Académique Documents

Professionnel Documents

Culture Documents

Phase Segregation in Polymer Thin Films. Elucidations by X-Ray and Scanning Force Micros PDF

Transféré par

Menelao ZubiriTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Phase Segregation in Polymer Thin Films. Elucidations by X-Ray and Scanning Force Micros PDF

Transféré par

Menelao ZubiriDroits d'auteur :

Formats disponibles

EUROPHYSICS LETTERS 15 February 1999

Europhys. Lett., 45 (4), pp. 526-532 (1999)

Phase segregation in polymer thin lms:

Elucidations by X-ray and scanning force microscopy

H. Ade

1

(

), D. A. Winesett

1

, A. P. Smith

2

, S. Qu

3

, S. Ge

3

, J. Sokolov

3

and M. Rafailovich

3

1

Department of Physics, North Carolina State University

Raleigh, NC 27695-8202, USA

2

Department of Materials Science and Engineering

North Carolina State University - Raleigh, NC 27695-8202, USA

3

Department of Materials Science and Engineering

SUNY@Stony Brook, Stony Brook, NY11794, USA

(received 15 July 1998; accepted in nal form 8 December 1998)

PACS. 83.10Nn Polymer dynamics.

PACS. 83.80Es Polymer blends.

PACS. 61.10Ht X-ray absorption spectroscopy: EXAFS, NEXAFS, XANES, etc.

Abstract. We have used quantitative X-ray microscopy in combination with Scanning

Force Microscopy to monitor the phase separation of spun cast thin lms of polystyrene and

poly(methyl methacrylate) blends upon annealing. Both techniques complement and enhance

each other in elucidating the complicated structures that develop as a function of annealing

time. We have determined the composition of the mixed phases that result from solvent

spin casting. We subsequently observe the sudden rearrangement into domains much smaller

than those originally formed. Unique, intricate hydrodynamic mass ow patterns form during

coarsening which are in qualitative agreement with recent simulations of phase segregation in

two-dimensional viscous uids. Complicated polymer-polymer interfaces persist even in the

later stages that are explained in terms of the geometric constraints of a thin lm and the

dependance of polymer viscosity on lm thickness.

Thin lm polymer blends have considerable technological importance and are used in

numerous applications ranging from multi-color photographic printing to paints, adhesives

and protective coatings. Compared to the bulk properties, less is known about the properties

of blends when they are processed into thin lms. Numerous studies [1-10] have shown that for

binary polymer blends the spinodal decomposition and coarsening process can be more complex

in thin lms where various boundary conditions are imposed. Most of the recent studies of

phase separation in thin lms relied on various scanning force and optical microscopy methods.

These methods can only probe features that vary in topography, mechanical properties or

have large dierences in reectivity, and hence these studies have mostly concentrated on

(

) E-mail: Harald ade@ncsu.edu

c EDP Sciences

h. ade et al.: phase segregation in polymer thin films etc. 527

Energy (eV)

290 300 310

A

b

s

o

r

p

t

i

o

n

c

o

e

f

f

i

c

i

e

n

t

(

m

-

1

)

0

5

10

15

20

PS

PMMA C

CH

3

CH

2

C O

O

CH

3

n

C CH

2 n

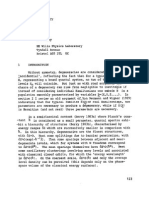

Fig. 1. Reference spectra of PS and PMMA normalized to the pre- and post-edge linear absorption

coecients of Henke [11], assuming a density of 1.07 g/cm

3

for PS and 1.19 g/cm

3

for PMMA [12].

the growth of large domains in the very late stages of phase separation [4, 6-10]. While

growing domain sizes can be observed, the determination of the local composition within

domains is elusive and these techniques are unable to unambiguously resolve the mass ow.

