Académique Documents

Professionnel Documents

Culture Documents

Engineering & Construction: Magnetic Particle Test Procedure

Transféré par

soledense5470Description originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Engineering & Construction: Magnetic Particle Test Procedure

Transféré par

soledense5470Droits d'auteur :

Formats disponibles

WASIT SRU & UTILITIES PROJECT,

PACKAGE # 3

Doc. No.

DES-1744-QA&QC-05

Descon Engineering FZE.

MAGNETIC PARTICLE

TEST PROCEDURE Rev. 00 Page1of13

Engineering & construction

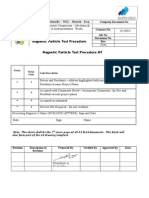

MAGNETIC PARTICLE TEST PROCEDURE

Document No. DES-1744-QA&QC-05

Purchase Order No.:

Equipment/Material: Stack

REV DATE DESCRIPTION PREPARED CHECKED APPROVED

00 11-9-2013 FOR FINAL/ CERTIFIED

B 12/2/2013 Issued for client review RONAK MEHTA RONAK MEHTA SAKET KUMAR

A 22/7/2012 Issued for client review RONAK MEHTA RONAK MEHTA SAKET KUMAR

DESCON ENGINEERING FZE

WASIT SRU & UTILITIES PROJECT,

PACKAGE # 3

Doc. No.

DES-1744-QA&QC-05

Descon Engineering FZE.

MAGNETIC PARTICLE

TEST PROCEDURE Rev. 00 Page2of13

TABLE OF CONTENT

SR. NO CONTENTS

1. SCOPE

2. PERSONNEL

3. EQUIPMENT AND SUPPLIES

4. EXAMINATION

5. INTERPRETATION OF INDICATION

6. EVALUATION OF INDICATION

7. ACCEPTANCE STANDARD

8. REPAIR REQUIREMENTS

9. DEMAGNETIZATION

10. POST EXAMINATION CLEANING

11. LIGIT METER

12. REPORTING SYSTEM

ATTACHMENT - 1

ATTACHMENT 2

WASIT SRU & UTILITIES PROJECT,

PACKAGE # 3

Doc. No.

DES-1744-QA&QC-05

Descon Engineering FZE.

MAGNETIC PARTICLE

TEST PROCEDURE Rev. 00 Page3of13

QUALITY CONTROL PROCEDURE

FOR

MAGNETIC PARTICLE EXAMINATION

WASIT SRU & UTILITIES PROJECT,

PACKAGE # 3

Doc. No.

DES-1744-QA&QC-05

Descon Engineering FZE.

MAGNETIC PARTICLE

TEST PROCEDURE Rev. 00 Page4of13

1.0 SCOPE

1.1 This procedure provides the general requirements, methods, techniques and

acceptance standards for wet powder examination using the continuous method

of examination using AC electromagnetic yoke technique on ferromagnetic

materials and welds and where accessibility to yoke contact permits meaningful

examination. This procedure is applicable for materials having thickness more

than 6 mm.

1.2 This procedure is used to determine the presence of discontinuities which are

open to examination surface.

1.3 This procedure is applicable when the temperature of material and wet powder

does not exceed 5

o

C to 52

o

C.

1.4 This procedure shall be used when specified in the ITP or drawings

1.5 ATTACHMENT 2 to this procedure details the essential and non essential

variables applicable for this procedure and their qualified range established by

demonstration of this procedure to the satisfaction of AI and certified by NDE

Level III as per Article 1, ASME Section V T-150 requirements.

1.6 Any change in an essential variable shall require re-qualification and certification

of this procedure by demonstration to AI and applicable revisions to this

procedure.

1.7 Any change in the non-essential variable does not require re-qualification but may

require revisions to this procedure.

