Académique Documents

Professionnel Documents

Culture Documents

Oil-Free Compressed Air System

Transféré par

Ronaldo JanglinCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Oil-Free Compressed Air System

Transféré par

Ronaldo JanglinDroits d'auteur :

Formats disponibles

600.

100

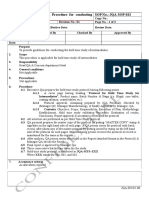

TITLE: Oil-Free Compressed Air System

AUTHOR: ________________________________________

Name/Title/Department

________________________________________

Signature/Date

CHECKED BY: ________________________________________

Name/Title/Department

________________________________________

Signature/Date

APPROVED BY: ________________________________________

Name/Title/Department

________________________________________

Signature/Date

REVISIONS:

YOUR COMPANY

VALIDATION STANDARD OPERATING PROCEDURE

SOP No. Val. 600.100 Effective date: mm/dd/yyyy

Approved by:

No. Section Pages Initials/Date

2002 by CRC Press LLC

SUBJECT: Oil-Free Compressed Air System

PURPOSE

To describe guideline for the validation of the oil-free compressed air system

RESPONSIBILITY

It is the responsibility of the technical service manager to follow the procedure. The

quality assurance manager is responsible for SOP compliance.

PROCEDURE

1. Types of Compressed Air Systems

Two types of compressed air systems are found in an aseptic manufacturing facility:

An instrument air system normally consists of conventional oil-lubricated

compressors and is used for operating instruments and machinery where

no contact with the product or product environment exists.

An oil-free compressed air system is normally used in aseptic areas and

often may be involved with product contact.

The system consists of an oil-free compressor, drier, storage tank, and distri-

bution system. The validation process consists of installation qualification, opera-

tional qualifications, and actual validation testing of the operational system.

2. Installation Qualification of Oil-Free Compressor

Verify and document specifications on purchase order against actual deliv-

ery.

Check and document that no oil or other lubricant is used in the compres-

sor.

Verify and document that all required utilities are connected properly.

Verify prestartup procedures.

Document calibration performed.

SOP No. Val. 600.100 Effective date: mm/dd/yyyy

Approved by:

2002 by CRC Press LLC

3. Installation Qualification of Compressed Air Storage Tank

Check and document that the materials of construction are as specified.

Check storage tank for adequate capacity.

Perform and document pressure hold test to determine that the leak rate

is within specification.

Perform and document the cleaning procedures after installation.

Check and document all pressure ratings.

Calibrate all critical pressure gauges and control sensors on the storage tank.

4. Installation Qualification Distribution System

Check and document that the materials of construction are as specified.

Follow the drawings of the system to trace the actual constructed system

and make an as built drawing.

Pressure test the system and document.

Clean the system with detergent or solvent and document the procedures.

Label all piping and components.

5. Operational qualification

5.1 Chemical investigation

Sampling procedure

Materials: Gas bag, 3.8 liter capacity (rubber bladder), with stopcock

Rubber tubing of appropriate size

Aluminium foil squares (10 10 cm)

Sampling: Use method as recommended by the manufacturer with all safety

precautions.

6. Identification

Procedure

Use gas chromatograph for the identification of compressed air. For comparison,

an air standard should be used.

SOP No. Val. 600.100 Effective date: mm/dd/yyyy

Approved by:

2002 by CRC Press LLC

Requirements

The identity test for oil-free compressed air must show a chromatogram with no

additional peaks other than those obtained with the air standard.

Frequency

Initial validation: once at all critical supply points

Revalidation: once at all critical supply points

7. Moisture Content

Procedure

Use dew-point meter to determine moisture content from critical supply point

Requirements

Moisture content measurements at supply point should not be greater than in-

house specification

Frequency

Initial validation: one test per day for the first 30 days of the operation of the

system from a different location each day. The test program should cover all critical

supply points.

Revalidation: one test from each critical supply point per month.

8. Oil Content

Procedure

Use oil indicators.

Requirements

Oil content of oil-free compressed air should be not more than 0.01 ppm.

