Académique Documents

Professionnel Documents

Culture Documents

(Flexible Connectors, Pressure Gauges+ Strainers & NRV) : Regulating Valve RV

Transféré par

27671410 évaluation0% ont trouvé ce document utile (0 vote)

16 vues4 pagesBib taps at basements to be clearly mention at open area lock shield type. 4]provide water hammer arrestors inside raw wash at basements. 5]return hot line to be with regulating valve RV not isolating valve. 6]return line to be start at distance not more than 8 mtr of last supply points.

Description originale:

Titre original

Water Comments

Copyright

© © All Rights Reserved

Formats disponibles

DOCX, PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentBib taps at basements to be clearly mention at open area lock shield type. 4]provide water hammer arrestors inside raw wash at basements. 5]return hot line to be with regulating valve RV not isolating valve. 6]return line to be start at distance not more than 8 mtr of last supply points.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme DOCX, PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

16 vues4 pages(Flexible Connectors, Pressure Gauges+ Strainers & NRV) : Regulating Valve RV

Transféré par

2767141Bib taps at basements to be clearly mention at open area lock shield type. 4]provide water hammer arrestors inside raw wash at basements. 5]return hot line to be with regulating valve RV not isolating valve. 6]return line to be start at distance not more than 8 mtr of last supply points.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme DOCX, PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 4

Dear Zahir .

refer to the following comments and rectify accordingly .

1]required pumps details connection to be shown (flexible connectors, pressure gauges+

strainers & NRV)

2]Bib taps at basements to be clearly mention at open area lock shield type .

3]provide expansion joints for the long pipe connection at building expansion joints .

4]provide water hammer arrestors inside raw wash at basements .

5]return hot line to be with regulating valve RV not isolating valve .

6]pipe size of return hot line corrected already on shared drop box copy .

7]return line to be start at distance not more than 8 mtr of last supply points (rectify return

points at female/male changing room+ toilets ).

8]provide water /hammer arrestor in all toilets .

9]under /ground tank shall be capacity 840 m3 . refer to the approved NOC .

10] roof tank capacity 190 m3 .

11]transfer pump 8 l/sec Head @ 5bar Head .

12] filtration pump sets shall be multi-media (2 duty+1standby )10 l/sec flow rate and 2

bar head .

13] provide description and quantity of one duty+standbye for all pumps +filtration .

14]indicate bypass header at tank discharge, and between pumps with normal closed valves

.

15] indicate backwash line of filtration to the tank breaker then to drain .

16]show the mechanical float valves inside tank (cupper ball type +Auto pumps float valves

) .

17]hot water calorifier to be 3 Nos each 2700 lit (63KW approx. each).

Cold side HOT SIDE

TEMP IN=15 C TEMP IN=90C

TEMP OUT =60 C TEMP OUT =80 C

18]SOFTNER : TWO NOS DUPLEX SOFTNER VESSEL IN PARALLEL FLOW RATE 12 L/SEC each .

19]softener pump to be shown in the basement = 12 l/sec at Bar .

20] hot water pump to be =9.7 m3/hr(2.7 L/sec) at 45 m .(note : to be revised and

calculated by contractor as per actual pipe routs and length).

21]main kitchen soft cold water line at basement to be 50 mm pipe size .

22]add normal cold water line to the kitchens .

23]pipe size of male and female changing room & shower to be as follow

C.W 40 mm

H.W 32

R.W 25

(already corrected on drop-box copy).

24] provide isolating valves for all bib taps in the basements for maintains purpose .

25]G/F provide water hammer arrestor for all toilets ,parper ,treatmet rooms .etc.

26] G/F keep each toilets with individual valves .

27]adjust location of regulating valve and return of hot line same in comments (8).

28] server room need one provision 15 mm pipe+bib tap for the close control unit .

29] add valves for all future and shell and core provisions urgent & add one cold water

line 50 mm .

30] indicate GRP TANK ACCESS LADDER & ACCESS OPENING+ VENT PIPE+INLET LINE +

BALL FLOAT VALVE AND Auto float valve and to be near the access .

31] provide proper description for all valves pipe size at roof drawing .

32]provid pressure gauges and tempruture gauges .

33] indicate pressure switch for all valves .

Booster pumps with VFD flow rate =5.2 l/sec at 4 Bar .

34] provide bypass between booster pump and gravity line + i.valves NC :normal closed.

