Académique Documents

Professionnel Documents

Culture Documents

Successful Dyeing of Polyester-Elastane Blends With Dispersol and Palanil Dyes

Transféré par

Muhammad Iqbal ShaikhCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Successful Dyeing of Polyester-Elastane Blends With Dispersol and Palanil Dyes

Transféré par

Muhammad Iqbal ShaikhDroits d'auteur :

Formats disponibles

Successful dyeing of

polyester/elastane blends with

Dispersol

and Palanil

dyes

Technical Information

EFT/TS 181

March 2000

Colorants

= Registered trademark of

BASF Aktiengesellschaft

1

Successful dyeing of

polyester/ elastane blends

with Dispersol and Palanil dyes

Compact Elastane

2

Elastane fibres are:

widely used to improve fit and comfort of underwear, sportswear and

outerwear

formed from a synthetic polymer containing at least 85% by weight of

segmented polyurethane

generally based on polyether soft segments

hydrophobic and open-structured with high affinity for disperse dyes

O = C = N - - CH

2

- - N = C = O + HO CH

2

CH

2

CH

2

CH

2

- O

n

OH

O = C = N N = C = O

hard

segment

hard

segment

+

Diamine

Polyester/Elastane Dyeing Problems

3

Dyeing polyester/elastane at 130 C

Permanent drawing of elastane fibre

Loss of stretch recovery power

Elastane fibres have higher affinity for disperse dyes than do

polyester fibres

Heavy staining of elastane fibres

Poor colour fastness of dyed polyester/elastane fabrics

Careful choice of

preparation chemicals

dyes

dyeing process

machinery with minimum tension

is essential for producing high quality dyed fabrics

Compact Elastane - Preparation for dyeing

4

Polyester/Elastane Fabrics Batchwise Preparation

30 C

water onIy

20 minutes

80 C

3.0 g/I KieraIon

MFB

1 g/I LufibroI

MSD

pH 3 - 4

foIIowed by 5 minute overfIow rinse at 80 C,

5 minute overfIow rinse at ambient temperature

Lufibrol MSD can be omitted if soft water is used

Stability of removed silicone oils emulsion is highest at pH 3-4

Elastane yarns are lubricated with a protective film of 2-5% silicone oil for

efficient fabric construction

Efficient removal of silicone oils before dyeing is important to:

reduce disperse dye stain on elastane fibres

reduce risk of spotting and staining during dyeing

reduce smoking during finishing

reduce migration of disperse dyes during storage of dyed fabrics

Kieralon MFB, used at acid pH, is an efficient scouring system for oil

removal

Compact Elastane

5

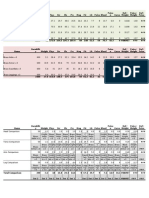

Disperse dyes dyed on polyester/elastane blends will.....

70 C 80 C 90 C 100 C 110 C 120 C 130 C

30 min at

130 C

Polyester

Elastane

Elastane

Migration test:

30 minutes at 130 C, pH 4.5

Elastane

Dispersol Yellow Brown C-VS 300

M&S C4A (50 C), rinsed only dyeings

Dispersol Red C-VS 300

Dispersol Navy C-VS 300

Polyester

migrated dye

before

migration

after

migration

...... preferentially dye the elastane fibre

...... migrate slowly from elastane to polyester

...... stain heavily in washing tests

Secondary

cellulose

acetate

(Dicel)

Bleached

unmercerised

cotton

Nylon 6.6

Polyester

(Terylene)

Acrylic

(Courtelle)

Wool

worsted

S.D.C. MULTIFIBRE TEST FABRIC

very little dye migrates from elastane to polyester after 30 minutes at 130 C in blank dyebath

disperse dyes build-up preferentially on elastane in a dyebath containing both polyester and elastane fibres

disperse dyes on elastane have poor wet fastness

Disperse Dye Stain on Elastane Fibres

6

Reduction clearing of dyed polyester/elastane fabrics under alkaline

conditions is essential to:

optimise the wet fastness

improve the storage fastness

optimise the shade stability to post heat setting

Disperse dyes vary greatly in ease of removal from elastane

Dye Selectionshould aim to produce, after reduction clearing:

little or no disperse dye on elastane (ideal)

disperse dye stain on-tone with polyester dyeing (second best)

