Académique Documents

Professionnel Documents

Culture Documents

Overview of Pakistani Leather Industry PDF

Transféré par

Muhammad Shahid RazaDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Overview of Pakistani Leather Industry PDF

Transféré par

Muhammad Shahid RazaDroits d'auteur :

Formats disponibles

OVERVIEW OF

PAKISTAN LEATHER

INDUSTRY

Submitted By:

Muhammad Shahid Raza

Muhammad Mushtaq Ahmed

Neseer Ahmed

Falak Sher

Submitted To:

Sir Aftab

Importance of Leather Industry In Pakistan

The second largest industry in regard to exports is the Leather Industry. Contributing more

than $800 million in 2009 to the foreign exchange in Pakistan, this industry has the potential of

delivering more and providing a large number of jobs by diversifying product range and

improving quality.

The leather industry in Pakistan is as old as the history of the country. During the colonial era

just a few number of tanneries were working in large cities such as Karachi, Lahore, New

Delhi etc. In the 1950s the number of well-equipped tanneries increased in Karachi, Lahore

and other major industrial cities. This number continued to rise for due to increase in demand

of finished products as well as raw material in the national and international market. There are

as much as 800 Tanneries in the country engaged in producing best quality finished leather of

Cow, Buffalo, and Sheep & Goat skins.. Leather manufacturers & exporters are determined to

increase export of quality finished leather and leather products.. Leather is one of a prolific

contributor to the countrys GDP and foreign exchange earnings, The Leather Industry of

Pakistan is employing more than 500,000 people directly or indirectly at this time of age

Leather industrys core products in Pakistan are leather garments, gloves, tanned leather and

footwear. In the 50s and 60s most of the tanned leather was exported in raw form but soon

after the local tanning industry making semi-finished leather made rapid progress in making

finished products due to availability of raw material, labor and growing demand in the foreign

market.

More than 450 units of leather garment manufacturers in Pakistan are producing approximately

5 million pieces against the production capacity of exceeding 7.5 million pieces. Similarly a

key sector in leather industry is the leather footwear industry which is capable of producing

200 million pairs annually and its current production is just 100 million pairs. Pakistans share

in the global skin and hides production is around 7% annually which can be doubled with just

the right amount of time and effort. One can assess that these statistics show the industrys

capabilities which are highly under-utilized.

Introduction and Background:

Leather industry, including leather products, is the second largest export earning sector after

textiles1 in Pakistan. Currently, this sector is contributing around $ 874 million2 a year but has

the potential to multiply volume of exports with the improvement of quality and diversification

in different range of products, specially garments and footwear. Leather garments and footwear

is a job-oriented sector providing employment to a very large segment of the society besides

earning foreign exchange for the country.

The leather industry consists of six sub-sectors namely, Tanning, Leather, Footwear, Leather,

Garments, Leather Gloves, Leather Shoe Uppers, and Leather Goods. The Tanning industry

plays a vital role in the progress of these sub-sectors by providing the basic material i.e.

leather. Today, Pakistan is among the leading countries in the production of Leather Garments

and Gloves. The leather and leather made-ups industry plays a significant role in the economy

of Pakistan and its share in GDP is 4%3. The leather finishing and made ups industries

represent an important sector in Pakistan, contributing almost more than half a billion US

dollars4 in foreign exchange earnings to the national exchequer. Export of leather and leather

items was $1.22 billion in 2007-08, $959 million in 2008-09 and $867 million in 2009-105.

These figures show that in the year 2009-10 exports have declined to 30 per cent of what

Pakistan was exporting in the year 2007-08 which is an alarming situation. Exports of 2010-11

have shown an upward trend but this was mainly due to higher prices leather in the

international market while in quantitative terms the increase was negligible. 1.5 million

animals were perished in 2010 floods and 95,523 animals were exported from July 2010 to

March 2011. This resulted in an acute shortage and increased prices of mutton from Rs270 to

Rs450 and beef from Rs154 to Rs350 per kg from 2008-09 to 2010-11.

