Académique Documents

Professionnel Documents

Culture Documents

Introduction To Mechatronics: 1. Explain Mechatronics With Neat Diagram? (5 Mark)

Transféré par

vasudevananishTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Introduction To Mechatronics: 1. Explain Mechatronics With Neat Diagram? (5 Mark)

Transféré par

vasudevananishDroits d'auteur :

Formats disponibles

MODULE 01

INTRODUCTION TO MECHATRONICS

1. Explain Mechatronics with neat diagram? (5 Mark)

The word was invented by the Japanese engineer in 1969

It is a combination of Mecha from Mechanisms and tronics from Electronics

It is a integration of Mechanical Engineering with Electronics and intelligent

computer control in design and manufacturing of the products

Mechatronics products have many mechanical functions replaces with electronic one.

Results : Greater flexibility , Easy reprogramming and redesign ,ability to carry out

automated data collection and reporting

It is not a fusing of mechanical and electronic systems, more than a control system

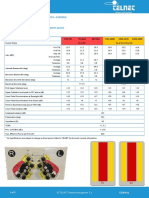

Basic block diagram of mechatronics system is shown below

2. State examples for Mechatronics system ?

Modern auto focus ,auto exposure camera

To use the camera we need to do is point it at the subject and press the button

to take the picture

Camera automatically pointing the object and adjust it aperture and shutter

speed to get a clear and sharp image

There is no maual adjusting of focus or aperture is required

Example 2

Digital Actuator

Analogue

Actuator

Digital Sensor

Analogue

Sensor

Mechanical

Systems

Microprocessor system for

control

Truck smart suspension

The suspension adjust the eneven loading to maintain a level platform

3.Define Mechatronics ? (3 Marks)

Mechatronics relates to synergistic integration of mechanical engineering,

electronics and intelligent computer control for design and manufacture of

industrial products and process

4.Explain the evolution of Mechatronics ? (5 Marks)

Modern mechatronics systems evolved through several stages and can be

categorized into the following broad categories

1. Stand Alone Systems :- Examples : Washing machine , CD players, auto focus

camera etc

2. Systems with high level distributed sensor-microcontroller-actuator

relationships:-Example : Wire aircraft

3. Large factory systems :- also a distributed system but links a number of major

subsystems such as machine centers,robots for part handling ,automated

inspection stations etc

4. Systems that incorporates intelligent control or artificial intelligence:-

Example: Humanoid robots

5.Explain the steps involved in designing a process ? (12 marks)

The design process involving number of stages :

1.The need

The design process begins with a need from a customer or a client.This may be

identified by the market research being used to establish the need of potential

customer

2. Analysis of the problem

The first stage in developing a system is to find out the true nature of the problem ie

analysing it . It is not defining the problem accurately can lead to wasted time on

design

3. Preparation of a specification

A specification of requirements can be prepared here. This will state the problem ,any

constraints placed on the solution and criteria may used to judge the quality of the

design. With stating the problem all functions together with the desired specifications

may specified here.

4. Generation of possible solutions

It is conceptual stage. Outline solutions are prepared here ie approximate size , shape

,materials and cost .

5. Selection of a suitable solution

The various solutions are evaluated and the most suitable one selected. Evaluation

will often involve the presentation of a system by the model.

6. Production of a detailed design

The details of the selected design has now to be worked out .This might require the

production of prototypes in order to determine the optimum details of the design

7. Production of working drawing

The selected design is the translated into working drawing.

6. What is a SYSTEMS with example ?

In designing mechatronics systems, one of the step involved is creation of a model of

the system so that prediction can be made regarding its behaviour when input occur.

A system can be a block or a box, which has an input or out, no need to go through

the internal mechanism of the block, just checking the input output relations

Modelling is used if we are representing a system with mathematical equations

Example

Spring

Input is a force F and output is an extension X

Equation used is F=kX, where k is a constant

Input Force Output Extension

7. What is Modelling a Systems with example ?

Response of any system to an input is not instantaneous

Example 1:- For a spring system, the relation between input and output is

F=kX, describes the relation in only steady state condition.

