Académique Documents

Professionnel Documents

Culture Documents

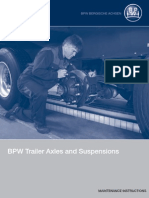

BPW Air Suspension Maintenance Instructions

Transféré par

RajaSekarsajjaDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

BPW Air Suspension Maintenance Instructions

Transféré par

RajaSekarsajjaDroits d'auteur :

Formats disponibles

32

33

8

7

3 1 2

4 5

6

6

Series ALO/SLO Series ALO/SLO with two-sided axle lift

Series ALM/SLM Series ALM/SLM with Kombi-Air Bag II

Series ALU/SLU Series DLU - Airlight

Direct

M

a

i

n

t

e

n

a

n

c

e

i

n

s

t

r

u

c

t

i

o

n

s

BPW Air suspensions

Visual inspection. Check all component parts for damage and wear.

1 Check condition of air bags.

2 Check air suspension level valves for condition,

sealtightness and general tightness.

3 Check shock absorber fastening for tightness.

Tightening torques with a torque wrench:

M 24 M = 420 Nm (390460 Nm)

for aluminium hanger brackets M = 320 Nm (300350 Nm)

4 Check spring mounting kit for tightness.

Tightening torques with a torque wrench:

M 22 M = 550 Nm (510600 Nm)

2)

M 24 M = 650 Nm (605715 Nm)

5 Check spring pivot bolts for tightness.

Tightening torques with a torque wrench:

hanger brackets up to 07/2001: M 30 M = 750 Nm (700825 Nm)

hanger brackets from 08/2001: M 30 M = 900 Nm (840990 Nm)

channel cross member: M 30 M = 900 Nm (840990 Nm)

6 Check air bag fastening for tightness.

Tightening torques with a torque wrench:

M 12 M = 66 Nm

M 16 M = 230 Nm

7 Check axle lift for tightness.

Tightening torques with a torque wrench:

supporting arm M 16 M = 230 Nm

cylinder M 16 M = 180 210 Nm

8 Check strap. Check condition and fastening.

1)

under extreme conditions, more frequently.

2)

When mounting new spring mounting kit components for Airlight II:

Tightening torque: M 22 M = 550 Nm + 90 angle tightening

3)

for use outside Europe

Valid: 01.11.2003

Maintenance work after expiry of the warranty period

Overview

For detailed description see pages 34 - 39

Visual checks or maintenance work

during the warranty period, see pages 9 11

Maintenance

r

e

c

o

m

m

e

n

d

e

d

a

n

n

u

a

l

l

y

a

f

t

e

r

t

h

e

w

a

r

r

a

n

t

y

p

e

r

i

o

d

e

x

p

i

r

e

s

,

3

y

e

a

r

s

o

f

f

r

o

a

d

,

5

o

r

8

y

e

a

r

s

o

n

r

o

a

d

1

)

H

a

l

f

y

e

a

r

l

y

a

f

t

e

r

e

x

p

i

r

y

o

f

t

h

e

w

a

r

r

a

n

t

y

p

e

r

i

o

d

1

)

3

)

34

2 Air installation circuit

After expiry of the warranty period:

Recommended halfyearly, after 1 year

offroad or 2 years onroad outside Europe

Recommended annually, after 3 years

offroad, 5 or 8 years onroad

Check air installation valves and line

connections for firm seating, damage and

sealtightness. Check valve linkage and

fastenings (arrows) for damage and tight

ness. The length of the valve lever and

permissible angular positions on the valve

linkage are shown in the illustration below.

35

M

a

i

n

t

e

n

a

n

c

e

i

n

s

t

r

u

c

t

i

o

n

s

Air levelling valve

Visual inspection

After expiry of the warranty period:

Recommended halfyearly, after 1 year

offroad or 2 years onroad outside Europe

Recommended annually, after 3 years

offroad, 5 or 8 years onroad

Check all component parts for wear

and damage.

