Académique Documents

Professionnel Documents

Culture Documents

Variable Damping

Transféré par

pavan_joshi_5Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Variable Damping

Transféré par

pavan_joshi_5Droits d'auteur :

Formats disponibles

AbstractNowadays, a passenger car suspension must has high

performance criteria with light weight, low cost, and low energy

consumption. Pilot controlled proportional valve is designed and

analyzed to get small pressure change rate after blow-off, and to get a

fast response of the damper, a reverse damping mechanism is adapted.

The reverse continuous variable damper is designed as a HS-SH

damper which offers good body control with reduced transferred input

force from the tire, compared with any other type of suspension

system. The damper structure is designed, so that rebound and

compression damping forces can be tuned independently, of which the

variable valve is placed externally. The rate of pressure change with

respect to the flow rate after blow-off becomes smooth when the fixed

orifice size increases, which means that the blow-off slope is

controllable using the fixed orifice size. Damping forces are measured

with the change of the solenoid current at the different piston

velocities to confirm the maximum hysteresis of 20 N, linearity, and

variance of damping force. The damping force variance is wide and

continuous, and is controlled by the spool opening, of which scheme is

usually adapted in proportional valves. The reverse continuous

variable damper developed in this study is expected to be utilized in

the semi-active suspension systems in passenger cars after its

performance and simplicity of the design is confirmed through a real

car test.

KeywordsBlow-off, damping force, pilot controlled

proportional valve, reverse continuous damper.

I. INTRODUCTION

O enhance the performance of the suspension system of

vehicles, electronically controlled suspension systems

have been studied and developed based upon the sky-hook

damping algorithm presented by Karnopp [1] in 1974. In the

1990's hydraulic active suspension systems emerged in J apan

[2]-[3].

The systems have disadvantages with the increase of weight,

energy consumption, and price since it needs separately

installed hydraulic semi-active suspension systems [4]-[5]. In

1994, a vehicle with a continuous variable damper appeared

[6]. In this system, the orifice in the piston valve was regulated

by a step motor of 9 to 140 steps, of which switching impact is

reduced, but the reaction speed becomes slow. During the

extension stroke, the damping force is changed over a wide

range, while the damping force various becomes limited during

the compression stroke.

In this study, a continuous variable damper was developed

for semi-active suspension systems of passenger cars. It has a

wide range of damping force in both compression and

extension strokes.

NOMENCLATURE

A [m

2

] Area

F [ kg ] Force

P [kg/m

2

] Pressure

Q [m

3

/s] Flow rate

Special characters

Cd [-] Coefficient of discharge

[kg/m

3

] Density

Subscripts

1 Inlet pressure (high pressure)

2 Orifice pressure( mediumpressure)

3. Outlet pressure (low pressure)

c Cross sectional area of fixed orifice

o Open

s Shut

sp Spring

v Cross sectional area of variable orifice

TABLE I

SKY-HOOK DAMPING ALGORITHM

Vertical motion of

body

(less than 2Hz)

Up Down

Compression Soft Hard

Relative motion

between body and

wheels Rebound Hard Soft

II. NECESSITY OF REVERSE TYPE DAMPER

In sky-hook damping algorithm, the damping force is

regulated according to the vertical motion of the body and the

relative motion between the body and the wheels that shows

four cases as in Table I. In this system, the damper should

response within 10 m/s, since the vehicle wheels oscillate faster

than 10Hz and additional valve mechanism may be installed to

control damping force during compression and extension

strokes, respectively. In the reverse damping mechanism, the

damping force is regulated mechanically by the inside fluid

state with no sensor to detect the relative motion between the

wheels and body due to the vertical vibration of body.

A Study on the Performance Characteristics of

Variable Valve for Reverse Continuous Damper

Se Kyung Oh, Young Hwan Yoon, and Ary Bachtiar Krishna

T

World Academy of Science, Engineering and Technology 32 2007

123

Hole

Disc

Slit

High pressure

Low pressure

P

Q

Blow-Off pressure

Fig. 1 Passive damper

III. ANALYSIS OF DAMPING

Fig. 2 shows a three stage variable damper, there is an

additional oil passage compared with the passive damper as

shown in Fig. 1. This shows the hydraulic circuit and pressure

flow rate relation. Damping force is controlled by the orifice

sizes. Variable orifice size is regulated in three stages, and also

damping force is changed in three stages.