Consequently, while a variety of morphologies that evolve during the phase separation process

in polymer thin lms have been observed [3-9], the composition of two- and three-dimensional

morphologies and its time-dependent evolution has never been directly determined in the early

stages of phase separation. In this report, we present the results of combining quantitative

Near Edge X-ray Absorption Fine Structure (NEXAFS) microscopy with Scanning Force

Microscopy (SFM) to observe and characterize the phase separation and coarsening in a thin

lm (146 nm) over a wide range of time scales. The model polymer blend utilized consisted

of monodisperse (Molecular weight Mw = 27000, Mw/Mn < 1.05) polystyrene (PS) and

poly(methyl methacrylate) (PMMA) (Mw = 27000, Mw/Mn < 1.1). We have determined

the composition of the phases in the as-spun lms, observed the phase separation into smaller

domains, and the development of ragged domains during the early stages of coarsening. Our

observations of the early stages are particularly interesting because recent lattice Boltzmann

simulations by Wagner and Yeomans [13] on thin layers of binary uids indicate that the early

stages of the spinodal decomposition process are even more sensitive to the dimensionality of

the lm than the later stages [14]. These results predict that the dominant growth mechanism

in thin lms depends on the competition between the relative viscosities, the diusivities of

the two liquids, as well as the amplitude of the surface capillary waves relative to the domain

size. In contrast to bulk spinodal decomposition, the resulting patterns are predicted to lack

scale invariance and to develop with time-dependent rate laws. Depending on the viscosities,

dierent morphologies, including ragged ones, can evolve. Our observations of the various time

domains and the formation of a ragged morphology are in qualitative agreement with Wagner

and Yeomans.

Thin lms composed of 50/50 weight percent PS/PMMA blends were spun cast out of

toluene solution onto Si substrates with a native oxide layer. The thickness of the lms,

143 nm, was determined by multiple wavelength ellipsometry. The lms were annealed for

varying times and sections were subsequently transferred to carbon-coated TEM grids for

investigation with the Stony Brook Scanning Transmission X-ray Microscope (STXM) [15-17]

at the National Synchrotron Light Source. We acquired NEXAFS images of the thin lms at

528 EUROPHYSICS LETTERS

photon energies that included characteristic peaks of the component polymers (see g. 1).

To obtain the composition proles from the transmission images we utilized the single-

value decomposition procedure described in ref. [18]. This procedure uses the carefully

measured absorption coecients from the reference homopolymers (g. 1). We determined

mass thickness maps of each constituent polymer, and compared the summed maps (total

thickness) to SFM topographs. The individual NEXAFS compositional maps were compared

to friction and lateral force measurements using a SFM with an externally driven amplitude

modulation. Due to the slight dierence in surface friction and modulus, these techniques

can be used to dierentiate between PS and PMMA phases [9, 19]. The surface composition

and interface morphology of the PMMA phase was also checked and compared to NEXAFS

microscopy by washing o the PS layer in cyclohexane, a selective solvent for PS.

From the quantitative NEXAFS maps (g. 2) we can see directly that the unannealed,

solution cast blend (g. 2A-C) is already phase separated into small PS-rich regions and

a continuous PMMA-rich phase. We observed signicant amounts of PS in a cyclohexane

washed unannealed sample with quantitative NEXAFS maps and sample averaged NEXAFS

spectroscopy (not shown here). Combining the results from the washed and unwashed sample,

we nd that the two polymers are partially mixed with the PMMA/PS concentration ratios

varying from about 80/20% in the continuous PMMA-rich matrix to about 20/80% in the

PS-rich islands. The NEXAFS maps also indicate a gradient layer between these domains

as well as a thin PMMA layer near the substrate. Since the polymers are immiscible in the

melt, the initial, mixed compositions observed are a result of co-dissolution in toluene during

the solvent casting process. From gs. 2D-F, we see that immediately upon annealing, in the

absence of solvent, drastic reorganization occurs. It is interesting to note that the large round

PS domains that form after annealing for one week (gs. 2P-R) are not simply a result of

the gradual coalescence of the small, PS-rich domains, which are observed prior to annealing.

Rather, the mixed PS/PMMA domains phase separate into smaller domains and form intricate

coarsening patterns for pure components (gs. 2D-L) similar to the ones predicted in ref. [13].