1 Air bags

After expiry of the warranty period:

Recommended halfyearly, after 1 year

offroad or 2 years onroad outside Europe

Recommended annually, after 3 years

offroad, 5 or 8 years onroad

Check air bags for external damage (sur

face cracking, abrasion, crease

formation, trapped foreign bodies etc.).

Replace air bags in the event of damage.

Safety notice

No welding should be carried out on steel

parts of air bags and pressure vessel! The

air suspension should only be filled with

compressed air when mounted or when the

mechanical height limit has been reached!

Danger of injury!

BPW Air suspensions

Maintenance work after expiry of the warranty period

Visual checks or maintenance work during the warranty period, see pages 9 11

4

36

5 Spring pivot bolts

After expiry of the warranty period:

Recommended halfyearly, after 1 year

offroad or 2 years onroad outside Europe

Recommended annually, after 3 years

offroad, 5 or 8 years onroad

Check bushes move vehicle backward and

forward slightly with the brake applied, or

move rolled spring ends with the aid of a

lever. No play should be present in the rolled

spring end when doing so. If the fastening is

loose the spring pivot bolt may be damaged.

Check the wear washers in the

hanger bracket.

Check the M 30 lock nut on the spring

pivot bolt for tightness.

Tightening torque with a torque wrench:

Air suspension hanger brackets

up to 07/2001 M 30 M = 750 Nm(700825 Nm)

from 08/2001 M 30 M = 900 Nm(840990 Nm)

Channel cross member

M 30 M = 900 Nm(840990 Nm)

The serviceable life of the rubber/ steel

bush is dependent on the tightness of the

inner steel bushing.

37

Singlesided lift

Twosided lift

Washer

T

u

r

n

p

r

o

o

f

d

e

v

i

c

e

spring pivot bolt spring pivot bolt

Spring pivot bolt bearing

with axle lift

3 Shock absorber fastening

After expiry of the warranty period:

Recommended halfyearly, after 1 year

offroad or 2 years onroad outside Europe

Recommended annually, after 3 years

offroad, 5 or 8 years onroad

Check lower and upper shock absorber

fastening for tightness.

Tightening torques with a torque wrench:

M 24 M = 420 Nm (390460 Nm)

In the case of alloy hanger bracket:

M 24 M = 320 Nm (300350 Nm)

4 Spring mounting kit

After expiry of the warranty period:

Recommended halfyearly, after 1 year

offroad or 2 years onroad outside Europe

Recommended annually, after 3 years

offroad, 5 or 8 years onroad

Check lock nuts of spring Ubolts for

tightness. If loose, tighten nuts alternately

a little at a time. No welding should be

performed on the trailing arm spring!

Tightening torques with a torque wrench:

M 22 M = 550 Nm (510605 Nm)

M 24 M = 650 Nm (605715 Nm)

When mounting new spring mounting kit

components for Airlight II:

Tightening torque:

M 22 M = 550 Nm + 90 angle tightening

BPW Air suspensions

Maintenance work after expiry of the warranty period

Visual checks or maintenance work during the warranty period, see pages 9 11

38

39

M

a

i

n

t

e

n

a

n

c

e

i

n

s

t

r

u

c

t

i

o

n

s

8 Check straps

After expiry of the warranty period:

Recommended halfyearly, after 1 year

offroad or 2 years onroad outside Europe

Recommended annually, after 3 years

offroad, 5 or 8 years onroad

Examine check straps and attachment.

Replace if necessary.

6 7 5 7

7

7

5

7 Axle lift

After expiry of the warranty period:

Recommended halfyearly, after 1 year

offroad or 2 years onroad outside Europe

Recommended annually, after 3 years

offroad, 5 or 8 years onroad

Check the M16 lock nuts on the lever arm

fixing and diaphragm cylinder to make sure

they are tight. Tighten with a torque

wrench if necessary.

