Académique Documents

Professionnel Documents

Culture Documents

So Do Binh Tich Ap

Transféré par

LongTranThienTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

So Do Binh Tich Ap

Transféré par

LongTranThienDroits d'auteur :

Formats disponibles

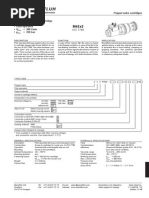

NORMAL PRESSURE BOOSTER UNIT

MODEL UD2

APPLICATIONS

1. Domestic : High-rise buildings, Condominiums, Apartments etc.

2. Commercial : Office buildings, Hotels, Shopping centres etc.

3. Industrial : High-rise factories, Manufacturing & processing industries applications etc.

4. Social service : Schools, Hospitals etc.

Hydro-pneumatic tank

Uses approved diaphragm

suitable for potable water

Control panel

Uses approved diaphragm

Controls pumps operation

from pressure and flow switches

Discharge pipe

Integrated manifold type

Robust & reliable construction.

Flow switch

Detects very low flow to cut off

operating pump thus reducing

frequency of on / off pump at

low flow

Pressure switches

Adjustable type - signal cut-in and

cut-out of pumps

Steel base

Integrating all components as

a single unit

Pump

Robust & high grade materials

provide long life reliable operation

Pressure gauge

Indicator of water pressure

Check valve

Quick closing action reduces

water hammer

CONTROL SYSTEM

6

Single

Operation

Parallel

Operation

Q1

Flow switch

operation range

Continuous pump

Uncontinuous

pump operation

range

Step 1) Both pumps are stopped when water tank is fully charged. In this

condition water is supplied from the pressure tank, and water

pressure in tank gradually decreases.

Step 2) No.1 pump starts at pressure P1 (Point c) and water is

Supplied from pump (and pressure tank)

Step 3) When more water is required and water pressure decreases to

P2(Point d), No.2 pump also starts, operation point shifts to Point

e and system shifts to parallel operation

Step 4) When water consumption decreases, water pressure in tank

increases and when pressure reaches P3 (Point f), No.2

pump is stopped and operation point shifts to point g.

Step 5) When water consumption further decreases, water pressure

in tank increases and pressure switch is turned off, and the

flow switch used to detect small flow, is turned off. When

both pressure and flow switches are off, No.1 pump

stops (Point h). Flow switch setting point is at small capacity

point, therefore pump continuous operation range is much

wider. Accordingly pump start frequency is greatly decreased.

1. All components are integrated on a rugged steel base. It is ready for use by only connecting with supply piping and to the power source.

2. Layout is very compact and much lighter than conventional units. It occupies lesser space and requires easier installation than conventional units.

3. The flow control system which prevents frequent start and stop of pumps, requires only small hydro-pneumatic pressure tank and ensures

constant fresh water supply.

4. Pumps are in parallel operation for high demand and alternating in low demand, suitable for energy saving.(Model UD2-D)

5. Various options are available on request.

FEATURES

6

5

1

2

3

4

P4

P1

P2

P3

SELECTION CHART AND MODEL CODE

Pressure Booster Unit Model Code

UD2 -S CDX 90/10

Pump model

Operation system

Constant speed pressure booster

S : 1 Pump operation system

D : 2 Pumps operation system

T : 3 Pumps operation system

SPECIFICATIONS

STANDARD

Model

Liquid handled property Fresh water, 0-40 degree C

Installation

Operation system

Indoor / Outdoor

Pump speed Constant

Control Controlled with pressure switch & flow switch*

AC, Three phase, 50Hz, 380V Power source

Max. working pressure

Allowable suction pressure

6 to 10 kg/cm

2

G (refer to model)

Min. : -0.3 kg/cm

2

, Max.: Refer to model

Pump operation No.

