Académique Documents

Professionnel Documents

Culture Documents

Expansion Tank Air Sep

Transféré par

organicspolybondCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Expansion Tank Air Sep

Transféré par

organicspolybondDroits d'auteur :

Formats disponibles

Expansion Tank Application

Characteristics of Water That Make Expansion Tanks Necessary

Water expands when it is heated (1000 gallons becomes about 1040 gallons when

heated from 40

F to 200

F).

Water is non-compressible for all practical purposes.

herefore! if pro"isions are not made for the expansion of water as it approaches

operating temperature! it will brea# out of the s$stem at the wea#est point! which is the

relief "al"e (hopefull$ there is one%).

1

Failure to specif$ an ade&uatel$ si'ed expansion

tan# results in(

Weeping from the relief "al"e as the s$stem c$cles from cold to hot

) resulting infusion of ma#e-up water when s$stem c$cles from hot to cool

*ntroduction of air into the s$stem (dissol"ed in the ma#e up water)! which

accelerates corrosion! and

*ntroduction of dissol"ed minerals into s$stem. +inerals e"entuall$ ,ba#e out, on

hot surfaces! such as the heat transfer areas of a boiler! a process which often results

in boiler failure. he process to failure follows(

- *n a boiler! the hot gasses on one side of a boiler section (or copper tube in

the e"ent of a copper tube boiler) reach temperatures in the range of 2-00-

.000 F. /n the other side! water flows at perhaps 200

o

F.

- 0nder normal circumstances! the water flowing on the cold side of the

heat transfer surface remo"es the heat from the metal as fast as it can be

added! #eeping the metal at a reasonable temperature. )s minerals enter

with the ma#e-up water! a coating of ba#ed-on minerals forms on the heat

transfer surface1 this coating increases in thic#ness with time. his

mineral la$er is a good insulator! and pre"ents the transfer of heat from the

metal to the water.

1

)n F2* customer recentl$ had a s$stem in which an automatic "al"e would close! isolating the relief

"al"e. *t too# six split pump bodies (2 failures of . pumps) before the real problem was disco"ered.

1

- herefore! the metal temperature rises and the metal e"entuall$ crac#s or

splits! resulting in boiler failure.

How an Expansion Tank Works

)n expansion tank is onl$ partiall$ full of water on start up. he rest of the tan#

contains air. )s the s$stem water expands! the added s$stem "olume mo"es into the

expansion tan#! compressing the air! thereb$ increasing the air pressure! which

3pushes bac#4 to increase the s$stem pressure.

) properl$ si'ed expansion tan#(

5imits

2

the s$stem operating pressure increase under the hot condition!

6ro"ides a safe s$stem pressure without rel$ing on the relief "al"e to discharge!

*nsures that pump 7682 re&uirements are met! and

9stablishes a point of ,'ero pressure change, for the s$stem! ensuring that there

will be no negati"e pressure points an$where in the s$stem

Air Elimination vs. Air Control

he s$stem designer first decides whether to use an air elimination s$stem or an

air control s$stem.

Air Elimination System and its Components

he s$stem below illustrates air elimination using an air scoop and air "ent. he

3captive air expansion tank (described on page .) allows for expansion. he air scoop

separates air from the water! and the "ent discharges that air to the e&uipment room.

Air Elimination System and its Components

2

7ote that it does not prevent an increase in s$stem pressure---:ust limits it%

2

he air control s$stem operates with an air separator that is not e&uipped with an

air "ent. herefore! it does not "ent the air! but instead sends it through a special tan#

fitting into a plain steel expansion tan#. 2ence it 3sa"es4 the separated air to help

pro"ide an air cushion. he 3tan# fitting4 wor#s in concert with the air separator and

pre"ents air from re-entering the s$stem on a cool down c$cle.

Air Control System

Expansion Tank Styles

Captive air tanks serve air separation systems. With this st$le! a rubber diaphragm

or bladder separates the water from a cushion of air! which is pre-charged into the tan#

during manufacturing. his is done through a 8chrader "al"e! the same fitting used to fill

bic$cle tires.

;ladder tan#s utili'e a rubber bag called a bladder. *f the tan# utili'es a bladder

capable of expanding to the full si'e of the tan#! as shown in Figure 1A! the tan# is

called a full acceptance tan#. *f the tan# uses a smaller bag that will not extend to the

full dimensions of the tan#! it is called a partial acceptance tan#.

<iaphragm tan#s! as shown in Figure 1b! emplo$ a diaphragm across the middle

portion of the tan#. he diaphragm cannot expand to the limits of the steel shell! ma#ing

diaphragm tan#s partial acceptance de"ices.

=enerall$ spea#ing! partial acceptance tan#s cost less! but full acceptance tan#s

accept more expansion in a smaller pac#age. <iaphragm tan#s are a"ailable in both

)8+9 code and non-)8+9 code designs. hese are referred to Code and Non-

Code tan#s. )8+9 st$les feature hea"ier dut$ construction and higher factors of safet$.

.

7on-code tan#s are generall$ best suited for residences or small commercial buildings (if

their use in commercial applications is allowed b$ local codes).