Frequency

Initial validation: one test per day for the first 30 days of the operation of the

system from all critical supply point locations each day.

SOP No. Val. 600.100 Effective date: mm/dd/yyyy

Approved by:

2002 by CRC Press LLC

Revalidation: one test from each critical supply point

9. Nonviable Particle Count

Procedure

The outlet of the supply point is opened and purged for 5 min. Adjust to a volume

flow of about 30 l/min. The particle counter is connected to the outlet; at the

maintained flow a minimum volume of 90 liters is monitored. Each supply point

should be investigated in the same way.

Requirements

No requirements; for information only

Frequency

Initial validation: once for each supply point.

Revalidation: every 3 months

9.1 System supply reliability test

Document the system pressure twice a day over a period of about 30 working days.

The data generated should be compared with the specifications of the system.

10. Certification

The system can be certified after successful execution and documentation of above

tests.

REASONS FOR REVISION

Effective date: mm/dd/yyyy

First time issued for your company, affiliates, and contract manufacturers

SOP No. Val. 600.100 Effective date: mm/dd/yyyy

Approved by:

2002 by CRC Press LLC

Vous aimerez peut-être aussi

- 9 C Validation Protocol TABLETDocument20 pages9 C Validation Protocol TABLETMohammed ZubairPas encore d'évaluation

- Micro ManualDocument55 pagesMicro ManualNiranjan PradhanPas encore d'évaluation

- Hold Time Study Ensures Clean Equipment QualityDocument11 pagesHold Time Study Ensures Clean Equipment QualityMarwa AhmedPas encore d'évaluation

- Hold Time Study 1Document3 pagesHold Time Study 1aboemadaldeenPas encore d'évaluation

- Hold Time Study SOP Indian Pharma 1Document3 pagesHold Time Study SOP Indian Pharma 1ziadddPas encore d'évaluation

- Microbial Limit Test Validation ProtocolDocument12 pagesMicrobial Limit Test Validation ProtocolMubarak Patel100% (2)

- Labaid Pharmaceuticals Limited: Deviation Control Status Open Closed TotalDocument33 pagesLabaid Pharmaceuticals Limited: Deviation Control Status Open Closed TotalgolamnobiPas encore d'évaluation

- Pure & Cure Healthcare Pvt. LTD.: Restricted CirculationDocument16 pagesPure & Cure Healthcare Pvt. LTD.: Restricted CirculationDarlenis RodriguezPas encore d'évaluation

- Cleaning Validation Protocol Powder Dosing MachineDocument4 pagesCleaning Validation Protocol Powder Dosing MachineIcee SinlapasertPas encore d'évaluation

- IQ-PQ-EQ Documents For FDC - IRN75Document12 pagesIQ-PQ-EQ Documents For FDC - IRN75Doan Chi ThienPas encore d'évaluation

- Performance QUALIFICATION OF RLAFDocument22 pagesPerformance QUALIFICATION OF RLAFBRIJENDRA KUMAR SINGHPas encore d'évaluation

- 2 CVPDocument5 pages2 CVPQAPas encore d'évaluation

- Empagliflozin TabletDocument3 pagesEmpagliflozin TabletAmik TuladharPas encore d'évaluation

- 8.3 Operation Qualification Protocol For Dispensing BoothDocument4 pages8.3 Operation Qualification Protocol For Dispensing BoothTanveer Ahmed Quadri100% (1)

- AHU Block-V Rev 00 - 2023Document36 pagesAHU Block-V Rev 00 - 2023Chirag S. PatelPas encore d'évaluation

- User Requirement Specification For Moisture Analyser: Company NameDocument6 pagesUser Requirement Specification For Moisture Analyser: Company Namevamshi krishnaPas encore d'évaluation

- SOP For Monitoring of Compressed Air - GasesDocument2 pagesSOP For Monitoring of Compressed Air - GasesAnonymous FZs3yBHh70% (1)

- Glimpses On Compressed Air System Validation TestDocument8 pagesGlimpses On Compressed Air System Validation Testvasant ugalePas encore d'évaluation