1 2 3

Pump model

CDX, 2CDX & 3M

Control panel

Pressure tank

Accessories

Starting method

Construction

Operation key

DOL(Up to 5.5kW) or Star-Delta(5.5 to 11kW)

Dust proof type

Touch panel key type

Construction

Capacity

Air precharged diaphragm type

Refer to model

OPTION

Pump model

Pressure tank

MODEL UD2

40

(S)

(D)

50 60 70 80 100 200 300 400 500 600 700 800 1000

(80) (100) (120) (140) (160) (200) (400) (600) (800) (1000) (1200) (1400) (1600) (2000)

(120) (150) (180) (210) (240) (300)

1 Pump

system

2 Pumps

system

1

2

3

4

5

6

7

8

10

9

S

u

p

p

l

y

p

r

e

s

s

u

r

e

(

k

g

/

c

m

2

G

)

UNIT SELECTION CHART (Speed Approx. 2900min-1) Pump model

NORMAL PRESSURE BOOSTER UNIT

Control panel & support, Pressure switch, Flow switch*, Pressure tank

Pressure gauge, Common base, Piping & valves, Electrical wiring

Note : Models for pump CMA1.00 & CDX 90/10 are UD2-D and UD2-T (2 Pumps and 3 pumps operation system) only.

(T)

3 Pumps

system

Note) * In case of pump model CDX90/10 & CMA, flow switch is not provided.

UD2-T UD2-S UD2-D

CMA,CDX, 2CDX & 3M CMA,CDX, 2CDX & 3M

Push button & selector switch type Push button & selector switch type

Large capacity upon requested

Other models upon requested

(600) (900) (1200) (1500) (1800) (2100) (2400) (3000)

Unit Capacity (L/min)

CMA1.00

CDX90/10

C

D

X

1

2

0

/

1

2

DIMENSIONS

M

a

x

.

A

p

p

r

o

x

.

9

0

0

260

Approx.

340

Discharge

Suction

145 145

290

Max.

Approx. 450

H

2

A

p

p

r

o

x

.

H

1

Discharge

H

2

M

a

x

.

A

p

p

r

o

x

.

1

1

0

0

100 100

Suction

W

Max.

Approx.800

A

p

p

r

o

x

.

H

1

200

300

L

100

300 160

L

100

W

Approx. 650

M

a

x

.

A

p

p

r

o

x

.

1

2

0

0

Max. Approx. 550

Discharge

Suction

H

2

A

p

p

r

o

x

.

H

1

H

2

Discharge

Suction

M

a

x

.

A

p

p

r

o

x

.

1

3

0

0

360

Max. Approx. 750

160

620

100 100

L

A

p

p

r

o

x

.

H

1

Pressure tank

3M32 : 1 piece

3M40 : 2 pieces

Approx. 425

20 20 25 25

Max. Approx. 670

Model kW Ds

UD2-S CDX120/12

H1 H2

UD2-S CDX120/20

UD2-S 2CDX120/15

UD2-S 2CDX120/20

UD2-S 2CDX120/30

UD2-S 2CDX120/40

UD2-S CDX200/20

UD2-S CDX200/25

UD2-S 2CDX200/30

UD2-S 2CDX200/40

UD2-S 2CDX200/50

R 1 1/4

Ds

Dd

Ds

(DIN 10bar

Flange)

Model kW Ds Dd

UD2-S 3M32-160/2.2

H1 H2 L

UD2-S 3M32-200/3.0

UD2-S 3M32-200/4.0

UD2-S 3M32-200/5.5

UD2-S 3M40-160/3.0

UD2-S 3M40-160/4.0

UD2-S 3M40-200/5.5

UD2-S 3M40-200/7.5

UD2-S 3M40-200/11

Model kW Ds Dd H1 H2

0.9

1.5

1.1

1.5

2.2

3.0

1.5

1.8

2.2

3.0

3.7

G 1 1/4

G 1 1/4

G 1 1/4

G 1 1/4

G 1 1/4

G 1 1/4

G 1 1/2

G 1 1/2

G 1 1/2

G 1 1/2

G 1 1/2

UD2-D CDX120/12

UD2-D CDX120/20

UD2-D 2CDX120/15

UD2-D 2CDX120/20

UD2-D 2CDX120/30

UD2-D 2CDX120/40

UD2-D CDX200/20

UD2-D CDX200/25

UD2-D 2CDX200/30

UD2-D 2CDX200/40

UD2-D 2CDX200/50

0.9

1.5

1.1

1.5

2.2

3.0

1.5

1.8

2.2

3.0

3.7

G 1 1/4

G 1 1/4

G 1 1/4

G 1 1/4

G 1 1/4

G 1 1/4

G 1 1/2

G 1 1/2

G 1 1/2

G 1 1/2

G 1 1/2

UD2-D CMA 1.00

UD2-D CDX 90/10

0.75

0.75

G 1

G 1 1/4

2.2

3.0

4.0

5.5

3.0

4.0

5.5

7.5

11

Ds

Dd

Dd

( DIN 10bar

Flange)

