Académique Documents

Professionnel Documents

Culture Documents

DPFG Wellhead Valves Leak Off Test Procedure RevC

Transféré par

HosseinCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

DPFG Wellhead Valves Leak Off Test Procedure RevC

Transféré par

HosseinDroits d'auteur :

Formats disponibles

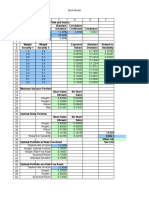

Wellhead valves leak test Procedure

Summary Page 2 to 2

Actions Page 3 to 6

[] Action S Shift Supervisor

LEGEND : () Verification PO Panel Operator

<> Safety Action O Plant Operator

HIERARCHY CONTROL REVISIONS

NAME DATE SIGNATURE

Revised by M L M L M L

Revision No. A B C D

Date 15/01/04

Revised by

Revision No.

Date

Date : 19/01/04 Revision : C Page : 1 / 6

DPFG/OP/06

8/1/2004 19/01/04

DOROOD PROJECT

Summary

Page No.

INITIAL STATE

() PRELIMINARIES 2

() D-101P wellhead valves leak test (DHSV,SSV,MV,WV)

() Preparation of sump caisson 3

() Wellhead valves leak test 3

() Empting the Liquid trap. 4

() Empting the sump caisson. 4

FINAL STATE

Date : 19/01/04 Revision : C Page : 2 / 6

2.4

Sump caisson empty

2.2

2.3

1

2

2.1

Liquid trap empty

The close drain sump caisson and pump are available

DPFG/OP/06

Wellhead valves leak test

Well D-101P opened and flowing

DPFG Platform is in operation

Production wells are opened

DOROOD PROJECT

Actions

S PO O

INITIAL STATE

PRELIMINARIES

<> Inform Kharg & KD platform about the operation. *

<> Ensure weather condition meets Total/ NIOC regulation. *

<> Ensure all personnel have H2S detector & Escape mask. *

<> Ensure personnel mobilised & Communication ok. *

<> Ensure sump caisson is available *

<> Ensure fresh hydraulic oil is available

<> Ensure stand by boat or other facility is available to empty Sump caisson. *

<> Ensure air supply is available for Sump Caisson pump. *

<> Inform Rig or standby boat about the operation. *

Wellhead valves leak test

Preparation of sump caisson

[] Connect air supply to pump. *

[] Connect discharge hose to pump. *

() Check the pump operation. *

[] keep close the discharge valve. *

Before starting leak test the start up valves of SCSSV,SSV and ESDV should be closed

in there respective hydraulic cabinet to avoid a valve closure by low pressure flow line.

Leak test - WING Valve

[] In the ESDV 1015 control cabinet PG-NFU-21 put start up valve in close position *

[] In the well control cabinet PG-NFU-21 put SCSSV and SSV start up valves in close position *

[] Close well head manual Wing valve.

[] Close 8" manual valve d/s wellhead choke HV 1210. *

[] Check choke is opened at normal flow. *

[] Wait for pressure stabilization / note pressure value each 5 mn. *

<> Record wellhead STATIC pressure (PG 1210). *

[] If pressure not stabilized, stop procedure and grease W.V opening and closing it. *

When the pressure is stabilized: *

[] Open 3/4'' vent ball valve fully ( 2'' FS 100 101 B523). *

a [] Open 3/4'' vent globe valve gradually through liquid trap and depressurize F/L d/s wing v/v *

[] When the flow line pressure is around 50% of static pressure close back 3/4'' vent v/v *

<> Note flow line pressure after 5, 10 and 15 mn ( PG 1212). *

[] If necessary repeat the action 2.2(a) & 2.3 *

<> RECORD Time and Pressure value. *

Date : 19/01/04 Revision : C Page : 3 / 6

2

2.2

2.1

1

Wellhead valves leak test

The close drain sump caisson and pump are available

Well D-101P in operation

DPFG/OP/06

DOROOD PROJECT

Actions

S PO O

Leak test - SSV 1211

[] In the ESDV 1015 control cabinet PG-NFU-21 put start up valve in close position *

[] In the well control cabinet PG-NFU-21 put SCSSV and SSV start up valves in close position *

# [] Close well head manual wing valve. *

# [] Close 8" manual valve d/s wellhead choke HV 1210.

# [] Check choke is opened at normal flow. *

<> Record wellhead STATIC pressure (PG 1210). *

[] Close SSV 1211 and note Wellhead static pressure after 5 mn time. *

[]

Open Wing valve.

