3.5 0.00358 0.01432

F/H 2.7 0.00349 0.01396

T-6 B 5.0 0.0105 0.042

F/H 3.6 0.0103 0.0412

T-7 B 7.8 0.0198 0.0792

TO-7 F 6.35 0.0192 0.0708

H 6.2 0.0157 0.0628

T-8 B 10.9 0.042 0.168

TO-8 F 8.53 0.0303 0.1316

H 8.5 0.0293 0.1172

T-9 B 15.0 0.0681 0.2724

TO-9 F/H 12.0 0.0538 0.2152

T-10 B 21.5 0.1303 0.5212

TO-10 F 18.2 0.1062 0.4592

H 18.1 0.1058 0.4232

T-11 B 28.8 0.1622 0.6488

TO-11 F/H 21.1 0.1461 0.5844

T-12 B 43.1 0.356 1.424

TO-12 F 30.33 0.2627 1.0508

H 30.3 0.2622 1.0488

TO-14 B 60.6 0.6045 2.418

F/H 42.6 0.4922 1.9688

TO-16 B 86.4 1.2755 5.102

F/H 72.6 1.1134 4.4536

TO-18 B 133.3 2.1525 8.61

F/H 123 1.9514 7.8056

TO-20 B 144.6 3.1765 12.706

F/H 158.3 3.0129 12.0516

TO-22 B 181.63 4.7861 19.1444

F/H 195.1 4.8954 19.5816

TO-25 B 281.1 8.129 32.516

Note: Weight & MI are with min. Bores

10

TYRE-FLEX COUPLING

APPLICATIONS OF TYRE-FLEX COUPLING

Tyre-flex coupling are generally used where,

higher shocks & vibration are present

torque fluctuations occurs

impact load occurs

misalignment requirements are more than any other

coupling

These couplings are widely used in reciprocating machines

like I. C. engines, piston pumps & compressors, bucket

elevators, foundry machinery, metal presses, hammer mills,

pulverisers, reciprocating conveyors, rubber machinery,

vibratory screens, clay working machinery, dynamometers,

line shafts, etc.

11

TYRE-FLEX COUPLING

HOW TO SELECT TYRE-FLEX COUPLING

While selecting the coupling, first choose the type of coupling, which

depends on application details like -

a) Type of driver & driven equipment

b) Type of load

c) Misalignment, temperature

d) Space limitations

e) Linear & torsional vibrations

f) Chemical or oil exposure

Then select the size of coupling for which information required is as

stated below.

Requirements

Application : Driver -

Driven -

Application Rating: Power (kW) - Speed(RPM) -

Shaft sizes: Driver - Driven -

Distance between shaft ends (DBSE) if required:

Service Factor (S.F.) to be required/recommended:

Selection Procedure

(a) Service Factor

Determine appropriate SERVICE FACTOR from table A if not given with

above details.

(b) Design Power

Multiply running power of driven machinery by the service factor. This

gives DESIGN POWER, which is used as a basis for coupling selection.

(c) Coupling Size

Refer to rating table for your required coupling size and read from the

appropriate speed column until a power equal to or greater than the

DESIGN POWER is found.

12

TYRE-FLEX COUPLING

(d) Bore size

Refer respective coupling dimensional table to check that the required

bores can be accommodated. If bore size of selected coupling cannot

accommodate the shaft size, then select next coupling size where shaft

size can be accommodated.

(e) While selecting coupling for high-speed application, check -

Peripheral speed = DN m/s

60

where D = Max. diameter of coupling in meters

N = RPM

If peripheral speed 30 m/s use Cast Iron material

30 60 m/s use Cast Steel materiel

(f) Collect the following information while selecting flange type tyre-

flex coupling

Get SAE flange size. If not then obtain following details -

* Flange outside diameter & thickness

* No.of holes, hole diameter and PCD

* Spacing of holes on flange

* Distance between engine flywheel and shaft

end of driven side for deciding total length of

coupling

13

TYRE-FLEX COUPLING

TYPICAL SERVICE FACTORS

Determination of service factors depends on torque fluctuation,

usage time, misalignment, type of application, rotating speed, no.

of start-stops, no. of reversals, etc .

From experience, service factor to be taken for different

applications are:

SERVICE FACTOR TABLE A

TYPE OF DRIVING UNIT

DRIVEN MACHINE CLASS

Electric motor,

steam turbine

Multi cylinder

IC engine or

steam engine or

water turbine

Single cylinder

IC engine or

steam engine

CLASS-1

Agitators, Brewing machinery, Centrifugal

Blowers, Conveyors, Centrifugal fans and

pumps, Generators, Sewage disposal

equipments, Evaporators, Feeders, Textile

machines, Wood working machines.

1.00

1.50

2.00

CLASS-2

Clay working machinery, Crane Hoists, Laundry

machinery, Machine Tools, Rotary mills, Paper

mill machinery, Non-uniformly loaded centrifugal

pumps, Rotary screens, Centrifugal

compressors, Shredders, Printing presses, Oil

industry, Mixers, Food industry, Beaters, Bucket

elevators, Gear pumps, Wood working

machinery, Textile machinery.