The Ministry of Commerce has always been in favor of exporting value added products like

meat, its products and finished leather goods. The export of live animals affects local meat and

leather industry negatively. Therefore, the government is in the process of establishing Halal

Food Certification System in Pakistan. This will help Pakistan to enter in the $600 billion6

international market.

LEATHER INDUSTRY PROFILE:

INTRODUCTION

At the time of independence there were only a few tanneries producing sole leather at a small

scale. In the early days of independence some tanneries were established in Karachi. In 1950's

some were established in Lahore and adjoining areas. The industry has flourished rapidly since

then. During 1950s well-equipped tanneries were set up at Karachi and Lahore, while during

60s and 70s more units were established at Hyderabad , Kasur, Sialkot, Multan, Sahiwal and

Gujranwala. Starting with the production of picked and vegetable tanned hides and skins, the

tanneries, today are producing not only wet blue and crust but also fully finished leather.

PRODUCTION CAPACITY:

TOTAL PRODUCTION CAPACITY OF OVERALL TANNERIES IN

PAKISTAN

Particulars Estimated Production

Capacity

Actual Production Utilization Rate

Tanned leather 90 Million Sqr meter 60 Million Sqr meter 67%

Leather

Garments/Apparels

7 Million Pieces 5 Million Pieces 71%

Leather Gloves 10 Million pairs 5 Million pairs 50%

Leather Footwear 200 Million Pairs 100 Million Pairs 50%

Source: Pakistan Tanneries Association

NOTE: Against a capacity of producing 90 million square feet of tanned leather, the tanneries

are presently producing only 60 million square feet tanned leather per year8.

Presently, there are some 461 leather garments/apparels making units, which annually produce

some 5.0 million pieces against a capacity of producing 7.0 million pieces. The 524 footwear

units in the country are currently producing 100 million pairs against a capacity for producing

200 million pairs, while 348 leather gloves units are producing 5.0 million pairs against a

capacity of making 10 million pairs annually9. These statistics clearly show that the capacity

of this sector remains highly under-utilized.

7 Pakistan Tanneries Association Website (www.pakistantanners.org)

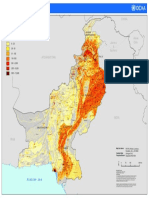

LOCATIONS OF TANNERIES AND MANUFACTURING UNITS IN

PAKISTAN

In Pakistan there are more than 2500 tanneries (registered& Un registered) and footwear

manufacturing units running in Pakistan. Over the years, the number of registered tanneries in

the country has increased from 529 in 1999 to 600 in 2003 and to 725 at present.These are

located in Karachi, Hyderabad, Lahore, Multan, Kasur, Faisalabad, Gujranwala, Sialkot,

Sahiwal, Sheikhupura and Peshawar10.The increase in the number of tanneries and increased

export can be attributed to increase in demand of tanned leather in the foreign market.

CATAGORIES OF LEATHER:

Leather Sector is divided into the following categories.

SOURCES OF RAW MATERIAL

Pakistan is fortunate that the raw material required by the industry is available in the country in

abundance. Local availability of raw materials and low wage cost gives the country a

competitive edge in the world market. In the leather industry the raw materials are by-products

of the meat industry, with the meat having higher value than the skin. Taxidermy also makes

use of the skin of animals, but generally the head and part of the back are used. Hides and

skins are also used in the manufacture of glue and gelatin. The primary sources of raw material

for the tanning industry are hides and skins from animals slaughtered for human consumption.

The following are the types of basic raw materials which are being used by this industry: -

Cow hides - Buffalo hides - Goat skins - Sheep skins.

1. Buffalo:

Buffalo is considered as the specialty of Pakistan in World, because of its ample availability in

Pakistan

2. Cow:

The cow material is considered a superior raw material upon buffalo because of its fine, tight

and comparatively uniform structure.

3. Goat:

It is good for making shoe upper leathers, garment and goods leather.