Dispersol Yellow C-VS 300

Palanil Yellow E-3G 200

Dispersol Crimson SF

Dispersol Red C-VS 300

Dispersol Blue XF

Palanil Dark Blue 3RT-CF

Before

reduction

clearing

After

reduction

clearing

Reduction Clear

3-4 g/l Hydrosulfite Conc. BASF

4-8 ml/l caustic soda 38 B

0.5 g/l Cyclanon

PE-Jet

20 minutes at 80 C

Compact Elastane

7

Dyeing temperatureshould take into account:

source and stability of elastane yarns

construction of the fabric

dyeing machinery available

colour fastness needed

Dyeing polyester/elastane fabrics at reduced dyeing temperatures

(e.g. 115 C) will minimise loss of stretch recovery power, but will result in:

reduced colour fastness

reduced shade reproducibility and more shading additions

poor coverage of polyester yarn variations (increased barr)

reduced colour yield

danger of shade change on post heat setting

Dyeing temperature for polyester/elastane is often a compromise

Dye and Process Selection

8

1. Dyeing at 115 C

Controlled Coloration of polyester/elastane blends with good shade

reproducibility at 115 C is possible with:

Palanil E dyes pale to medium shades

Dispersol C-VS dyes medium to heavy shades

1.1 Controlled Coloration

On-tone build-up ......

Recipe 1

0.11 % Palanil Yellow E-3G 200

0.11 % Palanil Red E-BF 200

0.08 % Palanil Blue E-R 150

Recipe 2

1.69 % Dispersol Yellow Brown C-VSE

0.21 % Dispersol Red C-VS 300

0.67 % Palanil Dark Blue 3RT-CF

70 C 80 C 90 C 100 C 110 C 115 C

15 min

115 C

30 min

115 C

45 min

115 C

Recipe 1

Recipe 2

...... all lead to:

...... and stability to heat setting ......

,E 0.9

Strength 113%

Hue 0.5 redder

,E 0.2

Strength 102%

Hue 0.2 yellower

B e st a ch i e v a b le R i g h t-F i rst-T i m e p e rfo rm a n ce

colour measurements on the above dyeings

Compact Elastane - Dyeing at 115 C

9

1.2 Colour fastness

Good washing to 50 C washing and to perspiration can be achieved by

efficient reduction clearing of all shades after dyeing (see pages 10 and 11 for

full application details)

Secondary

cellulose

acetate

(Dicel)

Bleached

unmercerised

cotton

Nylon 6.6

Polyester

(Terylene)

Acrylic

(Courtelle)

Wool

worsted

S.D.C. MULTIFIBRE TEST FABRIC

Secondary

cellulose

acetate

(Dicel)

Bleached

unmercerised

cotton

Nylon 6.6

Polyester

(Terylene)

Acrylic

(Courtelle)

Wool

worsted

S.D.C. MULTIFIBRE TEST FABRIC

Olive

0.23 % Palanil Yellow E-3G 200

0.12 % Palanil Red E-BF 200

0.10 % Palanil Blue E-R 150

Navy

0.02 % Dispersol Yellow C-VS 300

0.29 % Dispersol Yellow Brown C-VSE

1.38 % Palanil Dark Blue 3RT-CF

Black

0.06 % Dispersol Yellow Brown C-VSE

2.16 % Dispersol Black C-VSE

Cherry

0.47 % Dispersol Yellow Brown C-VSE

0.39 % Dispersol Red C-VS 300

0.02 % Palanil Dark Blue 3RT-CF

Olive

Navy

Black

Cherry

Olive

Navy

Black

Cherry

C06/B2S (50 C)

Alkaline Perspiration (E04)