REFERENCE DOCUMENT:

Saudi Aramco Specification No: SAEP -1145, SAEP-1142

Material Requisition of Hamworthy: MR 1970/07 REV 03

32-SAMSS-004, 32-SAMSS-029

Codes and standards (Latest Edition-2011):

ASME SEC-V Edition-2011 Addenda 2011a

2.0 PERSONNEL

2.1 Personnel performing and evaluating examination to this procedure shall be

qualified and certified according to Descon written practice, which meets the

requirement of SNT-TC-1A (2006 Edition).

2.2 Personnel performing Magnetic Particle Examination - MT Level I / lI

Personnel evaluating Magnetic Particle Examination - MT Level II / III

WASIT SRU & UTILITIES PROJECT,

PACKAGE # 3

Doc. No.

DES-1744-QA&QC-05

Descon Engineering FZE.

MAGNETIC PARTICLE

TEST PROCEDURE Rev. 00 Page5of13

3.0 EQUIPMENT AND SUPPLIES

3.1 Temple stick / Surface thermometer to check the examination surface temperature.

3.2 AC Electro-magnetic Yoke suitable to operate on single phase supply.

Each alternating current Electro-magnetic yoke shall have a minimum lifting

capacity of 10 lbs. (4.5 kg) at minimum and maximum pole spacing that will be

used

Standard weights of suitable size shall be used to verify this adequacy. These

standard weights shall be weighed with scale from a reputable manufacturer and

stenciled or otherwise marked with the applicable nominal weight prior to first

use. A weight need only be verified again if damaged in a manner that could

have caused potential loss material.

This check shall be carried out during the demonstration of this procedure and at

least once every year or earlier whenever the yoke is damaged & repaired or

when there is a doubt on the its lifting capacity.

3.3 Magnetic Particle Pie Field Indicator to determine the level & direction of magnetic

flux density.

3.4 The following brands of magnetic particle powder & white contrast paint

SUPPLIER MATERIAL PRODUCT

MAGNAFLUX

White Contrast

Background Paint

Wet Powder (in aerosol can)

Black Color

WCP-2

7HF

Any change in material from the above list shall require procedure demonstration.

3.3 The materials shall be used within the expiry dates mentioned on the spray

cans. Batch Test Certificates are not required. They can however be made

available when specifically required by the contract or specifications.

4.0 EXAMINATION

4.1 Surface Preparation

WASIT SRU & UTILITIES PROJECT,

PACKAGE # 3

Doc. No.

DES-1744-QA&QC-05

Descon Engineering FZE.

MAGNETIC PARTICLE

TEST PROCEDURE Rev. 00 Page6of13

4.1.1 Surfaces to be examined may be in the as welded, as rolled, as cast or as

forged condition. Grinding may be necessary in certain cases where surface

irregularities could mask unacceptable discontinuities.

4.2 Pre-Examination Cleaning

4.2.1 The surface to be examined and all the adjacent areas within at least 1 in. (25

mm) shall be cleaned by mechanical means and organic solvent to remove any

dart, grease, lint, scale, welding flux or spatter, oil or other matter which could

interfere with the examination.

4.3 Surface Contrast Enhancement

4.3.1 A thin uniform layer of nonmagnetic surface contrast paint (WCP-2) on

uncoated examination surface may be applied temporarily only in amounts

sufficient to enhance particle contrast, it shall be demonstrated that the

indications can be detected through the enhancement coating as per para T-

150 of ASME Section V Article 1. Actual thickness measurement of this

nonmagnetic contrast enhancement coating is not required.

4.4 Method of examination

4.4.1 Examination shall be done by continuous magnetization method, i.e. the

magnetizing current remains ON while the examination medium is being

applied.

4.5 Examination coverage

4.5.1 Examination shall be conducted with sufficient overlap to ensure 100%

coverage. The weld and at least 12.7 mm (1/2) of the base material on each

side of the weld shall be examined where possible.

4.6 Direction of magnetization

4.6.1 At least two(2) separate examinations shall be performed on each area to be

examined. During the second examination, the lines of magnetic flux lines shall

be approx. perpendicular to those used during the first examination.