The change rates of damping force are different with the

flow velocities, because there is only one blow-off pressure.

Fig.3 shows the hydraulic circuit and pressure-flow rate

relation of the variable damper designed to reduce the

difference of the damping force change rates in high and low

flow velocities. Three blow-off pressures result as the shutter

rotates. The hardest damping force takes place when first and

second orifices shut simultaneously. As the shutter rotates, the

first variable orifice opens, later on the second variable orifice

opens, accordingly pressure-flow rate relation varies. When

only the first variable orifice opens, the P-Q curves have abrupt

changes at blow-off pressures of first sub disc and main disc.

When both of first and second variable orifices open, the

damping force reduces suddenly at blow-off pressure of two

sub discs and main disc.

Hole

Disc

Slit

High pressure

Low pressure

Variable

orifice

(a) Hydraulic circuit (b) P-Q curves

Fig. 2 Three stage variable damper

In this study, to overcome such weakness, pilot controlled

proportional valve mechanism is utilized as shown in Fig. 4. In

reverse continuous variable damper, damping force can be

standardized but it is too hard to reduce the slope of the P-Q

curve after blow-off, since the orifice size cannot be increased

due to limited space.

(1)

(2)

(3)

(4)

(5)

(a) Hydraulic circuit

(b) P-Q curves

Fig. 3 Variable damper of orifice control

World Academy of Science, Engineering and Technology 32 2007

124

A

o

s A

High pressure(P )

Low pressure

(P )

A

c

A

v

3

P

2

1

Fig. 4 Schematic of pilot controlled proportional valve

Fig. 4, A

c

and A

v

are cross sectional areas of fixed and

variable orifices, respectively. These two orifices determine

control pressure P

2

before blow-off, oil flows through A

c

and

A

v

. Where F

o

, F

s

, F

sp

,A

o

and A

s

are valve opening and

shutting forces, initial load on the valve, two end cross

sectional areas of the valve, respectively. Flow rate of blow-off

is obtained as a function of A

v

(6)

F

sp

is constant, thus

A

o

< A

s

; Q increases at blow-off as A

v

decreases.

A

o

> A

s

; Q decreases at blow-off as A

v

decreases.

From the pressure-flow rate reaction, P-Q curve, at blow-off',

P

1

-P

2

can be calculated.

(7)

(8)

(9)

Fig. 5 and Fig. 6 show forces subject to the valve and

pressure with respect to flow rate.

In the case of A

o

< A

s

, for the small variation of A

v

, blow-off

pressure change a lot, for the constant increase of A

v

, blow-off

pressure reduces much in the beginning. But the reducing rate

lessens later. It is relatively hard to get high pressure with the

same flow rates.

In case of A

o

> A

s

, as in Fig. 5, since the angle between F

s

curve F

o

curve is larger than the case of A

o

< A

s

blow-off

pressure is less sensitive with respect to the A

v

variation. When

A

v

increases slightly, blow-off pressure decreases slightly. High

pressure can be obtained with a relatively small blow amount,

and all boundary of pressure can be decided easily.

Consequently, the case of A

o

> A

s

is desirable when the pilot

controlled proportional damper is utilized on suspension

systems.

A

o

A

o

s

A

A

o

s

A

s

A

s

A A

o

=

s

A A

o

>

s

A A

o

<

F

Q

F

s

Fo

=F

sp

F

Q

Fs

Fo

F

Q

Fs

Fo

Fig. 5 F-Q diagrams for

A

o

A

o

s

A

A

o

s

A

P

Q

P

Q

P

Q

s

A

s

A A

o

=

s

A A

o

>

s

A A

o

<

Fig. 6 P-Q diagrams for

World Academy of Science, Engineering and Technology 32 2007

125

Damping force

H-S Variable S-S Variable S-H

Solenoid current

Rebound damping force

Compression damping force

Fig. 7 Damping characteristic of reverse damper (HS-SH damper)

IV. VARIABLE VALVE DESIGN

Damping force is controlled by the orifice size of the piston

valve in most dampers, where the large of compression

damping force should be small enough to prevent cavitations in

extension chamber.