8ome bladder st$le tan#s utili'e a replaceable bladder While a replaceable bladder

sounds li#e a great idea! it is a difficult and time-consuming process to replace a bladder.

*t is often easier to simpl$ replace the whole tan#. 8o where access and clearance exists

to get a new tan# into the e&uipment room! designers often choose the less expensi"e

non-replaceable bag designs. For "er$ large tan#s! tan# replacement ma$ not be feasible!

so replaceable bladder tan#s pro"ide the best option. 7ote that diaphragms used in

diaphragm st$le tan#s are not replaceable.

Plain steel tanks (Figure 1A) are used in air control systems. hese simple "essels

ha"e no bag or bladder separating the air cushion from the fluid. 6lain steel tan#s are less

expensi"e than e&ui"alent bladder tan#s! but the$ are larger and often cost more to install

than capti"e air tan#s! for reasons discussed later. 6lain steel tan#s are a"ailable in

)8+9 and non-)8+9 configurations! but non->ode tan#s are generall$ used onl$ in

residences.

Figure 1A! "lain Steel #ank

Figure 1$! %iap&ragm #ank '"artial Acceptance(

4

Figure 1 C! $ladder #ank--Full Acceptance

Choosing the System an Tank Type

he decision of whether to use air control or air elimination is inherentl$ intertwined

with the tan# selection t$pe and "ice "ersa. he following factors contribute to the final

choice(

First cost) =enerall$ plain steel tan#s cost the least for a gi"en "olume of

expansion. 2owe"er! the following off-setting factors appl$(

o Si*e+space) 6lain steel tan#s are larger than bladder?diaphragm tan#s for

a gi"en application.

o Arrangement) 6lain steel tan#s must be suspended from the ceiling.

;ladder?diaphragm tan#s ma$ be suspended! mounted "erticall$ on the

floor! or hori'ontall$ on the floor! but the$ are generall$ mounted on the

floor for con"enience.

o Structural Support) 6lain steel tan#s usuall$ re&uire more robust

structural support because the$ are larger and hold more water.

herefore! the labor and material cost sa"ings for mounting capti"e air tan#s

generall$ o"erride the first cost ad"antage of plain steel tan#s! at least for cases

where the plain steel tan# would be around 200 gallons or more.

Simplicity o, -peration) /perators toda$ generall$ understand air elimination

s$stems better than air control s$stems. )ir elimination s$stems do awa$ with

@

concerns of waterlogged tan#s. he$ simplif$ start up! as 3sa"ing4 the proper

amount of air for the cushion in a plain steel tan# becomes a non-issue.

#aco Styles Are)

.eplaceable

/odel Acceptance $ladder0 Notes

CA Full 1es "otable -2! F%A

C$3 "artial No Non "otable

C3 "artial No '%iap&ragm( Non "otable

"A3 "artial 1es "otable! F%A

!ata "e#$ire for Si%ing the Expansion Tank

o properl$ si'e an expansion tan#! we must #now the following "alues(

8$stem "olume

Fill temperature!

Fill pressure!

+aximum design pressure!

+aximum design temperature.

5etAs consider each of these factors(

%etermine System 4olume b$ adding the water-holding capacities of all the

components of the piping s$stem! including boilers? chillers! coils! piping! air

separators! etc. 0se the tables at the end of this chapter to estimate the "olume

of piping and man$ common t$pes of 2B)> e&uipment. For items not shown

in the tables! use catalogs from specific manufacturers. 7ote that in determining

s$stem "olume! it is best to be safe. An undersized epansion tank results in

the problems outlined on Page 1. An oversized tank results in no operational

problems.

Fill temperature) he temperature of the water a"ailable to fill the s$stem. *n our

climate! use about 40 F.

C

Fill pressure) he pressure to which the s$stem will be initiall$ filled at start up.

he fill pressure setting on the fill valve establishes this pressure. (his "al"e admits

water to the s$stem whene"er the s$stem pressure falls below the fill "al"e setting). wo

factors impact the chosen fill pressure for a s$stem.

1 #&e ,ill pressure must li,t t&e 5ater to t&e &ig&est point in t&e system

Decall that 2..1 feet of water column e&uals a pressure of 1 68*! so a s$stem with

a high point in the piping of 2.E abo"e the fill "al"e re&uires a pressure of 10 68*= at

the "al"e (2.A?2..1). o this minimum pressure! add an additional @ 68*= safet$

margin. he reason( as the s$stem fills! the water displaces the air! which rises to

high points in the s$stem. )t start up this air must be manuall$ "ented using manual

air "ents. he pressure in the piping needs to be greater than atmospheric pressure

to insure that the air will readil$ mo"e from the pipe! through the air "ent! and into

the atmosphere. !n no case" should the fill pressure be less than 1#$1% P&!'" even

for one$story buildings. 8$stems operating at lower pressures simpl$ ta#e longer to

"ent.

(ample 1) *hat is the fill pressure recommended for a %+, high

system-

&olution) (%+./%.+1) 0 (1 P&!') 2 11 P&!'