All dyeings heat-set at 190 C for 30 seconds after reduction clearing

Compact Elastane - Dyeing at 115 C

10

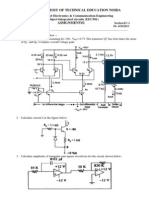

1.3 Dyeing/clearing Processes

Pale/medium shades Palanil E dyes

0 20 40 60 -20 -40 -60

0

20

40

60

80

100

-20

-40

YeIIow E-3G

BIue E-R

b

a

Red E-BF

BriIIiant BIue BG-CF

40 C

30 - 60 minutes

20 minutes

70 C

80 C

70 C

115 C

1-4 g/I SetamoI

BL

1 g/I PaIatex

PC

1-2 g/I PaIegaI

LP

pH 4 - 5 with

EuIysin

S or acetic acid

3-4 g/I HydrosuIfite Conc. BASF

4-8 mI/I caustic soda 38 B

0.5 g/I CycIanon

PE-Jet

disperse dyes

Compact Elastane - Dyeing at 115 C

11

Medium/heavy shades Dispersol C-VS dyes

YeIIow C-VS

YeIIow Brown C-VSE

BIack C-VSE/BIack C-GE

Green C-VS

PaIaniI Dark BIue 3RT-CF

Red C-VS

VioIet C-VS

Red C-4G

BIue C-VSA PaIaniI BriIIiant

BIue BG-CF

0 20 40 60 -20 -40 -60

0

20

40

60

80

100

-20

-40

RoyaI C-VS

b

a

Navy C-VSE

40 C

30 - 60 minutes

20 minutes

70 C

80 C

70 C

115 C

1-4 g/I SetamoI

BL

1 g/I PaIatex

PC

1-2 g/I PaIegaI

LP

pH 4 - 5 with

EuIysin

S or acetic acid

3-4 g/I HydrosuIfite Conc. BASF

4-8 mI/I caustic soda 38 B

0.5 g/I CycIanon

PE-Jet

disperse dyes

Compact Elastane - Dyeing at 125-130 C

12

2. Dyeing at 125-130 C

Controlled Coloration of polyester/elastane blends with good shade

reproducibility and optimum wet fastness at 125-130 C with:

Palanil E pale shades

Dispersol C-VS medium/heavy shades

Dispersol XF, SF heavy shades with highest wash fastness

2.1 Controlled Coloration

On-tone build-up ......

Recipe 1

0.11 % Palanil Yellow E-3G 200

0.11 % Palanil Red E-BF 200

0.08 % Palanil Blue E-R 150

Recipe 2

1.69 % Dispersol Yellow Brown C-VSE

0.21 % Dispersol Red C-VS 300

0.67 % Palanil Dark Blue 3RT-CF

Recipe 3

3.43 % Dispersol Yellow Brown XF

0.54 % Dispersol Rubine XFN

0.77 % Dispersol Navy XF

70 C 80 C 90 C 100 C 110 C 120 C 130 C

15 min

130 C

30 min

130 C

Recipe 1

Recipe 2

Recipe 3

Compact Elastane - Dyeing at 125-130 C

13

98%

0.9 yellower

99%

0.4 yellower

100%

0.3 redder

100%

0.5 yellower

Control

103%

0.1 redder

103%

0.3 yellower

108%

0.5 redder

112%

0.4 redder

91%

0.4 yellower

95%

0.01 redder

97%

0.04 redder

94%

0.2 yellower

Control

100%

0.02 yellower

102%

0.4 redder

101%

0.02 redder

103%

0.3 redder

125 C

15 minutes 30 minutes 45 minutes

130 C

135 C

125 C

15 minutes 30 minutes 45 minutes

130 C

135 C

92%

1.1 redder

99%

0.3 redder

100%

0.2 redder

96%

0.6 redder

Control

104%

0.2 yellower

103%

0.3 redder

109%

0.2 yellower

113%

0.4 yellower

125 C

15 minutes 30 minutes 45 minutes

130 C

135 C

...... with good time/temperature robustness ......

Recipe 1

Recipe 2

Recipe 3

...... all lead to:

...... and stability to heat setting ......