The initial changes in the rst few minutes are the most rapid (note the change in scale

between gs. 2A-F and G-L). This is qualitatively consistent with the results of ref. [13] which

show a rapid initial growth of patterns in the hydrodynamic ow regime. In addition, the

jagged ow patterns and rough interfaces in images 2D-K are similar to the patterns exhibited

in these simulations and occur when the wavelength of capillary waves is about the same as

the domain size [20]. Once the domains are circular, coalescence occurs through much slower

diusion/collision processes. This change in growth exponent, which is a function of the

patterns formed, leads to the predicted lack of scale invariance. From the STXM gures, one

can see additional features that are similar to those obtained in the simulations. For example,

we see the scale-dependent crossover from hydrodynamic ow to diusion/collision in gs. 2

E, H, F and K where large, interconnected domains with rough interfaces coexist with smaller,

circular domains. Since these circular domains can only grow via collisions with each other,

they remain trapped for long times within a matrix of the opposite phase. Since the ratio

between the relative viscosities and diusion coecients of the two components was shown to

determine the crossover between viscous ow and diusion limited regimes, we must rst know

these parameters before we can compare time scales quantitatively with the theoretical model

in ref. [13]. Previous work demonstrated that the diusion coecient of PS is a strong function

of the lm thickness or distance from the silicon interface [21]. Preliminary results show that

a similar dependence may exist for PMMA [22]. Consequently, the ratio of the diusivities

is changing as the three-dimensional morphology develops. This eect may also contribute to

the lack of scale invariance and explains the decrease in the dynamics observed with increasing

annealing time. The PMMA mass thickness varies from 110 nm in the PMMA-rich regions

h. ade et al.: phase segregation in polymer thin films etc. 529

A B C

D E F

G H I J K L

M N O

P Q R 1 week

2 hrs

30 min 30 min

2 min

0 min

6.0 m

6.0 m

4.0 m

4.0 m

2.0 m

2.0 m

G H I 10 min

Fig. 2. PS mass thickness (left column), PMMA mass thickness (middle column) and total thickness

maps (right column) of a nominally 143 nm thick 50/50 w/w% PS/PMMA blend annealed for (A-C)

0 min, (D-F) 2 min, (G-I) 10 min, (J-L) 30 min, (M-O) 2 hrs, and (P-R) 1 week. All images

are individually scaled for good contrast, with Black = 0 and White = maximum thickness. The

maximum thickness of the lms increases from 145 nm in A, to 460 nm in R. The raw data comprised

a set of four to six images for each sample area investigated, including energies corresponding to the

C==C 1s to

transition at 285.2 eV of the aromatic group of PS, the PS-dominated

peak at 295

eV, the C==O 1s to

transition of the carbonyl in the PMMA, and the pre and post edge images

at 281 and 310 eV, respectively. Single-value decomposition using densities of 1.07 g/cm

3

for PS and

1.19 g/cm

3

for PMMA resulted in the quantitative composition maps.

of the unannealed sample (g. 2B) to about 60 nm of pure PMMA in the continuous phase

after one week of annealing. The PMMA underneath the PS domains is on average less than

20 nm thick and even thinner near the edge. The PS thickness increases to approximately

450 nm in the spherical regions from an average thickness of approximately 70 nm in the

unannealed lm. This thickness dierence corresponds to a tenfold decrease in the diusion

coecient of PMMA [22]. The corresponding increase in the PS diusion coecient only

aects reorganization within the PS domains. Since PMMA forms the continuous phase in

these samples, it determines the rate at which the isolated PS regimes can collide and coalesce.

Experiments are currently in progress to measure the diusion coecient as a function of lm

530 EUROPHYSICS LETTERS

4.0 m

A B

Fig. 3. A Lateral force modulation and B topography maps of a sample annealed for 10 min.

thickness for PMMA. Coupled with the thickness maps shown in g. 2, we will then be able to

obtain quantitative comparisons with the theoretical models. Alternatively, lms forced into

a at geometry between two surfaces would facilitate a quantitative comparison to theory.