*

[] Open 3/4'' vent ball valve fully ( 2'' FS 100 101 B523). *

a [] Open 3/4'' vent globe valve gradually through liquid trap. *

[] Bleed wellhead static pressure to 50% of static pressure value. *

[] If necessary repeat the action 2.2(a) & 2.3 *

[] When the wellhead pressure is 50% of static pressure close back 3/4'' vent valve. *

[] Close back Wing valve. *

[] Follow and note WELLHEAD pressure every 5 mn till stabilisation (PG 1210). *

<> RECORD Time and Pressure value. *

[] Open back SSV 1211. *

Note : # Actions already done if the test is carried out after WING valve leak test .

Leak test - Master valve

[] In the ESDV 1015 control cabinet PG-NFU-21 put start up valve in close position *

[] In the well control cabinet PG-NFU-21 put SCSSV and SSV start up valves in close position *

# [] Close well head manual Wing valve. *

# [] Close 8" manual valve d/s wellhead choke HV 1210.

# [] Check choke is opened at normal flow. *

<> Record wellhead STATIC pressure (PG 1210). *

[] Close MASTER valve and note Wellhead static pressure after 5 mn time. *

[]

Open Wing valve.

*

[] Open 3/4'' vent ball valve fully ( 2'' FS 100 101 B523). *

a [] Open 3/4'' vent globe valve gradually through liquid trap. *

[] Bleed wellhead static pressure to 50% of static pressure value. *

[] If necessary repeat the action 2.2(a) & 2.3 *

[] When the wellhead pressure is 50% of static pressure close back 3/4'' vent valve. *

[] Close back Wing valve. *

[] Follow and note WELLHEAD pressure every 5 mn till stabilisation (PG 1210). *

<> RECORD Time and Pressure value. *

[] Open back MASTER valve. *

Note : # Actions already done if the test is carried out after SSV leak test .

Date : 19/01/04 Revision : C Page : 4 /6

DPFG/OP/06

Wellhead valves leak test

DOROOD PROJECT

Actions

S PO O

Leak test - SCSSV 1210 (DHSV)

Note : Follow Total company procedure steps to control SCSSV hydraulic oil quality and quantity.

[] In the ESDV 1015 control cabinet PG-NFU-21 put start up valve in close position *

[] In the well control cabinet PG-NFU-21 put SCSSV and SSV start up valves in close position *

# [] Close well head manual wing valve. *

# [] Close 8" manual valve d/s wellhead choke HV 1210. *

# [] Check choke is opened at normal flow. *

[] RECORD wellhead STATIC pressure (PG 1210). *

[] Close SCSSV 1210 control line final valve at wellhead. *

[] Install protective cap on SSV ' actuator rod end to avoid valve closure during SCSSV

[] hydraulic control line bleeding

[] Bleed the control line hydraulic trap pressure by opening the pump bleeder valve inside *

control cabinet *

[] Disconnect control line flexible hose end to control cabinet *

[] Open the SCSSV control line final valve at wellhead and collect the hydraulic oil into a *

measuring jar (check oil quality and quantity). *

[] Open Wing valve. *

[] Open 3/4'' vent ball valve fully ( 2'' FS 100 101 B523). *

a [] Open 3/4'' vent globe valve gradually through liquid trap. *

[] Bleed wellhead static pressure to 50% of static pressure value. *

[] If necessary repeat the action 2.2(a) & 2.3 *

[] When the wellhead pressure is 50% of static pressure close back 3/4'' vent valve. *

[] Close back Wing valve. *

[] Follow and note WELLHEAD pressure every 5 mn till stabilisation (PG 1210). *

<> RECORD Time and Pressure value. *

[] Normalize SCSSV control line connection *

[] Open back SCSSV 1210 (DHSV). *

Note : # Actions already done if the test is carried out after MASTER leak test .