,E 1.0

Strength 114%

Hue 0.3 yellower

,E 0.5

Strength 101%

Hue 0.1 yellower

,E 0.3

Strength 103%

Hue 0.1 yellower

B e st a ch i e v a b le R i g h t-F i rst-T i m e p e rfo rm a n ce

Compact Elastane - Dyeing at 125-130 C

14

2.2 Colour Fastness

Optimum wet fastness can be achieved by efficient reduction clearing of all

shades after dyeing (see pages 15, 16 and 17 for full application details)

Secondary

cellulose

acetate

(Dicel)

Bleached

unmercerised

cotton

Nylon 6.6

Polyester

(Terylene)

Acrylic

(Courtelle)

Wool

worsted

S.D.C. MULTIFIBRE TEST FABRIC

Olive

0.23 % Palanil Yellow E-3G 200

0.12 % Palanil Red E-BF 200

0.10 % Palanil Blue E-R 150

Navy 2

0.30 % Dispersol Yellow Brown XF

0.14 % Dispersol Rubine XFN

1.54 % Dispersol Navy XF

Navy

0.02 % Dispersol Yellow C-VS 300

0.29 % Dispersol Yellow Brown C-VSE

1.38 % Palanil Dark Blue 3RT-CF

Cherry 2

0.92 % Dispersol Yellow Brown XF

0.54 % Dispersol Rubine XFN

0.16 % Dispersol Crimson SF

Black

0.06 % Dispersol Yellow Brown C-VSE

2.16 % Dispersol Black C-VSE

Black 2

0.15 % Dispersol Yellow Brown XF

0.10 % Dispersol Rubine XFN

3.43 % Dispersol Black XF

Cherry

0.47 % Dispersol Yellow Brown C-VSE

0.39 % Dispersol Red C-VS 300

0.02 % Palanil Dark Blue 3RT-CF

C06/B2S (50 C)

Alkaline Perspiration (E04)

Olive

Navy

Navy 2

Black

Black 2

Cherry

Cherry 2

Olive

Navy

Navy 2

Black

Black 2

Cherry

Cherry 2

All dyeings heat-set at 190 C for 30 seconds after reduction clearing

Compact Elastane - Dyeing at 125-130 C

15

2.3 Dyeing/clearing procedures

Pale shades Palanil E dyes

0 20 40 60 -20 -40 -60

0

20

40

60

80

100

-20

-40

YeIIow E-3G

BIue E-R

b

a

Red E-BF

BriIIiant BIue BG-CF

40 C

15 - 30 minutes

20 minutes

70 C

80 C

70 C

125 - 130 C

1-4 g/I SetamoI

BL

1 g/I PaIatex

PC

pH 4 - 5 with

EuIysin

S or acetic acid

3-4 g/I HydrosuIfite Conc. BASF

4-8 mI/I caustic soda 38 B

0.5 g/I CycIanon

PE-Jet

disperse dyes

Compact Elastane - Dyeing at 125-130 C

16

Medium/heavy shades Dispersol C-VS dyes

YeIIow C-VS

YeIIow Brown C-VSE

BIack C-VSE/BIack C-GE

Green C-VS

PaIaniI Dark BIue 3RT-CF

Red C-VS

VioIet C-VS

Red C-4G

BIue C-VSA PaIaniI BriIIiant

BIue BG-CF

0 20 40 60 -20 -40 -60

0

20

40

60

80

100

-20

-40

RoyaI C-VS

b

a

Navy C-VSE

40 C

15 - 30 minutes

20 minutes

70 C

80 C

70 C

125 - 130 C

1-4 g/I SetamoI

BL

1 g/I PaIatex

PC

pH 4 - 5 with

EuIysin

S or acetic acid

3-4 g/I HydrosuIfite Conc. BASF

4-8 mI/I caustic soda 38 B

0.5 g/I CycIanon

PE-Jet

disperse dyes

Compact Elastane - Dyeing at 125-130 C

17

Heavy shades with highest wash fastness Dispersol XF, SF dyes

0 20 40 60 -20 -40 -60

0

20

40

60

80

100

-20

-40

FIavine XF

YeIIow Brown XF

Turquoise XF

BIue XF

Rubine XFN

Navy XF

BIack XF

b

a

Crimson SF

40 C

15 - 30 minutes

20 minutes

70 C

80 C

70 C

125 - 130 C

1-4 g/I SetamoI

BL

1 g/I PaIatex

PC

pH 4 - 5 with

EuIysin

S or acetic acid

3-4 g/I HydrosuIfite Conc. BASF

4-8 mI/I caustic soda 38 B

0.5 g/I CycIanon

PE-Jet

disperse dyes

Compact Elastane

18

Compact Elastane Top Tips

For successful dyeing of polyester/elastane fabrics

lowest dyeing temperature which produces level, well penetrated dyeings

low tension dyeing machinery

select dyes and chemicals for Controlled Coloration

efficient pre-scouring to remove silicone oils

efficient reduction clearing

lowest post heat-setting temperature which produces stable fabrics

Vous aimerez peut-être aussi

- Uvitex EDB Textile Whitener: Technical Data SheetDocument7 pagesUvitex EDB Textile Whitener: Technical Data Sheetraju_hosssenPas encore d'évaluation