When a force is applied , initially oscillations will occur before it settle down(

shown in the below figure )

The response of the systems are functions of time

Input Output

Force at t=0 Extension which

Changes with time

SPRING

SPRING

Example 2 :- If we switch on a kettle ,it take some time for the water in the kettle

to reach boiling point.

When a microprocessor controller gives a signal to the lens for focusing in an

automatic camera then it takes times before the lens reaches its position for correct

focusing

8. What are Connected Systems.Explain with examples ?

Consider a series of interconnected blocks, each has a specific function

Output of the first block will be the input of the second block

Example :- CD Player

Signal related quantity

to be measured

Signal in suitable form

for display

Value of the

quantity

o Three inter connected blocks

o CD Desk which has an input of a CD and an output of electrical signal, an

amplifier which has an input of these electrical signal and an output of

bigger electrical signals and a speaker which has an input of electrical

signal and an output of sound

Amplified O/P

Input Electrical

CD Signal Signal

9. what is a MEASUREMENT SYSTEM?Explain with an example ?

Measurement of systems has 3 basic elements

Sensor :-

o Responds to the quantity being measured by giving as its output signal

which is related to quantity

Example: - A thermometer is a temperature sensor

Input: - Temperature

Output: - e.m.f. related to temperature value

Signal conditioner :-

CD DESK

AMPLIFIER

LOUDSPEAKER

SENSOR SIGNAL

CONDITIONER

DISPLAY

Quantity being

measuremt

Signal related quantity

to be measured

Signal in suitable form

for display

Value of the

quantity

o Takes the signal from the sensor and manipulate it into a condition

which is suitable either for a display or a control system

o Example:- Output from a Thermocouple is a small em.f. and might fed

through an amplifier to obtain a bigger signal. Amplifier is the signal

conditioner

Display System

o Output from the signal conditioner is displayed

o Example:- A pointer moving across a scale or a digital readout

Example:- A digital thermometer

Input of temperature to a sensor ,probably a semiconductor diode

Potential difference across the sensor , at a constant current ,a measure of the

temperature

This potential difference is amplified by an operational amplifier

Amplified signal is of the form to be displayed

10. What is a CONTROL SYSTEMS?

A control system can be used to:

o Control some variables to some particular value eg:-a central heating system

where the temperature is controlled variable to a particular value

o Control the sequence of events eg:-a washing machine where when the dials

are set to a particular washing cycle ie sequence of events, appropriate to that

type of clothing

o Control whether an event occur or not ,eg:-a safety lock on a machine where it

cannot be operated until the guard is in position

SENSOR SIGNAL

CONDITIONER

DISPLAY

Quantity

being

measuremt

Temperature Potential Difference Bigger voltage

11. What is a FEED BACK ?

Consider the example of a control system, your body temperature; unless you are ill,

remains almost constant regardless the environment is hot or cold. To maintain this

temperature your body has a inbuilt temperature control system. If your temperature increases

above normal you sweat, decreases you shever.Both these mechanisms are to keep the body

temperature back to normal. The control system maintains the temperature constancy. System

has an input from sensors which tell what the temperature is and then compare this data with

what the temperature should be and provide the appropriate response in order to maintain the

required temperature. This is an example of feedback control systems.

Required Temperature

Body Temperature

Feed back of a data about actual temperature

Usually feedback control system has a thermostat or a controller which automatically

switches the controller off or on according to the difference between the set and actual

temperature.

12. Differentiate with example ,Open and Closed Loop Systems ?

There are mainly two type of control systems

o Open Loop Control System

o Closed Loop Control System

Example :- Room Heater

o Consider a room heater with 1kW and 2kW heating switch

o Open Loop System

Switch on the 1kW switch

The room will heat upto 1kW

If the climatic conditions changes then too heater will heat upto 1kW

There is no effect of the room condition

If the temperature increase or decrease , all the cases it will produce

same output

o Closed Loop System

System contains a thermostat

Body Temperature control

system

According to the room temperature changes thermostat sense the

difference

Produce output according to the set temperature

In this there is a feedback

13. With neat diagram explain the operation of Automatic Washing Machine ?

The operations are ordered in a time or event driven sequence

Controls are obtained with the help of set of relays or cam operated switches

Washing machine is an example for Sequential Control

A number of operations are carried out in a sequence

These may include

o Pre Wash Cycle :- A wash in cold water

o Main Wash Cycle :- A wash in hot water

o Rinse Cycle :- Rinsed with cold water in number of times

o Spinning to remove water from the clothes

A prewash involve opening a valve to fill the machine drum to the required level

Closing the valve

Switching ON the drum motor to rotate the drum for a specific time

Operate the pump to empty water

This operating sequence is called Program

For prewash cycle ,electrically operated valve is opened when a current is supplied