1.50

2.00

2.50

CLASS-3

Reciprocating conveyors, Crushers, Shakers,

Metal mills, Rubber machinery (Banbury mixers

& mills), Reciprocating compressors, Welding

sets, Freight & passenger elevators, Cooling

tower fans, Hammer mills, Reciprocating

pumps, Vibrating screens, Winches, Wire

drawing machines.

2.50

2.50

3.00

14

TYRE-FLEX COUPLING

FIT TOLERANCE GUIDE LINES FOR BORES WITH PARALLEL KEYS

Bore

Required Fit

Above

mm

To

mm

Shaft

Tolerances

Bore Tolerances

Shaft tolerance 25 k6

as per RATHI 25 100 m6

100 n6

H7

Shaft tolerance 50 k6

as per DIN 740/1 50 m6

H7

Shaft with 50 K7

unified system 50

h6

M8

all h8 N7

It is necessary to select required fit in order to -

1) Keep low backlash between hub & shaft.

2) Keep the hub stress under permissible range.

If these instructions on selection of fit are not followed there

is danger of bursting of the coupling.

There is a danger to human life due to broken parts flying

around.

TYRE-FLEX COUPLING

FINISH BORE & KEYWAY PROCEDURE

1. Rathi couplings are supplied with pilot bore unless asked for

finish bore. It should be bored to reqd. finish bore size by

taking the reference of the outside diameter (OD) of coupling

i.e. turn bore concentrically with respect (true) to the coupling

OD & not the hub dia. (Refer fig. A)

2. Clamp the hub OD on lathe and true the coupling OD. Ensure

finish bore concentricity w.r.t. coupling OD is better than

0.1mm.

3. Unless specified, std. tolerances provided for FB & keyway is

H7 and Js9 respectively.

4. Use dial bore gauge or plug gauges for respective size of bore.

(If plug gauge is used then ensure that Go end of gauge will

pass straight way throughout bore length.)

The maximum bore capacity as specified in Chart No. xxx and

should not be exceeded.

5. Make chamfer of reqd. size on both sides of bore.

6. Keyway to be done on slotting m/c. or broaching m/c. Mark

the keyway centre line such that key should come in between

two holes in tyre-flex coupling flange. (Refer fig. B)

7. Keyway shift from marked keyway centre line should be within

0.1 mm.

8. A tapped hole is provided on the hub at keyway location to

hold (lock) the key in shaft-hub with a set screw of suitable

size. This tapping is generally provided at midpoint of the

length through bore distance. If it is not possible to use set

screw at midpoint, suitable distance nearer to midpoint of the

length through bore is provided. (Refer fig. C)

1) Length of the set screw to be used on key for tightening

should be of length that will cover the threaded length of

hole.

2) Diameter of set screw should be equal to or less than keyway

width.

9. Use appropriate set screw to ensure effective locking of the

key.

For fitting couplings on splined shaft / taper shaft, please consult

RATHI.

Non observance of these instructions may lead to failure of the

coupling.

16

TYRE-FLEX COUPLING

FINISH BORE & KEYWAY PROCEDURE

17

TYRE-FLEX COUPLING

STANDARD TOLERANCES FOR FINISH BORE & KEYWAY

Unless otherwise specified, couplings are supplied with finish bores &

keyways in H7 & Js9 tolerances respectively & are as per ISO 286-

2:1988 standard.

A - Bore

B - Keyway Depth

C - Keyway Width

Basic Size (mm.) H7 Js9 For

Above Upto &

including

For Bore

(mm.)

For Keyway Width

(mm.)

Keyway Depth

(mm.)

3 6

+ 0.012

0

0.015

6 10

+ 0.015

0

0.018

+ 0.1

0

10 18

+ 0.018

0

0.021

18 30

+ 0.021

0

0.026

30 50

+ 0.025

0

0.031

+ 0.2

50 80

+ 0.030

0

0.037 0

80 120

+ 0.035

0

0.043

120 180

+ 0.040

0

0.050

+ 0.3

180 250

+ 0.046

0

0.057 0

250 315

+ 0.052

0

0.065

+ 0.4

315 400

+ 0.057

0

0.070 0

400 500

+ 0.063

0

0.077

+ 0.5

0

18

TYRE-FLEX COUPLING

INSTALLATION & ASSEMBLY INSTRUCTIONS

(A) BEFORE INSTALLATION

a. After removing the coupling from packing, thoroughly

inspect to ensure that they is/are as ordered & there no is

transit damage or loss.

b. Remove protective coating/lubricant from bores &

keyways. Remove all the bolts & nuts and dismantle the

assembly.

c. Follow instruction given on page no. 18, if couplings are

pilot bored. (Fig. 1)

(Fig. 1)

(B) MOUNTING PROCEDURE

Mount hubs/adapters (*) on their respective shafts with keys

such that the shaft ends are flush with inner face of the

adapter & tighten the set screw over the keys. Bring both the

coupling hubs/adapters (along with equipments) closer so as

to maintain gap `M' as shown in fig. 2. In case of spacer type

couplings, the gap `M' is equal to the spacer length (spacer

length is normally equal to the distance between shaft ends of

the equipments). Refer fig. 3 Refer Dimension M given in

table A1 & A2 on page nos. (25) & (26) respectively.