- Pretreatment of Fabrics That Contain SpandexDocument8 pagesPretreatment of Fabrics That Contain SpandexaymanPas encore d'évaluation

- 185 SeraDocument2 pages185 SerapravinthombrePas encore d'évaluation

- Sizing For Water-Jet Weaving: Textile Effects 1110015EDocument13 pagesSizing For Water-Jet Weaving: Textile Effects 1110015EagnberbcPas encore d'évaluation

- Indigo Package DyeingDocument8 pagesIndigo Package DyeingAwais ImranPas encore d'évaluation

- Food Calories Carb FAT Protein Notes Meal 1 2 Clean Egg MuffinsDocument3 pagesFood Calories Carb FAT Protein Notes Meal 1 2 Clean Egg MuffinsdsadasdsakdjsakljPas encore d'évaluation

- Standardization of Recipe For DyeingDocument7 pagesStandardization of Recipe For DyeingfreakishrosePas encore d'évaluation

- Recommended Exhaust Dyeing Process For EcoFRESH Yarn V3 00-2015 12 (En)Document5 pagesRecommended Exhaust Dyeing Process For EcoFRESH Yarn V3 00-2015 12 (En)Saidur Rahman SajibPas encore d'évaluation

- Polyester Blends DyeingDocument49 pagesPolyester Blends Dyeingwsarakarn100% (1)

- Oligomer RemoverDocument13 pagesOligomer RemoverL.N.CHEMICAL INDUSTRYPas encore d'évaluation

- Pad BatchDocument6 pagesPad BatchBabaPas encore d'évaluation

- One-Bath Dyeing of Blended FabricsDocument4 pagesOne-Bath Dyeing of Blended FabricsNguyễn Huy CườngPas encore d'évaluation

- Z&S PesDocument8 pagesZ&S Pesguven44Pas encore d'évaluation

- Z&s PADocument8 pagesZ&s PAguven44Pas encore d'évaluation

- Dyefix-CF - Dye Fixing Agent With Excellent Fastness To Chlorine.Document10 pagesDyefix-CF - Dye Fixing Agent With Excellent Fastness To Chlorine.L.N.CHEMICAL INDUSTRYPas encore d'évaluation

- Dyeing of Polyester - Cotton BlendsDocument2 pagesDyeing of Polyester - Cotton Blendstkr163Pas encore d'évaluation

- Reactive Dye and Disperse DyeDocument44 pagesReactive Dye and Disperse DyeNguyễn Huy Cường100% (1)

- Terasil Standard Dyeing MethodDocument1 pageTerasil Standard Dyeing MethodKhandaker Sakib FarhadPas encore d'évaluation

- Blind DyeingDocument6 pagesBlind Dyeingprabhulean14Pas encore d'évaluation

- Color FastnessDocument68 pagesColor FastnessDinesh VermaPas encore d'évaluation

- Dyeing of Polyester/Cellulose BlendsDocument17 pagesDyeing of Polyester/Cellulose Blendsnagpal_aakashPas encore d'évaluation

- Direct DyesDocument27 pagesDirect DyesrehanabbaciPas encore d'évaluation

- Session 12-14 Dyes - Application TypesDocument56 pagesSession 12-14 Dyes - Application TypesShagun SinhaPas encore d'évaluation

- Contineous Dyeing of Reactive DyesDocument9 pagesContineous Dyeing of Reactive DyesMohammed Atiqul Hoque ChowdhuryPas encore d'évaluation

- Batch To Batch and CreasesDocument32 pagesBatch To Batch and CreasesJohn VasilonikolosPas encore d'évaluation