4. Sheep:

Leather made from sheep raw materials has a very good and softer touch and is considered best

for leather garments.

The industry meets 75% of its needs of raw hides from local sources while rest of the 25-30

per cent is met through imports11.Pakistan imports raw hides from Saudi Arabia, Iran, and

China, Dubai, Sudan, Kenya, Australia and Italy.

STAGES OF LEATHER FORMATION:

1. Warehousing and sorting

In the raw material area the skins are preserved in salt, stored in controlled cool rooms and

before processing, presorted for quality and weight.

2. Soaking

The skin is soaked to remove dirt and salt.

3. De-Fleshing

During this process tissue, flesh and fat remnants are removed by a roller mounted knife.

4. Liming

By adding lime and sulphur compound the hair is removed from the skin.

5. Bating, pickling, tanning

During bating and pickling the skins are treated with acid and salt in preparation for tanning.

During tanning the skin fibres absorb the tanning agents. That's when the skin becomes leather.

6. Samming

During this process water is removed.

7. Splitting

In order to achieve an even specified thickness the leather is reduced in substance. The

resulting split-leather can than be processed further as suede.

8. Skiving

The grain leather is brought to an even thickness. Irregularities are removed from the reverse

side and the leather is separated into color-batches.

9. Sorting

The leather is sorted into various quality grades.

10. Neutralizing, filling out, dyeing and greasing

The acid resulting from the tanning process is neutralized. Then the dyeing takes place, where

appropriate with anilin-dye-stuffs. The greasing procedure will finally achieve the correct

softness.

11. Drying

Two methods are used to dry leather. The vacuum process during which moisture is removed

by suction and the hanging process, when leather is hung and taken through ovens.

12. Staking

Following drying the leather is mechanically staked in order to soften it. Further processes take

place in preparation for finishing.

13. Finishing

Here the leather is given its final surface treatment and look. Through processes of base coat,

coloring, embossing, ironing the leather becomes, depending on the demands of fashion, matt

or shiny, two-tone or uni-coloured, smooth or grained. The art of finishing lies in working in

wafer-thin layers without disturbing the natural look of the leather and its characteristics such

as suppleness and breath ability.

14. Quality Control

In between every process quality is controlled. Final control checks to ensure each individual

production is to specification and sortation into various trades.

15. Dispatch

The leather is measured electronically, wrapped and dispatched.

PERCENTAGE EXPORT GROWTH OF THE WORLD

Years Leather Sector World Export (US $

Billions)

Growth

2007 89.16

2008 98.23 10.2%

2009 111.21 13.2%

2010 117.03 5.2%

2011 97.06 -17.1%

2012 116.82 20.4%

2013 139.48 19.4%

Total Export of Leather sector increased from the US $ 89.16 billion in 2006 to US $ 98.23

billion in 2006. 10.2% increase depicts the increased sales before the global economic

recession. In 2007 the world export increased by 13.2% and by 2008 the percentage increase of

the total world export started falling .This decline attributes to overall decline in sale of

Leather articles and garments due to global financial recession. In the year 2009 the export

growth declined from being positive at 5.2% to negative at 17.1%. The decrease in the leather

sector was mainly due to the Chinese Footwear and other leather articles Replica of major

brands using artificial leather instead of real leather. Their prices are less than one fourth of the

actual brands but they are true copies of the real brand. During the years 2008-09 Animal

activists were successful in campaigning to stop the use of animal skins. They argued that

animals and rare animals are being killed for the sake of their skins. A fashion show was also

held in Paris and the theme of that show was Say No to Skins . This leads to negative

export growth. Another major reason was the implementation of stringent SPS laws in the

developing countries. The law prohibits handling of agricultural goods and sea food with bare

hands. In the year 2010 Total world exports of Leather sector achieved a positive 20.4%

growth and an export volume of US $ 116.82 billion. This increase in the Leather exports was

due to fashion trend of wearing leather jackets and leather trousers. The fashion hype boosted

after the 2010 Gran Prix Moto Bike Championship in Europe and USA.