After each Leak test step

> If wellhead pressure not stabilized after 30mn

> Or goes up too quickly

Stop procedure *

Grease valve opening / closing several times *

Restart procedure *

When leak test operation is completed reopen the well gradually. *

Particular care should be brought to flow line pressure / PSHH 1240 set at 46 bars. *

After well reopening, ensure the hydraulic pressure is correct in all cabinets. *

Reopen the start up valves of SCSSV,SSV and ESDV in there respective cabinets. *

DPFG/OP/06

Wellhead valves leak test

DOROOD PROJECT

Date : 19/01/04 Revision : C Page : 5 /6

Actions

S PO O

Empting the liquid trap.

[] Stop depressurizing by closing the vent valve.

[] Open fully liquid trap 2" drain ball vale.

[] Open gradually 2" globe valve.

() Monitor level in sump caisson.

Empting the Sump Caisson.

[] Close liquid trap drain valves to Sump Caisson.

[] Start the Sump caisson pump.

[] Open gradually discharge valve as the pressure increasing.

<> Monitor the liquid storage facility.

FINAL STATE

Date : 19/01/04 Revision : C Page :6 / 6

2.4

Well D-101P opened and flowing

Start up valves in open position in control cabinet

Note: Same procedure to be applied for D-102P

All pressure pilots lined up

Liquid trap empty

Sump caisson empty

2.3

DPFG/OP/06

Wellhead valves leak test

DOROOD PROJECT

Vous aimerez peut-être aussi

- LPR-N Tester Valve Funcionamiento 1Document33 pagesLPR-N Tester Valve Funcionamiento 1Александр КинтероPas encore d'évaluation

- Gas Seperator PDFDocument11 pagesGas Seperator PDFshy_boyPas encore d'évaluation

- Den Con CatalogDocument36 pagesDen Con Catalogbaskaran vPas encore d'évaluation

- Tech Manual 1222B: Booster Cylinder Assembly EH34-BC03Document21 pagesTech Manual 1222B: Booster Cylinder Assembly EH34-BC03jose perozoPas encore d'évaluation

- Tech Manual: 5.12", 10,000 Psi Working Pressure, Eh Series Single, Dual, Triple & Quad Combi BopDocument34 pagesTech Manual: 5.12", 10,000 Psi Working Pressure, Eh Series Single, Dual, Triple & Quad Combi BopRiski KurniawanPas encore d'évaluation

- PETE 417 - OnIX Oil Company - Final ReportDocument180 pagesPETE 417 - OnIX Oil Company - Final ReportEmir MazlumPas encore d'évaluation

- MGS Capacity CalculatorDocument13 pagesMGS Capacity CalculatorRodolfo MendezPas encore d'évaluation

- Texas Oil Tools: Packer Inserts & EnergizersDocument12 pagesTexas Oil Tools: Packer Inserts & Energizersshahrol effendy rodziPas encore d'évaluation

- Catalogo Fluid Control FMCDocument80 pagesCatalogo Fluid Control FMCGustavo JassoPas encore d'évaluation

- Balon Full Valve CatalogDocument51 pagesBalon Full Valve CatalogVictor Muñoz0% (1)

- Cameron Willis Choke ValvesDocument13 pagesCameron Willis Choke ValvesshyamPas encore d'évaluation

- M60eh44 Man 001Document40 pagesM60eh44 Man 001Riski KurniawanPas encore d'évaluation

- Mud Gate ValveDocument16 pagesMud Gate ValvesudhisnairPas encore d'évaluation

- Stripper TOT 2.50 10M DS34 TechMan1146Document13 pagesStripper TOT 2.50 10M DS34 TechMan1146Diego OspinaPas encore d'évaluation

- BOP Recertification Program BrochureDocument7 pagesBOP Recertification Program BrochureJoel SPas encore d'évaluation

- Diverter System Set Up - 20170701 - Rev0 (CW)Document2 pagesDiverter System Set Up - 20170701 - Rev0 (CW)ramyPas encore d'évaluation

- Maintenance Steps of Mud Gas SeparatorDocument1 pageMaintenance Steps of Mud Gas SeparatorNumbWong100% (1)