In the PS/PMMA blend system, the two polymers can also be dierentiated by the slight

dierence in their frictional coecient and solubility in dierent organic solvents. One can

therefore also study some of the surface and three-dimensional aspects of the PS/PMMA

interface with SFM. The limitation of washing is that only relatively pure PS regions are

dissolved [23] and that the PMMA remains in a distorted, swollen state. A comparison of the

SFM data to the STXM results allows, however, for the identication of possible artifacts. The

combination of the two methods showed indeed some additional aspects aecting the coarsening

and coalescence process. Figure 3 shows a lateral force modulation scan and topograph [24] of

the same sample imaged with STXM in gs. 2G-L. The low regions appear on average brighter

(or have larger friction) than the taller regions. The intricate morphology visible in the friction

image (g. 3A) matches the compositional images derived from NEXAFS (g. 2G). We can

associate the bright and dark areas of g. 3A with PMMA- and PS-rich regions, respectively,

and can conclude that there are indeed two dierent surface phases that match the phases

determined with STXM. Figure 4 shows the three-dimensional rendering of the topographical

scans of samples annealed for 10 minutes and 65 hours and washed in cyclohexane to remove

the PS phase. The remaining features are those of the pure PMMA phase. One can see that

at early times PMMA spikes [25] attached to a PMMA sublayer are distributed throughout

the sample. As annealing progresses (g. 2Q and 4B), each PS droplet is surrounded by a wall

of PMMA. Prior to the STXM experiments it was thought that the spikes within the walls of

g. 4B were impurities left behind by the solvent rinse. From gs. 2M-Rit is clear that these are

B

A

Fig. 4. AFM topographs of samples with the surface PS removed with cyclohexane: after 10 min

(A), and 64 h (B) of annealing.

h. ade et al.: phase segregation in polymer thin films etc. 531

some of the original spikes that formed at early times and were swept along with the receding

PS phase [26]. Similar small and isolated PS domains (seen as holes in the matrix of g. 4) are

also present in the PMMA phase. The PS features can easily be explained by diusion-limited

trapping where coalescence in a hostile PMMA matrix is only possible by collision of the

droplets [13]. The presence of the PMMA spikes inside the PS droplets is more perplexing.

From the SFM data, it is clear that these droplets are in contact with the PMMA sublayer that

is continuous throughout the samples. However, the spikes do not get absorbed within this

sublayer. This may be a manifestation of a two uid behavior [21] whereby diusion of the

spikes into the thin layer is signicantly inhibited due to the strong interaction pinning of the

PMMA chains in the thin layer to the Si substrate. PMMA domains become trapped between

the PS domain and a high-viscosity PMMA sublayer, resulting in a quasi 2-dimensional system

in analogy to the small PS domains trapped in the PMMA matrix. One should also note that

the PMMA interface beneath the PS droplets has a long wavelength undulation not apparent

on the PMMA surface in contact with vacuum (g. 2Q). This undulation appears as thickness

stripes in the PMMA map with an amplitude approximately 5-6 times larger than the RMS

roughness of the surrounding PMMA matrix (gs. 2N and 2Q). Since the RMS amplitude A

of capillary waves at an interface are also known to scale as A

1/2

or approximately 5

for this system [27] we believe that these features are caused by the resonant capillary modes

excited in the conned area beneath the PS droplets. These are the capillary modes that

were also invoked in ref. [13] and explain the rough features seen in the mostly 2-D patterns

(gs. 2G-O) observed at the initial stages of the coarsening process.

In summary, we have obtained new information about the composition, morphology and

dynamics during the phase separation process of thin lms of PS/PMMA blends prepared by

spin casting from toluene solution. We have monitored the phase separation process over a

wide range of times and observed three stages: 1) initial phase separation of the mixed phases,

2) rapid coarsening and unique mass ow patterns that are very dierent from the coarsening

of phase separation in 3-dimensional systems, and 3) coalescence similar to classic spinodal

decomposition in the late stages but with persisting complicated 3-dimensional interfaces. In

particular, we have observed the complex morphology during coarsening and the dierent

scaling regimes recently predicted by Wagner and Yeomans [13]. During the late stages, we

have observed PMMA spikes and capillary wave induced interface modulations below the

PS domains. To characterize the complicated structures formed and their evolutions we have

utilized quantitative compositional analysis based on NEXAFS microscopy in conjunction with

AFM techniques. Both techniques complement and enhance each other. Our approach will be

useful to study details about the dynamics of the phase separation process in a variety of thin

polymer lms.

***

NEXAFS data acquired with the Stony Brook STXM developed by the group of J. Kirz

and C. Jacobsen at SUNY Stony Brook (DOE grant DE-FG02-89ER60858; NSF grant

DBI-9605045). The zone plates were developed by S. Spector and C. Jacobsen of Stony

Brook and D. Tennant of Lucent Technologies Bell Labs (NSF grant ECS-9510499). HA,

DAW and APS are supported by an NSF Young Investigator Award (DMR-9458060). SQ

SG, MR, JS at Stony Brook supported by NSF DMR-9732230 (MRSEC Program) and DOE-

SG02-93-ER45481.