4.6.2 The level and direction of flux density can be established before examination

using a magnetic pie field indicator.

4.7 Magnetization & application of particles

4.7.1 Yoke shall be positioned with both legs in full contact with the inspection surface

as far as practicable. (Shall have a spacing not less than 75mm(3 inch) and not

greater than 200mm(8)) The effective width of magnetizing field is 1/4th of the

yoke spacing on each side of a line through the yoke centers.

WASIT SRU & UTILITIES PROJECT,

PACKAGE # 3

Doc. No.

DES-1744-QA&QC-05

Descon Engineering FZE.

MAGNETIC PARTICLE

TEST PROCEDURE Rev. 00 Page7of13

4.7.2 The current shall be turned ON after the yoke has been properly positioned on

the examination surface by a control switch built into yoke handles and the

particles applied while magnetization in ON. Flux level can be varied by a

control knob (if available) to a desirable degree as assessed by the field

indicator.

4.7.3 Wet particles are designed to be suspended in a vehicle contained in a light

petroleum based distillate with a wetting agent additive at a given concentration

and applied to the test surface by spraying as available in pre-mixed spray cans.

It is best for detection of small discontinuities as the suspension allows the

particles to float to the leakage field.

4.7.4 Particles shall be applied sparingly with spray can in such a manner that a light,

uniform coating settles upon the surface to be examined.

4.8 Examination Temperature

The temperature of the Consumables and the surface of the part to be examined shall

be between 5 C (40 F) to 52C (125 F). (The part & Consumables shall lieu as per

Consumables Manufacturers recommendations)

5.0 INTERPRETATION OF INDICATIONS

5.1 All examination shall be performed in natural or artificial white light. The white

light intensity at the inspection surface shall be minimum of 100 foot-candles

(1000 Lux).

5.2 The interpretation shall identify if an indication as false, non relevant, or

relevant. False and non relevant indications shall be proven as false or non

relevant. Interpretation shall be carried out to identify the locations of indications

and the character of the indication.

5.3 Surface discontinuities are indicated by accumulations of magnetic particles

which should contrast with the examination surface. The color of the magnetic

particles shall be sufficiently different than the color of the examination surface.

5.4 Linear indications are those having a length greater than 3 times the width.

5.5 Rounded indications are those of circular or elliptical shape with a length equal

to or less than 3 times the width.

6.0 EVALUATION OF INDICATIONS

6.1 All indications shall be evaluated in terms of the acceptance standards of the

referencing Code Section given below. Discontinuities on or near the surface

are indicated by retention of the examination medium. However, localized

surface irregularities due to machining marks or other surface conditions may

WASIT SRU & UTILITIES PROJECT,

PACKAGE # 3

Doc. No.

DES-1744-QA&QC-05

Descon Engineering FZE.

MAGNETIC PARTICLE

TEST PROCEDURE Rev. 00 Page8of13

produce false indications. Broad areas of particle accumulation, which might

mask indications from discontinuities, are prohibited, and such areas shall be

cleaned and reexamined.

6.2 Indications will be revealed by retention of magnetic particles. All such

indications are not necessarily imperfections, however, since excessive surface

roughness, magnetic permeability variations (such as at the edge of heat

affected zones) etc., may produce similar indications.

6.3 An indication of an imperfection may be larger than the imperfection that causes

it; however, the size of the indication is the basis for acceptance evaluation.

Only indications which have any dimension greater than 116 in. (1.5 mm) shall

be considered relevant. Any questionable or doubtful indications shall be

reexamined to determine whether or not they are relevant.

7.0 ACCEPTANCE STANDARD

7.1 Acceptance standard shall be as required by the applicable construction Code

such as ASME Code Section I, Section VIII DIV-1 or 2 and ASME B 31.1

7.2 The following acceptance criteria meet the requirements of the above Codes:

All cracks and relevant linear indications.