- Sprint CTU ContigencyPlanDocument32 pagesSprint CTU ContigencyPlanJawad Khan100% (1)

- Uztel OrizontalDocument5 pagesUztel OrizontalDorin RaduPas encore d'évaluation

- Well Stimulation VesselsDocument2 pagesWell Stimulation VesselsOscar RamirezPas encore d'évaluation

- MGMT of Annular Pressure in Offshore Wells - API RP 90Document17 pagesMGMT of Annular Pressure in Offshore Wells - API RP 90Aarony100% (1)

- Mud Gas Separator InfoDocument2 pagesMud Gas Separator InfoHIPAPPas encore d'évaluation

- DNV RP E101 (Jan2012) Re Certification of Well Equipment On Norwegian CSDocument18 pagesDNV RP E101 (Jan2012) Re Certification of Well Equipment On Norwegian CSNils Antoine FreundPas encore d'évaluation

- D392005428-MKT-001 6012 Bop PDFDocument2 pagesD392005428-MKT-001 6012 Bop PDFMitul PatelPas encore d'évaluation

- Tandem Booster m100Document12 pagesTandem Booster m100Leonardo Alvarez100% (1)

- SRP PUMP ASSEMBLY Parts and Accessories CatalogueDocument52 pagesSRP PUMP ASSEMBLY Parts and Accessories Catalogue000Pas encore d'évaluation

- Surface Safety Valve PsDocument2 pagesSurface Safety Valve PsmirzasdPas encore d'évaluation

- Cameron t32 IomDocument20 pagesCameron t32 IomJuan Carlos Sua SuaPas encore d'évaluation

- Tubing Gauge Paraffin Cutter.Document1 pageTubing Gauge Paraffin Cutter.Cesar Jara CobosPas encore d'évaluation

- High Pressure Fittings PDFDocument12 pagesHigh Pressure Fittings PDFHieu NguyenPas encore d'évaluation

- MTR's SO# 1009605Document20 pagesMTR's SO# 1009605ksi meritosPas encore d'évaluation

- DST Slip Joint PDFDocument8 pagesDST Slip Joint PDFcrni rokoPas encore d'évaluation

- Bop TestDocument1 pageBop TestAbdul Hameed OmarPas encore d'évaluation

- ABCO - Hammer UnionsDocument2 pagesABCO - Hammer UnionsOman Baptist ChurchPas encore d'évaluation

- Hytorc Pressure/Torque Conversion Chart For MXT Hydraulic Torque Wrenches Hytorc Pressure/Torque Conversion Chart For MXT Hydraulic Torque WrenchesDocument2 pagesHytorc Pressure/Torque Conversion Chart For MXT Hydraulic Torque Wrenches Hytorc Pressure/Torque Conversion Chart For MXT Hydraulic Torque WrenchesMarcello LaraPas encore d'évaluation

- Iadc WW Surfacestack Field 012214Document3 pagesIadc WW Surfacestack Field 012214DirafPas encore d'évaluation

- Da and Dhda Datasheet Master - XLSM - Hpu-Dhda118-4.1 Rev1Document3 pagesDa and Dhda Datasheet Master - XLSM - Hpu-Dhda118-4.1 Rev1jujuroyalePas encore d'évaluation

- ABS Fire and Safety Features For MODU - Part5Document40 pagesABS Fire and Safety Features For MODU - Part5Eyoma Etim100% (1)

- IWCF Surface Vertical Kill Sheet - API Field Units - Revised July 2010Document4 pagesIWCF Surface Vertical Kill Sheet - API Field Units - Revised July 2010rverretPas encore d'évaluation

- Alam-Al-Hoda Et Al-Coatings of Pipes and FittingsDocument12 pagesAlam-Al-Hoda Et Al-Coatings of Pipes and FittingsamoghimiPas encore d'évaluation

- Cup Type TesterDocument1 pageCup Type TesterJohnsPas encore d'évaluation

- Foss & Gaul PDFDocument17 pagesFoss & Gaul PDFnicolasbelliniPas encore d'évaluation