REFERENCES

[1] Reich S. and Cohen Y., J. Polymer Science: Polymer Phys. Ed., 19 (1981) 1255-1267.

[2] Bruder F. and Brenn R., Phys. Rev. Lett., 69 (1992) 624-627.

532 EUROPHYSICS LETTERS

[3] Genzer J. and Kramer E. J., Phys. Rev. Lett., 78 (1997) 4946-4949.

[4] Affrossman S., Henn G., ONeill S. A., Pethrick R. A. and Stamm M., Macromolecules,

29 (1996) 5010-5016.

[5] Kumacheva E., Li L., Winnik M. A., Shinozaki D. M. and Cheng P. C., Langmuir, 13

(1997) 2483-2489.

[6] Krausch G., Kramer E. J., Rafailovich M. H. and Sokolov J., Appl. Phys. Lett., 64 (1994)

2655-2657.

[7] Straub W., Bruder F., Brenn R., Krausch G., Bielefeldt H., Kirsch A., Marti O.,

Mlynek J. and Marko J. F., Europhys. Lett., 29 (1995) 353-358.

[8] Tanaka K., Takahara A. and Kajiyama T., Macromolecules, 29 (1996) 3232-3239.

[9] Walheim S., Boltau M., Mlynek J., Krausch G. and Steiner U., Macromolecules, 30

(1997) 4995-5003.

[10] Karim A., Slawecki T. M., Kumar S. K., Douglas J. F., Satija S., Han C. C., Russell

T. P., Liu Y., Overney R., Sokolov J. and Rafailovic M. H., Macromolecules, 31 (1998)

857-862.

[11] Henke B. L., Gullikson E. M. and Davis J. C., At. Data Nucl. Data Tables, 54 (1993)

181-342.

[12] Mark J. E., Physical Properties of Polymers Handbook (Woodbury, New York) 1996.

[13] Wagner A. J. and Yeomans J. M., Phys. Rev. Lett., 80 (1998) 1429-1432.

[14] The simulations by Wagner and Yeoman assume a at surface and only composition variations are

simulated. We can only compare to their calculations in the early stages when the samples are still

relatively at and the morphology is essentially two-dimensional. Once the large spheres develop

the surface tension and changes in viscosity become important, which has not been considered

by Wagner and Yeoman.

[15] Jacobsen C., Williams S., Anderson E., Brown M. T., Buckley C. J., Kern D., Kirz

J., Rivers M. and Zhang X., Opt. Commun., 86 (1991) 351.

[16] Ade H., Zhang X., Cameron S., Costello C., Kirz J. and Williams S., Science, 258

(1992) 972.

[17] Zhang X., Ade H., Jacobsen C., Kirz J., Lindaas S., Williams S. and Wirick S., Nucl.

Instrum. Methods Phys. Res. A, 347 (1994) 431-435.

[18] Zhang X., Balhorn R., Mazrimas J. and Kirz J., J. Struc. Biol., 116 (1996) 335-344.

[19] It should be noted that the dierences in surface friction and viscoelastic response are dependent

on the driving frequency and hence cannot be used as absolute determinations of chemical

composition.

[20] Capillary waves are also known to account for most of the roughness observed on the surface of

molten polymer lms (Zhao W. et al., Phys. Rev. Lett., 70 (1993) 1453).

[21] Zheng X., Rafailovich M. H., Sokolov J., Y S., Schwarz S. A., Sauer B. and Rubinstein

M., Phys. Rev. Lett., 79 (1997) 1453.

[22] Li Z., Tolan M., Hohr T., Kharas D., Qu S., Sokolov J., Rafailovich M. H., Lorenz H.,

Kotthaus J. P., Wang J., Sinha S. K. and Gibaud A., Macromolecules, 31 (1998) 1915-1920.

[23] From STXM imaging of the washed regions we were able to determine that even a small (ap-

proximately 20%) PMMA component prevents dissolution.