* FLANGE - Tyre-flex flange

* ADAPTER - Used in RST

or TS coupling

19

TYRE-FLEX COUPLING

For normal applications the shaft ends should be flush with

inner face of flange/adapter. They can protrude beyond the

clamping ring of flange/adapter or remain inside if reqd. but

sufficient gap should be allowed to take care of end float of

both shafts (i.e. axial misalignment). Refer fig. 2

(Fig. 2)

Ensure that the effective length of key is sufficient for

transmission of rated torque of coupling.

20

TYRE-FLEX COUPLING

(C) ALIGNMENT PROCEDURE

Alignment procedure is given separately for each type of alignment for

simplicity. However combination of all 3 types of misalignments may be

present at the same time.

(I) CHECKING PARALLEL ALIGNMENT

(fig 3a) (fig 3b)

Using straight edge (fig 3a): Align straight edge on OD of one

flange, measure gap X at 4 places 90 apart without rotating

shafts. Gap X should be less than the allowable initial parallel

misalignment (P) mentioned in Table A1.

Using dial gauge (fig 3b): Fix dial gauge on hub OD of one of the

halves & set plunger on the flange OD of another half. Rotate

the coupling slowly to one complete revolution by taking dial

gauge reading at 4 places 90 apart. The parallel misalignment

is half of the Total Indicated Reading (TIR) of dial gauge which is

equal to valve of P given in Table C1.

Follow the same procedure in case of spacer coupling as shown

in fig. 3c.

(fig. 3c)

21

TYRE-FLEX COUPLING

(II) CHECKING ANGULAR ALIGNMENT

(fig. 4a) (fig. 4b)

Measure gap M at 4 places 90 apart without rotating shafts.(Refer

fig. 4a) The difference in max. & min. gap will be the Total Indicated

Reading (TIR), which will be the angular misalignment present (Refer

table A1 for allowable TIR values in mm).

Using dial gauge (fig 4b) : Fix the dial gauge on flange OD of one of

the halve & set plunger on the face of another half as shown (Refer

fig. 4b). Rotate the coupling slowly to one complete revolution by

taking dial readings at 4 intervals 90 apart. The Total Indicated

Reading (TIR) will be the angular misalignment (Refer table A1).

Follow the same procedure in case of spacer coupling as shown in

fig. 4c.

(fig. 4c)

22

TYRE-FLEX COUPLING

III) CHECKING AXIAL MISALIGNMENT (End-Float)

Deviation from standard DBSE due to axial movement of

shaft is defined as axial misalignment. (End float). [For

normal applications if the shaft ends should be flushed

with inner face of flange. In some special cases the shaft

ends may protrude beyond the inner face of flange or may

remain inside if required.]

The distance between two faces of coupling halves is to be

maintained as specified. The variation in this distance

should not exceed the permissible initial axial misalignment

given in table A1.

Repeat the all above steps until the required permissible

initial misalignment limits are achieved. Tighten foundation

/ base frame bolts & ensure the tightening of set screws

over keys.

The misalignment capabilities shown in drawings & product

literature allow for dynamic conditions & variations. For

optimum service from the coupling, the installation

misalignment (initial misalignment) should not exceed 25%

of the maximum allowable misalignment limits. Allowance

should be made for any anticipated movements, which will

occur during operation (e.g. thermal movements)

IMPORTANT: The necessity for shields & guards varies with

individuals installations. The owner or user must provide

the required safety guards. Safety guards or shields are not

furnished by us with this equipments.

23

TYRE-FLEX COUPLING

TABLE A1

COUP. SIZE PERMISSIBLE INITIAL MISALIGNMENT DIST. BETWEEN

FLANGES

PARALLEL

/ RADIAL

AXIAL ANGULAR

* (Std. gap M)

P (mm) (mm) (degree) Total

Indicated

Reading

(TIR)

T

TO

T-4 0.275 0.32 0.5 0.7 21 -

T-5 0.325 0.42 0.5 0.87 25 -

T-6 0.4 0.5 0.5 1.09 30 -

T-7 / TO-7 0.475 0.58 0.5 1.25 42 16

T-8 / TO-8 0.525 0.65 0.5 1.45 44 21

T-9 / TO-9 0.6 0.75 0.5 1.64 49 24

T-10 / TO-10 0.65 0.82 0.75 2.82 54 20

T-11 / TO-11 0.725 0.92 0.75 3.05 51 21

T-12 / TO-12 0.8 1.0 0.75 3.45 54 25

TO-14 0.925 1.15 0.75 4.07 - 22

TO-16 1.05 1.32 1 6.02 - 8

TO-18 1.2 1.5 1 6.95 - 22

TO-20 1.325 1.65 1 7.48 - 30

TO-22 1.45 1.81 1 8.27 - 27

TO-25 1.65 2.06 1 9.28 - 30

T-4 0.275 0.32 0.5 0.7 21 -

Gap M in the above table is when angular & axial misalignments are

zero.