- Alkaline Weight Reduction of Polyester FabricsDocument1 pageAlkaline Weight Reduction of Polyester FabricssateeshgorePas encore d'évaluation

- Pad Steam 1Document22 pagesPad Steam 1aminkhojaPas encore d'évaluation

- Recomendaciones Modal 100%Document6 pagesRecomendaciones Modal 100%Alfredo GSPas encore d'évaluation

- Exhaust Dyeing Polyester With Disperse DyesDocument16 pagesExhaust Dyeing Polyester With Disperse DyesBurak EmekliogluPas encore d'évaluation

- Texturized PETDocument2 pagesTexturized PETGauri PuranikPas encore d'évaluation

- Tubifast As 5087 Ff-EnDocument4 pagesTubifast As 5087 Ff-EnrajasajjadPas encore d'évaluation

- Glauber Salt Vs Commom SaltDocument6 pagesGlauber Salt Vs Commom SaltRajeev MehraPas encore d'évaluation

- Benefits of Hot MercerizationDocument4 pagesBenefits of Hot MercerizationRokunuzzaman PramanikPas encore d'évaluation

- Silegen Softener SIS enDocument5 pagesSilegen Softener SIS enarkcgem100% (1)

- Right First Time Dyeing: RFT PrinciplesDocument8 pagesRight First Time Dyeing: RFT PrinciplesAnu MehtaPas encore d'évaluation

- Bezaktiv S Matrix DyesDocument25 pagesBezaktiv S Matrix DyesRezoanul HaquePas encore d'évaluation

- Aatcc NewletterDocument52 pagesAatcc NewletterlthyaguPas encore d'évaluation

- Advancements in Textile FinishingDocument14 pagesAdvancements in Textile FinishingJuan CubasPas encore d'évaluation

- Advantage of Reactive DyesDocument3 pagesAdvantage of Reactive Dyeschi005Pas encore d'évaluation

- AATCC - 89 - Mercerization in CottonDocument2 pagesAATCC - 89 - Mercerization in CottonNguyễn Công Thoại100% (1)

- Wet Processing Technology .Industrial Re PDFDocument153 pagesWet Processing Technology .Industrial Re PDFaauPas encore d'évaluation

- Cold Pad Bleaching of Woven FabricDocument4 pagesCold Pad Bleaching of Woven FabricPavan KumarPas encore d'évaluation

- Fabric Dyeing ProcessDocument6 pagesFabric Dyeing ProcessSURUCHI KUMARIPas encore d'évaluation

- Reactive DyesDocument24 pagesReactive DyesrehanabbaciPas encore d'évaluation

- Resep 1Document44 pagesResep 1Rahadian Noor MadanyPas encore d'évaluation

- One-Bath Dyeing Process For Polyester Cotton Blend Using Physical Mixtures of Reactive and DisperseDocument11 pagesOne-Bath Dyeing Process For Polyester Cotton Blend Using Physical Mixtures of Reactive and DisperseariefPas encore d'évaluation

- Dyeing FaultsDocument20 pagesDyeing FaultsMian Asif JavedPas encore d'évaluation

- Investigating An Appropriate Temperature For Heat Setting in A Stentermachine To Control The Stretch and Growth of A Cotton Spande 2165 8064 1000319Document9 pagesInvestigating An Appropriate Temperature For Heat Setting in A Stentermachine To Control The Stretch and Growth of A Cotton Spande 2165 8064 1000319Robiul AlamPas encore d'évaluation

- A Training Report ON Meter & Shrinkage Variation From Grey To Finish AT Anubha Industries Private LimitedDocument34 pagesA Training Report ON Meter & Shrinkage Variation From Grey To Finish AT Anubha Industries Private LimitedSK AzaharuddinPas encore d'évaluation

- Ripon 160312072524 PDFDocument21 pagesRipon 160312072524 PDFWulan Safrihatini100% (1)

- Heat SettingDocument20 pagesHeat SettingSharif Hassan100% (3)

- 10 5923 J Textile 20120106 03 PDFDocument9 pages10 5923 J Textile 20120106 03 PDFsonia aliPas encore d'évaluation