FACING PROBLEM :

Our manufacturing industry is heavily dominated by textiles and leather industries. The leather

industry is the second biggest export-oriented industry in the manufacturing sector and third in

the overall exports of Pakistan.

The current value of semi-finished leather and its byproducts sales is over Rs20 million, 65

per cent of which consists of tanning and dressing of leather only.

Unfortunately, neither any well-thought-out efforts have been made out in the past nor has the

importance of this sector ever been recognised by public and private sector.

Pakistan is losing its market share year after year, which is increasing the share of its

competitors: India, Bangladesh and China.

Fruits of the latest aesearch and sevelopment and innovations are not reaching Pakistan.

However, a few firms of this industry have increased product diversification on their own.

Pakistan faced 34 per cent decline in leather goods export last year, while India witnessed 20

per cent increase within the same period.

The Indian government has taken positive steps for its leather industry. Today, Indian leather

exporters have been able to increase 28 per cent exports.

Pakistan will only turn into a raw skin seller if the shift of technology and innovation remain

away from its leather industry for the upcoming years.

The cost of electricity in Pakistan is twice that of India, Bangladesh, China and Turkey.

Leather manufacturing is an uninterrupted process that requires a continuous supply of gas or

else valuable stocks may become rancid due to gas suspension.

The industrial sector has been facing gas supply shutdowns for the last two years. India and

Bangladesh cannot stand in leather quality to Pakistan but they are still enjoying multinational

investments due to stable law and order conditions.

According to the Beijing Times Magazine, Chinas leather industry is enhancing its

competitiveness by transforming its growth pattern.

In the next 10 to 20 years, China will change from a big leather production country into a real

brand titan.

The leather industry of Pakistan faces similar problems just like any other industry in the

country but it has massive potential for providing more employment, growth and exports than

any other industry.

Vous aimerez peut-être aussi

- Analysis of Leather Industry in PakistanDocument19 pagesAnalysis of Leather Industry in PakistanHasan AbidiPas encore d'évaluation

- Global Project Full and FinalDocument16 pagesGlobal Project Full and FinalFaizan Ahmad AfzalPas encore d'évaluation

- Bangladeshi Leather IndustryDocument8 pagesBangladeshi Leather IndustrySyed Nayem100% (1)

- A Quick Review of Emerging Leather Sector of BangladeshDocument10 pagesA Quick Review of Emerging Leather Sector of BangladeshAtabur RahmanPas encore d'évaluation

- Leather Industry of PakistanDocument80 pagesLeather Industry of PakistanFawad JafriPas encore d'évaluation

- Indian Leather IndustryDocument10 pagesIndian Leather IndustryMohammed BilalPas encore d'évaluation

- Fddi ReportDocument31 pagesFddi ReportvibhormahPas encore d'évaluation

- Sports Industry of PakistanDocument5 pagesSports Industry of Pakistanmariam100% (2)

- Sport Goods Pakistan BRIEFDocument15 pagesSport Goods Pakistan BRIEFSaadSilat67% (3)

- Leather Goods FinalDocument15 pagesLeather Goods FinalImran1978Pas encore d'évaluation

- Tayyaba ReportDocument19 pagesTayyaba Reportsidra abdal100% (2)

- Internship Report of Leather CoordinatorsDocument19 pagesInternship Report of Leather Coordinatorswaleed ahmadPas encore d'évaluation

- Internship Report of Leather CoordinatorsDocument22 pagesInternship Report of Leather CoordinatorsAmeer hamzaPas encore d'évaluation

- Export-Import Procedure and Documentation: Topic: Exporting Leather Products To Germany Hussain Chunawala Roll No. 07Document29 pagesExport-Import Procedure and Documentation: Topic: Exporting Leather Products To Germany Hussain Chunawala Roll No. 07Thomas KevinPas encore d'évaluation

