Académique Documents

Professionnel Documents

Culture Documents

P1700 NT

Transféré par

nimonhTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

P1700 NT

Transféré par

nimonhDroits d'auteur :

Formats disponibles

P-1700 NT11, NT06, & CL2611

Udel P-1700 polysulfones are tough, rigid, high-strength

thermoplastics that are suitable for continuous use up to

300F (149C). The resins are resistant to oxidation and

hydrolysis and withstand prolonged exposure to high tem-

peratures and repeated sterilization. Udel P-1700

polysulfones are highly resistant to mineral acids, alkali

and salt solutions. Their resistance to detergents and hy-

drocarbon oils is good, but they will be attacked by polar

solvents such as ketones, chlorinated hydrocarbons, and

aromatic hydrocarbons.

These resins are also highly resistant to degradation by

gamma or electron beam radiation. Electrical properties of

Udel P-1700 polysulfones are stable over a wide tempera-

ture range and after immersion in water or exposure to

high humidity.

The resins comply with 21CFR 177.1655 and may be

used in articles intended for repeated use in contact with

foods. Additionally, they are approved by the NSF, by the

Department of Agriculture for contact with meat and poul-

try, and by the 3-A Sanitary Standards of the Dairy Asso-

ciation.

In addition to the three color variants covered by this data

sheet, Udel polysulfone is available in a variety of trans-

parent and opaque colors.

Solvay Advanced Polymers, L.L.C.

4500 McGinnis Ferry Road

Alpharetta, Georgia 30005-3914

www.solvayadvancedpolymers.com

Product Data

UDEL

polysulfone

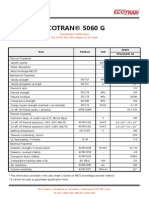

Typical Properties of Udel P-1700 Resins

ASTM Typical Values

(1)

Test U.S. Customary units SI units

Properties Method Value Units Value Units

General

Specific Gravity D 792 1.24 1.24

Water Absorption, 24 hours D 570 0.30 % 0.30 %

Melt Flow, 343C, 2.16 kg D 1238 6.5 g/10 min 6.5 g/10 min

Mold Shrinkage D 955 0.007 in/in 0.007 mm/mm

Mechanical

Tensile Strength D 638 10.2 kpsi 70.3 MPa

Tensile Modulus D 638 360 kpsi 2.48 GPa

Tensile Elongation at Break D 638 50-100 % 50-100 %

Flexural Strength D 790 15.4 kpsi 106.2 MPa

Flexural Modulus D 790 390 kpsi 2.69 GPa

Tensile Impact Strength D 1822 200 ft-lb/in

2

420 kJ/m

2

Impact Strength- Notched Izod D 256 1.3 ft-lb/in 69 J/m

Thermal

Deflection Temperature at 264 psi (1.8 MPa) D 648 345 F 174 C

Coefficient of Thermal Expansion D 696 31 ppm/F 56 ppm/C

Electrical

Dielectric Strength D 149 425 V/mil 17 kV/mm

Dielectric Constant @ 60 Hz D 150 3.03 3.03

Dielectric Constant @ 10

3

Hz 3.04 3.04

Dielectric Constant @ 10

6

Hz 3.02 3.02

Dissipation Factor @ 60 Hz D 150 0.0007 0.0007

Dissipation Factor @ 10

3

Hz 0.0010 0.0010

Dissipation Factor @ 10

6

Hz 0.0060 0.0060

Volume Resistivity D 257 3 x 10

16

ohm-cm 3 x 10

16

ohm-cm

Color

NT11 ( Natural) light amber

NT 06 (Natural) very light amber

CL 2611 (Clear) nearly water white

1) Actual properties of individual batches will vary within specification limits.

Drying

Udel P-1700 polysulfones must be dried before they are

fabricated to avoid streaking, splaying, or bubbling. Pellets

can be dried in a circulating hot air oven or in a dehumidi-

fied hopper dryer.

To oven dry, spread the pellets on trays to a 1-2 inch

depth and dry for 3.5 hours at 275 to 325F (135 to

163C). Handle the dried resin carefully to prevent reab-

sorption of moisture from the atmosphere.

To hopper dry, use inlet air with a dew point of -25F

(-32C) at a temperature of 275 to 325F (135 to 163C)

and a residence time of 3.5 hours.

Injection Molding

Udel P-1700 resins can be readily injection molded on

standard screw injection equipment. Although it is recom-

mended that the shot size be between 50 and 75% of ma-

chine capacity, Udel P-1700 resins have excellent thermal

stability, and good results have been obtained with shot

sizes as small as 10% of capacity. Stock temperature will

generally range from 625 to 725F (330 to 385C), de-

pending on mold design and the type of equipment being

used.

Mold temperatures of at least 250F (121C) are recom-

mended. In the case of complex parts requiring long flow

lengths or having thin crosssections, or where low resid-

ual stress levels are required, the mold temperatures

should be 300 to 325F (149 to 163C).