- Project Lycra UpdateDocument60 pagesProject Lycra UpdateAshiq KhanPas encore d'évaluation

- KAPP Garments Washing ChemicalsDocument6 pagesKAPP Garments Washing ChemicalsRezoanul HaquePas encore d'évaluation

- Intro, Classification & Functions of Auxiliaries .PPTX Lecture 123Document16 pagesIntro, Classification & Functions of Auxiliaries .PPTX Lecture 123nida0% (1)

- Fixation of PrintsDocument8 pagesFixation of PrintsyuvarajPas encore d'évaluation

- Dyeing CalculationDocument6 pagesDyeing CalculationRihan Ahmed RubelPas encore d'évaluation

- Effects of Different Pretreatment Processes On Viscose Fabrics in Different Types and PropertiesDocument10 pagesEffects of Different Pretreatment Processes On Viscose Fabrics in Different Types and PropertiesFathi MustafaPas encore d'évaluation

- The Identification of Vat Dyes on Cellulosic MaterialsD'EverandThe Identification of Vat Dyes on Cellulosic MaterialsPas encore d'évaluation

- Valleylab Force 2 Electrosurgical Generator - Service ManualDocument74 pagesValleylab Force 2 Electrosurgical Generator - Service ManualDavid Orlando Cordova Navarrete100% (1)

- Change LogDocument8 pagesChange Logionut_catalin517Pas encore d'évaluation

- Downloaded LicensesDocument3 pagesDownloaded LicensesdsadasdsakdjsakljPas encore d'évaluation

- How To InstallDocument1 pageHow To InstalldsadasdsakdjsakljPas encore d'évaluation

- Product Sheet Radon OptoDocument1 pageProduct Sheet Radon OptodsadasdsakdjsakljPas encore d'évaluation

- Lecture ScheduleDocument2 pagesLecture ScheduledsadasdsakdjsakljPas encore d'évaluation

- Ventillator/CPAP: Name Rate Fio2 PIP Peep Insp. TimeDocument1 pageVentillator/CPAP: Name Rate Fio2 PIP Peep Insp. TimedsadasdsakdjsakljPas encore d'évaluation

- Mexican RadiationDocument1 pageMexican RadiationdsadasdsakdjsakljPas encore d'évaluation

- Elastane Blends1Document37 pagesElastane Blends1Foued Ben Salem100% (1)

- Photoshop For 3D (2010)Document59 pagesPhotoshop For 3D (2010)Ahmed SamiPas encore d'évaluation

- 10 Step To Configure Cisco Call Manager ExpressDocument1 page10 Step To Configure Cisco Call Manager ExpressSudhir Vats100% (2)

- Week 1 SundayDocument1 pageWeek 1 SundaydsadasdsakdjsakljPas encore d'évaluation

- Week 1 Tuesday Thursday SaturdayDocument1 pageWeek 1 Tuesday Thursday SaturdaydsadasdsakdjsakljPas encore d'évaluation

- D D D D D D: Description/ordering InformationDocument13 pagesD D D D D D: Description/ordering InformationdsadasdsakdjsakljPas encore d'évaluation

- Week 1 Monday Wednesday FridayDocument1 pageWeek 1 Monday Wednesday FridaydsadasdsakdjsakljPas encore d'évaluation

- Dark Souls Armor AotA Calculator - XLSX - 0 - 1Document2 pagesDark Souls Armor AotA Calculator - XLSX - 0 - 1dsadasdsakdjsakljPas encore d'évaluation

- Jss Academy of Technical Education NoidaDocument2 pagesJss Academy of Technical Education NoidadsadasdsakdjsakljPas encore d'évaluation

- Mtu Academic Calendar 2013-14Document3 pagesMtu Academic Calendar 2013-14needhikhurana@gmail.comPas encore d'évaluation

- Dark Souls Armor AotA Calculator - XLSX - 0Document2 pagesDark Souls Armor AotA Calculator - XLSX - 0dsadasdsakdjsakljPas encore d'évaluation

- Subnetting Secrets Book 1Document0 pageSubnetting Secrets Book 1Gulshan NematovaPas encore d'évaluation

- ATmega16 PDFDocument359 pagesATmega16 PDFAndre PdPas encore d'évaluation