Ds

(DIN 10 bar

Flange)

50 R1 1/2

65 R 2

50 R1 1/2

50 R1 1/2

50 R1 1/2

65 R 2

65 R 2

65 R 2

65 R 2

W

UD2-D 3M32-160/2.2

UD2-D 3M32-200/3.0

UD2-D 3M32-200/4.0

UD2-D 3M32-200/5.5

UD2-D 3M40-160/3.0

UD2-D 3M40-160/4.0

UD2-D 3M40-200/5.5

UD2-D 3M40-200/7.5

UD2-D 3M40-200/11

2.2

3.0

4.0

5.5

3.0

4.0

5.5

7.5

11

50

65

50

50

50

65

65

65

65

Model kW Ds Dd H1 H2 L

465

486

465

465

486

486

465

486

465

486

486

206

218

206

206

218

218

206

218

206

218

218

625

675

675

675

650

650

695

695

695

232

232

260

260

260

232

260

260

260

410

410

410

410

410

410

410

410

520

675

695

675

675

695

695

675

695

675

695

695

677

675

206

218

206

206

218

218

206

218

206

218

218

197

206

480

480

480

480

480

480

480

480

480

480

510

480

480

755

805

805

805

800

800

850

850

850

232

232

260

260

260

232

260

260

260

520

520

520

560

520

520

560

560

650

48

57

57

63

72

64

77

89

100

Weight

Weight

31

35

34

36

42

45

33

36

44

44

51

Weight

61

68

66

69

82

88

65

70

86

86

102

59

59

R 1 1/2

R 1 1/2

R 1 1/2

R 1 1/2

R 1 1/2

R 1 1/2

R 2

R 2

R 2

R 2

R 2

R 1 1/4

R 1 1/4

106

119

132

150

111

125

152

175

198

Weight

65

80

65

65

65

80

80

80

80

DIMENSION TABLE

DIMENSION TABLE

DIMENSION TABLE DIMENSION TABLE

Unit : H1 to W (mm)

Weight (kg)

Unit : H1 to H2 (mm)

Weight (kg)

L

385

430

25

25

W

340

350

340

340

340

340

340

340

340

430

430

430

430

430

430

430

430

430

430

430

160

MODEL UD2-S CDX & 2CDX MODEL UD2-S 3M

MODEL UD2-D CMA, CDX & 2CDX MODEL UD2-D 3M

Note : (1) kW is shown output per 1 pump.

(2) All specifications subject to change without prior notice.

NORMAL PRESSURE BOOSTER UNIT

Unit : H1 to W (mm)

Weight (kg)

Unit : H1 to L (mm)

Weight (kg)

Head Office : 3rd FL., ACME Building,125 Petchburi Rd., Tungphayathai,Rajthevee, Bangkok 10400, Thailand

Tel: 66 (2) 612 0322 Fax: 66 (2) 612 0331

Factory : Navanakorn Industrial Promotion Zone, 56/17 Moo 20, Tumbon Klong nung, Amphur Klong luang, Pathumthani,

Tel : 66(2) 520 5245-51 Fax : 66(2) 520 5253 ,E-mail : info@ebara.co.th Website : www.ebara.co.th

EBARA

(THAILAND) LIMITED

copyright 2009 Ebara (Thailand) Limited all right reserved

Vous aimerez peut-être aussi

- UD FullDocument6 pagesUD FullkennykaparangPas encore d'évaluation

- Pompe EbaraDocument5 pagesPompe EbarafouadPas encore d'évaluation

- Proportional Reducing ValveDocument8 pagesProportional Reducing ValvediabalziabPas encore d'évaluation

- Catalog Tehnic Pompe MultiCut 20-76Document6 pagesCatalog Tehnic Pompe MultiCut 20-76Anghelescu-Topliceanu Georgiana AndreeaPas encore d'évaluation