Relevant rounded indications with dimension greater than 3/16 in. (5.0 mm)

In-line porosity i.e. four (4) or more relevant porosity indications separated by

1/16 in. (1.5 mm) or less edge to edge.

In addition, the following criteria shall be applicable for ASME B 31.1 items

Ten (10) or more rounded indications in any 6 sq.in. (3870 mm

2

) of surface with

the major dimension of this area not to exceed 6 in. (150 mm) with the area

taken in the most unfavorable location relative to the indications being

evaluated.

7.3 For non-load bearing attachment welds as determined by Design Engineer

where this examination is required, the area shall be examined to an extent of

10% of total length or as described on the applicable drawings. The acceptance

criteria shall be that the examination area should be essentially free of cracks.

Rounded indications are not a factor in acceptability of welds. However, in case

of appreciable number & size of rounded indications rectifications and re-

examinations may be required.

8.0 REPAIR REQUIREMENTS

Unacceptable imperfections shall be repaired and reexamination made to assure

removal or reduction to an acceptable size. Whenever an imperfection is repaired by

chipping or grinding and subsequent repair by welding is not required, the excavated

area shall be blended into the surrounding surface so as to avoid sharp notches,

crevices, or corners. Where welding is required after repair of an imperfection, the area

WASIT SRU & UTILITIES PROJECT,

PACKAGE # 3

Doc. No.

DES-1744-QA&QC-05

Descon Engineering FZE.

MAGNETIC PARTICLE

TEST PROCEDURE Rev. 00 Page9of13

shall be cleaned and welding performed in accordance with a qualified welding

procedure.

Treatment of indications believed nonrelevant: Any indication which is believed to be

nonrelevant shall be regarded as an imperfection unless it is shown by reexamination

by the same method or by the use of other nondestructive methods and/or by surface

conditioning that no unacceptable imperfection is present.

Examination of areas from which defects have been removed: After a defect is thought

to have been removed and prior to making weld repairs, the area shall be examined by

suitable methods to ensure it has been removed or reduced to an acceptably sized

imperfection.

Reexamination of Repair areas. After repairs have been made, the repaired area shall

be blended into the surrounding surface so as to avoid sharp notches, crevices, or

corners and reexamined by the liquid penetrant method and by all other methods of

examination that were originally required for the affected area, except that, when the

depth of repair is less than the radiographic sensitivity required, reradiography may be

omitted.

9.0 DEMAGNETIZATION

9.1 When residual magnetism in the part could interfere with subsequent processing

or usage, the part shall be demagnetized any time after completion of the

examination.

9.2 Magnetization with AC yoke has an advantage of a self-demagnetizing

effect.

9.3 Demagnetization is not mandatory if it does not pose any problems to

subsequent fabrication operation.

10.0 POST EXAMINATION CLEANING

10.1 Post examination cleaning is necessary only in those cases where residual

magnetic particles could interfere with subsequent processing or with service

requirements. If post cleaning is deemed necessary it shall be done promptly

after evaluation by coarse water rinsing or water spray or solvent wiping, which

does not adversely affect the part.

11.0 LIGHT METER

11.1 Calibrated white light meter was used to establish the light intensity required for

examination. It was observed that a 100W/220V bulb gives sufficient light

intensity (1000 Lux) at a distance of 300mm.

WASIT SRU & UTILITIES PROJECT,

PACKAGE # 3

Doc. No.

DES-1744-QA&QC-05

Descon Engineering FZE.

MAGNETIC PARTICLE

TEST PROCEDURE Rev. 00 Page10of13

11.2 The white light meter shall be calibrated at least once in a year or whenever the

meter has been damaged or repaired or there is a doubt on the accuracy of the

meter.

11.3 If the meter has not been in use for one year or more, calibration shall be done

before being used.

11.4 Calibrated white light meter shall be used when it is required to establish the

required light intensity for any other light source and distance.