- Leather Industry and The Export Market of India..Sanjay YadavDocument50 pagesLeather Industry and The Export Market of India..Sanjay Yadavsanjayyadav007Pas encore d'évaluation

- Leather Exporting PDFDocument20 pagesLeather Exporting PDFAyman BrohiPas encore d'évaluation

- Export & ImportDocument29 pagesExport & ImportKhan ZiaPas encore d'évaluation

- Report On Analysis of Leather Industry in National and International ContextDocument42 pagesReport On Analysis of Leather Industry in National and International ContextJahir HasanPas encore d'évaluation

- FootwearDocument18 pagesFootweargehanun100% (1)

- Textile IndustryDocument31 pagesTextile IndustryVineet KumarPas encore d'évaluation

- International BusinessDocument25 pagesInternational BusinessIshita GosaliaPas encore d'évaluation

- Pakistan Shoe IndustryDocument14 pagesPakistan Shoe IndustryShaheen_8392% (13)

- SMEDA Polo T-Shirts Stitching UnitDocument24 pagesSMEDA Polo T-Shirts Stitching UnitMuhammad Noman0% (1)

- Shoes Project by Usman AkramDocument30 pagesShoes Project by Usman Akramfdrz200887100% (1)

- Business - Plan - of - Leather - Products - GlemKore International (Opc) PVT LTD, SBIDocument21 pagesBusiness - Plan - of - Leather - Products - GlemKore International (Opc) PVT LTD, SBIUjjwal SenPas encore d'évaluation

- A Crisis in Textile IndustryDocument21 pagesA Crisis in Textile Industrymmtanveer78688% (8)

- Operations Management of Bata Shoes PakistanDocument17 pagesOperations Management of Bata Shoes Pakistancoolbouy8578% (9)

- Export Merchandising and Exim End Term Jury Report: National Institute of Fashion TechnologyDocument24 pagesExport Merchandising and Exim End Term Jury Report: National Institute of Fashion TechnologyGaurav RawatPas encore d'évaluation

- Leather Industry PresentationDocument18 pagesLeather Industry PresentationSara Pervez100% (1)

- Scenario of Indian Readymade Garment Export in The Post2-Ashish GoyalDocument73 pagesScenario of Indian Readymade Garment Export in The Post2-Ashish GoyalArunKumarPas encore d'évaluation

- Leather Products Export To GermanyDocument35 pagesLeather Products Export To GermanyAbhijeet Kulshreshtha100% (3)

- Consumer Behaviour of ChinarDocument68 pagesConsumer Behaviour of Chinarnehra_007100% (1)

- Rafhan 140428034724 Phpapp02Document18 pagesRafhan 140428034724 Phpapp02Shakir AbdullahPas encore d'évaluation

- Factors Influencing International Market Selection & SegmentationDocument19 pagesFactors Influencing International Market Selection & Segmentationarvind_pathak_460% (5)

- Marketing PlanDocument16 pagesMarketing Plannayima jannatPas encore d'évaluation

- Bareeze (PVT) LimitedDocument83 pagesBareeze (PVT) LimitedZubair Saleem Khan100% (1)

- Internship Report On Chen OneDocument22 pagesInternship Report On Chen Oneusman_sandhu306100% (1)

- Domestic Technical Textile Industry Surgical Sutures Marekt Size PDFDocument440 pagesDomestic Technical Textile Industry Surgical Sutures Marekt Size PDFranachamanPas encore d'évaluation

- Sugar Industry of PakistanDocument30 pagesSugar Industry of Pakistanadnaneconomist100% (9)

- Global Market Entry Strategies: Licensing, Investment, and Strategic AlliancesDocument48 pagesGlobal Market Entry Strategies: Licensing, Investment, and Strategic Alliancesankitbatra88Pas encore d'évaluation

- Power Looms Summer Training ProjectDocument100 pagesPower Looms Summer Training ProjectSagar Virani100% (1)