[24] A DI3000 AFM was used to create this image with an external modulation unit designed especially

for these measurements. Since the polymer lm is much larger in the lateral than in the normal

direction, there is much less damping of a lateral alternating force eld which enhances the image

contrast.

[25] The actual angle of these features is rather shallow. Their appearance gets exaggerated by the

display of the SFM data.

[26] The spikes right at the rim might be swelling artifacts of spikes that are right inside the rim or

swollen encapsulated PS domains that have not yet merged with the large PS domains, and hence

did not dissolve in the cyclohexane rinse. We have no real evidence from the NEXAFS data for

PMMA spikes outside the PS domains. The amplitude of all features appear larger on the AFM

scans than the STXM due to swelling of the PMMA in the cyclohexane washing process. The

frequency of these spikes is less in the NEXAFS images than in the SFM images shown due to

the longer annealing times for the sample imaged with NEXAFS.

[27] Anastasiadis S. H., Gancarz I. and Koberstein J., Macromolecules, 21 (1988) 2980.

Vous aimerez peut-être aussi

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Brainstorms (Chapter 00 - Preface) - Daniel C. Dennett PDFDocument2 pagesBrainstorms (Chapter 00 - Preface) - Daniel C. Dennett PDFMenelao ZubiriPas encore d'évaluation

- (Ebook - PDF - Mathematics) - Abstract AlgebraDocument113 pages(Ebook - PDF - Mathematics) - Abstract Algebrambardak100% (2)

- Lectures On Classical Mechanics. John C. Baez PDFDocument76 pagesLectures On Classical Mechanics. John C. Baez PDFMenelao ZubiriPas encore d'évaluation

- Geospatial Data and Systems PDFDocument116 pagesGeospatial Data and Systems PDFMenelao ZubiriPas encore d'évaluation

- B Mass PDFDocument66 pagesB Mass PDFMenelao ZubiriPas encore d'évaluation

- Septic Tank Systems For Large Flow Applications PDFDocument10 pagesSeptic Tank Systems For Large Flow Applications PDFMenelao ZubiriPas encore d'évaluation

- Collective Enhancement of Radial Transport in A Nonneutral Plasma PDFDocument3 pagesCollective Enhancement of Radial Transport in A Nonneutral Plasma PDFMenelao ZubiriPas encore d'évaluation

- Unsteady Two-Dimensional Theory of A Flapping Wing PDFDocument25 pagesUnsteady Two-Dimensional Theory of A Flapping Wing PDFMenelao ZubiriPas encore d'évaluation

- NONCOMMUTATIVE GEOMETRY and MOTIVES (THE THERMODYNAMICS OF ENDOMOTIVES) - ALAIN CONNES, Et. Al PDFDocument54 pagesNONCOMMUTATIVE GEOMETRY and MOTIVES (THE THERMODYNAMICS OF ENDOMOTIVES) - ALAIN CONNES, Et. Al PDFMenelao Zubiri100% (1)

- Discrete Vector Spatial Solitons in A Nonlinear Waveguide Array PDFDocument13 pagesDiscrete Vector Spatial Solitons in A Nonlinear Waveguide Array PDFMenelao ZubiriPas encore d'évaluation

- Transport of A Nonneutral Electron Plasma Due To Electron Collisions With Neutral Atoms PDFDocument6 pagesTransport of A Nonneutral Electron Plasma Due To Electron Collisions With Neutral Atoms PDFMenelao ZubiriPas encore d'évaluation

- Aspects of Degeneracy. Michael v. Berry PDFDocument18 pagesAspects of Degeneracy. Michael v. Berry PDFMenelao ZubiriPas encore d'évaluation

- Trapped-Particle-Mediated Damping and Transport PDFDocument12 pagesTrapped-Particle-Mediated Damping and Transport PDFMenelao ZubiriPas encore d'évaluation

- Localized Multi-Dimensional Optical Pulses in Non-Resonant Quadratic Materials PDFDocument9 pagesLocalized Multi-Dimensional Optical Pulses in Non-Resonant Quadratic Materials PDFMenelao ZubiriPas encore d'évaluation

- Bierman - Does Consciousness Collapse The WavefunctionDocument11 pagesBierman - Does Consciousness Collapse The WavefunctiondomaninaPas encore d'évaluation