- VPP - ZetasizerDocument11 pagesVPP - ZetasizerprathimaPas encore d'évaluation

- Hold Time Stability Studies in Pharmaceutical Industry Review 2167 7689.1000104Document8 pagesHold Time Stability Studies in Pharmaceutical Industry Review 2167 7689.1000104iloveit52252Pas encore d'évaluation

- Systems-Based Inspections For Cleaning Validation: ObjectivesDocument11 pagesSystems-Based Inspections For Cleaning Validation: ObjectivesPrashansa Shrestha100% (1)

- Example RA For Transport To Regulated MarketsDocument7 pagesExample RA For Transport To Regulated MarketsDoan Chi ThienPas encore d'évaluation

- Hold Time Protocol FinalDocument20 pagesHold Time Protocol FinalSolomon0% (1)

- REVERSE LAMINAR AIR FLOW UNIT SPECIFICATIONSDocument8 pagesREVERSE LAMINAR AIR FLOW UNIT SPECIFICATIONSAndreas StathatosPas encore d'évaluation

- Facility Requirement SpecificationDocument3 pagesFacility Requirement SpecificationDarlenis RodriguezPas encore d'évaluation

- Procedure For Leak Testing of Strips - BlistersDocument7 pagesProcedure For Leak Testing of Strips - BlistersashishdrPas encore d'évaluation

- 2 Process Validation QandA Version 4 (June 2011) - Adopted 18th PPWG Meeting PDFDocument4 pages2 Process Validation QandA Version 4 (June 2011) - Adopted 18th PPWG Meeting PDFVishal SomaniPas encore d'évaluation

- Performance Qualification Protocol FOR Automatic Capsule Filling MachineDocument13 pagesPerformance Qualification Protocol FOR Automatic Capsule Filling Machinemehrdarou.qaPas encore d'évaluation

- GMP Particle Monitoring Requirements and SystemsDocument47 pagesGMP Particle Monitoring Requirements and Systemsparam540Pas encore d'évaluation

- Case Study-Temperature & Humidity Mapping Study & Qualification of A Cold Room in QatarDocument3 pagesCase Study-Temperature & Humidity Mapping Study & Qualification of A Cold Room in QatarVacker Group UAE100% (1)

- PQ For Water Treatment PlantDocument29 pagesPQ For Water Treatment PlantDilawar Bakht100% (2)

- Process Validation Protocol XXX 60 MG TabletsDocument33 pagesProcess Validation Protocol XXX 60 MG TabletsfarPas encore d'évaluation

- 30 ML Moulded Vial Filling OQDocument15 pages30 ML Moulded Vial Filling OQSubhash NaiduPas encore d'évaluation

- SOP For Karl Fisher Titration-Sophie - RadwanDocument3 pagesSOP For Karl Fisher Titration-Sophie - RadwanzhobeysPas encore d'évaluation

- 01 Cleaning Validation of Vibratory Sifter CLV 01Document2 pages01 Cleaning Validation of Vibratory Sifter CLV 01Ravi YadavPas encore d'évaluation

- 215-Operation and Calibration of Dissolution Apparatus (VDA-8D) New NewDocument4 pages215-Operation and Calibration of Dissolution Apparatus (VDA-8D) New NewDeepak ChaudharyPas encore d'évaluation

- D.Y.Patil. College of Pharmacy, Pune: Instrument DetailsDocument3 pagesD.Y.Patil. College of Pharmacy, Pune: Instrument DetailsNavdeep ChaudharyPas encore d'évaluation

- Validate Furosemide Tablet ProcessDocument26 pagesValidate Furosemide Tablet ProcessPatricia Joyce Malabanan SunglaoPas encore d'évaluation

- Alarm Verification Protocol FOR Incubators (Microbiology, Q-Block)Document10 pagesAlarm Verification Protocol FOR Incubators (Microbiology, Q-Block)cpkakope100% (1)