In this study, to assure enough variable range of damping

force in compression, external variable valve is installed, and to

get fast response at small pressure change rate after blow-off, a

reverse pilot controlled proportional valve is designed. The

reverse damper, which is a HS-SH damper as shown in Fig. 7,

offers good body control with reduced transferred input force

from time, compared with other types of dampers.

The variable valve in designed as reverse type, as in Fig. 7,

which has H-S range, where extension damping force is hard

and compression damping force is soft, and S-H range with soft

extension damping and hard compression damping.

Fig. 8 shows continuous variable valve which was designed

in this study, where extension at compression variable valves

werehao assembled in series, for oil to flow to compression

chamber from extension chamber through extension variable

valve in extension stroke, in compression stroke, oil flows to

extension chamber from compression chamber through

compression valve

The damping force is controlled by regulating disc

pressure in pilot valve by the change of spool opening

according to the solenoid input currency.

V. DAMPER DESIGN

Fig. 9 shows variable damper in this study, which is an

external variable valve type damper. In piston, then is a hole to

assure blow only to extension chamber, and on the extension

chamber side of the side thin plate is located to roll as a check

valve. In body valve, there is a hole in the same way, to assure

oil flows only to compression chamber. To prevent oil leakage

from the chambers O-rings are installed in the middle cylinder.

Fig. 8 Sectional drawing of continuous variable valve

Fig. 9 Sectional drawing of variable damper

During extension stroke, oil flows as follows:

1) Extension chamber inner cylinder upper hole

extension variable valve inner cylinder lower hole

compression chamber.

2) Reservoir chamber body valve compression chamber.

During compression stroke, oil flows as follows:

3) Compression chamber piston valve extension

chamber.

World Academy of Science, Engineering and Technology 32 2007

126

Fig. 10 Photograph of reverse continuous variable damper

4) Compression chamber inner cylinder lower hole

compression variable valve guide in the reservoir chamber

reservoir chamber.

Flow rate is calculated as the product of the cross sectional

area of the piston rod and flow velocity. There is no relation

between extension damping forces and compression damping

force, which are to be controlled independently using extension

variable valve and compression variable valve, respectively

Fig. 10 shows the reverse continuous variable damper

developed in this study.

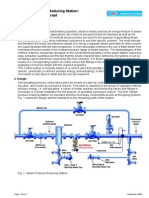

VI. VARIABLE VALVE

It takes too much time and endeavors to tune the assembled

continuous variable damper using damping force tester. To

save time and endeavor, variable valve and damper are tuned

separately. Fig. 11 shows schematic diagram of the experiment

circuit to test the variable valve during extension and

compression stroke. To prevent the influence of test valve

opening, compensation flow control valve is used. Fig. 12 and

Fig. 13 shows pressure vs. flow rate curve.

As solenoid current becomes large, that is, the fixed orifice

size increases the blow-off slope decreases. This result

coincides with the results of Fig. 6. Thus, the blow-off slope

can be controlled by regulating the fixed orifice size

Fig. 11 Schematic diagram of the experimental circuit

0 2 4 6 8 10

0

20

40

60

80

100

0 (A)

0.2 (A)

0.4 (A)

0.5 (A)

0.6 (A)

0.7 (A)

P

r

e

s

s

u

r

e

(

B

a

r

)

Flow rate (lpm)

Fig. 12 P-Q characteristic at hole orifice 1.0x2

0 2 4 6 8 10

0

20

40

60

80

100

0 (A)

0.2 (A)

0.4 (A)

0.5 (A)

0.6 (A)

0.7 (A)

P

r

e

s

s

u

r

e

(

B

a

r

)

Flow rate (lpm)

Fig. 13 P-Q characteristic at hole orifice 1.0x4

Fig. 14 shows pressure change with respect to solenoid

current in certain flow amount, which shows similar change

pattern to the damping force change in reverse damper.