and switch off when it ceases

This valve allow cold water into the drum for a period of time predetermined

Microprocessors are used to operate switches

A sensor is used to sense the water level in the drum

14. With neat diagram explain the working of a DIGITAL CAMERA AND

AUTOFOCUS ?

A basic system used with less expensive camera in open loop system

CLOCK -

Input

Program

Control

Unit

PUMP

VALVE

MOTOR

HEATER

WASHING

MACHINE

DRUM

IR Pulse Sent Out

Return IR sent

out

Micro

Processor

Signal

Conditionin

g

Motor

Lens

position

Shutter button press

When the photographer presses the shutter button , a transducer on front camera send

pulses of IR light towards the subject of the photograph

The IR pulses bounces off the subject and reflected back to the camera where the

transducer pick them up.

For each metre the subject is distance from the camera, the round trip is about 6ms

The time difference between the output and the return pulse is fed to microprocessor

This has a set of values stored in the memory

Output rotates the lens housing and moves the lens to a position where the object is in

focus

Maximum limit for this camera is 10m

If the distance is higher than 10m microprocessor output goes high and lens moves to

infinity settings

The above system is used in expensive cameras involves triangulation

Pulse of infrared radiation are sent out and the reflected signals are not received by

the same transducer

The receiver has a mask across it

The microprocessor gives an output which causes lens to move and simultaneously

the mass to move across the transducer

The mask contains a slot which is move across the face of the transducer

The movement of lens and the slot continues until the return pulses are able to pass

through the slot and impact on the transducer

Output of the transducer leads to microprocessor to stop the movement of the lens ,so

give the in focus position

14. Explain with neat diagram working of a ENGINE MANAGEMENT SYSTEM ?

The engine management system of a car is responsible for managing the ignition and

fuelling requirements of the engine

For a four stroke combustion engine, there are several cylinders

Each of which has a piston connected to a common crankshaft and each carries a four

stroke operation sequence shown below

When the piston moves down, the valve opens and the air-fuel mixture is drawn into

the cylinder

When the piston moves up, valve closes and air-fuel mixture is compressed

When the piston is near to top of the cylinder the spark plug ignites the mixture with a

resulting expansion of hot gases, causes piston to move back down and cycle repeated

Piston of each cylinders are connected to common crankshaft and their power stroke

occur at different times so that there is continuous power for rotating the crankshaft

Power and speed of the engine are controlled by varying the ignition timing and the

fuel-air mixture

Modern car engines are done this by a microprocessor

Basic elements are shown below

For ignition timing , crankshaft drives a distributor which makes electrical contact for

each spark plug in turn and a timing wheel

Timing wheel generate pulses to indicate the crankshaft position

Microprocessor then adjust the timing at which high voltage pulses are sent to the

distributor so that they occur at right moment of time

Vous aimerez peut-être aussi

- Mechatronics Unit 1 & 4 Notes PDFDocument86 pagesMechatronics Unit 1 & 4 Notes PDFSt. Anne's CET (EEE Department)Pas encore d'évaluation

- EEA-430 Introduction To Mechatronics: D R. Abdul Attayyab Khan Email AddressDocument16 pagesEEA-430 Introduction To Mechatronics: D R. Abdul Attayyab Khan Email AddressAamir MansoorPas encore d'évaluation

- Me 2401 Mechatronics Unit 1 NotesDocument60 pagesMe 2401 Mechatronics Unit 1 NotesSivagami PunithavathiPas encore d'évaluation

- Mechatronic System ElementDocument73 pagesMechatronic System ElementAbhijit AtoliyaPas encore d'évaluation