35] indicate AAV : auto air vent at top of risers .

36] circulation hot water pump and piping with calorifire incorrect adjust inlet of pumps

separate .

37] indicate pressure vessel for booster sets .(write : contractor shall submit selection and

proper calculation for vessel )

38]ROOF DRAWING :SEGRGATE BETWEEN cold water supply in the circuits & softwater line (ONLY TO

THE KITCHEN +TYPICAL ICE MACHINE LEVEL)

Vous aimerez peut-être aussi

- Swimming Pool Calculation GuideDocument4 pagesSwimming Pool Calculation Guide276714177% (13)

- SK200-8 YN11 Error CodesDocument58 pagesSK200-8 YN11 Error Codest544207189% (37)

- Energy Losses in BendsDocument8 pagesEnergy Losses in BendsVikramSingh0% (3)

- HWG - Boq-1Document13 pagesHWG - Boq-1Prashant Singh ChauhanPas encore d'évaluation

- Predstavitev Prednosti Novih AQUAREA F-Generacije Toplotnih ČrpalkDocument51 pagesPredstavitev Prednosti Novih AQUAREA F-Generacije Toplotnih ČrpalkBurek TurekPas encore d'évaluation

- DESUPERHEATERDocument4 pagesDESUPERHEATERghkashyap1Pas encore d'évaluation

- Balancing Circuits for Optimal FlowDocument75 pagesBalancing Circuits for Optimal Flowmaxmorek100% (1)

- Condenser Water and Cooling Tower in Thermal Power PlantDocument131 pagesCondenser Water and Cooling Tower in Thermal Power PlantVivek TiwariPas encore d'évaluation

- 2011 VND O&M ManualDocument12 pages2011 VND O&M Manualsequeira.cedric6742Pas encore d'évaluation

- 4.condenser & Feed Water SystemsDocument62 pages4.condenser & Feed Water SystemsAjit Kumar100% (1)

- 9A23702 Process Equipment Design in BiotechnologyDocument4 pages9A23702 Process Equipment Design in BiotechnologysivabharathamurthyPas encore d'évaluation

- Controlled Circulation PumpDocument5 pagesControlled Circulation PumpLakshminarayanPas encore d'évaluation

- Dump TubeDocument4 pagesDump TubeKrishna KumarPas encore d'évaluation

- KPM - Wet Services Rev 1Document16 pagesKPM - Wet Services Rev 1Waqar Ahmed ShaikhPas encore d'évaluation

- Im316 Flow MeasurementDocument67 pagesIm316 Flow MeasurementSelvarajPas encore d'évaluation

- Fluid Mechanics & Hydraulic Machines Lab ManualDocument75 pagesFluid Mechanics & Hydraulic Machines Lab ManualvenkiteshksPas encore d'évaluation

- Mechanical Engineering Design Guideline SummaryDocument10 pagesMechanical Engineering Design Guideline SummaryJeffrey NgPas encore d'évaluation

- M&E RequirementDocument11 pagesM&E Requirementmunim87100% (1)

- Piping Eveporative COndensersDocument12 pagesPiping Eveporative COndensersscribd99190Pas encore d'évaluation

- Stator Water Cooling System - Stage-2Document12 pagesStator Water Cooling System - Stage-2raghavendran raghuPas encore d'évaluation

- A Block Flow DiagramDocument35 pagesA Block Flow DiagramJerry SimonPas encore d'évaluation

- Velocity of Water in PipeDocument4 pagesVelocity of Water in Pipeabidch143100% (1)

- Annexure-I (Sprinkler System)Document5 pagesAnnexure-I (Sprinkler System)ashilvantPas encore d'évaluation

- TR-036 Trane Chiller Rehab Ilia Ti OnDocument3 pagesTR-036 Trane Chiller Rehab Ilia Ti OnJoel Maximo Javines MangaoangPas encore d'évaluation

- Basic of Hydronics SystemsDocument7 pagesBasic of Hydronics SystemskzyahtunPas encore d'évaluation

- FM & HM Lab Lab Manual PDFDocument37 pagesFM & HM Lab Lab Manual PDFSri Gaja Govind BabuPas encore d'évaluation

- Common Points To Trac Fujico.Document2 pagesCommon Points To Trac Fujico.venka07Pas encore d'évaluation

- Fluid Mechanics Lab ManualDocument33 pagesFluid Mechanics Lab Manualkannan_kcetPas encore d'évaluation