- DS DVS DML DLDocument4 pagesDS DVS DML DLGabi PPas encore d'évaluation

- GEK-105281B (Guia de Seleccion de Motores)Document4 pagesGEK-105281B (Guia de Seleccion de Motores)Erick Daniel Toyo MarinPas encore d'évaluation

- Grundfos MTS Screw Spindle PumpDocument68 pagesGrundfos MTS Screw Spindle PumpAnonymous lswzqlo100% (1)

- Pompa Submersibila Lorentz Ps200 HRCDocument4 pagesPompa Submersibila Lorentz Ps200 HRCginghinacPas encore d'évaluation

- pt3 4diaphragm DrumPumpsDocument29 pagespt3 4diaphragm DrumPumpsMatthew NievesPas encore d'évaluation

- Pompa Dari Embung Ke Bak Sirkulasi / Penjernih: ContentsDocument11 pagesPompa Dari Embung Ke Bak Sirkulasi / Penjernih: ContentsewamihawkPas encore d'évaluation

- Energy-Saving Chillers With Screw Compressor Using Environmentally Friendly Refrigerant R134aDocument30 pagesEnergy-Saving Chillers With Screw Compressor Using Environmentally Friendly Refrigerant R134atechnokakiPas encore d'évaluation

- Multi-H Eng 50hzDocument8 pagesMulti-H Eng 50hzIzquierdo AlfedPas encore d'évaluation

- DSG ValvesDocument17 pagesDSG ValvesChris RoederPas encore d'évaluation

- Textile IndustryDocument2 pagesTextile IndustryKendra Terry100% (1)

- Description Value: Printed From Grundfos CAPSDocument5 pagesDescription Value: Printed From Grundfos CAPSmaungmyokyawPas encore d'évaluation

- Bombas Pentax SADocument48 pagesBombas Pentax SAAgustin CahuanaPas encore d'évaluation

- Sys A CDocument40 pagesSys A Cdnageshm4n244Pas encore d'évaluation

- Atos HidraulicaDocument8 pagesAtos HidraulicaFabinhoTowerPas encore d'évaluation

- En Daten MS-MFDocument20 pagesEn Daten MS-MFcazan93Pas encore d'évaluation

- 30HXC CNDocument12 pages30HXC CNtechnokakiPas encore d'évaluation

- MIL Control Valve Specification and Sizing CalculationDocument34 pagesMIL Control Valve Specification and Sizing CalculationRahulTewari67% (3)

- Amacan PDocument52 pagesAmacan PGogyPas encore d'évaluation

- Grundfosliterature 146014Document12 pagesGrundfosliterature 146014Mario Daniel MoreiraPas encore d'évaluation

- D 631 Series ValvesDocument12 pagesD 631 Series ValvesJosé OlavePas encore d'évaluation

- 2.va1 Gedi 00HTF M M5 PHL 0001 - 1Document23 pages2.va1 Gedi 00HTF M M5 PHL 0001 - 1hoangduythanhqbPas encore d'évaluation

- Chiller Koolman CgakDocument8 pagesChiller Koolman Cgakfabieduarte440Pas encore d'évaluation

- Gear Pumps "PLC" Series - Group 2: Technical CataloguesDocument11 pagesGear Pumps "PLC" Series - Group 2: Technical CataloguesHorea CordunianuPas encore d'évaluation

- Min1244a12 - Tag 130-Pu-029Document7 pagesMin1244a12 - Tag 130-Pu-029Monty MathewsPas encore d'évaluation

- SubmersibleDewateringPumps E10361Document20 pagesSubmersibleDewateringPumps E10361Rolando AlvaradoPas encore d'évaluation

- LS200 Series Liquid Level SwitchesDocument4 pagesLS200 Series Liquid Level SwitchesJavy PantojaPas encore d'évaluation

- Mini Unitary Chiller - HovalDocument94 pagesMini Unitary Chiller - HovalIosif BabiasPas encore d'évaluation

- Grundfosliterature 3081235Document156 pagesGrundfosliterature 3081235Uhudhu AhmedPas encore d'évaluation

- Pedrollo 2CPDocument8 pagesPedrollo 2CPBenicio Joaquín Ferrero BrebesPas encore d'évaluation