0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0 1.1 1.2

-50

-40

-30

-20

-10

0

10

20

30

40

50

60

70

0.05m/s

0.1m/s

0.3m/s

P

r

e

s

s

u

r

e

(

B

a

r

)

Current (A)

Fig. 14 P-I characteristic of variable valve

World Academy of Science, Engineering and Technology 32 2007

127

VII. CONTINUOUS VARIABLE DAMPER

0.2 0.4 0.6 0.8 1.0 1.2

-80

-40

0

40

80

120

160

200

Reb. 0.05m/s

Com. 0.05m/s

Reb. 0.1 m/s

Com. 0.1 m/s

Reb. 0.3 m/s

Com. 0.3 m/s

D

a

m

p

i

n

g

F

o

r

c

e

(

k

g

f

)

Current (A)

Fig. 15 F-I characteristics of reverse continuous variable damper

0.0 0.2 0.4 0.6 0.8 1.0 1.2 1.4

-200

-100

0

100

200

300

400

500

600

0.2A

0.4A

0.5A

0.6A

0.7A

0.9A

1.0A

1.2A

D

a

m

p

i

n

g

f

o

r

c

e

(

k

g

f

)

Velocity (m/s)

Fig. 16 F-V characteristics of reverse continuous variable damper

In Fig. 16, damping force change with respect to solenoid

current is shown, when piston velocities are 0.5, 0.1, and 0.3

m/sec. From the figure, it is known that the linearity of damping

force change is good, maximum hysteresis is below 20kgf, and

reverse mechanism, which is of H-S, S-S, S-H range, is

operated. Fig.16 shows damping force with respect to

excitation velocity at the different solenoid currents. Excitation

displacements are 40 mm, velocities are from 0.01 m/sec to 1.5

m/sec. When solenoid current is 0.2 A, H-S appears, but S-H

appears with 1.2 A solenoid current.Damping force variation

ranges are 200 kgf in extension at 90 kgf in compression at the

velocity of 0.3 m/sec

VIII. CONCLUSION

To develop continuous variable damper for semi-active

suspension of a passenger cars, variable damping mechanisms

were analyzed and a damper was designed and developed. The

performance was confirmed through experiments.

The variable valve was developed with pilot proportional

valve, which has wide continuous variance of damping force,

and reverse damping mechanism to get prompt response, by the

spool opening.

The reverse continuous variable damper was developed, in

which extension and compression damping force was tuned

independently by extension and compression valves,

respectively, and variable valve was placed externally.

Semi-active suspensions are to be in the mainstream of the

future passenger car suspensions, because of high performance

with low cost and low energy consumption also market share is

expected to be extended.

REFERENCES

[1] D. C. Karnopp, M. J . Grosby, and R. A. Harward, , "Vibration control

using semi-active force generator", ASME, J. of engineering for industry,

vol. 98, May 1974

[2] S. Buma, H. Kondo, K. Sato, and T. Aburaya, "Development of the

Toyota Active Control Suspension for the 1989 Celica", Toyota technical

paper, Vol. 40, No. 2. 1990

[3] S. Buma, H. Satou, T. Yonekawa, Y. Ohnuma, K. Hattori, and M.

Shiguhara, "Synthesis and Development of the Active Control

Suspension", JSME (C) Vol. 57, No. 534, 1991.

[4] D. Knutson, "Selection and Design of Electrohydraulic Valves for

Electrically-Controlled Automotive Suspension System", SAE 912500,

1991

[5] F. Wobner, P. Causeman, "Continuously Adjustable Shock Absorber",

AVEC 92(1992.9), 923055, 1992

[6] J . Emura, S. Kakizaki, F. Yamaoka, and M. Nakamura, "Development of

the Semi-Active Suspension SystemBased on the Sky-hook Damper

Theory", SAE 940863, 1994.

Se Kyung Oh was born on March 06, 1948, Yi-Sung, Kyungbuk, South Korea.

He is Doctor of hydraulic engineering fromPukyong National University,

Busan, South Korea. He was with School of Mechanical and Aerospace

Engineering, Gyeongsang National University, Institute of Marine Industry,

445 Inpyongdong - Tongyong, South Korea, as professor on hydraulic

engineering area.

Young Hwan is Doctor in hydraulic engineering from Busan National

University, Busan, South Korea. He works in Shinho System, Co. Ltd, #B-702,

Sangyong IT Twin Tower, 442-5, Sangdaewon-dong, J ungwon-gu, Seongnam,

Gyeonggido, South Korea, as Director.

Ary Bachtiar Krishna Putra is Ph.D student in Gyeongsang National

University, Tongyong, South Korea. This work was supported by the New

University for Regional Innovation Projects (NURI) project. He was PhD.