12.0 REPORTING SYSTEM

Examination results shall be reported on the attached form (ATTACHMENT 1).

ATTACHMENT 1

WASIT SRU & UTILITIES PROJECT,

PACKAGE # 3

Doc. No.

DES-1744-QA&QC-05

Descon Engineering FZE.

MAGNETIC PARTICLE

TEST PROCEDURE Rev. 00 Page11of13

WASIT SRU & UTILITIES PROJECT,

PACKAGE # 3

Doc. No.

DES-1744-QA&QC-05

Descon Engineering FZE.

MAGNETIC PARTICLE

TEST PROCEDURE Rev. 00 Page12of13

WASIT SRU & UTILITIES PROJECT,

PACKAGE # 3

Doc. No.

DES-1744-QA&QC-05

Descon Engineering FZE.

MAGNETIC PARTICLE

TEST PROCEDURE Rev. 00 Page13of13

Vous aimerez peut-être aussi

- Pmi Procedure: Superflow Pumps Pvt. LTDDocument6 pagesPmi Procedure: Superflow Pumps Pvt. LTDashish tiwariPas encore d'évaluation

- Russindo Group Vacuum Box Test ProcedureDocument5 pagesRussindo Group Vacuum Box Test ProcedureIkhsan Dalimunthe100% (2)

- Cp16 Issue Renewal and Recertification of PCN Levels 1 & 2 CertificatesDocument19 pagesCp16 Issue Renewal and Recertification of PCN Levels 1 & 2 Certificatesndt_inspectorPas encore d'évaluation

- Muksyn Engineering Radiographic Testing ProcedureDocument24 pagesMuksyn Engineering Radiographic Testing Procedurecloud23100% (1)

- DPT ProcedureDocument4 pagesDPT ProcedureRohit Attri100% (1)

- Liquid Dye Penetrant Test Inspection Sample ProcedureDocument8 pagesLiquid Dye Penetrant Test Inspection Sample Procedureم.ذكى فضل ذكىPas encore d'évaluation

- Vacuum Box TestingDocument8 pagesVacuum Box Testingergyap100% (4)

- Al-Uqlah Central Processing Facility Water Level & Settlement TableDocument12 pagesAl-Uqlah Central Processing Facility Water Level & Settlement TableSantosh Kumar BogelaPas encore d'évaluation

- Wash Tank Repair & Improvement Minas and Petapahan ProjectDocument9 pagesWash Tank Repair & Improvement Minas and Petapahan ProjectEndika Alfan100% (2)

- Dye Penetrant Testing ProcedureDocument5 pagesDye Penetrant Testing ProcedureTabish Shaikh50% (2)

- NDTDocument38 pagesNDTNishant B MayekarPas encore d'évaluation

- External Visual Examination Procedure: Procedure No. BCE/VT/005-2021/Rev-0Document8 pagesExternal Visual Examination Procedure: Procedure No. BCE/VT/005-2021/Rev-0BCE DePas encore d'évaluation

- PT Tests of Service Water Tank WeldsDocument9 pagesPT Tests of Service Water Tank WeldsRhoteram Vikku100% (1)

- Procedure For Vacuum Box TestingDocument3 pagesProcedure For Vacuum Box TestingZakirUllahPas encore d'évaluation

- PT Procedure GeneralDocument9 pagesPT Procedure Generalvsnaiduqc100% (1)

- Report-1683-1 B1 25mm 14 10 2020Document7 pagesReport-1683-1 B1 25mm 14 10 2020sakthi velPas encore d'évaluation

- FLOORMAP3Di-R High Speed MFL Floor Scanner with STARS Top & Bottom Defect DiscriminationDocument6 pagesFLOORMAP3Di-R High Speed MFL Floor Scanner with STARS Top & Bottom Defect Discriminationjose ocanaPas encore d'évaluation