- HoldTime 01Document4 pagesHoldTime 01Anonymous GPLMks1pPas encore d'évaluation

- 04 Cleaning Validation of Empty Capsule Loader 04Document2 pages04 Cleaning Validation of Empty Capsule Loader 04Ravi YadavPas encore d'évaluation

- 03 - Revised MOS - AIR BALANCINGDocument8 pages03 - Revised MOS - AIR BALANCINGEditor EditorPas encore d'évaluation

- Standard Operating Procedure Somatec: Title: Sop For Pao TestDocument3 pagesStandard Operating Procedure Somatec: Title: Sop For Pao TestMajed HossainPas encore d'évaluation

- Checklist of Validation of Dy Heat SterilizerDocument8 pagesChecklist of Validation of Dy Heat Sterilizersami2210Pas encore d'évaluation

- What Are The Key Benefits of Validation?Document6 pagesWhat Are The Key Benefits of Validation?siva sankarPas encore d'évaluation

- Water Treatment System (Sistem Pengolahan Air Spa)Document38 pagesWater Treatment System (Sistem Pengolahan Air Spa)Tjen MolynaPas encore d'évaluation

- DQ - CRAB For Lyo LoadingDocument30 pagesDQ - CRAB For Lyo Loadingdhanu_lagwankarPas encore d'évaluation

- Sop Cleaning Rev 06 - 2018 Rev Baru (Repaired)Document20 pagesSop Cleaning Rev 06 - 2018 Rev Baru (Repaired)FajarRachmadiPas encore d'évaluation

- Installation and Operation For Climate IncubatorDocument29 pagesInstallation and Operation For Climate IncubatorFilipa ChinêsPas encore d'évaluation

- Cleaning ValidationDocument17 pagesCleaning ValidationMollidain SandeepPas encore d'évaluation

- IQDocument12 pagesIQManish Shah0% (1)

- Xoxiban 20mg Tab VPDocument13 pagesXoxiban 20mg Tab VPziauddin bukhariPas encore d'évaluation

- Annual Product Quality Review (APQR) SOP - PharmaBDocument14 pagesAnnual Product Quality Review (APQR) SOP - PharmaBrehmat ali100% (1)

- Pantoprazole 40mg InjectionDocument36 pagesPantoprazole 40mg Injectiondaizhussain004Pas encore d'évaluation

- Performance Qualification Protocol (PQP) For (Autoclave), Located inDocument17 pagesPerformance Qualification Protocol (PQP) For (Autoclave), Located inlouayPas encore d'évaluation

- ICH Quality Guidelines: An Implementation GuideD'EverandICH Quality Guidelines: An Implementation GuideAndrew TeasdalePas encore d'évaluation

- Good Distribution Practice A Complete Guide - 2020 EditionD'EverandGood Distribution Practice A Complete Guide - 2020 EditionPas encore d'évaluation

- Validation Master Plan A Complete Guide - 2020 EditionD'EverandValidation Master Plan A Complete Guide - 2020 EditionPas encore d'évaluation

- Ti00065den 1717Document40 pagesTi00065den 1717Ronaldo JanglinPas encore d'évaluation

- Instruction Manual Testo Gas AnalyzerDocument20 pagesInstruction Manual Testo Gas AnalyzerTim KuPas encore d'évaluation

- Bbwin HotkeysDocument4 pagesBbwin HotkeysRonaldo JanglinPas encore d'évaluation

- Bbwin HotkeysDocument4 pagesBbwin HotkeysRonaldo JanglinPas encore d'évaluation

- Quick Killer Plus C INALDocument1 pageQuick Killer Plus C INALRonaldo JanglinPas encore d'évaluation

- Installation Instructions F-452N: Blue-WhiteDocument4 pagesInstallation Instructions F-452N: Blue-WhiteRonaldo JanglinPas encore d'évaluation

- Radial Tonebone Bassbone Bass Preamp 2 Channel Built in Direct Box With XLR Output Powerful EQDocument3 pagesRadial Tonebone Bassbone Bass Preamp 2 Channel Built in Direct Box With XLR Output Powerful EQRonaldo JanglinPas encore d'évaluation