Tightening torques with a torque wrench:

supporting arm M 16 M= 230 Nm

cylinder M 16 M= 180 210 Nm

Check for wear on the bump stop on the

lever arm or the stop for the doublesided

lift. Make sure they are secure.

M 12 M= 66 Nm

BPW Air suspensions

Maintenance work after expiry of the warranty period

Visual checks or maintenance work during the warranty period, see pages 9 11

5

6

6 Air bag fastenings

After expiry of the warranty period:

Recommended halfyearly, after 1 year

offroad or 2 years onroad outside Europe

Recommended annually, after 3 years

offroad, 5 or 8 years onroad

Check air bag fixing screws or nuts for

tightness.

Tightening torques with a torque wrench:

M 12 M= 66 Nm

M 16 M= 230 Nm

Vous aimerez peut-être aussi

- Dayco X16xelDocument2 pagesDayco X16xeldzadza2Pas encore d'évaluation

- Audi Q7 A005Q720020-Basic Equipment From Model Year 2007Document1 302 pagesAudi Q7 A005Q720020-Basic Equipment From Model Year 2007Fábio MagnoPas encore d'évaluation

- Podizna Osovina SAFDocument9 pagesPodizna Osovina SAFPavle StevanovicPas encore d'évaluation

- Volume 2-01 Truck SpecificationDocument2 pagesVolume 2-01 Truck SpecificationnurrahmatPas encore d'évaluation

- SPL Konfort 7xx Full en Rev01Document8 pagesSPL Konfort 7xx Full en Rev01kallatisPas encore d'évaluation

- Engine Tdi 6 Cyl Ea897 Gen2 Service Manual EngDocument334 pagesEngine Tdi 6 Cyl Ea897 Gen2 Service Manual EngTomislav TodorovskiPas encore d'évaluation

- TATA Minibus 407 MaintainanceDocument13 pagesTATA Minibus 407 MaintainancePraveen Kumar ReddyPas encore d'évaluation

- 1720 K Mcs en (10d)Document4 pages1720 K Mcs en (10d)Dylan Jay DattPas encore d'évaluation

- Inf12215 GBDocument4 pagesInf12215 GBqyzzypPas encore d'évaluation

- Q7 2009 3.0TDi CATADocument418 pagesQ7 2009 3.0TDi CATAJose raulPas encore d'évaluation

- Starbus Ultra PDFDocument27 pagesStarbus Ultra PDFHarshal DhanawadePas encore d'évaluation

- SM 32Document1 790 pagesSM 32Guilherme Soldateli VidottoPas encore d'évaluation

- MAINTAIN COOLANT LEVELDocument6 pagesMAINTAIN COOLANT LEVELAgustin BerriosPas encore d'évaluation

- Portal Axle Design PDFDocument5 pagesPortal Axle Design PDFUmesh JadhavPas encore d'évaluation

- Parts List For S4Document3 pagesParts List For S4Alessandro SouzaPas encore d'évaluation

- 5060 Extreme Front Fork Workshop ManualDocument52 pages5060 Extreme Front Fork Workshop ManualSaharaMCPas encore d'évaluation

- Skoda Octavia 1 98-10Document117 pagesSkoda Octavia 1 98-10Kovacs ZsoltPas encore d'évaluation

- D3 LCCDocument36 pagesD3 LCCstankovukanovicPas encore d'évaluation

- Injection Pump Test SpecificationsDocument1 pageInjection Pump Test SpecificationsLTurbo100% (1)

- Spare Parts List: Forward and Reversible PlateDocument40 pagesSpare Parts List: Forward and Reversible PlatePawelPas encore d'évaluation

- Acme A349 Service ManualDocument34 pagesAcme A349 Service ManualCristian DavidPas encore d'évaluation

- Maxus Axle Assembly GuideDocument19 pagesMaxus Axle Assembly GuidepeckerrPas encore d'évaluation