- Fail Safe or TR RegulatorDocument2 pagesFail Safe or TR RegulatorYeit HauPas encore d'évaluation

- Well-Vac v.2 2-18Document133 pagesWell-Vac v.2 2-18Nerymar Coromoto Parra BustamantePas encore d'évaluation

- Circulating SwagesDocument1 pageCirculating Swageskaveh-bahiraeePas encore d'évaluation

- Series 150 Overshots Supplement: Instruction Manual 1150ADocument25 pagesSeries 150 Overshots Supplement: Instruction Manual 1150AForos IscPas encore d'évaluation

- QBH Ram Bop'S: 4-1/16" 15,000 Psi WPDocument32 pagesQBH Ram Bop'S: 4-1/16" 15,000 Psi WPjuan olarte0% (1)

- ANNEX VIII BOP Testing, Inspection, Training and MaintenanceDocument5 pagesANNEX VIII BOP Testing, Inspection, Training and MaintenanceMohsen Shk100% (1)

- Data Sheet of Double Studded Adapter FlangeDocument3 pagesData Sheet of Double Studded Adapter FlangeAGSMotoVlog 06100% (1)

- Detailed Working Instruction: South Azadegan Oil Field Epd Project AZNS-163/ 7" Liner Lap Inflow TestDocument9 pagesDetailed Working Instruction: South Azadegan Oil Field Epd Project AZNS-163/ 7" Liner Lap Inflow TestMehdi NorouziPas encore d'évaluation

- Mahad3 - WaterLess Fracturing TechnologyDocument48 pagesMahad3 - WaterLess Fracturing Technologycj100% (1)

- Ram BOP Manual BookDocument28 pagesRam BOP Manual BookIgor Ungur100% (2)

- Cameron Hydraulic Gate Valves Type F & FCDocument3 pagesCameron Hydraulic Gate Valves Type F & FCJuan Sebastian Diaz CuadrosPas encore d'évaluation

- Surge Tank: Pressurized Vessel H S Gas Leaving The Surge Tank Is Burned OffDocument13 pagesSurge Tank: Pressurized Vessel H S Gas Leaving The Surge Tank Is Burned OffMahmoud Ahmed Ali AbdelrazikPas encore d'évaluation

- SS3100 2.375 DHSIT Valve Maintenance Manual Rev 7 10010661Document54 pagesSS3100 2.375 DHSIT Valve Maintenance Manual Rev 7 10010661Eduardo Oyarzun0% (1)

- Carbon Capture and Storage: The Legal Landscape of Climate Change Mitigation TechnologyD'EverandCarbon Capture and Storage: The Legal Landscape of Climate Change Mitigation TechnologyPas encore d'évaluation

- Clusters Wellhead Valves Leak Off Test Procedure SDocument6 pagesClusters Wellhead Valves Leak Off Test Procedure SHosseinPas encore d'évaluation

- Vane Presiune DN40 - DN250Document28 pagesVane Presiune DN40 - DN250iza66bellPas encore d'évaluation

- Shutdown Isolation Procedures1Document4 pagesShutdown Isolation Procedures1eng20072007Pas encore d'évaluation

- Simops Test Monthly Leak / Hold Test For SCSSV / SSV North West ClusterDocument2 pagesSimops Test Monthly Leak / Hold Test For SCSSV / SSV North West ClusterHosseinPas encore d'évaluation

- Simops Test Monthly Leak / Hold Test For SCSSV / SSV South ClusterDocument1 pageSimops Test Monthly Leak / Hold Test For SCSSV / SSV South ClusterHosseinPas encore d'évaluation

- Simops Test Monthly Leak / Hold Test For SCSSV / SSV South ClusterDocument1 pageSimops Test Monthly Leak / Hold Test For SCSSV / SSV South ClusterHosseinPas encore d'évaluation

- Simops Test Leak / Hold Test For SCSSV / SSV North East ClusterDocument4 pagesSimops Test Leak / Hold Test For SCSSV / SSV North East ClusterHosseinPas encore d'évaluation

- Simops Test Leak / Hold Test For SCSSV / SSVDocument4 pagesSimops Test Leak / Hold Test For SCSSV / SSVHosseinPas encore d'évaluation