Note : For permissible maximum misalignments, refer table A2.

The permissible initial misalignments given in the above

table must not be exceeded during installation.

The permissible initial misalignments given in the above

table parallel, axial and angular must not occur

simultaneously.

24

TYRE-FLEX COUPLING

TABLE A2

COUP. SIZE PERMISSIBLE MAXIMUM MISALIGNMENT DIST. BETWEEN

FLANGES

PARALLEL

/ RADIAL

AXIAL ANGULAR

* (Std. gap M)

P mm

(mm) (degree) Total Indicated

Reading (TIR)

T TO

T-4 1.1 1.3 2 2.86 21 -

T-5 1.3 1.7 2 3.49 25 -

T-6 1.6 2.0 2 4.36 30 -

T-7 / TO-7 1.9 2.3 2 5.03 42 16

T-8 / TO-8 2.1 2.6 2 5.83 44 21

T-9 / TO-9 2.4 3.0 2 6.56 49 24

T-10 / TO-10 2.6 3.3 3 11.32 54 20

T-11 / TO-11 2.9 3.7 3 12.20 51 21

T-12 / TO-12 3.2 4.0 3 13.84 54 25

TO-14 3.7 4.6 3 16.30 - 22

TO-16 4.2 5.3 4 24.10 - 8

TO-18 4.8 6.0 4 27.80 - 22

TO-20 5.3 6.6 4 29.92 - 30

TO-22 5.8 7.25 4 33.06 - 27

TO-25 6.6 8.25 4 37.11 - 30

Gap M in the above table is when angular & axial misalignments are

zero.

Important: At the time of installation, INITIAL misalignments should not

exceed 25% of the permissible maximum misalignments.

Note: For permissible initial misalignments, refer table A1.

The maximum permissible misalignments given in the above

table must not be exceeded during operation.

The maximum permissible misalignments given in the above

table parallel, axial and angular must not occur

simultaneously.

25

TYRE-FLEX COUPLING

(D) ASSEMBLY PROCEDURE

After ensuring that the equipments are aligned properly, follow the

instructions as given below for assembly of couplings.

FOR T/TO/TFH

Open Tyre and fit it over the T/TO/TFH flanges ensuring that the Tyre

beads are properly inserted between the T/TO/TFH flanges & the

internal/external rings. It may be necessary to strike the outside

diameter (i.e. circumference) of Tyre with a small mallet. When seated

there should be a gap E between the Tyre ends. Tighten clamping

ring screws evenly (half turn a time) working round each flanges until

the required screw torque is achieved. Refer table B for gap E and

clamping screw tightening torque.

FOR RST

Clamp one clamping ring to T/TO flange mounted on shaft. Then

insert the flange mounted RST shaft assembly (along with clamping

ring) between RST adapter & T/TO flange and bolt it to the RST

adapter. Fit the T element as per above instructions. (Refer fig. 5 )

Fig. 5

26

TYRE-FLEX COUPLING

FOR TS

Clamp one clamping ring to each T/TO to flange. Then insert them

in between two adapter and bolt it to TS adapter as shown in fig.

6. Fit the T element as per above instructions.

Fig. 6

IMPORTANT : If the supplied coupling is dynamically balanced,

ensure that the match marks (e.g. nos., alphabets) are in straight

line & unidirectional before bolting the spacer assy. with both the

adapters. It is applicable to non-spacer couplings where match

marks on hubs / adapters have to be matched.

The tyre must not come in contact with cleaning agent.

The necessity of shields and guards varies with

individual installations. The owner or user must

provide the required safety guards. Safety guards or

shields are not in our scope of supply.

Use Loctite to prevent the loosening of threads, if required.

27

TYRE-FLEX COUPLING

TABLE B

RECOMMENDED TIGHTENING TORQUE

COUPLING

SIZE

BOLT SIZE TIGHTENING

TORQUE (Nm)

END GAP

E (mm)

T-4 M6 X 1P 15 3

T-5 M6 X 1P 15 3

T-6 M6 X 1P 15 3

T-7 M8 X 1.25P 24 3

T-8 M8 X 1.25P 24 3

T-9 M10 X 1.5P 40 3

T-10 M10 X 1.5P 40 3

T-11 M12 X 1.75P 40 3

T-12 M12 X 1.75P 50 3

T-14 M12 X 1.75P 55 3

T-16 M16 X 2P 80 3

T-18 M16 X 2P 105 3

T 20 M 20 X 2.5P 120 3

T 22 M 20 X 2.5P 165 3

T- 25 M 24 X 3P 165 3

Tightening torque must be observed as given above &

tightening of the opposite bolts to be done.