Example 6) 7&at is t&e ,ill pressure recommended ,or a 168 &ig&

system0

Solution) '168+691( : '; "S<=( > 1?68@ #&ere,ore revert to t&e

minimum o, 16 "S<=

6 #&e ,ill pressure must prevent cavitation As a rule of thumb, perform the

NPSH calculations when designing a system for 21 degrees or greater, and the

pump NPSHr is greater than 2!2" feet. *f the fill pressure determined b$ the

building height is insufficient to pre"ent ca"itation! find a lower 7682r pump or

resort to a higher fill pressure .

/aximum %esign "ressure( 0se a maximum operating pressure is normall$ input at

about @-10 68*= below the relief "al"e setting. (Delief "al"es often 3weep4 at settings

below their relief setting. he @-10 68*= margin minimi'es the chance of weeping).

he relief "al"e setting is determined b$ a combination of factors including(

F

1. he maximum pressure rating of e&uipment in the s$stem! such as boilers!

chillers! pumps and accessories. hough relief "al"es ma$ be ordered for an$

setting! distributors stoc# relief "al"es set at .0G! @0G! F@G and 12@G! so one of

these pressures is normall$ chosen. All ot&er ,actors being eAual! t&e &ig&er

t&e maximum design pressure! t&e smaller t&e expansion tank

2. he relati"e price of a"ailable bac#flow pre"enters. 0sing a .0G relief "al"e

results in an inexpensi"e bac#flow pre"enter. *n small buildings! this often fa"ors

a setting of .0G in spite of the fact that other items in the s$stem would withstand

a higher pressure.

Demember the pressure will be higher than at other points in the s$stem than it is at the

expansion tan# if the tan# is properl$ located at the pump suction. For eample" the

pressures at the discharge of the pump 3ill be higher by the amount the of pump head.

4herefore" 3hen selecting the relief valve setting" take into account the location of the

valve and the pressures at other points in the system to avoid eceeding e5uipment

pressure ratings.

Example) he h$dronic components of a s$stem carr$ a rating of 12@ 68*=. he

designer selects a relief "al"e setting of 12@ 68*= and si'es his expansion tan#

accordingl$. he contractor installs the relief "al"e on the suction side of the pump. he

pump is pro"ides a head of F0A. When the s$stem heats up! the pressure on the suction

side of the pump (point of connection to the expansion tan#) reaches 120 68*=. hin#

about the pressure on the discharge side of the pump with the pump in operation. *s the

s$stem ade&uatel$ protected against o"er pressuri'ationH

/aximum %esign #emperature

For heating s$stems use either the maximum expected normal operating

temperature of the boiler (or the high limit setting on the boiler for a bit more safet$).

For chilled water s$stems! use the maximum expected temperature of the water s$stem

on a summer da$ with the cooling s$stem is turned off (perhaps I@-10@ degrees).

-

Selecting the Expansion Tank

his was formerl$ a manual calculation! but toda$ we plug the s$stem "olume! fill

temperature! fill pressure! maximum design temperature! and maximum design

pressure into the aco7et software to select multiple si'es and t$pes of tan#s for our

consideration.

For buildings of two stories and less and relief "al"e settings of .0 68*=! $ou

ma$ use the 3Juic# 8i'ing >hart4 on page 14 of this chapter to pic# Flexcon (and

similar) non-)8+9 and aco )8+9 capti"e air tan#s.

&lycol Corrections

7ote that both eth$lene and prop$lene gl$col expand more than water. *f $ou are

using gl$col! inflate the system volume before entering manual selection tables

such as the 6uick &izing Chart7 6lease see the gl$col correction factors on page 1C

of this chapter.

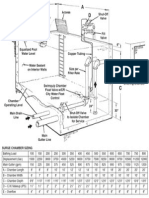

'oint of Connection to the System

he point where the expansion tan# connects to the s$stem is called the point of #ero

pressure change. he reason is that the pressure in the tan# and at the point of

connection is the same whether the pump is off or on. he diagram below shows s$stem

pressures throughout a s$stem with the pump off (upper figure) and on (lower figure)

when the tan# is properly connected to the suction side of the pump.

I

Loads

Boiler

Pump

Air Vent

Exp. Tank

Air Vent

23'

12 PSIG 12 PSIG

ill

2 PSIG 2 PSIG

A (

! "

Pressure !rops

B to "# 1 PSI

" to !# $ PSI

! to A# 2 PSI

1 2 P S I G

Pump %ead & 21'

'( PSI)

2 1 P S I G

10 PSIG

4 PSIG

he diagram below shows what will happen to the s$stem pressures at "arious points

when the expansion tan# is improperl$ connected to the discharge side. 7ote that with

the pump connected to the discharge side of the pump! the pressure can become a

"acuum at some points in the s$stem. his could create 7682 problems (Wh$H). *t

could also result in air being drawn into the s$stem. he example shows the importance

of ha"ing the point of 'ero pressure change (the point of connection to the expansion

tan#) at the inlet to the pump.

o most people! the idea that improper tan# connection location could cause the

pump to 3pull4 rather than to 3push4 is counter-intuiti"e. o pro"e our point! we will

demonstrate this in our lab! showing that this is reall$ true%

Demember that 3the point of 'ero pressure change4 onl$ refers to the fact that the

pressure will not change whether the pump is 3on4 or 3off.4

.

he pressure W*55 change

as the s$stem temperature changes.