- Pipe FrictionDocument4 pagesPipe FrictionShubham ChauhanPas encore d'évaluation

- Condenser Performance Analysis and Its ImprovementDocument23 pagesCondenser Performance Analysis and Its Improvementanup_nair100% (1)

- Closed Expansion TankDocument4 pagesClosed Expansion Tanka_salehiPas encore d'évaluation

- Fluid MechanicsDocument35 pagesFluid MechanicsJohn Ely Collado Bantog0% (1)

- Basic Design Guidelines For Mechanical Engineering SystemsDocument10 pagesBasic Design Guidelines For Mechanical Engineering SystemsImranMustaffaPas encore d'évaluation

- Minor LossesDocument9 pagesMinor LossesRamanaReddy DareddyPas encore d'évaluation

- A Basic Design Guideline For Mechanical Engineering SystemsDocument10 pagesA Basic Design Guideline For Mechanical Engineering SystemsmdazmizakiPas encore d'évaluation

- Steam BlowingDocument25 pagesSteam Blowingelrajil0% (1)

- Sizing of Water Supply Pipes and Drainage and Vent PipesDocument16 pagesSizing of Water Supply Pipes and Drainage and Vent PipesMarlo ClaroPas encore d'évaluation

- The Mathematics of Pumping Water: AECOM Design BuildDocument9 pagesThe Mathematics of Pumping Water: AECOM Design BuildAdel SharifiPas encore d'évaluation

- 131A Piping BrochureDocument12 pages131A Piping Brochuredeanewing11Pas encore d'évaluation

- Boiler Types and Parts GuideDocument29 pagesBoiler Types and Parts GuideAJITSPATILPas encore d'évaluation

- 0.water Supply Course GuideDocument6 pages0.water Supply Course GuideAJMAL TPas encore d'évaluation

- Calculation ReportDocument29 pagesCalculation Reportvictor.sPas encore d'évaluation

- Three Phase Horizontal Test SeparatorDocument1 pageThree Phase Horizontal Test SeparatorAnonymous TadQZYIPas encore d'évaluation

- Experiment No 7Document7 pagesExperiment No 7Faizan Ahmed67% (3)

- EES Problems W21 ModifiedDocument2 pagesEES Problems W21 Modifiedabhishek.anand12Pas encore d'évaluation

- Grundfos UPBasic Circulator pumps data bookletDocument12 pagesGrundfos UPBasic Circulator pumps data bookletwwwdotcomatPas encore d'évaluation

- 35,000 kg/hr Water-Tube Boiler Design & Construction SpecDocument7 pages35,000 kg/hr Water-Tube Boiler Design & Construction SpecRabindranath Hendy TagorePas encore d'évaluation

- Coolant: InspectionDocument32 pagesCoolant: InspectionAiman NasirPas encore d'évaluation

- Quick Guide For Pump Selection - EngDocument43 pagesQuick Guide For Pump Selection - EngadelPas encore d'évaluation

- Water Supply Design ChecklistDocument5 pagesWater Supply Design ChecklistAli OsmanPas encore d'évaluation

- Saunier Duval Thema C23 Installation ManualDocument20 pagesSaunier Duval Thema C23 Installation ManualZmarandoiu SorinaPas encore d'évaluation

- Pipe Friction LossDocument6 pagesPipe Friction LossHoongPas encore d'évaluation

- ReticulationDocument118 pagesReticulationIzzul Hazim100% (1)

- AED Design Requirements - Water Tanks and System Distribution - Sep09 PDFDocument23 pagesAED Design Requirements - Water Tanks and System Distribution - Sep09 PDFAvonodOiratulcPas encore d'évaluation

- Interviw Question & AnswersDocument7 pagesInterviw Question & AnswersKhaleel RehmanPas encore d'évaluation

- Process Plant ServicesDocument11 pagesProcess Plant ServicesByme GsckcPas encore d'évaluation

- Manejadora Adp Lennox PDFDocument15 pagesManejadora Adp Lennox PDF45saulPas encore d'évaluation

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersD'EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersPas encore d'évaluation

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGD'EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGPas encore d'évaluation

- Fcu Schedule Dubai Inn Port Saeed 19-05-2015Document8 pagesFcu Schedule Dubai Inn Port Saeed 19-05-20152767141Pas encore d'évaluation