Weld line strength of Udel P-1700 resins is generally ex-

cellent, but it is good design practice to avoid weld lines in

areas known to be subject to high stress.

Standard Packaging and Labeling

Udel P-1700 polysulfone resins are packaged in multiwall

paper bags containing 55.115 pounds (25 kg) of material.

Special packaging can be supplied upon request. Individ-

ual packages will be plainly marked with the product num-

ber, the color, the lot number, and the net weight.

Product Safety and Emergency Service

For product safety information or a Material Safety Data

Sheet on a product of Solvay Advanced Polymers

1 (800) 621-4557

1 (770) 772-8880 outside of U.S.

For information or help in an emergency such as a spill,

leak, fire or explosion, call day or night:

Emergency Health Information

1 (800) 621-4590

1 (770) 772-5177 outside of U.S.

Emergency Spill Information

CHEMTREC 1 (800) 424-9300

1 (703) 527-3887 outside of U.S.

collect calls accepted

For Additional Information

Technical Service

1 (800) 621-4557

Customer Service

1 (800) 848-9744

U-50038 Copyright 2001, Solvay Advanced Polymers, L.L.C. All rights reserved. R 02/08

To our actual knowledge, the information contained herein is accurate as of the date of this document. However, neither Solvay Advanced Polymers, LLC nor any of its affiliates makes any warranty, ex-

press or implied, including merchantability or fitness for use, or accepts any liability in connection with this information or its use. This information is for use by technically skilled persons at their own dis-

cretion and risk and does not relate to the use of this product in combination with any other substance or any other process. This is not a license under any patent or other proprietary right. The user alone

must finally determine suitability of any information or material for any contemplated use, the manner of use and whether any patents are infringed. This information gives typical properties only and is not

to be used for specification purposes. Solvay Advanced Polymers, LLC reserves the right to make additions, deletions, or modifications to the information at any time without prior notification.

Udel is a registered trademark of Solvay Advanced Polymers, L.L.C.

Udel P-1700 NT11, NT06, & CL2611

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Compd Data Sheet 1040G ISO Ver 150106Document1 pageCompd Data Sheet 1040G ISO Ver 150106nimonhPas encore d'évaluation

- Type Test Method Unit: PhysicalDocument1 pageType Test Method Unit: PhysicalnimonhPas encore d'évaluation

- Compd Data Sheet 5060G ISO Ver 150106Document1 pageCompd Data Sheet 5060G ISO Ver 150106nimonhPas encore d'évaluation

- Ecotran PPT (English)Document15 pagesEcotran PPT (English)nimonhPas encore d'évaluation

- Compd Data Sheet 1040G ASTM Ver 150106Document1 pageCompd Data Sheet 1040G ASTM Ver 150106nimonhPas encore d'évaluation

- Compd Data Sheet 5060G ASTM Ver 150106Document1 pageCompd Data Sheet 5060G ASTM Ver 150106nimonhPas encore d'évaluation

- T50 800 01Document5 pagesT50 800 01nimonhPas encore d'évaluation

- Zytel 80G33HS1L BK104Document3 pagesZytel 80G33HS1L BK104nimonhPas encore d'évaluation

- k224 hgr24Document1 pagek224 hgr24nimonhPas encore d'évaluation

- TRVX50X9Document2 pagesTRVX50X9nimonhPas encore d'évaluation

- EMS Long Fibre Reinforced PolyamidesDocument44 pagesEMS Long Fibre Reinforced PolyamidesnimonhPas encore d'évaluation

- Week One To Five 11Document105 pagesWeek One To Five 11Sathish KumarPas encore d'évaluation

- AW191 (Cosmoplene PP)Document1 pageAW191 (Cosmoplene PP)nimonhPas encore d'évaluation

- PV701 Polyram ISODocument1 pagePV701 Polyram ISOnimonhPas encore d'évaluation

- DOE Optim2012Document41 pagesDOE Optim2012nimonhPas encore d'évaluation

- Rhodia - Tds - Technylstar S 218 v30 Black 31 N - enDocument5 pagesRhodia - Tds - Technylstar S 218 v30 Black 31 N - ennimonhPas encore d'évaluation

- Hdpe H355jaDocument2 pagesHdpe H355janimonh100% (1)

- Eastman Polymers - Processing and Mold Design GuidelinesDocument44 pagesEastman Polymers - Processing and Mold Design GuidelinesnimonhPas encore d'évaluation

- Injection Molding GuideDocument33 pagesInjection Molding Guidethangkhungpro0% (1)

- Pj701 Pj702-Polyram Iso (Abs-Asa)Document1 pagePj701 Pj702-Polyram Iso (Abs-Asa)nimonhPas encore d'évaluation

- Engenharia PolimerosDocument263 pagesEngenharia PolimerosmarcioufcgPas encore d'évaluation

- PolymersDocument80 pagesPolymersnimonhPas encore d'évaluation

- Mech3100 L 1 2007Document24 pagesMech3100 L 1 2007nimonhPas encore d'évaluation