- Unit 1Document30 pagesUnit 1Rajasekaran RPas encore d'évaluation

- UNIT 1 MechatronicsDocument15 pagesUNIT 1 MechatronicsMuthuvel M82% (17)

- 1-Introduction MechatronicsDocument34 pages1-Introduction Mechatronicsteklaykibrom3Pas encore d'évaluation

- 000 Digital Control LecturesDocument67 pages000 Digital Control LecturesPX PRPas encore d'évaluation

- B.Tech. Project Progress Report: Progres Presentation For Final ProjectDocument20 pagesB.Tech. Project Progress Report: Progres Presentation For Final ProjectSolomon MebrahtuPas encore d'évaluation

- MechatronicsDocument26 pagesMechatronicsGlen Peter Miranda100% (2)

- Mechatronics QBDocument25 pagesMechatronics QBKarthik Perumal SwamyPas encore d'évaluation

- Mechatronics Unit 1Document46 pagesMechatronics Unit 1GopinathPas encore d'évaluation

- Group 5.full Report Control EngineeringDocument21 pagesGroup 5.full Report Control Engineeringputri farrahPas encore d'évaluation

- Control EngineeringDocument7 pagesControl Engineeringuet158Pas encore d'évaluation

- ME 461 Control Engineering: Semester: July 2017Document32 pagesME 461 Control Engineering: Semester: July 2017Sudipta PaulPas encore d'évaluation

- Mechatronics NotesDocument90 pagesMechatronics NotesSanskar AgrawalPas encore d'évaluation

- Chapter One:: Introduction To Industrial Automation and ControlDocument75 pagesChapter One:: Introduction To Industrial Automation and ControlamrPas encore d'évaluation

- Chapter OneDocument12 pagesChapter OneMengistu BirukePas encore d'évaluation

- Control System Engineering LABs ManualDocument39 pagesControl System Engineering LABs ManualAbrash Khan Sikandri100% (1)

- PID Controller For Heating Resistive ElementDocument8 pagesPID Controller For Heating Resistive Elementviteliof4110Pas encore d'évaluation

- Me2401 Two MarksDocument2 pagesMe2401 Two MarkssivaramanmePas encore d'évaluation

- Examples of Control Systems:: Lecture OneDocument4 pagesExamples of Control Systems:: Lecture OnemornyPas encore d'évaluation

- L-02 (SM) (IA&C) ( (EE) NPTEL) - Architecture of Industrial Automation SystemsDocument21 pagesL-02 (SM) (IA&C) ( (EE) NPTEL) - Architecture of Industrial Automation SystemsRaymond EsmeraldaPas encore d'évaluation

- Mechatronics:: Unit I Mechatronics, Sensors and ActuatorsDocument31 pagesMechatronics:: Unit I Mechatronics, Sensors and ActuatorsChandra HasanPas encore d'évaluation

- Mechatronics NotesDocument131 pagesMechatronics NotesNagarajPas encore d'évaluation

- Process ControlDocument261 pagesProcess ControlLunokhod Rover50% (2)

- Unit - 1 - Basic Concept of Mechatronics - StuDocument32 pagesUnit - 1 - Basic Concept of Mechatronics - StuLovely SinghPas encore d'évaluation

- PID Control Without Math: The Darker Side by Robert LacosteDocument7 pagesPID Control Without Math: The Darker Side by Robert LacosteNae GoguPas encore d'évaluation

- Systems of MechatronicsDocument4 pagesSystems of MechatronicsVignesh GPas encore d'évaluation

- Introduction To Control Systems: June 2022Document13 pagesIntroduction To Control Systems: June 2022omar ManPas encore d'évaluation

- Plagiarism Checker X Originality: Similarity Found: 58%Document9 pagesPlagiarism Checker X Originality: Similarity Found: 58%Junaid AnwarPas encore d'évaluation

- ON-OFF Temperature Control System Using MicroprocessorDocument4 pagesON-OFF Temperature Control System Using Microprocessorsoach123Pas encore d'évaluation