- Special Features of The MEGANE Sports TourerDocument102 pagesSpecial Features of The MEGANE Sports Tourerhrc555Pas encore d'évaluation

- Le Tonkinois Varnish: Eberspacher Fuel Supply Faults 1Document9 pagesLe Tonkinois Varnish: Eberspacher Fuel Supply Faults 1ziroopPas encore d'évaluation

- Opel Corsa C Coolant Pump ReplacementDocument10 pagesOpel Corsa C Coolant Pump ReplacementAndrásBakosPas encore d'évaluation

- Engine Throtle FailureDocument2 pagesEngine Throtle FailuremarcglebPas encore d'évaluation

- Audi A8 Fuse Locations and Functions GuideDocument42 pagesAudi A8 Fuse Locations and Functions GuideToks VilmantasPas encore d'évaluation

- Print Version - 2006-2014 Fiat Ducato Fuse Box DiagramDocument5 pagesPrint Version - 2006-2014 Fiat Ducato Fuse Box DiagramlogisztikaPas encore d'évaluation

- Engine General: 303-01B Engine - 1.4L Duratorq-Tdci (DV) Diesel 2004 - 2012 Fusion Description and OperationDocument14 pagesEngine General: 303-01B Engine - 1.4L Duratorq-Tdci (DV) Diesel 2004 - 2012 Fusion Description and OperationHenrique AlmeidaPas encore d'évaluation

- Land Rover Defender CatalogueDocument69 pagesLand Rover Defender CataloguepablogarciaclPas encore d'évaluation

- DIAGNOSE YD25 TIMING CHAIN FAULTSDocument4 pagesDIAGNOSE YD25 TIMING CHAIN FAULTSMihaela GeorgescuPas encore d'évaluation

- Crank mechanism assembly for D4204T5 engineDocument13 pagesCrank mechanism assembly for D4204T5 engineCristianPas encore d'évaluation

- TGX 6x4 RigidDocument4 pagesTGX 6x4 RigidDorin PricopPas encore d'évaluation

- Cutting-Edge Automotive Diagnostic Equipment Functions ManualDocument4 pagesCutting-Edge Automotive Diagnostic Equipment Functions ManualRichard Andrianjaka LuckyPas encore d'évaluation

- NSeries Specification IsuzuDocument2 pagesNSeries Specification IsuzuByte_Rafael100% (2)

- F3B-07!01!2014 Gearbox ManualDocument39 pagesF3B-07!01!2014 Gearbox ManualMartin PaynePas encore d'évaluation

- S0020028920-Nr 89 Sensors and Senders in Škoda Vehicles - Safety and ConvenienceDocument48 pagesS0020028920-Nr 89 Sensors and Senders in Škoda Vehicles - Safety and ConvenienceIongornistuPas encore d'évaluation

- Bert Rowe's Mercedes Benz 'A' Class InfoDocument26 pagesBert Rowe's Mercedes Benz 'A' Class InfoeliahPas encore d'évaluation

- Service: Wheel and Tire GuideDocument113 pagesService: Wheel and Tire GuidealexPas encore d'évaluation

- Rattling Noise After Engine Start For Several Seconds: Complaint: AttachmentsDocument2 pagesRattling Noise After Engine Start For Several Seconds: Complaint: AttachmentsWILFRED TSI-KAHPas encore d'évaluation

- Air Mass Sensor For VW TDI Engines PDFDocument2 pagesAir Mass Sensor For VW TDI Engines PDFSrđan PavićPas encore d'évaluation

- Service: Audi A6 1998Document77 pagesService: Audi A6 1998Kovács EndrePas encore d'évaluation

- VW Passat b6 Brake Systems EngDocument93 pagesVW Passat b6 Brake Systems EngDanyBobPas encore d'évaluation