28

TYRE-FLEX COUPLING

INSTALLATION & REMOVAL OF FLANGES/ADAPTERS

WITH TAPER BUSHES.

Sizes - 1008 to 3030 Size - 3525 to 5050

A) TO ASSEMBLE

1. Clean and de-grease the bore and taper surfaces of the bush and the

tapered bore of the flanges/adapters. Insert the bush in the coupling

flanges/adapters and line up the holes (half thread holes must line up

with half straight holes)

2. Lightly oil the grub screws (bush size 1008 to 3030) or the cap screws

(bush size 3525 to 5050) and screw them loosely in holes threaded in

flanges/adapter shown thus in diagram, do not tighten yet.

3. Clean and de-grease the shaft. Fit the coupling flanges/adapter with

taper bush on shaft and locate in desired position.

4. When using a key it should first be fitted in the shaft keyway. There

should be a top clearance between the key and the keyway in the bore.

5. Using a hexagon socket wrench, gradually tighten the grub/cap

screws in accordance with the torques as listed in the Table C of screw

tightening torques.

6. When the drive has been operating under load for half to one hour

check and ensure that the screw are not loosened. If found loose take

appropriate steps.

29

TYRE-FLEX COUPLING

B) FOR REMOVAL

1. Slacken all screws. Remove one or two according to number of

jacking off holes shown thus in the diagram. Insert these screws in

jacking off holes.

2. Tighten screw(s) uniformly and alternately until the bush is loose in

the flanges/adapters and coupling is free on the shaft.

3. Remove coupling assembly from the shaft.

TABLE C

Taper Bush Screw Screw

Size

tightening

Torque(Nm]

Size Qty Tightening

Wrench

Size

1008 5.6 1/4 BSW 2 3

1108

1210 20 3/8 BSW 2 5

1215

1610 20 3/8 BSW 2 5

1615

2012 31 7/16 BSW 2 6

2017

2517 48 1/2 BSW 2 6

2525

3020 90 5/8 BSW 2 8

3030

3525 112 1/2 BSW 3 10

3535

4030 170 5/8 BSW 3 12

4040

4545 192 3/4 BSW 3 14

5050 271 7/8 BSW 3 14

30

Vous aimerez peut-être aussi

- Tyre-Flex Coupling DeatilsDocument19 pagesTyre-Flex Coupling DeatilsDnyanesh BhaleraoPas encore d'évaluation

- Power Stream Couplings-Specn SheetsDocument6 pagesPower Stream Couplings-Specn SheetsAmol PatkiPas encore d'évaluation

- Catalog HRC Jaw CouplingsDocument8 pagesCatalog HRC Jaw CouplingsMadan Yadav100% (1)

- Pump VSPDocument12 pagesPump VSPMiguel V. PalPas encore d'évaluation

- Mixed Flow PumpsDocument2 pagesMixed Flow PumpssahildhingraPas encore d'évaluation

- Multitec RO - 1777.82-10 Instruciones de OperaciónDocument20 pagesMultitec RO - 1777.82-10 Instruciones de OperaciónAlvialvarezPas encore d'évaluation

- Manual Cat Pump Model 45Document4 pagesManual Cat Pump Model 45Jhon Jairo Maestre UribePas encore d'évaluation

- IP Pump DataSheet CNLBDocument2 pagesIP Pump DataSheet CNLBVikk Suriya100% (1)

- What Is DampenerDocument12 pagesWhat Is DampenerReyPas encore d'évaluation

- b3311 722-2Document7 pagesb3311 722-2Arnaldo BenitezPas encore d'évaluation

- Fan Calculation MooreDocument8 pagesFan Calculation MooreArjun GirishPas encore d'évaluation

- Complete - Nicholson Designers Guide - 3rd EditionDocument177 pagesComplete - Nicholson Designers Guide - 3rd Editionwdelgado2011Pas encore d'évaluation

- Oerlikon Leybold Roots Blower Vacuum Pump CatalogDocument40 pagesOerlikon Leybold Roots Blower Vacuum Pump CatalogYasir Ali100% (1)

- KCDocument3 pagesKCSandheepKumarPas encore d'évaluation

- GouldsDocument11 pagesGouldsKaren Isabel Ambiado Rivas100% (1)

- EagleBurgmann H7N enDocument5 pagesEagleBurgmann H7N enbryandownPas encore d'évaluation

- What Is The Best Silicon Carbide Wear Face Material For My Mechanical SealDocument3 pagesWhat Is The Best Silicon Carbide Wear Face Material For My Mechanical SealMahmoud Al HomranPas encore d'évaluation

- Resources Mechanical AESSEAL Guides AUTODocument16 pagesResources Mechanical AESSEAL Guides AUTOmanoPas encore d'évaluation