- PumpDocument12 pagesPumpwwwdotcomatPas encore d'évaluation

- HR E576qDocument12 pagesHR E576qIsanka SathsaraneePas encore d'évaluation

- Chiller Selection Building A+j Cooling Only Rev 2Document7 pagesChiller Selection Building A+j Cooling Only Rev 2Anton WelgemoedPas encore d'évaluation

- Solinoid Popet ValveDocument3 pagesSolinoid Popet ValvesaqureshPas encore d'évaluation

- Daba50 PDFDocument20 pagesDaba50 PDFCatalin StanPas encore d'évaluation

- PumpDocument6 pagesPumpNiladri JanaPas encore d'évaluation

- 30HXC-High COP China CatalogDocument12 pages30HXC-High COP China CatalogAnit SinghPas encore d'évaluation

- CDLF Catalogue GuomeipumpDocument7 pagesCDLF Catalogue Guomeipumpanon_6965157Pas encore d'évaluation

- Convincing Worldwide: HERMETIC Pumps in The Refrigeration IndustryDocument24 pagesConvincing Worldwide: HERMETIC Pumps in The Refrigeration IndustryWaseem HassanPas encore d'évaluation

- Paquete Miller 7.5 y 10 TonsDocument12 pagesPaquete Miller 7.5 y 10 TonscarlamarianaeliasPas encore d'évaluation

- fp50 fp100 fp200Document10 pagesfp50 fp100 fp200ducmanh83Pas encore d'évaluation

- Further Product Details: Position Qty. Description CRE 64-2-2 A-F-A-E-HQQEDocument10 pagesFurther Product Details: Position Qty. Description CRE 64-2-2 A-F-A-E-HQQEitsirc67Pas encore d'évaluation

- Chiller Selection Building C, E+F Heat Pump Rev 1Document7 pagesChiller Selection Building C, E+F Heat Pump Rev 1Anton WelgemoedPas encore d'évaluation

- Moulded Case Circuit Breakers: New DU Series 20 A To 250 ADocument8 pagesMoulded Case Circuit Breakers: New DU Series 20 A To 250 AtanushagrPas encore d'évaluation

- Water Hydraulic TestDocument5 pagesWater Hydraulic TestcomyahoothanhPas encore d'évaluation

- CR 5 9 A A A e HqqeDocument5 pagesCR 5 9 A A A e HqqeAlexander Ramos GutierrezPas encore d'évaluation

- Data Sheet Tag 180-Pu-011eDocument8 pagesData Sheet Tag 180-Pu-011eSarah PerezPas encore d'évaluation

- Optyma CU Leaflet - 46CDocument8 pagesOptyma CU Leaflet - 46CRahul PatilPas encore d'évaluation

- Hidria-Clint - Toplotne Pumpe - Chak 1208-pDocument2 pagesHidria-Clint - Toplotne Pumpe - Chak 1208-pMuhidin KozicaPas encore d'évaluation

- Fedos Rekos KardosDocument34 pagesFedos Rekos KardosIlija RunjajicPas encore d'évaluation

- WDocument4 pagesWRidwan NugrahaPas encore d'évaluation

- Dayliff Control PanelsDocument2 pagesDayliff Control Panelscyruskulei100% (1)

- Hydraulics and Pneumatics: A Technician's and Engineer's GuideD'EverandHydraulics and Pneumatics: A Technician's and Engineer's GuideÉvaluation : 4 sur 5 étoiles4/5 (8)

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1D'EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Évaluation : 3.5 sur 5 étoiles3.5/5 (3)

- A Guide to Vintage Audio Equipment for the Hobbyist and AudiophileD'EverandA Guide to Vintage Audio Equipment for the Hobbyist and AudiophilePas encore d'évaluation

- The Utilization of Silica Sand As A Water Filter For A Sustainable Water Management SystemDocument4 pagesThe Utilization of Silica Sand As A Water Filter For A Sustainable Water Management SystemSteve Spencer YuPas encore d'évaluation

- Pumping Apparatus Driver/Operator Handbook, 2 EditionDocument56 pagesPumping Apparatus Driver/Operator Handbook, 2 EditionJose AndradePas encore d'évaluation

- Report On Grey Water RecyclingDocument8 pagesReport On Grey Water RecyclingLeya RosePas encore d'évaluation

- Water Demand ComputationDocument4 pagesWater Demand ComputationlhytePas encore d'évaluation