- Vaccum Test MethodDocument4 pagesVaccum Test MethodMahmud AlamPas encore d'évaluation

- Radiographic Testing ProcedureDocument12 pagesRadiographic Testing ProcedureAdham AhmedPas encore d'évaluation

- UT Procedure Rev.0Document32 pagesUT Procedure Rev.0Goutam Kumar Deb100% (2)

- Oil Leak Test ProcedureDocument7 pagesOil Leak Test ProcedurekokoPas encore d'évaluation

- Magnetic Particle Testing ReporDocument2 pagesMagnetic Particle Testing ReporGabriela MotaPas encore d'évaluation

- PTS-1012 - RA Hardness Test ReportDocument1 pagePTS-1012 - RA Hardness Test ReportPetrotrim ServicesPas encore d'évaluation

- Reviewed UT Procedure 10-12-2016Document18 pagesReviewed UT Procedure 10-12-2016Muhammad Maulana100% (1)

- Ultrasonic Testing Procedure for B & C ScanningDocument10 pagesUltrasonic Testing Procedure for B & C ScanningMohamed HassanPas encore d'évaluation

- Radiography Testing Procedure: Procedure No. BCE/RT/003-2018/Rev-1.0Document13 pagesRadiography Testing Procedure: Procedure No. BCE/RT/003-2018/Rev-1.0BCE DePas encore d'évaluation

- 5111FA-Assessment Report-Shell & Roof Rev.1Document14 pages5111FA-Assessment Report-Shell & Roof Rev.1Hosam AhmedPas encore d'évaluation

- Job Procedure For PWHT of Storage Tanks: 10 of Ramadan City, Industrial Area A1, EgyptDocument5 pagesJob Procedure For PWHT of Storage Tanks: 10 of Ramadan City, Industrial Area A1, EgyptShubham ShuklaPas encore d'évaluation

- Silverwing B Scan ReportDocument46 pagesSilverwing B Scan ReportpjhollowPas encore d'évaluation

- Report - Form - MT - PT - RT - Ut - Cal - 2015Document9 pagesReport - Form - MT - PT - RT - Ut - Cal - 2015YuwantoniAlPas encore d'évaluation

- Ea 4 15 G Rev01 May 2015 Rev PDFDocument24 pagesEa 4 15 G Rev01 May 2015 Rev PDFandrej_voloscuk13Pas encore d'évaluation

- MPI Cal Cert-002 SampleDocument1 pageMPI Cal Cert-002 SampleJohn OLiverPas encore d'évaluation

- Final Draft en Iso Fdis 15548-2 - 2007Document39 pagesFinal Draft en Iso Fdis 15548-2 - 2007gorkembaytenPas encore d'évaluation

- Bureau Veritas MFL Procedure for Heat Exchanger TubesDocument12 pagesBureau Veritas MFL Procedure for Heat Exchanger TubesThinh Nguyen100% (1)

- Liquid Penetrant Testing PT PTDocument1 pageLiquid Penetrant Testing PT PTzaw lin ooPas encore d'évaluation

- Ndic MFL A 10rev03!26!2010 SignedDocument10 pagesNdic MFL A 10rev03!26!2010 SignedMarcus ThomasPas encore d'évaluation

- PTDocument7 pagesPTMohdHuzairiRusliPas encore d'évaluation

- Hydro Vs PneumaticDocument4 pagesHydro Vs PneumaticAnonymous rYZyQQot55Pas encore d'évaluation

- Nde Map & Nde Procedure (Sudah Di Revisi)Document4 pagesNde Map & Nde Procedure (Sudah Di Revisi)Hardika SambilangPas encore d'évaluation

- NDT and IRIS Status RCON SD 2015extractedDocument9 pagesNDT and IRIS Status RCON SD 2015extractedWIZKHALIFA100% (1)

- Visual Examination ProcedureDocument23 pagesVisual Examination ProcedureEdAlmPas encore d'évaluation

