Académique Documents

Professionnel Documents

Culture Documents

Tips On Kiln Operation

Transféré par

Vipan Kumar Dogra0 évaluation0% ont trouvé ce document utile (0 vote)

221 vues1 pageCement Kiln operation Tips

Titre original

Tips on Kiln Operation

Copyright

© © All Rights Reserved

Formats disponibles

DOC, PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentCement Kiln operation Tips

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme DOC, PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

221 vues1 pageTips On Kiln Operation

Transféré par

Vipan Kumar DograCement Kiln operation Tips

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme DOC, PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 1

Tips On Kiln Operation

Every 1 % reduction in free lime, increases 10 25 kcal/k

clinker !eat consumption"

Every 10% increase in pre!eater e#it temp", increases $%10

kcal/k clinker !eat consumption"

Every 10% increase in clinker temp", increases 2 kcal/k clinker

!eat consumption"

Every 1% increase in kiln &' e#it O2% , increases $ kcal/k

clinker !eat consumption"

Every 1% increase in residue(kiln feed) in *0 micron , increases

5%10 kcal/k clinker !eat consumption"

Every 0"1 increase in silica modulus, increases 10kcal/k

clinker !eat consumption"

Every 1% increase in kiln feed +,-, increases 15 kcal/k clinker

!eat consumption"

Every 100 .lain increase in cement , increases 1"5 k/!/0T

po/er cons1n"

Every 1% reduction in primary air, reduces 0"$ kcal/k clinker

!eat cons1n"

Every 10 deree centirade increase in flame temperature ,

increases 1% kiln production"

Every 100 .laine increase in cement, increases 1"5 0pa

strent!"

Every 1% increase in fine coal moisture, reduces 10 to 12

deree centirade flame temperature"

Every 1% reduction in clinker%free lime, increases 2"0 % 34, in

clinker"

Every 1% increase in 34, reduces 0"4 to 0"5 k/!/0T clinker

rindin enery consumption"

Vous aimerez peut-être aussi

- Calcined ClayDocument3 pagesCalcined ClaytimothyPas encore d'évaluation

- 2.02.burning Zone CoatingDocument2 pages2.02.burning Zone CoatingJCSPas encore d'évaluation

- Alkali CyclesDocument14 pagesAlkali CyclesElwathig BakhietPas encore d'évaluation

- A To ZDocument126 pagesA To ZMohamed Osama RagaaPas encore d'évaluation

- Process Control IEEE Eml RDocument40 pagesProcess Control IEEE Eml RFran JimenezPas encore d'évaluation

- Kiln Control and OperationDocument56 pagesKiln Control and OperationLe Hoang100% (1)

- By Pass System in The Dry ProcessDocument34 pagesBy Pass System in The Dry Processfaheemqc100% (1)

- PR GRI P07-08 How To Optimise A Ball ChargeDocument6 pagesPR GRI P07-08 How To Optimise A Ball ChargepawanroyalPas encore d'évaluation

- Dinesh Agrawal: Dry-ProcessDocument19 pagesDinesh Agrawal: Dry-ProcessSantanu PachhalPas encore d'évaluation

- K - Constant For Cooler Fan FlowsDocument4 pagesK - Constant For Cooler Fan FlowsVijay Bhan100% (1)

- Cement Mill: History Materials Ground Temperature Control Ball MillsDocument5 pagesCement Mill: History Materials Ground Temperature Control Ball MillsAli HadiPas encore d'évaluation

- Surface Area of GMDocument6 pagesSurface Area of GMAnoop TiwariPas encore d'évaluation

- Heat Balance For Kiln: Jasveer SinghDocument4 pagesHeat Balance For Kiln: Jasveer SinghAlok RanjanPas encore d'évaluation

- Cement Technology Cement ChemistryDocument22 pagesCement Technology Cement Chemistryshani5573Pas encore d'évaluation

- Cement Grinding Vertical Roller Mills Versus Ball Mills 1654248086Document17 pagesCement Grinding Vertical Roller Mills Versus Ball Mills 1654248086Salah Romdani100% (1)

- User Guide PDFDocument27 pagesUser Guide PDFbulentbulut100% (1)

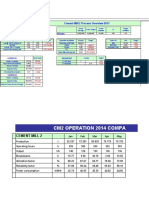

- CM2 Process Media Mix Up 2014 2015Document31 pagesCM2 Process Media Mix Up 2014 2015Junaid MazharPas encore d'évaluation

- C Clliinnkkeerr:: Rreeaaccttiioonnss Iinn Tthhee KkiillnnDocument3 pagesC Clliinnkkeerr:: Rreeaaccttiioonnss Iinn Tthhee KkiillnnFamiloni LayoPas encore d'évaluation