- WildcraftDocument7 pagesWildcraftRutvi VithaniPas encore d'évaluation

- TEXTILE Industry in PakistanDocument14 pagesTEXTILE Industry in Pakistanimroz_alamPas encore d'évaluation

- Case Study Meat OneDocument22 pagesCase Study Meat OneMahrukh ZubairPas encore d'évaluation

- Raymond Visit ReportDocument12 pagesRaymond Visit ReportMandy Terrell100% (1)

- Final Term Paper On BD RMG IndustryDocument41 pagesFinal Term Paper On BD RMG Industrytanvir75% (4)

- Retailing Case TJ MaxxDocument36 pagesRetailing Case TJ Maxxasarenk100% (1)

- Leather and FootwearDocument10 pagesLeather and FootwearArun SudarshanPas encore d'évaluation

- Project Management BFT VIDocument33 pagesProject Management BFT VIAman DeepPas encore d'évaluation

- Marketing Strategy of Nishat Textile Mills Assignment IIDocument8 pagesMarketing Strategy of Nishat Textile Mills Assignment IINaureen AyubPas encore d'évaluation

- Leather ExportsDocument24 pagesLeather ExportsMehwishAbidPas encore d'évaluation

- Leather Industry in PakisatnDocument5 pagesLeather Industry in PakisatnMuqadas RehmanPas encore d'évaluation

- Leather Industry 4Document36 pagesLeather Industry 4helperforeu50% (2)

- Leather Industry of PakistanDocument25 pagesLeather Industry of PakistanFarjad Asif0% (1)

- Leather Industry of PakiatanDocument9 pagesLeather Industry of PakiatanRahim EjazPas encore d'évaluation

- Leather IndustryDocument22 pagesLeather Industryminnie908Pas encore d'évaluation

- Chapter 1Document14 pagesChapter 1dr_ashishvermaPas encore d'évaluation

- Indian Footwear IndustryDocument23 pagesIndian Footwear IndustryEshuGupta2208Pas encore d'évaluation

- Leather Industry of PakistanDocument80 pagesLeather Industry of Pakistanfarhan.edict33% (3)

- Report On Leather Sector-1Document49 pagesReport On Leather Sector-1Muhammad Umar AshrafPas encore d'évaluation

- HR Processes in Bank Alfalah Limited: Submitted ToDocument41 pagesHR Processes in Bank Alfalah Limited: Submitted ToUmair RiazPas encore d'évaluation

- Zafar Iqbal CVDocument2 pagesZafar Iqbal CVbilalhanifPas encore d'évaluation

- Pak StudyDocument61 pagesPak StudyKainat BilalPas encore d'évaluation

- Six Point MovementDocument22 pagesSix Point MovementSayed Jaber Chowdhury100% (1)

- Case Study Pakistan Model Shariah Governance Framework PDFDocument17 pagesCase Study Pakistan Model Shariah Governance Framework PDFsyedtahaali100% (3)

- Early Problems PDFDocument2 pagesEarly Problems PDFRashidAli76% (33)

- Why Did Pakistan Lose The War of 1971?: SEPTEMBER 12, 2017Document3 pagesWhy Did Pakistan Lose The War of 1971?: SEPTEMBER 12, 2017Taha YousafPas encore d'évaluation

- 2017 11 Economics Sample Paper 02 Ans Ot8ebDocument5 pages2017 11 Economics Sample Paper 02 Ans Ot8ebramukolakiPas encore d'évaluation

- BS Computer Science PDFDocument72 pagesBS Computer Science PDFSheraz Ali100% (1)

- PAK749 Pakistan Landscan Population A3 L 20130826Document1 pagePAK749 Pakistan Landscan Population A3 L 20130826hassaan.mustafa123Pas encore d'évaluation

- Presentation ON: Partition of Bengal in 1905Document11 pagesPresentation ON: Partition of Bengal in 1905Aman RanjanPas encore d'évaluation