- GarbarinoDocument46 pagesGarbarinoMinh Hoàng Nguyễn HữuPas encore d'évaluation

- 2GDocument8 pages2GGaurav Panditrao UdanshivPas encore d'évaluation

- Ajustes y ToleranciasDocument1 pageAjustes y ToleranciasRay Rodriguez SanchezPas encore d'évaluation

- Dv300 STD MMDocument40 pagesDv300 STD MMjacklyn ade putraPas encore d'évaluation

- Rotating Face Mechanical SealsDocument3 pagesRotating Face Mechanical SealsSufi Lord NewPas encore d'évaluation

- 4 Hermetic Chemical Pumps Single Stage Series CN CNF CNK PDFDocument16 pages4 Hermetic Chemical Pumps Single Stage Series CN CNF CNK PDFmiguel callataPas encore d'évaluation

- Gear CouplingsDocument15 pagesGear CouplingsVishweshwar MadhavPas encore d'évaluation

- E04 Using Kalsi Seals in Washpipe AssembliesDocument17 pagesE04 Using Kalsi Seals in Washpipe AssembliesSuresh Kumar MittapalliPas encore d'évaluation

- Api 53Document2 pagesApi 53andrey2509Pas encore d'évaluation

- File 61 PDFDocument40 pagesFile 61 PDFNguyenHuanPas encore d'évaluation

- Rexnord Elastomer CouplingDocument20 pagesRexnord Elastomer Couplingidontlikeebooks100% (1)

- Dynamic Seal in The Fertilizer Industry 11-09Document9 pagesDynamic Seal in The Fertilizer Industry 11-09Souvik Singha RoyPas encore d'évaluation

- 279D Combination GearboxDocument1 page279D Combination GearboxJorge Vásquez CarreñoPas encore d'évaluation

- Coupling John CraneDocument15 pagesCoupling John Cranelubricacion100% (2)

- Curvas Bombas SihiDocument22 pagesCurvas Bombas SihiAlex Serna RestrepoPas encore d'évaluation

- FLOWSERVE CPXV AP73611BDocument48 pagesFLOWSERVE CPXV AP73611Broyert80Pas encore d'évaluation

- Pump Cavitation and NPSHDocument10 pagesPump Cavitation and NPSHshiel175Pas encore d'évaluation

- Tubular Casing Pumps by KSBDocument16 pagesTubular Casing Pumps by KSBGogy0% (1)

- Smit Panther 2Document2 pagesSmit Panther 2Axl AndoniuPas encore d'évaluation

- Mark DarcoDocument48 pagesMark DarcoMohammad QasimPas encore d'évaluation

- JBJ Techniques LTD Screw PumpsDocument49 pagesJBJ Techniques LTD Screw Pumpsreach_arindomPas encore d'évaluation

- The Sealing of Mixers and AgitatorsDocument4 pagesThe Sealing of Mixers and AgitatorsSubbarayan Saravanakumar100% (1)

- Allweiler Catalogue 0140P083Document8 pagesAllweiler Catalogue 0140P083pietroPas encore d'évaluation

- Horizontal & SuHorizontal & Sump Pumpmp PumpsDocument105 pagesHorizontal & SuHorizontal & Sump Pumpmp PumpsAnonymous dHLFEZuhBa50% (2)

- Jensen Mixer Series 600 IOM 2010Document24 pagesJensen Mixer Series 600 IOM 2010SergioPas encore d'évaluation

- 2019 NEW AquFlow CatalogDocument24 pages2019 NEW AquFlow CatalogAkbar HussainiPas encore d'évaluation

- Bladder AccumulatorsDocument16 pagesBladder AccumulatorsAlessandro NunesPas encore d'évaluation

- Compressed Air Basics Part 4 - Rotary Screw CompressorsDocument7 pagesCompressed Air Basics Part 4 - Rotary Screw CompressorssandeepPas encore d'évaluation

- Sample Pump Rebuild Report - 0Document21 pagesSample Pump Rebuild Report - 0Trịnh Đức HạnhPas encore d'évaluation

- ViFlow Funke GB PDFDocument8 pagesViFlow Funke GB PDFukalPas encore d'évaluation

- Couplings SKFDocument112 pagesCouplings SKFSergio SabaPas encore d'évaluation

- FA25i FA5i FA5Ti Parts Information AirToolProDocument48 pagesFA25i FA5i FA5Ti Parts Information AirToolProEslam Saeed100% (1)

- Rathi Tyre Flex User ManualDocument28 pagesRathi Tyre Flex User ManualJason Wei Han LeePas encore d'évaluation

- No.13 PRT2 Timing Belt Rings 01 UK PDFDocument4 pagesNo.13 PRT2 Timing Belt Rings 01 UK PDFhepcomotionPas encore d'évaluation

- Catalog Mud Pump 25864Document24 pagesCatalog Mud Pump 25864agus100% (1)

- SEBF8164 - Specification For Liner Measurement and Salvage of 3500 Series EnginesDocument19 pagesSEBF8164 - Specification For Liner Measurement and Salvage of 3500 Series Enginesyahmanmahira4Pas encore d'évaluation