- Inleaking AirDocument6 pagesInleaking Airirfan100% (2)

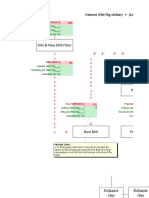

- VRM-Fill Data Only in Yellow Cells: Total Feed (MT) Clinker (MT) Gypsum (MT) Slag (MT)Document2 pagesVRM-Fill Data Only in Yellow Cells: Total Feed (MT) Clinker (MT) Gypsum (MT) Slag (MT)Sahadeb Manna100% (1)

- The Effect of Coal Ash On Synthesis and Properties of C3SDocument6 pagesThe Effect of Coal Ash On Synthesis and Properties of C3SNam HuynhPas encore d'évaluation

- 3 CementDocument22 pages3 CementnecdetdalgicPas encore d'évaluation

- Co2 Emission Per Ton ClinkerDocument5 pagesCo2 Emission Per Ton ClinkerJunaid Mazhar50% (2)

- Priya Cement Raw MixDocument6 pagesPriya Cement Raw MixJCS100% (1)

- Modelled Fate of Sulphur and Chlorine in Rotary Kilns Part I PDFDocument10 pagesModelled Fate of Sulphur and Chlorine in Rotary Kilns Part I PDFJohn GiannakopoulosPas encore d'évaluation

- 007.heat Balance - New - 25072023hoDocument30 pages007.heat Balance - New - 25072023hoGauranka MoranPas encore d'évaluation

- Mill ProcessDocument6 pagesMill ProcesskamjulajayPas encore d'évaluation

- 4 - False Air Profile Dry Preheater KilnDocument1 page4 - False Air Profile Dry Preheater KilnSundara SubramaniyanPas encore d'évaluation

- CO Sources PDFDocument11 pagesCO Sources PDFElwathig BakhietPas encore d'évaluation

- Bowmanville Cement Technology - Kiln SystemsDocument16 pagesBowmanville Cement Technology - Kiln SystemsMohamed SaadPas encore d'évaluation

- Impact of Alkali, Sulphur and Chlorine in The KilnDocument3 pagesImpact of Alkali, Sulphur and Chlorine in The KilnJa Phe Ti100% (1)

- Ball Charge DesignDocument12 pagesBall Charge DesignPaulo VidasPas encore d'évaluation

- Department of Chemical EngineeringDocument19 pagesDepartment of Chemical EngineeringPandia RajanPas encore d'évaluation

- Ceramic Ball in Cement IndustryDocument6 pagesCeramic Ball in Cement IndustryMauricio PortillaPas encore d'évaluation

- International Cement Review, September 2002: Burning The MixDocument5 pagesInternational Cement Review, September 2002: Burning The MixarylananylaPas encore d'évaluation

- Tf1 - Co2 Protocol v3Document80 pagesTf1 - Co2 Protocol v3indrabudhiPas encore d'évaluation

- Plant Location: Preheater Feed Preheater String - Calciner TypeDocument33 pagesPlant Location: Preheater Feed Preheater String - Calciner TypeDilnesa EjiguPas encore d'évaluation

- Kiln ParametersDocument4 pagesKiln ParametersMsjPas encore d'évaluation

- JW DZ 02a eDocument37 pagesJW DZ 02a eChumpol ChantangPas encore d'évaluation

- Improvement of Productivity Using Tromp Curve MeasDocument11 pagesImprovement of Productivity Using Tromp Curve MeasRachit Bansal BJ20099Pas encore d'évaluation

- The Cement Grinding Office: Home About Us Services Mining Area Links and ContactDocument2 pagesThe Cement Grinding Office: Home About Us Services Mining Area Links and ContactVisnu SankarPas encore d'évaluation

- Common Problems in Cement Plant: One Issue From Each SectionDocument7 pagesCommon Problems in Cement Plant: One Issue From Each SectionYhanePas encore d'évaluation

- NOx Reduction PDFDocument7 pagesNOx Reduction PDFfahimulehsanPas encore d'évaluation

- Process Control of LURM MillDocument6 pagesProcess Control of LURM Millimam janiPas encore d'évaluation

- Instruction For Filling Up The Form-Sb & Keeping Records and Information For Verification ProcessDocument57 pagesInstruction For Filling Up The Form-Sb & Keeping Records and Information For Verification ProcessBùi Hắc HảiPas encore d'évaluation

- Detailed Study of Burining Problems Caused by Sulphur: Prepared by Suraj Bhaskaran Process EngineerDocument14 pagesDetailed Study of Burining Problems Caused by Sulphur: Prepared by Suraj Bhaskaran Process Engineerbsuraj100% (2)