- Disco 3 FBH Workshop Manual Thermo Top VDocument46 pagesDisco 3 FBH Workshop Manual Thermo Top VDaniele GardellinPas encore d'évaluation

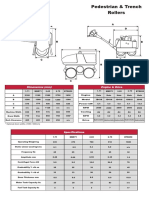

- Pedestrian & Trench Rollers: Engine & Drive Dimensions (MM)Document4 pagesPedestrian & Trench Rollers: Engine & Drive Dimensions (MM)MuhaiminPas encore d'évaluation

- Maysan Mando Ticari Arac KataloguDocument52 pagesMaysan Mando Ticari Arac KataloguСергей ТищенкоPas encore d'évaluation

- ErrorDocument16 pagesErrorيوسف وليد عبد الرحيمPas encore d'évaluation

- Ks Si 0014 en WebDocument0 pageKs Si 0014 en WebMoaed KanbarPas encore d'évaluation

- Volkswagen SDI 2.5L 75-5 Diesel Marine Engine Service Repair Manual PDFDocument30 pagesVolkswagen SDI 2.5L 75-5 Diesel Marine Engine Service Repair Manual PDFjnfksmemmsPas encore d'évaluation

- Mercedes E 270 CDI auto parts directoryDocument128 pagesMercedes E 270 CDI auto parts directoryJunren KhooPas encore d'évaluation

- Euro 3 Euro 3: Chassis 6x6Document4 pagesEuro 3 Euro 3: Chassis 6x6Dwanny VHPas encore d'évaluation

- Man KatalogDocument131 pagesMan KatalogИП Astana Diesel RepairPas encore d'évaluation

- Bär Original Spare PartsDocument52 pagesBär Original Spare PartsArians MarkitansPas encore d'évaluation

- Pricelist Acc Actros 2013Document7 pagesPricelist Acc Actros 2013MinaSaeedPas encore d'évaluation

- TATA Indica Owners Manual & Servie BookDocument164 pagesTATA Indica Owners Manual & Servie BookPedro Zabala100% (1)

- Tpi 2029086 - 1Document9 pagesTpi 2029086 - 1Marius SuvarPas encore d'évaluation

- BPW Trailer Axles and Suspensions Maintenance InstructionsDocument49 pagesBPW Trailer Axles and Suspensions Maintenance InstructionsStephenson100% (1)

- WPKT 0005Document3 pagesWPKT 0005José BenavidesPas encore d'évaluation

- F50LX Cap 03 (Manutenzione)Document12 pagesF50LX Cap 03 (Manutenzione)pivarszkinorbertPas encore d'évaluation

- Raw 4x4 BrochureDocument1 pageRaw 4x4 BrochureRajaSekarsajjaPas encore d'évaluation

- Heavy Vehicle Dynamics Comparison Between Leaf Spring HydropneumaticDocument7 pagesHeavy Vehicle Dynamics Comparison Between Leaf Spring HydropneumaticRajaSekarsajjaPas encore d'évaluation

- Hydro Pneumatic DamperDocument6 pagesHydro Pneumatic DamperRajaSekarsajjaPas encore d'évaluation

- Hytrel Design GuideDocument37 pagesHytrel Design GuidecountzeroaslPas encore d'évaluation

- Hydro Pneumatic DamperDocument6 pagesHydro Pneumatic DamperRajaSekarsajjaPas encore d'évaluation

- Properties of Common Spring MaterialsDocument2 pagesProperties of Common Spring MaterialsArnaldo Morbid CruzPas encore d'évaluation

- Carbon It RidingDocument3 pagesCarbon It RidingRajaSekarsajjaPas encore d'évaluation

- Nitro - CarburizingDocument9 pagesNitro - CarburizingRajaSekarsajjaPas encore d'évaluation

- HEF TreatmentDocument12 pagesHEF TreatmentRajaSekarsajjaPas encore d'évaluation