- LiDocument12 pagesLi2767141Pas encore d'évaluation

- 19 7 2015Document2 pages19 7 20152767141Pas encore d'évaluation

- 13 7 2015Document4 pages13 7 20152767141Pas encore d'évaluation

- Dynamics of Primary and Secondary Chilled Water SystemsDocument13 pagesDynamics of Primary and Secondary Chilled Water SystemsBen MusimanePas encore d'évaluation

- Fcu Schedule Dubai Inn Port Saeed 19-05-2015Document8 pagesFcu Schedule Dubai Inn Port Saeed 19-05-20152767141Pas encore d'évaluation

- MEP Provisions For Generator 24-06-2015-Layout1Document1 pageMEP Provisions For Generator 24-06-2015-Layout12767141Pas encore d'évaluation

- Fcu Schedule Dubai Inn Port Saeed 19-05-2015Document8 pagesFcu Schedule Dubai Inn Port Saeed 19-05-20152767141Pas encore d'évaluation

- Fcu Schedule Dubai Inn Port Saeed 19-05-2015Document8 pagesFcu Schedule Dubai Inn Port Saeed 19-05-20152767141Pas encore d'évaluation

- Pipe Sizes and Floor Distribution ReportDocument4 pagesPipe Sizes and Floor Distribution Report2767141Pas encore d'évaluation

- Pipe Sizes and Floor Distribution ReportDocument4 pagesPipe Sizes and Floor Distribution Report2767141Pas encore d'évaluation

- Electric Duct HeaterDocument3 pagesElectric Duct Heater2767141Pas encore d'évaluation

- Xylem Industries Pumpset Project DocumentationDocument3 pagesXylem Industries Pumpset Project Documentation2767141Pas encore d'évaluation

- Xylem Industries Pumpset Project DocumentationDocument3 pagesXylem Industries Pumpset Project Documentation2767141Pas encore d'évaluation

- Fire DetailshhDocument6 pagesFire Detailshh2767141Pas encore d'évaluation

- 211201Document8 pages2112012767141Pas encore d'évaluation

- Electric Duct HeaterDocument3 pagesElectric Duct Heater2767141Pas encore d'évaluation

- 02.21regulationfp 4.0featuresandlifesafetyrequirementsDocument16 pages02.21regulationfp 4.0featuresandlifesafetyrequirements2767141Pas encore d'évaluation

- WATER HEAT PIPES For Dehumidification and Heat RecoveryDocument5 pagesWATER HEAT PIPES For Dehumidification and Heat Recovery2767141Pas encore d'évaluation

- Mechanical Section: 23 73 23 BMSDocument3 pagesMechanical Section: 23 73 23 BMS2767141Pas encore d'évaluation

- Staircase PressurizationDocument8 pagesStaircase PressurizationSimon LawPas encore d'évaluation

- Ir - 112 - 5th FloorDocument2 pagesIr - 112 - 5th Floor2767141Pas encore d'évaluation

- Internal Equity, Taxes, and Capital StructureDocument2 pagesInternal Equity, Taxes, and Capital Structure2767141Pas encore d'évaluation

- Solar Cooling (Case Study)Document146 pagesSolar Cooling (Case Study)2767141100% (2)

- Chapter - 8 - 2009 (Ebook in PDF)Document16 pagesChapter - 8 - 2009 (Ebook in PDF)2767141Pas encore d'évaluation

- Ncpfirst - X-Form - PDF Example: (Epc - Dedicated Front Cover Sheet Here)Document12 pagesNcpfirst - X-Form - PDF Example: (Epc - Dedicated Front Cover Sheet Here)Anil100% (1)

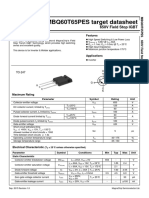

- MBQ60T65PES Target Datasheet: 650V Field Stop IGBTDocument1 pageMBQ60T65PES Target Datasheet: 650V Field Stop IGBTamrPas encore d'évaluation

- Optimized Skid Design For Compress Sor PackagesDocument5 pagesOptimized Skid Design For Compress Sor Packagessantosh kumarPas encore d'évaluation

- Advanced Fluid Characterization (Schlumberger)Document8 pagesAdvanced Fluid Characterization (Schlumberger)Astrid Hardtke100% (1)

- A380-LEVEL III - ATA 26 Fire - Smoke DetectionDocument42 pagesA380-LEVEL III - ATA 26 Fire - Smoke DetectionAbolfazl Mazloomi100% (2)