- The Coliform Index and Waterborne Disease Problems of Microbial Drinking Water AssessmentDocument199 pagesThe Coliform Index and Waterborne Disease Problems of Microbial Drinking Water Assessmentfajar waskitoPas encore d'évaluation

- Handbook On Sanitation-Pub 393-1965Document95 pagesHandbook On Sanitation-Pub 393-1965Ray Carlson100% (1)

- Staff Report Hope Village Pdr-21-21 (P) Pln2109-0100 PDFDocument25 pagesStaff Report Hope Village Pdr-21-21 (P) Pln2109-0100 PDFMelissa R.Pas encore d'évaluation

- Dilg & Lgus Water Supply Development: The Roles INDocument23 pagesDilg & Lgus Water Supply Development: The Roles INDidielyn AmbosPas encore d'évaluation

- ME F341 Prime Movers and Fluid Machines: BITS PilaniDocument25 pagesME F341 Prime Movers and Fluid Machines: BITS PilaniAbhishekSinghalPas encore d'évaluation

- Go Septic TankDocument6 pagesGo Septic TankAnniesonPas encore d'évaluation

- Plumbing Design CheckListDocument10 pagesPlumbing Design CheckListabdullah amanullahPas encore d'évaluation

- On-Site Wastewater Disposal in Clay SoilsDocument6 pagesOn-Site Wastewater Disposal in Clay SoilsEdmar CardenasPas encore d'évaluation

- Shimla ReportDocument31 pagesShimla ReportDiya Finding New WaysPas encore d'évaluation

- Census India 2011Document14 pagesCensus India 2011Darad HarshPas encore d'évaluation

- River Guides For British Columbia - Kayak GuidebooksDocument2 pagesRiver Guides For British Columbia - Kayak Guidebooksdicktracy11Pas encore d'évaluation

- Engineer's Report (Piggery)Document6 pagesEngineer's Report (Piggery)MORIEL PRADOPas encore d'évaluation

- s8q Pa PDFDocument2 pagess8q Pa PDFZulfi RahmanPas encore d'évaluation

- WRM of Bengawan Solo RiverDocument35 pagesWRM of Bengawan Solo RiverAhmad Hanafi MubarokPas encore d'évaluation

- Concept Paper Joint Case Study Sri Lanka WssDocument16 pagesConcept Paper Joint Case Study Sri Lanka WssRogemar BrillantesPas encore d'évaluation

- Building Water Supply System Is A System inDocument60 pagesBuilding Water Supply System Is A System inShudhan NambiarPas encore d'évaluation

- Glandless Motor PumpsDocument4 pagesGlandless Motor PumpsmalsttarPas encore d'évaluation

- Konica Medical Film Processor Srx-201: PrecautionsDocument20 pagesKonica Medical Film Processor Srx-201: Precautionsdarwin_mdozaPas encore d'évaluation

- CE 424, Engineering Hydrology: John F. QuillopeDocument16 pagesCE 424, Engineering Hydrology: John F. QuillopeRicoyan YanPas encore d'évaluation

- Fire Protection SystemDocument8 pagesFire Protection SystemGerald Paul SumagpaoPas encore d'évaluation

- Eng Hydrology Assignment 7 of UPDocument2 pagesEng Hydrology Assignment 7 of UPAnimeshPas encore d'évaluation

- PrecipitationDocument18 pagesPrecipitationAlexandra Shun MandrezaPas encore d'évaluation

- MKWD Projects Report 2021Document7 pagesMKWD Projects Report 2021Roland AnaumPas encore d'évaluation

- QCS 2010 Section 27 Part 4Document3 pagesQCS 2010 Section 27 Part 4Saif AbdullaPas encore d'évaluation

- METHOD STATEMENT FOR PLUMBING SYSTEM INSTALLATION Rev-B - 16 Jan 2020Document10 pagesMETHOD STATEMENT FOR PLUMBING SYSTEM INSTALLATION Rev-B - 16 Jan 2020szaharatulainiPas encore d'évaluation

- Ashrae Standard: Ashrae Standard Energy Standard For Buildings Except Low-Rise Residential BuildingsDocument16 pagesAshrae Standard: Ashrae Standard Energy Standard For Buildings Except Low-Rise Residential BuildingsDhayanandh MuruganPas encore d'évaluation