- Design With Plastics. Focus - Injection MoldingDocument72 pagesDesign With Plastics. Focus - Injection MoldingPrithviraj Daga100% (6)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- DIVAR IP All-In-One 7000 3U Datasheet 51 en 66297110155Document5 pagesDIVAR IP All-In-One 7000 3U Datasheet 51 en 66297110155Javier RochaPas encore d'évaluation

- Welcome To Our 2Nd Topic: History of VolleyballDocument6 pagesWelcome To Our 2Nd Topic: History of VolleyballDharyn KhaiPas encore d'évaluation

- Carinthia Katalog DownloadDocument16 pagesCarinthia Katalog DownloadOperator_010100% (2)

- Joby Aviation - Analyst Day PresentationDocument100 pagesJoby Aviation - Analyst Day PresentationIan TanPas encore d'évaluation

- Regression Analysis Random Motors ProjectDocument22 pagesRegression Analysis Random Motors ProjectPrateek AgrawalPas encore d'évaluation

- LinkageDocument9 pagesLinkageHarshu JungharePas encore d'évaluation

- Filipino Construction TermsDocument6 pagesFilipino Construction TermsAdrian Perez75% (4)

- GBJ0232 - en GLX 3101 T2Document43 pagesGBJ0232 - en GLX 3101 T2mnbvqwert100% (2)

- DP November 2017 Examination Schedule en PDFDocument4 pagesDP November 2017 Examination Schedule en PDFSuperlucidoPas encore d'évaluation

- Ap, Lrrsisal of Roentgenograph, Ic: I SsayDocument30 pagesAp, Lrrsisal of Roentgenograph, Ic: I SsayMindaugasStacevičiusPas encore d'évaluation

- Maintenance Páginas-509-580Document72 pagesMaintenance Páginas-509-580Alexandra Gabriela Pacheco PrietoPas encore d'évaluation

- Pellicon 2 Validation Guide PDFDocument45 pagesPellicon 2 Validation Guide PDFtakwahs12135Pas encore d'évaluation

- GB GW01 14 04 02Document2 pagesGB GW01 14 04 02Muhammad LukmanPas encore d'évaluation

- ARK - Intel® Core™ I3-370m Processor (3M Cache, 2Document3 pagesARK - Intel® Core™ I3-370m Processor (3M Cache, 2Delzi Guindra AdriPas encore d'évaluation

- Concrete Super Structure ReportDocument43 pagesConcrete Super Structure ReportLivian TeddyPas encore d'évaluation

- 9A02502 Transmission of Electric PowerDocument6 pages9A02502 Transmission of Electric PowersivabharathamurthyPas encore d'évaluation

- Solar Charge Controller: Solar Car Solar Home Solar Backpack Solar Boat Solar Street Light Solar Power GeneratorDocument4 pagesSolar Charge Controller: Solar Car Solar Home Solar Backpack Solar Boat Solar Street Light Solar Power Generatorluis fernandoPas encore d'évaluation

- Presentation AcetanilideDocument22 pagesPresentation AcetanilideNovitasarii JufriPas encore d'évaluation

- Types of Loads Considered For Design of BridgeDocument45 pagesTypes of Loads Considered For Design of BridgeAbhishek100% (1)

- The History of AstrologyDocument36 pagesThe History of AstrologyDharani Dharendra DasPas encore d'évaluation

- Exercise On Word Formation 2 (Unit 2 - Advanced) : Tran Dai Nghia High School For The GiftedDocument3 pagesExercise On Word Formation 2 (Unit 2 - Advanced) : Tran Dai Nghia High School For The GiftedEveryonehateshiuzo 2.0Pas encore d'évaluation

- Valdez, Shenny RoseDocument3 pagesValdez, Shenny Roseyeng botzPas encore d'évaluation

- Underground Equipment SelectionDocument44 pagesUnderground Equipment SelectionCherotich Silas cheboseiPas encore d'évaluation

- The Process: by Andy ZoppeltDocument4 pagesThe Process: by Andy ZoppeltMark Stephen HuBertPas encore d'évaluation

- Qasr Al Sarab Desert Resort Location Map June2012Document1 pageQasr Al Sarab Desert Resort Location Map June2012Anant GârgPas encore d'évaluation

- Usp Description and SolubilityDocument1 pageUsp Description and SolubilityvafaashkPas encore d'évaluation

- Hevi-Bar II and Safe-Lec 2Document68 pagesHevi-Bar II and Safe-Lec 2elkabongscribdPas encore d'évaluation

- Kami Export - Subject Complements-1 PDFDocument3 pagesKami Export - Subject Complements-1 PDFkcv kfdsaPas encore d'évaluation

- Basics of Population EducationDocument4 pagesBasics of Population EducationLAILANIE DELA PENAPas encore d'évaluation

- Asteroids Prospective EnergyDocument710 pagesAsteroids Prospective EnergySlavica Otovic100% (1)