- Knowledge Sharing Training On Grinding Operation by Alok VermaDocument29 pagesKnowledge Sharing Training On Grinding Operation by Alok VermaBir SinghPas encore d'évaluation

- Tube Mill OptimisationDocument7 pagesTube Mill OptimisationJoko DewotoPas encore d'évaluation

- Calculation For CO2 Released During CalcinationDocument4 pagesCalculation For CO2 Released During CalcinationD N SHARMAPas encore d'évaluation

- Tromp Curve Example PDFDocument3 pagesTromp Curve Example PDFThaigroup Cement100% (1)

- Tips On Kiln OperationDocument1 pageTips On Kiln OperationJohn GiannakopoulosPas encore d'évaluation

- Tips For Kiln OperationDocument1 pageTips For Kiln OperationFerdinand MassawePas encore d'évaluation

- Mod 7Document47 pagesMod 7mkpq100% (1)

- Sample ProblemsDocument10 pagesSample ProblemsRichard ValdezPas encore d'évaluation

- New Solvent Method of Prepn For CuPc With Yield 99%Document23 pagesNew Solvent Method of Prepn For CuPc With Yield 99%jiji_loePas encore d'évaluation

- WHR Calculation For Cement KilnDocument11 pagesWHR Calculation For Cement KilnHieu DuongPas encore d'évaluation

- Tips On Kiln OperationDocument10 pagesTips On Kiln OperationElwathig Bakhiet100% (2)

- Boiler Room SavingsDocument79 pagesBoiler Room SavingsmrfxitPas encore d'évaluation

- KC 1.8 Chloride Cycles PDFDocument4 pagesKC 1.8 Chloride Cycles PDFgabigrig100% (1)

- Bioethanol Manufacturing From Lignocellulosic BiomassDocument7 pagesBioethanol Manufacturing From Lignocellulosic BiomassRifqiPas encore d'évaluation

- Lump Formation in Cement SiloDocument2 pagesLump Formation in Cement SiloVipan Kumar Dogra100% (1)

- Anti Aging ExcersiesDocument8 pagesAnti Aging ExcersiesVipan Kumar DograPas encore d'évaluation

- 6.1 Determination of Raw Mixture BurnabilityDocument2 pages6.1 Determination of Raw Mixture BurnabilityVipan Kumar DograPas encore d'évaluation

- Combustion Gas Volumes in Coal or Oil or Natural Gas FiringDocument1 pageCombustion Gas Volumes in Coal or Oil or Natural Gas FiringVipan Kumar DograPas encore d'évaluation

- Mantra Pushpam Hidden MeaningDocument13 pagesMantra Pushpam Hidden MeaningVipan Kumar DograPas encore d'évaluation

- Utiilzation Factor PDFDocument7 pagesUtiilzation Factor PDFVipan Kumar DograPas encore d'évaluation

- NM3 To ACTUAL M3Document3 pagesNM3 To ACTUAL M3Vipan Kumar DograPas encore d'évaluation

- 7 Most Common Problem in Pyro Processing For Kiln and CoolerDocument10 pages7 Most Common Problem in Pyro Processing For Kiln and CoolerVipan Kumar DograPas encore d'évaluation

- Guru GitaDocument3 pagesGuru GitaVipan Kumar DograPas encore d'évaluation

- Minor Hindu Gods Part2Document8 pagesMinor Hindu Gods Part2Vipan Kumar DograPas encore d'évaluation

- Gas Volume CalculationsDocument2 pagesGas Volume CalculationsVipan Kumar DograPas encore d'évaluation

- Cement Plant - Energy OptimisationDocument12 pagesCement Plant - Energy OptimisationSatya MakhijaPas encore d'évaluation

- Final Q Curves and P Curves From Corresponding Fan Curves: 1. Actual 2. ActualDocument1 pageFinal Q Curves and P Curves From Corresponding Fan Curves: 1. Actual 2. ActualVipan Kumar DograPas encore d'évaluation

- Kiln Heat Balance 1Document33 pagesKiln Heat Balance 1Vipan Kumar Dogra75% (4)

- Acid Dew Point Corrosion ChimneyDocument4 pagesAcid Dew Point Corrosion Chimneyzementhead100% (1)

- A Scientific LookDocument2 pagesA Scientific LookVipan Kumar DograPas encore d'évaluation

- A Scientific LookDocument2 pagesA Scientific LookVipan Kumar DograPas encore d'évaluation

- Coal GrindingDocument2 pagesCoal GrindingVipan Kumar DograPas encore d'évaluation