.

his is a difficult concept. hin# of it this wa$. With the pump off and the s$stem at a stable temperature!

a fixed "olume of air is in the air cushion. here is also a fixed "olume of water in the s$stem. 8impl$

starting or stopping the pump does not affect the "olume of water in the s$stem. Without a change in water

"olume! the air cushion cannot compress or expand. Without a compression or expansion! the air pressure

will not change and therefore the pressure exerted on the water b$ the air cushion will not change1 therefore

the s$stem pressure at the point of connection cannot change. +a#e senseKsort ofH

10

Loads

Boiler

Air Vent Air Vent

23'

12 PSIG 12 PSIG

2 PSIG 2 PSIG

A (

! "

Pressure !rops

B to "# 1 PSI

" to !# $ PSI

! to A# 2 PSI

Pump %ead & 21'

'( PSI)

1 2 P S I G

1 PSIG

Pump

ill

Exp. Tank

-5 PSIG

3 P S I G

CAST )"*N (*)+E" WATE" C*NTENT ,&A++*NS-

.*" (*)+E"S MAN/.ACT/"E! 0123 T* '"ESENT

*+. ,ESI!E*TIAL

"+--E,"IAL

I*!.ST,IAL

"+--E,"IAL

I*!.ST,IAL

+ "AST I,+*

/ATE, B+ILE,

"+*VE,TIBLE T+

STEA-

/ATE, +*L0

SE"TI+*S

B.,*%A-

2 SE,IES

-B%

WATE"

C*NTENT

B.,*%A-

P1

-B%

WATE"

C*NTENT

B.,*%A-

2 SE,IES

-B%

WATE"

C*NTENT

2 31 4.3

3 12 5.4

3 24 6.7

1 142 6.8 212 00.1

$ 13$ 3.3 321 58.2 2$3 05.1

5 1$3 2.4 353 65.6 315 03.1

2 121 8.7 335 61.0 352 08.1

( 212 8.8 3(( 36.1 322 01.1

14 233 9.4 1$2 27.2 351 40.1

11 $23 22.6

12 $2$ 84.0

13 53( 88.1

13 211 95.8

11 253 91.6

1$ (3$ 13.4

15 ((2 077.1

12 14$1 072.8

1( 1123 004.3

24 112$ 009.4

21 1232 046.7

22 1314 041.8

1321 060.4

11$4 034.9

*+TE#

1. "6art is 7ased on Burn6am 8ast iron 7oiler 9as :ired.

2. I: 7oiler is oil :ired sele8t -B% load and use next lar9er si;e :or <ater 8ontent.

3. or 7oilers made 7e:ore 1($1 8onsult manu:a8turers literature.

11

Water :ol$me Containe in Common H:AC E#$ipment

Fan Coils! Bnit 4entilators! Cabinet Ceaters! $ooster Coils

&allons 'er Coil "ow

inned

/idt6

'in86es)

inned Len9t6 'in86es)

12 23 34 3$ 32 32 $4 52 23

$ 4.11 4.11 4.1( 4.22 4.2$ 4.34 4.35 4.31 4.12

( 4.15 4.22 4.22 4.33 4.3( 4.31 4.1$ 4.$5 4.5(

12 4.22 4.34 4.35 4.31 4.12 4.$4 4.51 4.(4 1.41

Air Candling Bnits and $uilt Bp Coils

&allons 'er Coil "ow

inned

/idt6

'in86es)

inned Len9t6 'in86es)

12 23 34 3$ 32 $4 52 23 ($ 142 124 132 133

12 4.22 4.34 4.35 4.31 4.$4 4.51 4.(4 1.41 1.24 1.31 1.14 1.$1 1.24

12 4.33 4.31 4.1$ 4.$5 4.(4 1.12 1.31 1.15 1.24 2.42 2.21 2.35 2.54

23 4.31 4.$4 4.51 4.(4 1.24 1.14 1.24 2.14 2.34 2.54 3.44 3.2( 3.1(

34 4.1$ 4.51 4.(3 1.12 1.14 1.25 2.21 2.$2 3.44 3.35 3.53 3.12 3.3(

3$ 4.$5 4.(4 1.12 1.31 1.24 2.21 2.54 3.13 3.1( 3.43 3.3( 3.(3 1.3(

32 4.5( 1.41 1.31 1.15 2.14 2.$2 3.13 3.$5 3.1( 3.52 1.23 1.55 $.2(

32 4.(4 1.24 1.14 1.24 2.34 3.44 3.1( 3.1( 3.5( 1.3( 1.(( $.1( 5.1(

Estimated 4olume <n 7ater C&illers '=allons in Evaporator(

,e8ipro8atin9 and S8re< "ompressor .nits

Tons 11 24 21 34 34 14 $4 51 144 124 114 244

Gallons $ 2 14 11 15 21 21 34 14 $4 51 (4

"entri:u9al .nits

Tons 244 144 514 1444 1214 1144

Gallons 34 144 121 124 214 321

12

Water :ol$me Containe in Common H:AC E#$ipment

,Contin$e-

S&ell and #ube Ceat Exc&angers

S6ell

!ia.