Student in Mechanical and System Engineering, Gyeongsang National

University, 445 Inpyongdong - Tongyong, South Korea.

World Academy of Science, Engineering and Technology 32 2007

128

Vous aimerez peut-être aussi

- Stepless Variable Capacity ControlDocument7 pagesStepless Variable Capacity Controlswapneel_kulkarniPas encore d'évaluation

- Influence of Axial Compressor Flow Passage Geometry Changes On Gas Turbine Engine Work ParametersDocument10 pagesInfluence of Axial Compressor Flow Passage Geometry Changes On Gas Turbine Engine Work ParametersDyahSeptiWidhayatiPas encore d'évaluation

- Wartsila CPP PaperDocument4 pagesWartsila CPP Papergatheringforgardner9550Pas encore d'évaluation

- 1.1.1 Functions of Flow-Control ValvesDocument24 pages1.1.1 Functions of Flow-Control Valvesatashi baran mohantyPas encore d'évaluation

- SS 09Document3 pagesSS 09Ajaykumar TiwariPas encore d'évaluation

- Effects of Compressor Interstage PDFDocument38 pagesEffects of Compressor Interstage PDFeamazomPas encore d'évaluation

- 205 Drag Valves For Boiler Feedpump RecirculationDocument6 pages205 Drag Valves For Boiler Feedpump Recirculationesakkiraj1590Pas encore d'évaluation

- Lab 5 - Operating Characteristics of A Centrifugal PumpDocument9 pagesLab 5 - Operating Characteristics of A Centrifugal PumpGianne Nigelle DoriaPas encore d'évaluation

- Centrifugal Compressor Surge and Speed ControlDocument13 pagesCentrifugal Compressor Surge and Speed ControlDaniel Puello RodeloPas encore d'évaluation

- DesignRules For HighDampingDocument8 pagesDesignRules For HighDampingRajesh MalikPas encore d'évaluation

- 6.9 Calculation of Flow Quantity Through An Orifice: Equivalent To P Multiplied by QDocument3 pages6.9 Calculation of Flow Quantity Through An Orifice: Equivalent To P Multiplied by Qviano_octaPas encore d'évaluation

- Some Aspects of Numerical Simulation of Control Valves For Steam TurbinesDocument1 pageSome Aspects of Numerical Simulation of Control Valves For Steam TurbinesSharat ChandraPas encore d'évaluation

- Flow Control ValvesDocument6 pagesFlow Control ValvesMohamed RadwanPas encore d'évaluation

- 1 s2.0 S1877705816313145 MainDocument5 pages1 s2.0 S1877705816313145 MainKenny Lex LutorPas encore d'évaluation

- Characteristics of Control ValveDocument9 pagesCharacteristics of Control ValvecomodusPas encore d'évaluation

- Computational Fluid Dynamic Analysis of Flow Coefficient For Pan Check ValveDocument4 pagesComputational Fluid Dynamic Analysis of Flow Coefficient For Pan Check ValveMax KocourPas encore d'évaluation

- Variable Trim Compressor - A New Approach To Variable Compressor GeometryDocument10 pagesVariable Trim Compressor - A New Approach To Variable Compressor GeometryAlbert CalderonPas encore d'évaluation

- Fan PerformanceDocument8 pagesFan PerformanceRajeevAgrawalPas encore d'évaluation

- Valvulas STEPLESSDocument10 pagesValvulas STEPLESSHerlin MorenoPas encore d'évaluation

- Stepless Variable Capacity ControlDocument7 pagesStepless Variable Capacity ControlMOHAMADPas encore d'évaluation

- 7 - Control Valve CharacteristicsDocument11 pages7 - Control Valve CharacteristicsAhmed ShahabiPas encore d'évaluation

- Valve Characteristic Is The Relation Between The Flow Through The Valve and The Valve Stem PositionDocument13 pagesValve Characteristic Is The Relation Between The Flow Through The Valve and The Valve Stem PositionPortia ShilengePas encore d'évaluation

- Kaltfrase - BM - 1000 - 1200 - 1300 - 30 - 2 - & - 2 - PB - BK HidraulicoDocument249 pagesKaltfrase - BM - 1000 - 1200 - 1300 - 30 - 2 - & - 2 - PB - BK Hidraulicosebastian blancoPas encore d'évaluation