- Fyp FormatDocument12 pagesFyp FormatAsad LaghariPas encore d'évaluation

- MA PAKISTAN STUDIES Course OutlineDocument18 pagesMA PAKISTAN STUDIES Course Outlinemadiha009Pas encore d'évaluation

- PEL. Relationship ManagementDocument11 pagesPEL. Relationship ManagementAhmed AitsamPas encore d'évaluation

- The Interim Constitution of Pakistan 1972Document11 pagesThe Interim Constitution of Pakistan 1972Saveeza Kabsha Abbasi100% (1)

- General ZiaDocument4 pagesGeneral Ziahassan sardarPas encore d'évaluation

- National Transmission & Despatch Company Limited: Office OrderDocument1 pageNational Transmission & Despatch Company Limited: Office OrderumairPas encore d'évaluation

- Allwin Academy Current Affairs PDF Jan To July PDFDocument343 pagesAllwin Academy Current Affairs PDF Jan To July PDFvignesh varmaPas encore d'évaluation

- 2-Altaf Gauhar's VersionDocument13 pages2-Altaf Gauhar's VersionSaptarshi BasuPas encore d'évaluation

- Intermediate Admissions 2013: 2nd Merit ListDocument6 pagesIntermediate Admissions 2013: 2nd Merit ListSyed Adnan KhalidPas encore d'évaluation

- Ayub Khan ReformsDocument7 pagesAyub Khan ReformsReeno RehmanPas encore d'évaluation

- Central Superior Services: by Marzia Ali ChangaziDocument11 pagesCentral Superior Services: by Marzia Ali ChangaziShayan aminPas encore d'évaluation

- Looking Back by Allah Bux Syed: AutobiographyDocument291 pagesLooking Back by Allah Bux Syed: AutobiographySyed Jaffer100% (2)

- Css Result 2004-Written & FinalDocument11 pagesCss Result 2004-Written & FinalAfra Siyab KhanPas encore d'évaluation

- General Knowledge of PakistanDocument18 pagesGeneral Knowledge of PakistanSajjad AliPas encore d'évaluation

- India AfghanistanDocument7 pagesIndia AfghanistanAadhya ChhabraPas encore d'évaluation

- Governance Reforms in PakistanDocument14 pagesGovernance Reforms in PakistanWaqas AleemPas encore d'évaluation

- Article - Study of Utilizing Residual Spaces Under Flyovers in LahoreDocument16 pagesArticle - Study of Utilizing Residual Spaces Under Flyovers in LahoreBiris GabrielPas encore d'évaluation

- Pak301 Solved McqsDocument5 pagesPak301 Solved McqsAijaz khan100% (1)

- Ma2022 GazetteDocument2 935 pagesMa2022 GazetteMuhammad AwaisPas encore d'évaluation

- PPL Exam Secrets Guide: Aviation Law & Operational ProceduresD'EverandPPL Exam Secrets Guide: Aviation Law & Operational ProceduresÉvaluation : 4.5 sur 5 étoiles4.5/5 (3)

- 2023/2024 ASVAB For Dummies (+ 7 Practice Tests, Flashcards, & Videos Online)D'Everand2023/2024 ASVAB For Dummies (+ 7 Practice Tests, Flashcards, & Videos Online)Pas encore d'évaluation

- Drilling Supervisor: Passbooks Study GuideD'EverandDrilling Supervisor: Passbooks Study GuidePas encore d'évaluation

- Medical Terminology For Health Professions 4.0: Ultimate Complete Guide to Pass Various Tests Such as the NCLEX, MCAT, PCAT, PAX, CEN (Nursing), EMT (Paramedics), PANCE (Physician Assistants) And Many Others Test Taken by Students in the Medical FieldD'EverandMedical Terminology For Health Professions 4.0: Ultimate Complete Guide to Pass Various Tests Such as the NCLEX, MCAT, PCAT, PAX, CEN (Nursing), EMT (Paramedics), PANCE (Physician Assistants) And Many Others Test Taken by Students in the Medical FieldÉvaluation : 4.5 sur 5 étoiles4.5/5 (2)