- Unit 4: Fault Analysis EssentialsDocument9 pagesUnit 4: Fault Analysis EssentialsBALAKRISHNAN100% (2)

- Field Joint CoatingDocument7 pagesField Joint CoatingTeodor EzaruPas encore d'évaluation

- Glycerol Production, Consumption, Prices, Characterization and New Trends in CombustionDocument19 pagesGlycerol Production, Consumption, Prices, Characterization and New Trends in CombustionmkamalzamanPas encore d'évaluation

- Упражнения на отработку Second ConditionalDocument6 pagesУпражнения на отработку Second ConditionalНаргиля ГаджиеваPas encore d'évaluation

- Anomaly Events GuideDocument33 pagesAnomaly Events GuideRichard LittlesPas encore d'évaluation

- Wipro CSR BBDocument35 pagesWipro CSR BBYogesh GomsalePas encore d'évaluation

- Eastern Visayas State University-Ormoc City CampusDocument3 pagesEastern Visayas State University-Ormoc City Campuskhellian villameroPas encore d'évaluation

- QQ Reference List (July 2010)Document11 pagesQQ Reference List (July 2010)gabox707Pas encore d'évaluation

- 64 Meeting January 7-8, 2013Document42 pages64 Meeting January 7-8, 2013ymadhukumarPas encore d'évaluation

- Diesel Engine Power Plant GuideDocument51 pagesDiesel Engine Power Plant GuideShashank ShastriPas encore d'évaluation

- Final Et NotesDocument123 pagesFinal Et NotesyounusmohamadPas encore d'évaluation

- Cassette SPDocument3 pagesCassette SPalex_darPas encore d'évaluation

- MSC.1 Circ.1197 Amendments To The Unified Interpretations To Solas Chapters II-1And XII Approved by MSC Circ.1176Document5 pagesMSC.1 Circ.1197 Amendments To The Unified Interpretations To Solas Chapters II-1And XII Approved by MSC Circ.1176youngfpPas encore d'évaluation

- 436 - 1 - 1 - Sampling of CoalDocument24 pages436 - 1 - 1 - Sampling of CoalSudhanshu DashPas encore d'évaluation

- Reduce Your Energy Bill - Increase Your Confidence: Air-Cooled Liquid Chillers and Heat Pumps 40-160 KWDocument6 pagesReduce Your Energy Bill - Increase Your Confidence: Air-Cooled Liquid Chillers and Heat Pumps 40-160 KWGonADFPas encore d'évaluation

- Chapter 6 Current and Voltage Relations On A Transmission LineDocument22 pagesChapter 6 Current and Voltage Relations On A Transmission LineNaomie2 KoguemPas encore d'évaluation

- Cable Installation Manual For Power and Control Cables: Global ReachDocument100 pagesCable Installation Manual For Power and Control Cables: Global Reacharjmandquest100% (1)

- Chapter 2 Internal Combustion Engine Performance ParametersDocument10 pagesChapter 2 Internal Combustion Engine Performance ParametersFlancPas encore d'évaluation

- Utilization of Lignocellulosic Biomass by Oleaginous Yeast and Bacteria For Production of Biodiesel and Renewable DieselDocument18 pagesUtilization of Lignocellulosic Biomass by Oleaginous Yeast and Bacteria For Production of Biodiesel and Renewable DieselIkrar AdiPas encore d'évaluation

- Electrocardiograf Ym412i Service ManualDocument14 pagesElectrocardiograf Ym412i Service ManualramarservmedPas encore d'évaluation

- ST 2DDocument257 pagesST 2Dsaul100% (1)

- NewsStand - 24 of October 2021Document16 pagesNewsStand - 24 of October 2021Ahmed MansourPas encore d'évaluation

- Accuspin 1 120V 230VDocument60 pagesAccuspin 1 120V 230VAndrew HolmesPas encore d'évaluation

- Javan 1961 - POPULATION INVERSION AND CONTINUOUS OPTICAL MASER OSCILLATION IN A GAS DISCHARGE CONTAINING A He-Ne MIXTUREDocument8 pagesJavan 1961 - POPULATION INVERSION AND CONTINUOUS OPTICAL MASER OSCILLATION IN A GAS DISCHARGE CONTAINING A He-Ne MIXTURECayo Julio CesarPas encore d'évaluation