&allon;.oot < Shell +ength

In S6ell In Tu7es

3 4.33 4.23

$ 1.4 4.1

2 1.2 4.(

14 2.3 1.2

12 3.4 2.2

13 1.4 2.$

1$ $.1 3.1

12 2.4 3.1

24 14.4 1.1

23 11.4 5.1

=============================================================================

4-DB/E -F 7A#E. <N "<"<N= '=ADD-NS "E. D<NEAD F--#(

T0PE >? @? 1? 1A1B3? 1A1B2? 2? 2A1B2? 3? 3? 1? $?

STEEL

PIPE

.41$ .422 .431 .452 .141 .152 .214 .321 .$$5 1.44 1.34

"+PPE,

T.BE

.412 .421 .433 4$1 .4(2 .1$1 .214 .315 .$21 1.44 1.34

T0PE 2? 14? 12? 13? 1$? 12? 24? 23?

STEEL

PIPE

2.$4 3.4( 1.22 5.1$ (.32 12.13 11.11 21.(3

Pex >? I.!. 1.4 GallonB144 eet

Pex 1B2? I.!. 1.$ GallonB144 eet

*+TES#

Pipe 8oils '7en86 8oils) C si;e as pipin9

"ommer8ial :in tu7e D residential 7ase7oard C si;e as pipin9

1.

Water :ol$me Containe in Common H:AC E#$ipment

,Contin$e-

================================================================

14

:ol$me of Commercial Air Separators

Moel !iam.= > +ength= > &allons

A"A2 2.$ 12 1

A"A2.1 14.51 24 2

A"A3 12.51 23.21 13

A"A3 1$ 2(.13 21

A"A1 1$ 31.21 25

A"A$ 24 3$.51 14

A"A2 24 31.32 1$

A"A14 23 3(.1 (5

A"A12 34 1$.(3 153

A"A13 3$ $1 22$

A"A1$ 3$ 51.1 311

A"A12 32 53.21 33(

A"A24 32 22.21 $3(

-odel -B% Gallons

EV%A214 214 1.3

EV%A144 144 $.1

EV%A514 514 11.(

EV%A1444 1444 1$.3

EV%A1144 1144 15.3

EV%A2444 2444 12.1

Based on T6ermal Solutions

Copper .in (oilers

Expansion Tank Eui8k Si;in9 "6art

BASE! +*# 3+ T+ 244F 12 PSIG ILLF 34 PSIG ,ELIE

S0STE- V+L.-E

I* GALL+*S

S0STE- EGP.

-I*. A""EPT

-I*I-.-

TA*H V+L.

LEG"+*

-+!EL *+.

TA"+

-+!EL *+.

21

14

51

144

121

114

151

244

221

214

251

344

321

314

351

344

321

314

351

144

121

114

151

$44

$21

$14

$51

544

521

514

551

244

221

214

251

(44

(21

(14

(51

1444

1421

1414

4.(

1.2

2.$

3.1

3.3

1.3

$.1

5.4

5.(

2.2

(.5

14.1

11.3

12.3

13.2

13.4

13.(

11.2

1$.5

15.$

12.3

1(.3

24.2

21.1

21.(

22.2

23.5

23.$

21.3

2$.3

25.2

22.1

2(.4

2(.2

34.5

31.$

32.1

33.3

33.2

31.1

3$.4

3$.(

2.12

3.31

$.13

2.51

14.2(

13.4$

11.23

15.32

1(.$4

21.55

23.(1

2$.13

22.31

34.32

32.$$

33.23

35.42

3(.1(

31.35

33.11

31.53

35.(4

14.42

12.2$

13.33

1$.$4

12.5(

$4.(5

$3.11

$1.32

$5.14

$(.$2

51.21

53.43

5$.21

52.3(

24.1$

22.53

23.(2

25.14

2(.25

(1.31

V,11

V,34

V,$4

V,(4

V,(4

V,(4

SGV,34

SGV,34

SGV,34

SGV,34

SGV,$4

SGV,$4

SGV,$4

SGV,(4

SGV,(4

SGV,(4

SGV,(4

SGV,114

SGV,114

SGV,114

SGV,114

SGV,114

SGV,114

SGV,114

SGV,1$4

SGV,1$4

SGV,1$4

SGV,1$4

SGV,1$4

SGV,1$4

SGV,1$4

SGV,1$4

SGV,1$4

SGV,1$4

"G11

"G11

"G34

"G34

"G32

"G23

"G23

"G23

"G23

"G23

"G23

"G134

"G134

"G134

"G134

"G134

"G134

"BG154

"BG154

"BG154

"AG154

"BG213

"BG213

"BG213

"BG213

"BG213

"BG213

"BG213

"BG213

"BG213

"BG213

"BG344

"BG344

"BG344

"BG344

"BG344

"BG344

"BG314

"BG314

"BG314

"BG314

"BG314

*+TES# LEG"+* TA*HS C *+* "+!EF -AG. /P 144 PSIGF -AG. TE-P 234

TA"+ TA*HS C AS-E "+!EF -AG. /P 121 PSIGF -AG. TE-P 234

1@

"+,,E"TI+* A"T+,S +,

EGPA*SI+* + ET%0LE*E GL0"+L

'Based on 14 ill Temperature)