- OSHA3404laboratory Safety Guidance PDFDocument52 pagesOSHA3404laboratory Safety Guidance PDFRonaldo JanglinPas encore d'évaluation

- Sartorius BalanzasDocument8 pagesSartorius BalanzasRonaldo JanglinPas encore d'évaluation

- Calibration Fundamentals ExplainedDocument10 pagesCalibration Fundamentals ExplainedCris RonaldPas encore d'évaluation

- Cubase 100w Bass User PDFDocument12 pagesCubase 100w Bass User PDFRonaldo JanglinPas encore d'évaluation

- Risk-Based Approaches in GMP's ProjectDocument27 pagesRisk-Based Approaches in GMP's ProjectRonaldo JanglinPas encore d'évaluation

- Leavitt - Guitar Duets 2nd GTRDocument14 pagesLeavitt - Guitar Duets 2nd GTRRonaldo JanglinPas encore d'évaluation

- Bassbone: Tonebone Smart SheetDocument1 pageBassbone: Tonebone Smart SheetRonaldo JanglinPas encore d'évaluation

- Testo 175 PDFDocument40 pagesTesto 175 PDFRonaldo JanglinPas encore d'évaluation

- IE FinalDocument2 pagesIE FinalRonaldo JanglinPas encore d'évaluation

- FUS1020 EngrSpecDocument2 pagesFUS1020 EngrSpecRonaldo JanglinPas encore d'évaluation

- Leavitt - Guitar Duets 1st GTRDocument14 pagesLeavitt - Guitar Duets 1st GTRRonaldo Janglin100% (1)

- A Practical Guide To Applying Impact and Risk Concepts To Equipment Qualification For Non-Critical Processes For Topical and Oral Product Applications PDFDocument6 pagesA Practical Guide To Applying Impact and Risk Concepts To Equipment Qualification For Non-Critical Processes For Topical and Oral Product Applications PDFRonaldo JanglinPas encore d'évaluation

- 500sm Sani Bomba MoynoDocument4 pages500sm Sani Bomba MoynoRonaldo JanglinPas encore d'évaluation

- HI7022L LOTE 7187sDocument1 pageHI7022L LOTE 7187sRonaldo JanglinPas encore d'évaluation

- Mecmesin BFG Basic Force Gauge 2005-Current ManualDocument16 pagesMecmesin BFG Basic Force Gauge 2005-Current ManualRonaldo JanglinPas encore d'évaluation

- Charlie Parker Omnibook For Guitar 8-17Document10 pagesCharlie Parker Omnibook For Guitar 8-17Ronaldo Janglin100% (1)

- Pressure Drop 5CDDocument1 pagePressure Drop 5CDRonaldo JanglinPas encore d'évaluation

- Lite-On LTH-301-07 Optocoupler Data SheetDocument5 pagesLite-On LTH-301-07 Optocoupler Data SheetRonaldo JanglinPas encore d'évaluation

- Infra R RojoDocument4 pagesInfra R RojoRonaldo JanglinPas encore d'évaluation

- Root Chords A EBGDocument3 pagesRoot Chords A EBGRonaldo JanglinPas encore d'évaluation

- Starline Tours - Website Booking ReceiptDocument2 pagesStarline Tours - Website Booking ReceiptRonaldo JanglinPas encore d'évaluation

- 07779342Document80 pages07779342Ronaldo JanglinPas encore d'évaluation

- Purocept ADocument2 pagesPurocept ARonaldo JanglinPas encore d'évaluation

- 43-101 Technical Report Quimsacocha, February 2009Document187 pages43-101 Technical Report Quimsacocha, February 2009Marco Vinicio SotoPas encore d'évaluation

- Spcr-TagbayaganDocument76 pagesSpcr-TagbayaganReycia Vic QuintanaPas encore d'évaluation

- Christmas Around the WorldDocument16 pagesChristmas Around the WorldVioleta Veljanovska100% (1)

- Indian War of Independence 1857 - Part 2Document150 pagesIndian War of Independence 1857 - Part 2BISWAJIT MOHANTYPas encore d'évaluation