- Unit 1Document20 pagesUnit 1tguna21Pas encore d'évaluation

- Title: Introduction To Control System and Their Real Life Application and ExamplesDocument4 pagesTitle: Introduction To Control System and Their Real Life Application and ExampleskalimullahPas encore d'évaluation

- Bytronic SistemDocument6 pagesBytronic SistemSedat IriçPas encore d'évaluation

- HVAC Control Systems and Building Automation System PDFDocument19 pagesHVAC Control Systems and Building Automation System PDFStephany Montero100% (5)

- Week 1 - Intro To Control SystemsDocument45 pagesWeek 1 - Intro To Control SystemsArkie BajaPas encore d'évaluation

- 309 Mechatronics MCQDocument27 pages309 Mechatronics MCQMr.G.Chandrasekar mechanicalstaffPas encore d'évaluation

- Introduction To Mechatronics: Lecture #1Document44 pagesIntroduction To Mechatronics: Lecture #1Mohammed ZainPas encore d'évaluation

- Mechatronics MCQDocument27 pagesMechatronics MCQShivani Ekant Yadav100% (14)

- Lab 2Document3 pagesLab 2Vu LePas encore d'évaluation

- Feedback Control System: Output - Desired OutputDocument13 pagesFeedback Control System: Output - Desired OutputApril BalcePas encore d'évaluation

- Cpe 315 Feedback Control System LessonsDocument28 pagesCpe 315 Feedback Control System Lessonskeny amigablePas encore d'évaluation

- Watt's Speed Governor ForDocument18 pagesWatt's Speed Governor ForMuhammad Tayyab YousafzaiPas encore d'évaluation

- Mechatronics: Notes by Arulsahayabeni, M.E.Document125 pagesMechatronics: Notes by Arulsahayabeni, M.E.beniPas encore d'évaluation

- W EE 418 - Lecture 1 Overview and IntroductionDocument56 pagesW EE 418 - Lecture 1 Overview and IntroductionGGAP LASTPas encore d'évaluation

- Chapter 01Document10 pagesChapter 01Gustavo CedenoPas encore d'évaluation

- Transfer Functions Examples Part 1Document21 pagesTransfer Functions Examples Part 1Gideon Moyo0% (1)

- Done MechDocument24 pagesDone MechJeyaram kumarPas encore d'évaluation

- Industrial Protection Over Smoke Temperature and LDRDocument58 pagesIndustrial Protection Over Smoke Temperature and LDRPradeep Avanigadda100% (2)

- Lecture 01 Overview of Control SystemsDocument32 pagesLecture 01 Overview of Control Systemscesar ruizPas encore d'évaluation

- TransducerDocument8 pagesTransducerTeoh Chia Yang100% (1)

- Introduction To Control SystemsDocument47 pagesIntroduction To Control SystemsMih Sy Santos-SilvaPas encore d'évaluation

- EEE 402 Exp1Document5 pagesEEE 402 Exp1Sunil KumarPas encore d'évaluation

- Arduino Measurements in Science: Advanced Techniques and Data ProjectsD'EverandArduino Measurements in Science: Advanced Techniques and Data ProjectsPas encore d'évaluation

- Power Electronics Applied to Industrial Systems and Transports: Volume 5: Measurement Circuits, Safeguards and Energy StorageD'EverandPower Electronics Applied to Industrial Systems and Transports: Volume 5: Measurement Circuits, Safeguards and Energy StoragePas encore d'évaluation

- Disitllation and SDC - FinalDocument1 pageDisitllation and SDC - FinalvasudevananishPas encore d'évaluation

- Programmable ControllersDocument35 pagesProgrammable ControllersvasudevananishPas encore d'évaluation

- Mechatronics - Module1Document13 pagesMechatronics - Module1vasudevananishPas encore d'évaluation

- Modern Control TheroryDocument11 pagesModern Control TheroryvasudevananishPas encore d'évaluation

- Periodic Solutions: Lesson ObjectivesDocument18 pagesPeriodic Solutions: Lesson ObjectivesvasudevananishPas encore d'évaluation

- Read 9780849318900 Computational Hydraulics and Hydrology An IllustDocument2 pagesRead 9780849318900 Computational Hydraulics and Hydrology An IllustDimitri JankoskiPas encore d'évaluation