- Cowl DeflectionDocument7 pagesCowl DeflectionSrinivasan GunasekaranPas encore d'évaluation

- 07 Fluid Transports EquipmentsDocument12 pages07 Fluid Transports EquipmentsarfpowerPas encore d'évaluation

- Axial Compressor Chapter OneDocument15 pagesAxial Compressor Chapter OnenazeemlngPas encore d'évaluation

- Pneumatic - Book (5-17) PDFDocument13 pagesPneumatic - Book (5-17) PDFibnu100% (1)

- Flow Control ValvesDocument24 pagesFlow Control Valvesmk_chandru100% (1)

- Flowing Well PerformanceDocument57 pagesFlowing Well PerformanceTogoumas Djide100% (4)

- Flowing Well PerformanceDocument57 pagesFlowing Well PerformancemkwendePas encore d'évaluation

- Pump FundamentalsDocument127 pagesPump FundamentalsSheik Mohd50% (2)

- 3 Way ValveDocument8 pages3 Way ValveSoni Kristianto TariganPas encore d'évaluation

- Análisis of Ducted Propeller Design 1970-PhD - OosterveldDocument127 pagesAnálisis of Ducted Propeller Design 1970-PhD - Oosterveldfacio8483Pas encore d'évaluation

- Empuje Axial en Bombas VerticalesDocument6 pagesEmpuje Axial en Bombas VerticalesKaler Soto PeraltaPas encore d'évaluation

- Valve Control 0406Document15 pagesValve Control 0406Catalin PruncuPas encore d'évaluation

- PrdsDocument0 pagePrdssandi1111Pas encore d'évaluation

- Compressible Flow Across A Varying Area PassageDocument4 pagesCompressible Flow Across A Varying Area PassageGaurav VaibhavPas encore d'évaluation

- Ducted Prop For STOL PaperDocument8 pagesDucted Prop For STOL PaperLEADAPas encore d'évaluation

- Acoustical Modeling of Reciprocating Compressors With Stepless Unloaders PDFDocument12 pagesAcoustical Modeling of Reciprocating Compressors With Stepless Unloaders PDFRapee PuaksungnoenPas encore d'évaluation

- Pavc Complete Hy28 2662 CDDocument46 pagesPavc Complete Hy28 2662 CDMoein Emani100% (1)

- Antisurge Control SystemDocument10 pagesAntisurge Control Systemlac1981Pas encore d'évaluation

- Handout Water PumpDocument7 pagesHandout Water PumpGarrett KnappPas encore d'évaluation

- Sai New RegenerativeDocument20 pagesSai New RegenerativeMahesh APas encore d'évaluation

- Performance and Experimentation On Centrifugal PumpDocument10 pagesPerformance and Experimentation On Centrifugal PumpLohith AcharyaPas encore d'évaluation

- Control Valve Actuators and PositionersDocument23 pagesControl Valve Actuators and PositionersPg LisenPas encore d'évaluation

- Linear Hydraulic CircuitsDocument11 pagesLinear Hydraulic CircuitsBetileno QuadAlexPas encore d'évaluation

- Guidelines For Selecting The Proper Valve CharacteristicDocument6 pagesGuidelines For Selecting The Proper Valve CharacteristicIamPedroPas encore d'évaluation

- Pump Performance Four Quadrante - Pumping Thru ESPDocument8 pagesPump Performance Four Quadrante - Pumping Thru ESPTarcísio PortoPas encore d'évaluation

- Numerical Simulation of PCV ValveDocument5 pagesNumerical Simulation of PCV Valve11751175Pas encore d'évaluation

- t000005801 PDFDocument7 pagest000005801 PDFMohammed Hassan B KorainaPas encore d'évaluation

- Antisurge Control SystemDocument10 pagesAntisurge Control Systemsopan saPas encore d'évaluation

- 3 Surging Phenomena in Centrifugal Gas CompressorDocument33 pages3 Surging Phenomena in Centrifugal Gas CompressorDwi Muhammad PamungkasPas encore d'évaluation

- Analitcka Studija Dinamike I Stabinosti Sigurnosnog VentilaDocument8 pagesAnalitcka Studija Dinamike I Stabinosti Sigurnosnog VentilaMarko RisticPas encore d'évaluation