- Transient Characteristics of A Hydraulically Interconnected Suspension System PDFDocument12 pagesTransient Characteristics of A Hydraulically Interconnected Suspension System PDFmanteghPas encore d'évaluation

- Leaf Spring CatalogueDocument1 pageLeaf Spring CatalogueRajaSekarsajjaPas encore d'évaluation

- Parabolic Leaf Spring OptimizationDocument8 pagesParabolic Leaf Spring OptimizationRajaSekarsajjaPas encore d'évaluation

- 021 025Document5 pages021 025marcglebPas encore d'évaluation

- Evaluation of Coating PerformanceDocument14 pagesEvaluation of Coating PerformanceRajaSekarsajjaPas encore d'évaluation

- Vehiclestandardscodeofpracticesection 2 Feb 2004Document100 pagesVehiclestandardscodeofpracticesection 2 Feb 2004Abhiyan Anala ArvindPas encore d'évaluation

- Damping Curves UpdateDocument9 pagesDamping Curves UpdateRajaSekarsajjaPas encore d'évaluation

- WeldingDocument129 pagesWeldingAnilkumar Cm93% (15)

- Damping Force at Zero Velocity ExplainedDocument6 pagesDamping Force at Zero Velocity ExplainedRajaSekarsajjaPas encore d'évaluation

- Disc Spring SheetDocument2 pagesDisc Spring SheetRajaSekarsajjaPas encore d'évaluation

- Silent Bloc Bushing PDFDocument1 pageSilent Bloc Bushing PDFRajaSekarsajjaPas encore d'évaluation

- Tubular Piston RodsDocument1 pageTubular Piston RodsRajaSekarsajjaPas encore d'évaluation

- Software - Shock Absorber and Vehicle Dynamic SimulationDocument14 pagesSoftware - Shock Absorber and Vehicle Dynamic Simulationnbkate07Pas encore d'évaluation

- Shock Absorber Performance Test Rig: Ubique SystemsDocument1 pageShock Absorber Performance Test Rig: Ubique SystemsRajaSekarsajjaPas encore d'évaluation

- PTFE Piston RingsDocument21 pagesPTFE Piston RingsRajaSekarsajjaPas encore d'évaluation

- An Introduction To Automotive Suspension SystemsDocument19 pagesAn Introduction To Automotive Suspension SystemsSahil ChouhanPas encore d'évaluation

- 3-D Measurements On PistonsDocument4 pages3-D Measurements On PistonsRajaSekarsajjaPas encore d'évaluation

- PTFE Piston RingsDocument21 pagesPTFE Piston RingsRajaSekarsajjaPas encore d'évaluation

- Damper Control ValveDocument2 pagesDamper Control ValveRajaSekarsajjaPas encore d'évaluation

- Where The Graphs Come FromDocument7 pagesWhere The Graphs Come FromRajaSekarsajjaPas encore d'évaluation

- Dhuaa PDFDocument8 pagesDhuaa PDFAhmadMoaazPas encore d'évaluation

- Industrial engine spare parts catalogDocument189 pagesIndustrial engine spare parts catalogBheema SolankePas encore d'évaluation

- Factors Affecting Knocking in Si Engines PDFDocument2 pagesFactors Affecting Knocking in Si Engines PDFFrancisco0% (1)

- Empty container handler fuel filter changeDocument54 pagesEmpty container handler fuel filter changeGeorge Jhonson50% (2)

- Hyundai Forklift SpecificationDocument12 pagesHyundai Forklift Specificationabd halimPas encore d'évaluation

- DifferentialsDocument48 pagesDifferentialsEngine Tuning UpPas encore d'évaluation

- Axial Piston Double Motors DMVA SeriesDocument4 pagesAxial Piston Double Motors DMVA SeriesnferreiPas encore d'évaluation

- BMW XDrive DSCDocument25 pagesBMW XDrive DSCManual100% (2)