- Nonlinear Waves, Nonlinear Optics and Your Communications Future PDFDocument19 pagesNonlinear Waves, Nonlinear Optics and Your Communications Future PDFMenelao ZubiriPas encore d'évaluation

- QUANTUM, CLASSICAL and SEMICLASSICAL ADIABATICITY. MICHAEL V. BERRY PDFDocument14 pagesQUANTUM, CLASSICAL and SEMICLASSICAL ADIABATICITY. MICHAEL V. BERRY PDFMenelao ZubiriPas encore d'évaluation

- Spontaneous Emission Enhancement Near Nanoparticles PDFDocument6 pagesSpontaneous Emission Enhancement Near Nanoparticles PDFMenelao ZubiriPas encore d'évaluation

- THE INDEX OF A PAIR OF PROJECTIONS. AVRON, SEILER and SIMON PDFDocument18 pagesTHE INDEX OF A PAIR OF PROJECTIONS. AVRON, SEILER and SIMON PDFMenelao ZubiriPas encore d'évaluation

- Non-Oberbeck-Boussinesq Effects in Strongly Turbulent Rayleigh-Bénard Convection PDFDocument35 pagesNon-Oberbeck-Boussinesq Effects in Strongly Turbulent Rayleigh-Bénard Convection PDFMenelao ZubiriPas encore d'évaluation

- Relativistic Electron Energy Loss and Electron-Induced Photon Emission in Inh - de PDFDocument4 pagesRelativistic Electron Energy Loss and Electron-Induced Photon Emission in Inh - de PDFMenelao ZubiriPas encore d'évaluation

- Doppler Velocimetry of Cryogenic Ion Plasmas PDFDocument2 pagesDoppler Velocimetry of Cryogenic Ion Plasmas PDFMenelao ZubiriPas encore d'évaluation

- Long-Time Dynamics of The Modulational Instability of Deep Water Waves PDFDocument18 pagesLong-Time Dynamics of The Modulational Instability of Deep Water Waves PDFMenelao ZubiriPas encore d'évaluation

- Effect of Carbon Black and Silica Fillers in Elastomer Blends PDFDocument10 pagesEffect of Carbon Black and Silica Fillers in Elastomer Blends PDFMenelao ZubiriPas encore d'évaluation

- CRYSTALLIZATION IN THE THIN and ULTRATHIN FILMS OF POLY (ETHYLENE-VINYL ACETATE) and L.LD. POLYETH PDFDocument9 pagesCRYSTALLIZATION IN THE THIN and ULTRATHIN FILMS OF POLY (ETHYLENE-VINYL ACETATE) and L.LD. POLYETH PDFMenelao ZubiriPas encore d'évaluation

- Ionic Liquids. J.D. Holbrey, K.R. Seddon PDFDocument14 pagesIonic Liquids. J.D. Holbrey, K.R. Seddon PDFMenelao ZubiriPas encore d'évaluation

- Thermal-Noise Effect On The Transition To Rayleigh-Bénard Convection PDFDocument4 pagesThermal-Noise Effect On The Transition To Rayleigh-Bénard Convection PDFMenelao ZubiriPas encore d'évaluation

- Dynamics of Fluctuations in A Fluid Below The Onset of Rayleigh-Bénard Convection PDFDocument13 pagesDynamics of Fluctuations in A Fluid Below The Onset of Rayleigh-Bénard Convection PDFMenelao ZubiriPas encore d'évaluation

- COBE-DMR-NORMALISATION For INFLATIONARY FLAT DARK MATTER MODELS PDFDocument10 pagesCOBE-DMR-NORMALISATION For INFLATIONARY FLAT DARK MATTER MODELS PDFMenelao ZubiriPas encore d'évaluation

- LOCAL CORRELATION OF PHOTOEMISSION ELECTRON MICROSCOPY and STM AT A DEFINED C. S. S PDFDocument7 pagesLOCAL CORRELATION OF PHOTOEMISSION ELECTRON MICROSCOPY and STM AT A DEFINED C. S. S PDFMenelao ZubiriPas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Boiler Performance & Technical Data JT-K13467-E01-0Document15 pagesBoiler Performance & Technical Data JT-K13467-E01-0Puntanata Siagian0% (1)