-AG. TE-P

I ET%0LE*E GL0"+L B0 V+L.-E

144

24I 34I 14I

1.$4 1.23 1.(4

134 1.22 1.32 1.14

1$4 1.24 1.33 1.34

124 1.11 1.21 1.31

244 1.13 1.22 1.22

224 1.14 1.1( 1.23

234 1.42 1.15 1.22

+ultipl$ 9xpansion for Water imes )bo"e Figures or *nflate 8$stem Bolume ;efore

8electing an# (7ot De&uired if 0sing aconet)

"+,,E"TI+* A"T+,S +,

EGPA*SI+* + P,+P0LE*E GL0"+L

'Based on 14 ill Temperature)

-AG. TE-P

I P,+P0LE*E GL0"+L B0 V+L.-E

144

24I 34I 14I

1.12 2.3$ 2.53

124 1.11 2.2$ 2.33

134 1.13 2.4$ 2.15

1$4 1.13 1.2$ 2.42

124 1.12 1.$$ 1.2(

244 1.11 1.13 1.$3

224 1.14 1.35 1.31

234 1.4( 1.34 1.11

+ultipl$ 9xpansion for Water imes )bo"e Figures or *nflate 8$stem Bolume ;efore

8electing an# (7ot De&uired if 0sing aconet)

1C

Vous aimerez peut-être aussi

- Expansion Tank ApplicationDocument16 pagesExpansion Tank Applicationarln_605551822Pas encore d'évaluation

- Basic Data & Course Rules of ThumbDocument10 pagesBasic Data & Course Rules of Thumbburhan kathiriaPas encore d'évaluation

- ASHRAE - The Fundamentals of Expansion Tanks PDFDocument7 pagesASHRAE - The Fundamentals of Expansion Tanks PDFAntonio LebrunPas encore d'évaluation

- The Fundamentals of Expansion Tanks: Column Engineer'S NotebookDocument13 pagesThe Fundamentals of Expansion Tanks: Column Engineer'S NotebookSdferwste SrqrePas encore d'évaluation

- ASHRAE Journal - Tips To Reduce Chilled Water Plant Costs - TaylorDocument6 pagesASHRAE Journal - Tips To Reduce Chilled Water Plant Costs - TaylorsajuherePas encore d'évaluation

- Boiler Fittings and AccessoriesDocument30 pagesBoiler Fittings and Accessorieskowsar0221Pas encore d'évaluation

- Pumping Away From Point of No Pressure ChangeDocument6 pagesPumping Away From Point of No Pressure ChangesalamrefighPas encore d'évaluation

- Troubleshoot in Heat Exchangers HP 1996Document5 pagesTroubleshoot in Heat Exchangers HP 1996piolinwalls100% (1)

- Cavitations 1-3: The Mcnally InstituteDocument5 pagesCavitations 1-3: The Mcnally InstituteBaqirMuhammadPas encore d'évaluation

- Typical Questions For Piping EngineerDocument4 pagesTypical Questions For Piping EngineerBudy SinagaPas encore d'évaluation

- Cooling Tower TDPDocument34 pagesCooling Tower TDPjayan perkasaPas encore d'évaluation

- Piping 30000Document14 pagesPiping 30000Prasanta Kumar BeheraPas encore d'évaluation

- Preventing Steam Coil FailureDocument3 pagesPreventing Steam Coil FailureSjeverPas encore d'évaluation

- Design Buckstay in Steam BoilersDocument9 pagesDesign Buckstay in Steam BoilerszaidinPas encore d'évaluation

- CDB Filters CatalogDocument47 pagesCDB Filters CatalogjasonlaiymPas encore d'évaluation

- Mep April 2023Document14 pagesMep April 2023chandramohandass22Pas encore d'évaluation

- Taco Expansion TankDocument20 pagesTaco Expansion TankDhirendra Singh RathorePas encore d'évaluation

- Air-Cooled Heat Exchangers Fin-Fan: by M.M.SorourDocument64 pagesAir-Cooled Heat Exchangers Fin-Fan: by M.M.SorourNader GaafarPas encore d'évaluation

- Eco Saver 20 ManualDocument17 pagesEco Saver 20 ManualshawngPas encore d'évaluation

- Taco Air SeparatorDocument12 pagesTaco Air Separatoremongclooney11Pas encore d'évaluation

- 2011 10 Idris Anwer Engro UreaKnowHow - Com Urea Stripper Leakage Identification&RDocument11 pages2011 10 Idris Anwer Engro UreaKnowHow - Com Urea Stripper Leakage Identification&RWaqas HabibPas encore d'évaluation