- CMAP Reporting - Operating ManualDocument46 pagesCMAP Reporting - Operating ManualJesus E ContrerasPas encore d'évaluation

- UT Procedure GuideDocument15 pagesUT Procedure GuideAmir Reza RashidfarokhiPas encore d'évaluation

- VT Procedure 1Document1 pageVT Procedure 1Mahmoud Alwasif50% (2)

- MEENA Internation NDT TrainingDocument45 pagesMEENA Internation NDT Trainingahmzahid100% (1)

- Magnetic Particle Testing Report SummaryDocument4 pagesMagnetic Particle Testing Report Summarypankaj ranaPas encore d'évaluation

- ACFM Applications1Document12 pagesACFM Applications1naoufel1706Pas encore d'évaluation

- Tofd 2022Document28 pagesTofd 2022ahmed elezabyPas encore d'évaluation

- CV Aravind API InspectorDocument12 pagesCV Aravind API Inspectorநான் மகான் அல்லPas encore d'évaluation

- Radiography Test & Liquid Penetrant Test ProcedureDocument7 pagesRadiography Test & Liquid Penetrant Test ProcedurePrashant MalvePas encore d'évaluation

- Helium Leak Testing DubaiDocument32 pagesHelium Leak Testing DubaiAbhijitPas encore d'évaluation

- j34 A Doc Ve 678138 Pmi ProcedureDocument20 pagesj34 A Doc Ve 678138 Pmi Proceduremohdbaquer_024100% (1)

- F07-Visual Inspection Report NEWDocument1 pageF07-Visual Inspection Report NEWmohd as shahiddin jafriPas encore d'évaluation

- Si EvertDocument4 pagesSi EvertLaxmikant TiwariPas encore d'évaluation

- SSIS VT Procedure Rev 0 25112011Document14 pagesSSIS VT Procedure Rev 0 25112011Salman KhanPas encore d'évaluation

- Industrial radiography A Complete Guide - 2019 EditionD'EverandIndustrial radiography A Complete Guide - 2019 EditionPas encore d'évaluation

- Magnetic Particle Test Procedure Magnetic Particle Test Procedure MTDocument14 pagesMagnetic Particle Test Procedure Magnetic Particle Test Procedure MTsamer8saif100% (3)

- Procedure For Magnetic Particle Examination 1.0 SCOPEDocument3 pagesProcedure For Magnetic Particle Examination 1.0 SCOPEpmkar100% (1)

- ULTRASONIC TESTING PROCEDUREDocument14 pagesULTRASONIC TESTING PROCEDUREshifa0% (1)

- ATT MT-2.0 Rev. 1 ProcedureDocument13 pagesATT MT-2.0 Rev. 1 ProcedurewalitedisonPas encore d'évaluation

- Welding HandbookDocument48 pagesWelding HandbookMohan Prasad.M93% (27)

- Eddy Current TheoryDocument5 pagesEddy Current TheorypondpakkaPas encore d'évaluation

- ET Level IDocument15 pagesET Level Isoledense5470100% (3)

- PTDocument8 pagesPTnike_y2kPas encore d'évaluation

- NDTDocument64 pagesNDTmohamedyoussef1Pas encore d'évaluation

- Manual of Visual TestingDocument15 pagesManual of Visual Testingsoledense5470Pas encore d'évaluation

- CH - 1 Electric Charges and Fields Typed NotesDocument11 pagesCH - 1 Electric Charges and Fields Typed NotesMk tequbePas encore d'évaluation

- Magnetism and Electromagnetism by PavanDocument13 pagesMagnetism and Electromagnetism by PavanGopipavanPas encore d'évaluation

- Vector Calculus R16Document87 pagesVector Calculus R16Meghna SahaPas encore d'évaluation

- Support Material Term 1 XII PhysicsDocument269 pagesSupport Material Term 1 XII PhysicsSumit SharmaPas encore d'évaluation