- Pilot's Handbook of Aeronautical Knowledge (2024): FAA-H-8083-25CD'EverandPilot's Handbook of Aeronautical Knowledge (2024): FAA-H-8083-25CPas encore d'évaluation

- The Science of Self-Discipline: The Willpower, Mental Toughness, and Self-Control to Resist Temptation and Achieve Your GoalsD'EverandThe Science of Self-Discipline: The Willpower, Mental Toughness, and Self-Control to Resist Temptation and Achieve Your GoalsÉvaluation : 4.5 sur 5 étoiles4.5/5 (77)

- Preclinical Physiology Review 2023: For USMLE Step 1 and COMLEX-USA Level 1D'EverandPreclinical Physiology Review 2023: For USMLE Step 1 and COMLEX-USA Level 1Pas encore d'évaluation

- Master the Boards USMLE Step 3 7th Ed.D'EverandMaster the Boards USMLE Step 3 7th Ed.Évaluation : 4.5 sur 5 étoiles4.5/5 (6)

- Outliers by Malcolm Gladwell - Book Summary: The Story of SuccessD'EverandOutliers by Malcolm Gladwell - Book Summary: The Story of SuccessÉvaluation : 4.5 sur 5 étoiles4.5/5 (17)

- NCLEX-RN Exam Prep 2024-2025: 500 NCLEX-RN Test Prep Questions and Answers with ExplanationsD'EverandNCLEX-RN Exam Prep 2024-2025: 500 NCLEX-RN Test Prep Questions and Answers with ExplanationsÉvaluation : 5 sur 5 étoiles5/5 (1)

- NCLEX-RN Exam Prep 2024-2025: 500 NCLEX-RN Test Prep Questions and Answers with ExplanationsD'EverandNCLEX-RN Exam Prep 2024-2025: 500 NCLEX-RN Test Prep Questions and Answers with ExplanationsPas encore d'évaluation

- CUNY Proficiency Examination (CPE): Passbooks Study GuideD'EverandCUNY Proficiency Examination (CPE): Passbooks Study GuidePas encore d'évaluation

- Airplane Flying Handbook: FAA-H-8083-3C (2024)D'EverandAirplane Flying Handbook: FAA-H-8083-3C (2024)Évaluation : 4 sur 5 étoiles4/5 (12)

- 1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideD'Everand1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideÉvaluation : 3.5 sur 5 étoiles3.5/5 (7)

- Textbook of Plastic and Reconstructive SurgeryD'EverandTextbook of Plastic and Reconstructive SurgeryDeepak K. Kalaskar B.Tech PhDÉvaluation : 4 sur 5 étoiles4/5 (9)

- Note Taking Mastery: How to Supercharge Your Note Taking Skills & Study Like a GeniusD'EverandNote Taking Mastery: How to Supercharge Your Note Taking Skills & Study Like a GeniusÉvaluation : 3.5 sur 5 étoiles3.5/5 (10)

- Substation Maintenance Electrical Technician: Passbooks Study GuideD'EverandSubstation Maintenance Electrical Technician: Passbooks Study GuidePas encore d'évaluation

- The Official U.S. Army Survival Guide: Updated Edition: FM 30-05.70 (FM 21-76)D'EverandThe Official U.S. Army Survival Guide: Updated Edition: FM 30-05.70 (FM 21-76)Évaluation : 4 sur 5 étoiles4/5 (1)

- Certified Professional Coder (CPC): Passbooks Study GuideD'EverandCertified Professional Coder (CPC): Passbooks Study GuideÉvaluation : 5 sur 5 étoiles5/5 (1)

- 2024/2025 ASVAB For Dummies: Book + 7 Practice Tests + Flashcards + Videos OnlineD'Everand2024/2025 ASVAB For Dummies: Book + 7 Practice Tests + Flashcards + Videos OnlinePas encore d'évaluation