- Steam TrapDocument10 pagesSteam TrapvictorvikramPas encore d'évaluation

- Chapter 8 Steam PipingDocument14 pagesChapter 8 Steam PipingChen WsPas encore d'évaluation

- SealedTankPresentation by IEEEDocument5 pagesSealedTankPresentation by IEEESupratik MukherjeePas encore d'évaluation

- American Society of Mechanical Engineers Standard Boilers Pressure VesselsDocument8 pagesAmerican Society of Mechanical Engineers Standard Boilers Pressure VesselsPedro Oporto IIIPas encore d'évaluation

- Hot Water Circulation - Designers GuideDocument3 pagesHot Water Circulation - Designers GuideAntonio LebrunPas encore d'évaluation

- Valves: Continuing Education From The American Society of Plumbing EngineersDocument19 pagesValves: Continuing Education From The American Society of Plumbing Engineers185412Pas encore d'évaluation

- Lesson Diaphragm Valves, Pinch Valves and Instrument Valves: Sub-ObjectiveDocument8 pagesLesson Diaphragm Valves, Pinch Valves and Instrument Valves: Sub-Objectivemister pogiPas encore d'évaluation

- Engineering Tips-Cooling TowerDocument6 pagesEngineering Tips-Cooling TowerSharon LambertPas encore d'évaluation

- Mold VentingDocument13 pagesMold Ventingmecaunidos7771Pas encore d'évaluation

- The Quickest and Easiest Steps To Set-Up The Simple Water Fuel-How It WorksDocument11 pagesThe Quickest and Easiest Steps To Set-Up The Simple Water Fuel-How It WorksdavomusikPas encore d'évaluation

- Specifications: BA001 Relief ValveDocument2 pagesSpecifications: BA001 Relief Valvejosiah_rPas encore d'évaluation

- Cascade Bowl (Spout)Document5 pagesCascade Bowl (Spout)Pramendra7Pas encore d'évaluation

- Fis128 en AqDocument12 pagesFis128 en Aqjerin samPas encore d'évaluation

- Amcot Cooling Tower Corporation: Operating Instructions and Service Manual For Model ST 3 1500Document13 pagesAmcot Cooling Tower Corporation: Operating Instructions and Service Manual For Model ST 3 1500HECTOR IBARRAPas encore d'évaluation

- Engineering Letter: IndustrialsteamheatingsystemsDocument8 pagesEngineering Letter: Industrialsteamheatingsystemsmontie3Pas encore d'évaluation

- CONDENSER SchemeDocument47 pagesCONDENSER SchemeAbhishek SinhaPas encore d'évaluation

- Heat Exchanger Lab Report Shell and TubeDocument26 pagesHeat Exchanger Lab Report Shell and TubeAbdur Rehman67% (3)

- Coil Circuiting - SerpentineDocument8 pagesCoil Circuiting - Serpentinebruce1312100% (1)

- Reduce Expansion Tank Sizes Up to 80Document20 pagesReduce Expansion Tank Sizes Up to 80enlightened1718100% (1)

- CHEVRON Shell and Tube Exchanger Component Design ConsiderationsDocument42 pagesCHEVRON Shell and Tube Exchanger Component Design Considerationsbabak mir80% (5)

- Instruction Manual Vacuum CondenserDocument12 pagesInstruction Manual Vacuum CondenserGarry BernzPas encore d'évaluation

- AMCOT Cooling Tower Operations ManualDocument9 pagesAMCOT Cooling Tower Operations Manualroberto_perraciniPas encore d'évaluation

- Thermowells in LNG Carrier Liquid LinesDocument4 pagesThermowells in LNG Carrier Liquid LinesFernando Igor AlvarezPas encore d'évaluation

- TD Vs IB TrapDocument5 pagesTD Vs IB TrapKailas NimbalkarPas encore d'évaluation

- Steam Exchanger Operation and ComponentsDocument10 pagesSteam Exchanger Operation and ComponentsMahmoud Ahmed Ali AbdelrazikPas encore d'évaluation

- Jacketed VesselDocument4 pagesJacketed Vesselnithansa100% (1)

- 150 Chemical Engineering Interview QuestionsDocument40 pages150 Chemical Engineering Interview QuestionsCheenee SiringanPas encore d'évaluation

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingD'EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingÉvaluation : 5 sur 5 étoiles5/5 (3)

- Simple Plumbing Repairs for the Home and FarmsteadD'EverandSimple Plumbing Repairs for the Home and FarmsteadPas encore d'évaluation

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitD'EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitPas encore d'évaluation

- Oil and Gas Artificial Fluid Lifting TechniquesD'EverandOil and Gas Artificial Fluid Lifting TechniquesÉvaluation : 5 sur 5 étoiles5/5 (1)

- Linotype Manual: Giving Detailed Instructions of the Proper Adjustment and Care of the LinotypeD'EverandLinotype Manual: Giving Detailed Instructions of the Proper Adjustment and Care of the LinotypePas encore d'évaluation