- Resumo I4Document10 pagesResumo I4Damy ManesiPas encore d'évaluation

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGD'EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGPas encore d'évaluation

- Hydraulics and Pneumatics: A Technician's and Engineer's GuideD'EverandHydraulics and Pneumatics: A Technician's and Engineer's GuideÉvaluation : 4 sur 5 étoiles4/5 (8)

- Understanding Welding Symbols Terms and DefinitionsDocument23 pagesUnderstanding Welding Symbols Terms and DefinitionsseymaPas encore d'évaluation

- AWS - Welding SymbolsDocument1 pageAWS - Welding SymbolsAli Saifullizan IsmailPas encore d'évaluation

- Deciphering Weld SymbolsDocument11 pagesDeciphering Weld SymbolsAhmad Reza AtefPas encore d'évaluation

- A675/A675MDocument5 pagesA675/A675Mpavan_joshi_5100% (1)

- Anodising ProcessDocument7 pagesAnodising Processpavan_joshi_5Pas encore d'évaluation

- Understanding Welding Symbols Terms and DefinitionsDocument23 pagesUnderstanding Welding Symbols Terms and DefinitionsseymaPas encore d'évaluation

- Understanding Welding Symbols Terms and DefinitionsDocument23 pagesUnderstanding Welding Symbols Terms and DefinitionsseymaPas encore d'évaluation

- Aluminium SpecificationDocument4 pagesAluminium Specificationpavan_joshi_5Pas encore d'évaluation

- Circlip Design PDFDocument6 pagesCirclip Design PDFpavan_joshi_5Pas encore d'évaluation

- Astm D610 PDFDocument6 pagesAstm D610 PDFAmbarPas encore d'évaluation

- Socket Set Screw SizeDocument2 pagesSocket Set Screw Sizepavan_joshi_5Pas encore d'évaluation

- Delrin 100P NC010Document4 pagesDelrin 100P NC010Keshav JhanwarPas encore d'évaluation

- Technical Notehowmanythreads PDFDocument4 pagesTechnical Notehowmanythreads PDFGatyo GatevPas encore d'évaluation

- 8.mech - IJME - Fluid - Flow - Nitin v. SatputeDocument10 pages8.mech - IJME - Fluid - Flow - Nitin v. Satputeiaset123Pas encore d'évaluation

- GD&TDocument7 pagesGD&Tpavan_joshi_5Pas encore d'évaluation

- Astm D 714 PDFDocument5 pagesAstm D 714 PDFpavan_joshi_550% (4)

- GD&TDocument26 pagesGD&Tpavan_joshi_5Pas encore d'évaluation

- GD&TDocument19 pagesGD&Tpavan_joshi_5Pas encore d'évaluation

- Technical Notehowmanythreads PDFDocument4 pagesTechnical Notehowmanythreads PDFGatyo GatevPas encore d'évaluation

- Press Information: New Product With World-First Front Fork Technology Released at EICMA 2014Document3 pagesPress Information: New Product With World-First Front Fork Technology Released at EICMA 2014pavan_joshi_5Pas encore d'évaluation

- GD&TDocument17 pagesGD&Tpavan_joshi_5Pas encore d'évaluation

- Metric Set ScrewDocument1 pageMetric Set Screwpavan_joshi_5Pas encore d'évaluation

- Section 2: Early System vs. G.D.&T. SystemDocument6 pagesSection 2: Early System vs. G.D.&T. Systempavan_joshi_5Pas encore d'évaluation

- Helpful Hints 2Document68 pagesHelpful Hints 2Uygur Zeren100% (5)

- Retaining Ring DesignDocument3 pagesRetaining Ring Designpavan_joshi_5Pas encore d'évaluation

- CFDDocument36 pagesCFDpavan_joshi_5Pas encore d'évaluation

- A-Type Circlip Detail PDFDocument2 pagesA-Type Circlip Detail PDFsunildhimankumarPas encore d'évaluation

- Explanation of Surface RoughnessDocument8 pagesExplanation of Surface RoughnessN.Palaniappan100% (6)

- Smalley RingsDocument6 pagesSmalley RingsjPas encore d'évaluation

- Delrin 100P NC010Document4 pagesDelrin 100P NC010Keshav JhanwarPas encore d'évaluation