- Jeem Shift2Document33 pagesJeem Shift2Yash TandonPas encore d'évaluation

- Continuity equation essentialsDocument12 pagesContinuity equation essentialsdagushPas encore d'évaluation

- Electromagnetic Fields and Waves Course SyllabusDocument10 pagesElectromagnetic Fields and Waves Course SyllabusHalefom HailePas encore d'évaluation

- Rocket Equation Derivation NotesDocument7 pagesRocket Equation Derivation NotesSrikar GhooliPas encore d'évaluation

- Modeling Packed Bed Reactors for Hydrogen ProductionDocument6 pagesModeling Packed Bed Reactors for Hydrogen ProductionElbahi DjaalabPas encore d'évaluation

- Applying Gauss's Law to Determine Electric FieldsDocument25 pagesApplying Gauss's Law to Determine Electric FieldsSayyad aliPas encore d'évaluation

- Advantages of Multi-Flux MethodsDocument10 pagesAdvantages of Multi-Flux MethodsNaeem KhanPas encore d'évaluation

- PHY150 Elctricity and Magnetism Experiment 5Document7 pagesPHY150 Elctricity and Magnetism Experiment 5hfzfrdPas encore d'évaluation

- Actinometria QuimicaDocument42 pagesActinometria QuimicasgpizarroPas encore d'évaluation

- A One-Step Finite Element Method For Multi Conductor Skin Effect ProblemsDocument8 pagesA One-Step Finite Element Method For Multi Conductor Skin Effect Problemsmaninina65Pas encore d'évaluation

- $electrostaticsDocument24 pages$electrostaticsAtul VermaPas encore d'évaluation

- Surface area and integrals over surfacesDocument8 pagesSurface area and integrals over surfacesTidal SurgesPas encore d'évaluation

- Electric Charges and Fields l4 Physics Class 12 Cbse by Ashu SirDocument15 pagesElectric Charges and Fields l4 Physics Class 12 Cbse by Ashu Sirvedantu495Pas encore d'évaluation

- Chapter 24Document40 pagesChapter 24anwartufailwazirPas encore d'évaluation

- XII Electrostatics and Capacitor ModuleDocument127 pagesXII Electrostatics and Capacitor ModuleKS ARPITPas encore d'évaluation

- Maxwell's Equations ExplainedDocument33 pagesMaxwell's Equations ExplainedMekashaw AndargePas encore d'évaluation

- CapacitorsDocument68 pagesCapacitorsNikunj GautamPas encore d'évaluation

- Dielectric Properties Module SummaryDocument70 pagesDielectric Properties Module SummaryKadiyala Chandra Babu NaiduPas encore d'évaluation

- Modelling and Simulation of The Water-Gas Shift in A Packed Bed Membrane ReactorDocument87 pagesModelling and Simulation of The Water-Gas Shift in A Packed Bed Membrane ReactorWu ChengliangPas encore d'évaluation

- Curl & DivergenceDocument4 pagesCurl & DivergenceArnab DasPas encore d'évaluation

- Gen Physics Midterm ReviewerDocument13 pagesGen Physics Midterm ReviewerKiyoshi TakeuchiPas encore d'évaluation

- chpt2 Vector Analysis Part 2Document25 pageschpt2 Vector Analysis Part 2Ahmet imanlıPas encore d'évaluation

- Approach To The Theory of Electromagnetic and Gravitational Fields, 2nd Ed.Document7 pagesApproach To The Theory of Electromagnetic and Gravitational Fields, 2nd Ed.Jefrey Ternera GutiérrezPas encore d'évaluation

- Lecture Notes On Streamlines and Electric Flux DensityDocument5 pagesLecture Notes On Streamlines and Electric Flux DensitySweetlineSoniaPas encore d'évaluation

- EE8391 QB 04 - by LearnEngineering - inDocument20 pagesEE8391 QB 04 - by LearnEngineering - inKeerthiSahaPas encore d'évaluation