- Chimneys & Fireplaces: They Contribute to the Health Comfort and Happiness of the Farm Family - How to Build ThemD'EverandChimneys & Fireplaces: They Contribute to the Health Comfort and Happiness of the Farm Family - How to Build ThemPas encore d'évaluation

- Pneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshD'EverandPneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshPas encore d'évaluation

- Combining DOAS and VRF, Part 2 of 2Document9 pagesCombining DOAS and VRF, Part 2 of 2miniongskyPas encore d'évaluation

- Bolger Group Logistics Consultants To Management - Pdfwarehouse Fire ComplianceDocument6 pagesBolger Group Logistics Consultants To Management - Pdfwarehouse Fire ComplianceminiongskyPas encore d'évaluation

- Sugar - Fluid Flow VelocitiesDocument4 pagesSugar - Fluid Flow VelocitiesminiongskyPas encore d'évaluation

- Combining DOAS and VRF, Part 1 of 2Document8 pagesCombining DOAS and VRF, Part 1 of 2miniongskyPas encore d'évaluation

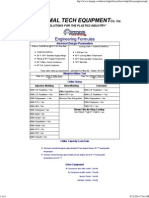

- "Solutions For The Plastics Industry": Co. IncDocument4 pages"Solutions For The Plastics Industry": Co. IncminiongskyPas encore d'évaluation

- Improving Efficiency With Variable-Primary Flow - Air Conditioning Content From HPAC EngineeringDocument7 pagesImproving Efficiency With Variable-Primary Flow - Air Conditioning Content From HPAC EngineeringminiongskyPas encore d'évaluation

- Selecting Chillers, Chilled Water Systems - Consulting-Specifying EngineerDocument5 pagesSelecting Chillers, Chilled Water Systems - Consulting-Specifying EngineerminiongskyPas encore d'évaluation

- Types and efficiencies of fuel-fired boilersDocument4 pagesTypes and efficiencies of fuel-fired boilersminiongskyPas encore d'évaluation

- Glossary - Education - CAGI - Compressed Air and Gas InstituteDocument6 pagesGlossary - Education - CAGI - Compressed Air and Gas InstituteminiongskyPas encore d'évaluation

- Application & Design of Energy Recovery Wheels - Airxchange, Inc PDFDocument8 pagesApplication & Design of Energy Recovery Wheels - Airxchange, Inc PDFminiongskyPas encore d'évaluation

- FMDS 1-35 Green Roof SystemsDocument27 pagesFMDS 1-35 Green Roof SystemsminiongskyPas encore d'évaluation

- FM Global Property Loss Prevention Data Sheets: List of FiguresDocument13 pagesFM Global Property Loss Prevention Data Sheets: List of FiguresminiongskyPas encore d'évaluation

- 16 Ways To Reduce HVAC Energy in Supermarkets and RetailDocument4 pages16 Ways To Reduce HVAC Energy in Supermarkets and RetailminiongskyPas encore d'évaluation

- Expert Cooling Tower Repair, LLC - 303.790Document4 pagesExpert Cooling Tower Repair, LLC - 303.790eimrehPas encore d'évaluation

- Cooling-Tower Design Tips - Air Conditioning Content From HPAC EngineeringDocument3 pagesCooling-Tower Design Tips - Air Conditioning Content From HPAC EngineeringminiongskyPas encore d'évaluation

- APEC Building Codes, Regulations and StandardsDocument227 pagesAPEC Building Codes, Regulations and StandardsminiongskyPas encore d'évaluation

- Table 6 - Demographic2Document1 pageTable 6 - Demographic2miniongskyPas encore d'évaluation

- ACH Recommended air changes per hourDocument2 pagesACH Recommended air changes per hourminiongskyPas encore d'évaluation

- Air King Ventilation Ashrae 62Document5 pagesAir King Ventilation Ashrae 62miniongskyPas encore d'évaluation

- Table - Hot Water Temperatures22Document2 pagesTable - Hot Water Temperatures22miniongskyPas encore d'évaluation

- Table - Hot Water Temperatures NHSDocument1 pageTable - Hot Water Temperatures NHSminiongskyPas encore d'évaluation

- Table - First Hour RatingDocument1 pageTable - First Hour RatingminiongskyPas encore d'évaluation

- Table 1MDocument2 pagesTable 1MminiongskyPas encore d'évaluation

- Surge ChamberDocument1 pageSurge ChamberminiongskyPas encore d'évaluation

- Evaporative Pool DehumidificationDocument9 pagesEvaporative Pool DehumidificationminiongskyPas encore d'évaluation

- Back To Basics - Water HeatersDocument5 pagesBack To Basics - Water HeatersminiongskyPas encore d'évaluation

- Characteristics, Behavior, and Properties of LPG - Petronas Energy Philippines, IncDocument2 pagesCharacteristics, Behavior, and Properties of LPG - Petronas Energy Philippines, IncminiongskyPas encore d'évaluation

- Back To Basics - Water Pipe SizingDocument5 pagesBack To Basics - Water Pipe Sizingminiongsky100% (1)

- Design Considerations of Water FeaturesDocument102 pagesDesign Considerations of Water Featuresminiongsky100% (1)