- Marketing Strategy of Air-Conditioning Companies: Project SynopsisDocument13 pagesMarketing Strategy of Air-Conditioning Companies: Project SynopsisSrikanta ChoudhuryPas encore d'évaluation

- Présentation Transportation ManagementDocument14 pagesPrésentation Transportation ManagementHiba Hmito100% (1)

- The Role of Women in The Livelihood Strategies of The House Hold: Case of Geressie Woreda, Gamo Zone, EthiopiaDocument95 pagesThe Role of Women in The Livelihood Strategies of The House Hold: Case of Geressie Woreda, Gamo Zone, Ethiopiaermias eshetu100% (3)

- Divide and Conquer (Closest Pair, Convex Hull, Strassen Matrix Multiply) DemoDocument27 pagesDivide and Conquer (Closest Pair, Convex Hull, Strassen Matrix Multiply) DemoAnand KumarPas encore d'évaluation

- Improving Students' Science Process SkillsDocument9 pagesImproving Students' Science Process SkillsNovia RahmawatiPas encore d'évaluation

- Installation & Testing of Fire Protection SystemsDocument7 pagesInstallation & Testing of Fire Protection Systemssunny_84tPas encore d'évaluation

- Anorexia NervosaDocument2 pagesAnorexia NervosaDhea Mae MadisPas encore d'évaluation

- Din en 1320-1996Document18 pagesDin en 1320-1996edcam13Pas encore d'évaluation

- Mast Bending Stress Calculation: Antenna 1Document6 pagesMast Bending Stress Calculation: Antenna 1Vinay KumarPas encore d'évaluation

- Organization Structure Training KAJARIADocument30 pagesOrganization Structure Training KAJARIAViswanth GanaparthiPas encore d'évaluation

- SIC CodeDocument424 pagesSIC CodeZohra MerchantPas encore d'évaluation

- Railway Electrification Projects Budget 2019-20Document9 pagesRailway Electrification Projects Budget 2019-20Muhammad Meraj AlamPas encore d'évaluation

- Prometheus BoundDocument10 pagesPrometheus BoundPhillip HosfeldtPas encore d'évaluation

- English Task Resumido 2Document12 pagesEnglish Task Resumido 2Luis ArmandoPas encore d'évaluation

- Vectors FoundationDocument8 pagesVectors FoundationNaning RarasPas encore d'évaluation

- Durango GS 6-7 Helitack OutreachDocument4 pagesDurango GS 6-7 Helitack OutreachdcgmPas encore d'évaluation

- Telemark PulloverDocument2 pagesTelemark Pulloverkidknits100% (1)

- M2030 PA300 Siren Data Sheet 5-2021Document2 pagesM2030 PA300 Siren Data Sheet 5-2021parak014Pas encore d'évaluation

- This Is Your Presentation TitleDocument28 pagesThis Is Your Presentation TitleStephanie AcarapiPas encore d'évaluation

- Management of Septic Shock in An Intermediate Care UnitDocument20 pagesManagement of Septic Shock in An Intermediate Care UnitJHPas encore d'évaluation

- Biology Standard XII Human Reproduction WorksheetDocument10 pagesBiology Standard XII Human Reproduction WorksheetPriya SinghPas encore d'évaluation

- Operating Systems: Chapter 3: DeadlocksDocument46 pagesOperating Systems: Chapter 3: DeadlocksManoel Katlib100% (1)

- Iot Finals Clap Switch Group 5Document15 pagesIot Finals Clap Switch Group 5RICHYBOY SALACPas encore d'évaluation

- Steel 17-4PH MmpdsDocument18 pagesSteel 17-4PH MmpdsManoj ManoharanPas encore d'évaluation

- BASIC IMMUNOLOGY TERMSDocument2 pagesBASIC IMMUNOLOGY TERMSAnnicoldjohn LariozaPas encore d'évaluation

- Ego7 Manual enDocument76 pagesEgo7 Manual ensullivanj69Pas encore d'évaluation