- Parts Catalog of YC6T Marine Diesel EngineDocument76 pagesParts Catalog of YC6T Marine Diesel Engineமுத்து தேவேந்திரன்Pas encore d'évaluation

- EN How To Replace The Front Suspension Strut Mount On NISSAN X TRAIL T30Document7 pagesEN How To Replace The Front Suspension Strut Mount On NISSAN X TRAIL T30EduardoPas encore d'évaluation

- Mobile Crane Grue Mobile: Technical Data Caractéristiques TechniquesDocument32 pagesMobile Crane Grue Mobile: Technical Data Caractéristiques TechniquesLeonardo Nascente100% (1)

- 10-1001 For EMS - 30-1001Document6 pages10-1001 For EMS - 30-1001Javier RojasPas encore d'évaluation

- Marine Diesel D11 Inboard Service Protocol SummaryDocument3 pagesMarine Diesel D11 Inboard Service Protocol Summarytomo776Pas encore d'évaluation

- Nissan CLDocument18 pagesNissan CLmohhizbarPas encore d'évaluation

- MAS-10 Steering System and Wheel Alignment PDFDocument25 pagesMAS-10 Steering System and Wheel Alignment PDFJ Naveen KumarPas encore d'évaluation

- BRUTE FORCE 750 4x4i Eps PDFDocument190 pagesBRUTE FORCE 750 4x4i Eps PDFDANIEL BELLAPas encore d'évaluation

- Case-450 DXDocument4 pagesCase-450 DXPavan SunkaraPas encore d'évaluation

- Vl3 Lista Preturi 2014Document1 pageVl3 Lista Preturi 2014Zanfir AlexandruPas encore d'évaluation

- FIS BOOK 3: AERO ENGINE (PISTON) CHAPTERSDocument71 pagesFIS BOOK 3: AERO ENGINE (PISTON) CHAPTERSabhishek soniPas encore d'évaluation

- Log WVWZZZ1KZBW221099 180170km 111952miDocument9 pagesLog WVWZZZ1KZBW221099 180170km 111952miManjula GovindPas encore d'évaluation

- Reachstacker Performance & SpecsDocument8 pagesReachstacker Performance & SpecsHugo Julian Sanchez MayorgaPas encore d'évaluation

- 1999 Odyssey Wiring DiagramsDocument98 pages1999 Odyssey Wiring Diagramsmike100% (1)

- SSP 414 4MOTION With Four-Wheel Drive Coupling Generation IVDocument28 pagesSSP 414 4MOTION With Four-Wheel Drive Coupling Generation IVfrancois.garcia31100% (1)

- Aftermarket Wheel Installation GuidelinesDocument1 pageAftermarket Wheel Installation GuidelinesCindyPas encore d'évaluation

- ELECTRIC-ELECTRONIC+SYSTEM StralisDocument356 pagesELECTRIC-ELECTRONIC+SYSTEM Stralisali80% (5)

- Engine assembly and repair progress reportDocument5 pagesEngine assembly and repair progress reportCwsPas encore d'évaluation

- Mazda 3 J638CDocument1 571 pagesMazda 3 J638CAlexe VictorPas encore d'évaluation

- Coupon Code - Sum10: Summer Time SALE! 10% OFF On All PartsDocument13 pagesCoupon Code - Sum10: Summer Time SALE! 10% OFF On All PartsriqtorresPas encore d'évaluation

- TCS Performance Products Catalog 2015Document36 pagesTCS Performance Products Catalog 2015scribdfourmePas encore d'évaluation

- Keyless Entry System: Wiring Diagram of The Main UnitDocument1 pageKeyless Entry System: Wiring Diagram of The Main UnithamayunPas encore d'évaluation

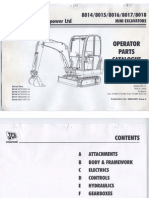

- JCB 8017 Parts BookDocument216 pagesJCB 8017 Parts Bookjdgiaco100% (16)