- Ilaya Flood Control - PERTDocument1 pageIlaya Flood Control - PERTMichael Jorge Bernales0% (1)

- Antec 1200 ManualDocument11 pagesAntec 1200 ManualmhtradePas encore d'évaluation

- Migration ToolkitDocument124 pagesMigration Toolkitdaruwin cristianPas encore d'évaluation

- CP2105Document24 pagesCP2105acechoePas encore d'évaluation

- Cisco B200M4 - Compatability MatrixDocument73 pagesCisco B200M4 - Compatability MatrixmmihmPas encore d'évaluation

- Network Lab MCQDocument7 pagesNetwork Lab MCQ5006 AbineshPas encore d'évaluation

- Eurocode 3 Part 6 PDFDocument2 pagesEurocode 3 Part 6 PDFDominic100% (1)

- SMU - Java Programming-Model Question PaperDocument32 pagesSMU - Java Programming-Model Question PaperTanmay MajumderPas encore d'évaluation

- Blaupunkt True Wireless Earphone BTW-Lite - ManualDocument17 pagesBlaupunkt True Wireless Earphone BTW-Lite - ManualKiran KissanPas encore d'évaluation

- A Line Follower Robot-ICCAE 2010Document6 pagesA Line Follower Robot-ICCAE 2010Ioan DorofteiPas encore d'évaluation

- Icjecapu 09Document7 pagesIcjecapu 09meghanamavuru30Pas encore d'évaluation

- Catalogo Mass Parts - Accesorios Final - 2017Document50 pagesCatalogo Mass Parts - Accesorios Final - 2017Carlos Reconco100% (1)

- PDG - 2017 Latest (New Dryer)Document4 pagesPDG - 2017 Latest (New Dryer)mohd fadhilPas encore d'évaluation

- Internet Usage PolicyDocument8 pagesInternet Usage PolicyRaven ShieldPas encore d'évaluation

- VSCode Shortcuts CheatSheetDocument51 pagesVSCode Shortcuts CheatSheetMarko TodorovicPas encore d'évaluation

- ISAA HoA4 (Unit-5)Document10 pagesISAA HoA4 (Unit-5)052 Deepak NaralaPas encore d'évaluation

- T & C Fastener Co, LTD.: Certified Material Test ReportDocument1 pageT & C Fastener Co, LTD.: Certified Material Test Reportlady romeroPas encore d'évaluation

- Spi FlashDocument17 pagesSpi FlashmikhaccPas encore d'évaluation

- SW2000 DSDocument4 pagesSW2000 DSargaPas encore d'évaluation

- Yale Smart Home Alarm Manual: Conexis L1Document36 pagesYale Smart Home Alarm Manual: Conexis L1harari itirPas encore d'évaluation

- Dec - 2018 - NEO - Siren Output OptionsDocument4 pagesDec - 2018 - NEO - Siren Output OptionsAndre EinsteinPas encore d'évaluation

- Medium-Voltage Surge Arresters US - Catalog HP-AR 25 PDFDocument47 pagesMedium-Voltage Surge Arresters US - Catalog HP-AR 25 PDFfrostssssPas encore d'évaluation

- Essentials of Rational Clearcase Module 7: Integrating Parallel DevelopmentDocument28 pagesEssentials of Rational Clearcase Module 7: Integrating Parallel DevelopmentmnreddyPas encore d'évaluation

- Silicon Chip 2009-01 PDFDocument78 pagesSilicon Chip 2009-01 PDFhmdv100% (1)

- DS ANT TNA352A33rDocument3 pagesDS ANT TNA352A33rEdelPas encore d'évaluation

- Lab 3 Abowd and Beales Framework FormatDocument2 pagesLab 3 Abowd and Beales Framework FormatPhilipPas encore d'évaluation

- Custom YTD, PTD in Essbase FormulaDocument11 pagesCustom YTD, PTD in Essbase Formulaegie72Pas encore d'évaluation

- Steer Gear 1Document40 pagesSteer Gear 1gilangpasekaPas encore d'évaluation

- The It Audit ProcessDocument38 pagesThe It Audit Processalbert moldonPas encore d'évaluation