- Sigraflex UniversalDocument6 pagesSigraflex UniversalJan SmitPas encore d'évaluation

- Chapter1 Fiber IntroDocument24 pagesChapter1 Fiber IntroSai Indrakaran Reddy CherabuddiPas encore d'évaluation

- fsd35 Technical Information 6845 PDFDocument6 pagesfsd35 Technical Information 6845 PDFAndani RafikaPas encore d'évaluation

- Matter (Science Form 1 - Short Notes)Document1 pageMatter (Science Form 1 - Short Notes)jrpyroPas encore d'évaluation

- Current Electricity WorksheetDocument6 pagesCurrent Electricity WorksheetRohan ChackoPas encore d'évaluation

- Sunday Afternoon, October 27, 2013: TechnologyDocument283 pagesSunday Afternoon, October 27, 2013: TechnologyNatasha MyersPas encore d'évaluation

- Ethylene Ethanol DEE H2O: Senyawa Input Reaktor Output Reaktor KG/HR Kmol/hr KG/HRDocument11 pagesEthylene Ethanol DEE H2O: Senyawa Input Reaktor Output Reaktor KG/HR Kmol/hr KG/HRyohanamd14Pas encore d'évaluation

- Organic Chemistry 7th Edition Bruice Test BankDocument10 pagesOrganic Chemistry 7th Edition Bruice Test BankCarolHutchinsonmrwjn100% (14)

- Problem Set 3-Chapter 6 - Failure Theories-Selected ProblemsDocument22 pagesProblem Set 3-Chapter 6 - Failure Theories-Selected ProblemsIsmail DoğanPas encore d'évaluation

- Hydraulic Oil Hy-Gard Transmission John DeereDocument7 pagesHydraulic Oil Hy-Gard Transmission John DeereLuis Sanchez LlicoPas encore d'évaluation

- Iso 10993 23 2021Document15 pagesIso 10993 23 2021Katerin MartínezPas encore d'évaluation

- Hilman Rollers Instruction Manual PDFDocument22 pagesHilman Rollers Instruction Manual PDFMohd Fadli0% (1)

- Chapter Three 3.0 Materials and Methods 3.1 Sample CollectionDocument3 pagesChapter Three 3.0 Materials and Methods 3.1 Sample CollectionAmjad AliPas encore d'évaluation

- 01-Samss-039 18122016Document14 pages01-Samss-039 18122016ELNA83Pas encore d'évaluation

- Lab Manual (March-July 2018)Document37 pagesLab Manual (March-July 2018)haikalPas encore d'évaluation

- ErDocument27 pagesErAsif UllahPas encore d'évaluation

- Laidler 5Document116 pagesLaidler 5Teresa Cano100% (1)

- Chem 360 Stu Man 554275Document94 pagesChem 360 Stu Man 554275Sukhvir AujlaPas encore d'évaluation

- RT Procedure 10.09.16Document9 pagesRT Procedure 10.09.16mukeshsingh6Pas encore d'évaluation

- Tool Wear MechanismDocument9 pagesTool Wear MechanismDevansh AgrawalPas encore d'évaluation

- Glass and Brittle Plastics RegisterDocument3 pagesGlass and Brittle Plastics RegisterAdnan Meghani100% (3)

- Review Proses CumeneDocument15 pagesReview Proses Cumenerachma tiaPas encore d'évaluation

- Cell Disruption Techquines: By: Ritika SharmaDocument20 pagesCell Disruption Techquines: By: Ritika SharmaArup ChakrabortyPas encore d'évaluation

- Dynamic Modelling of Arch Dams PDFDocument137 pagesDynamic Modelling of Arch Dams PDFSanjay SibalPas encore d'évaluation

- Drizo IranDocument12 pagesDrizo IranDiego1980bPas encore d'évaluation

- Fastron Gold 5w 30 API SNDocument2 pagesFastron Gold 5w 30 API SNTemanta TariganPas encore d'évaluation

- What Is 21 CFR Part 11Document26 pagesWhat Is 21 CFR Part 11chemtabPas encore d'évaluation

- Atomic and Molecular Physics - NET-JRFDocument25 pagesAtomic and Molecular Physics - NET-JRFLineesh100% (1)

- Sika Injection 20Document3 pagesSika Injection 20the pilotPas encore d'évaluation