- HeliCoil Stud-Lock ApplicationsDocument2 pagesHeliCoil Stud-Lock ApplicationsAce Industrial SuppliesPas encore d'évaluation

- Continental TorquesDocument13 pagesContinental Torquesfredtanner100% (2)

- 37° Tube Fittings: Instrumentation SolutionsDocument9 pages37° Tube Fittings: Instrumentation SolutionsNilesh MistryPas encore d'évaluation

- FAG TPI 155 TAROL Product Services de enDocument24 pagesFAG TPI 155 TAROL Product Services de enalvangel2004Pas encore d'évaluation

- Double Acting and Spring Return Pneumatic Actuators For On/off or Modulating Control of Most Quarter Turn Applications. Output Torques To 2385 NMDocument6 pagesDouble Acting and Spring Return Pneumatic Actuators For On/off or Modulating Control of Most Quarter Turn Applications. Output Torques To 2385 NMTeun HaperenPas encore d'évaluation

- RandD ShaftDocument4 pagesRandD ShaftloloPas encore d'évaluation

- Cost Estimation of Storage TankDocument2 pagesCost Estimation of Storage Tankmiteshmayur84% (19)

- Tender Requirement: Maharashtra State Power Generation Company LimitedDocument3 pagesTender Requirement: Maharashtra State Power Generation Company Limiteder_sanjaypatelPas encore d'évaluation

- Fixed Bed and Fluidized BedDocument33 pagesFixed Bed and Fluidized Bedشاكر العاقلPas encore d'évaluation

- Paint CalculatorDocument3 pagesPaint Calculatorer_sanjaypatelPas encore d'évaluation

- Fag India CRB & SRB Dt. 01-02-14Document9 pagesFag India CRB & SRB Dt. 01-02-14ps1amsPas encore d'évaluation

- Tata Consulting Engineers Limited Minimum Inspection Requirements For Butterfly ValvesDocument2 pagesTata Consulting Engineers Limited Minimum Inspection Requirements For Butterfly Valveser_sanjaypatelPas encore d'évaluation

- 298 Reg CodeDocument4 pages298 Reg Codeer_sanjaypatelPas encore d'évaluation

- Estimasi Fuel ConsumptionDocument7 pagesEstimasi Fuel ConsumptionDanu PutraPas encore d'évaluation

- Discount Factor TableDocument1 pageDiscount Factor TableAhmad Kosasih100% (1)

- CP 040brochure WEBDocument28 pagesCP 040brochure WEBabsalon_jarvPas encore d'évaluation

- Fosroc Nitobond AR and HAR 1209Document1 pageFosroc Nitobond AR and HAR 1209er_sanjaypatelPas encore d'évaluation

- 1 Tubefail PDFDocument29 pages1 Tubefail PDFer_sanjaypatelPas encore d'évaluation

- Of Worj16, For Water Plant 1. Quality byDocument6 pagesOf Worj16, For Water Plant 1. Quality byMOST PASONPas encore d'évaluation

- 27372Document6 pages27372ghostghost123Pas encore d'évaluation

- Alkalinity PHDocument47 pagesAlkalinity PHidownloadbooksforstuPas encore d'évaluation

- dwhufrrohgvfuhzfkloohuv: Product ManualDocument24 pagesdwhufrrohgvfuhzfkloohuv: Product Manualer_sanjaypatel100% (1)

- Saral RogopcharDocument405 pagesSaral Rogopcharyogi9075% (4)

- Vibration MathDocument4 pagesVibration Mathyianisr5990Pas encore d'évaluation

- Vibration Monitoring System-3500 PDFDocument27 pagesVibration Monitoring System-3500 PDFer_sanjaypatel100% (1)

- Chiller ManualDocument85 pagesChiller Manualer_sanjaypatel100% (2)

- Effect of Air Ingress in BoilersDocument6 pagesEffect of Air Ingress in BoilersAnvita Chebrolu100% (1)

- Case Studies On Boiler Tube ErosionDocument13 pagesCase Studies On Boiler Tube Erosionpankajbtc007100% (1)

- Final Ea R-Infra SummaryDocument29 pagesFinal Ea R-Infra Summaryer_sanjaypatelPas encore d'évaluation

- McQuay PFS C Installation Manual EngDocument17 pagesMcQuay PFS C Installation Manual EngAnbarasan Nagarajan100% (1)

- Vibration MathDocument4 pagesVibration Mathyianisr5990Pas encore d'évaluation

- Calculation of Machine RatesDocument12 pagesCalculation of Machine Rateser_sanjaypatelPas encore d'évaluation

- Seminar On: Flexibilisation of Thermal Power PlantsDocument4 pagesSeminar On: Flexibilisation of Thermal Power Plantser_sanjaypatelPas encore d'évaluation

- Mechanical Gland PackingDocument8 pagesMechanical Gland Packinger_sanjaypatelPas encore d'évaluation

- Smooth Roll Crusher PDFDocument2 pagesSmooth Roll Crusher PDFer_sanjaypatelPas encore d'évaluation

- ENGINEERING DESIGN GUILDLINE General Plant Cost Estimating Rev01web PDFDocument27 pagesENGINEERING DESIGN GUILDLINE General Plant Cost Estimating Rev01web PDFKetan RasalPas encore d'évaluation

- SplinesDocument5 pagesSplinesmahesh_belgavi100% (1)

- MD Stress Shafts Keys Couplingsppt For ReviewDocument103 pagesMD Stress Shafts Keys Couplingsppt For ReviewKent Tunacao100% (1)

- ZAPEX CouplingDocument22 pagesZAPEX CouplingWaris La Joi WakatobiPas encore d'évaluation

- A2fm PDFDocument46 pagesA2fm PDFTea DabeticPas encore d'évaluation

- Eaton 750 - 850 SpecsDocument20 pagesEaton 750 - 850 SpecsKevins Small Engine and Tractor ServicePas encore d'évaluation

- Helical Gears: Definition and Useful InformationDocument13 pagesHelical Gears: Definition and Useful InformationRobert Michael CorpusPas encore d'évaluation

- Upload MD1 - Lecture 8 - Keys, Couplings 2021Document16 pagesUpload MD1 - Lecture 8 - Keys, Couplings 2021PotatoFryPas encore d'évaluation

- ZF Duoplan - en 2k GearDocument42 pagesZF Duoplan - en 2k GearSasi DharanPas encore d'évaluation

- MAE 322 Machine Design Shafts - 3: Dr. Hodge Jenkins Mercer UniversityDocument28 pagesMAE 322 Machine Design Shafts - 3: Dr. Hodge Jenkins Mercer UniversityChaiyuth ArmyforcePas encore d'évaluation

- Gearex: KTR-N Sheet: Edition: 40311 en 1 of 22 4Document22 pagesGearex: KTR-N Sheet: Edition: 40311 en 1 of 22 4Carlos Humberto Arana NovoaPas encore d'évaluation

- NORD Gear Box ManualDocument216 pagesNORD Gear Box Manualsgupta_615796100% (5)

- NEF Coupling Catalog English 20061201Document48 pagesNEF Coupling Catalog English 20061201Aryo WicaksonoPas encore d'évaluation

- Fenner Keyless DrivesDocument56 pagesFenner Keyless DrivesroytamaltanuPas encore d'évaluation

- Samputensili Tools en v007Document24 pagesSamputensili Tools en v007M.NatarajanPas encore d'évaluation

- (Print 3) Milling MachineDocument32 pages(Print 3) Milling MachineMunem Shahriar100% (1)

- Metal Workrs N1 Exam MemosDocument79 pagesMetal Workrs N1 Exam MemosThembelihle HadebePas encore d'évaluation

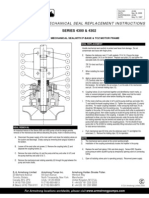

- Mechanical Seal Replacement InstructionsDocument1 pageMechanical Seal Replacement InstructionsGiorgio FerPas encore d'évaluation

- Zexel MD354508Document8 pagesZexel MD354508jomicostagomesPas encore d'évaluation

- SEW Gearmotor Operating Instructions DespieceDocument106 pagesSEW Gearmotor Operating Instructions Despieceomar_1211Pas encore d'évaluation

- Keyway Sizing ChartDocument1 pageKeyway Sizing Chartdsley100% (2)

- ELPEX Flexible CouplingDocument24 pagesELPEX Flexible CouplingWaris La Joi WakatobiPas encore d'évaluation

- General Purpose Overrunning Clutches FRB 400 Through 800: Installation InstructionsDocument4 pagesGeneral Purpose Overrunning Clutches FRB 400 Through 800: Installation InstructionsPedro AbregúPas encore d'évaluation

- X ( J / ËEÚŒ ( EÚ - EÚ Æ ( Æ "I HDocument8 pagesX ( J / ËEÚŒ ( EÚ - EÚ Æ ( Æ "I HTuna garadaPas encore d'évaluation

- Syntec Servo Products Specification Manual - V2.5.2Document122 pagesSyntec Servo Products Specification Manual - V2.5.2Trí Chốt100% (1)

- Bauer Gears BG SerieDocument192 pagesBauer Gears BG SeriemanrecialPas encore d'évaluation

- Acople Flender Highly Flexible CouplingsDocument88 pagesAcople Flender Highly Flexible Couplingsmarcelo castilloPas encore d'évaluation

- Propeller Installation ProcedureDocument2 pagesPropeller Installation Proceduredanilo laraPas encore d'évaluation

- Thurs CatDocument13 pagesThurs Catneptuno97Pas encore d'évaluation

- l19146 Xa02uen E1 CombinedDocument41 pagesl19146 Xa02uen E1 CombinedErik HansonPas encore d'évaluation