- WH Valves Leak Test TemplateDocument4 pagesWH Valves Leak Test TemplateHossein100% (1)

- Leak Test For SCSSV / SSVDocument5 pagesLeak Test For SCSSV / SSVHosseinPas encore d'évaluation

- Simops Test Leak / Hold Test For SCSSV / SSV North East ClusterDocument3 pagesSimops Test Leak / Hold Test For SCSSV / SSV North East ClusterHosseinPas encore d'évaluation

- 11, November 06 Leak TestDocument4 pages11, November 06 Leak TestHosseinPas encore d'évaluation

- Simops Test Leak / Hold Test For SCSSV / SSV North East ClusterDocument3 pagesSimops Test Leak / Hold Test For SCSSV / SSV North East ClusterHosseinPas encore d'évaluation

- August - D 121 P SCSSV and SSV Leak TestDocument1 pageAugust - D 121 P SCSSV and SSV Leak TestHosseinPas encore d'évaluation

- Simops Test Leak / Hold Test For SCSSV / SSV North East ClusterDocument3 pagesSimops Test Leak / Hold Test For SCSSV / SSV North East ClusterHosseinPas encore d'évaluation

- Simops Test Leak / Hold Test For SCSSV / SSV North East ClusterDocument3 pagesSimops Test Leak / Hold Test For SCSSV / SSV North East ClusterHosseinPas encore d'évaluation

- September - D 120 P SCSSV and SSV Leak TestDocument1 pageSeptember - D 120 P SCSSV and SSV Leak TestHosseinPas encore d'évaluation

- Water Injection Wells SSV Integrity Checks-ProcedureDocument3 pagesWater Injection Wells SSV Integrity Checks-ProcedureHosseinPas encore d'évaluation

- Simops Test Leak / Hold Test For SCSSV / SSV North East ClusterDocument3 pagesSimops Test Leak / Hold Test For SCSSV / SSV North East ClusterHosseinPas encore d'évaluation

- WH Valves Leak Test Template (New)Document2 pagesWH Valves Leak Test Template (New)HosseinPas encore d'évaluation

- Simops Test Leak / Hold Test For SCSSV / SSV North East ClusterDocument2 pagesSimops Test Leak / Hold Test For SCSSV / SSV North East ClusterHosseinPas encore d'évaluation

- Water Injection Wells Chokes Integrity CheckDocument1 pageWater Injection Wells Chokes Integrity CheckHosseinPas encore d'évaluation

- Simops Test Leak / Hold Test For SCSSV / SSV North East ClusterDocument2 pagesSimops Test Leak / Hold Test For SCSSV / SSV North East ClusterHosseinPas encore d'évaluation

- Water Injection Performance TestDocument3 pagesWater Injection Performance TestHosseinPas encore d'évaluation

- SSV&SCSSV Leak Test Calculation ControlDocument3 pagesSSV&SCSSV Leak Test Calculation ControlHosseinPas encore d'évaluation

- Cameron Report, D 104WI Choke Repair 28-02-06Document2 pagesCameron Report, D 104WI Choke Repair 28-02-06HosseinPas encore d'évaluation

- SSV&SCSSV Leak TestDocument3 pagesSSV&SCSSV Leak TestHosseinPas encore d'évaluation

- Water Injection Wells SSV Integrity ChecksDocument1 pageWater Injection Wells SSV Integrity ChecksHosseinPas encore d'évaluation

- NWC Cleanness After Workover 8.6.08-JcsDocument1 pageNWC Cleanness After Workover 8.6.08-JcsHosseinPas encore d'évaluation

- DPFG, D 103WI Choke Repair, 10.12.05Document1 pageDPFG, D 103WI Choke Repair, 10.12.05HosseinPas encore d'évaluation

- BKM 10e Ch07 Two Security ModelDocument2 pagesBKM 10e Ch07 Two Security ModelJoe IammarinoPas encore d'évaluation

- Course Guide Pe1 PDFDocument4 pagesCourse Guide Pe1 PDFrahskkPas encore d'évaluation

- L Addison Diehl-IT Training ModelDocument1 pageL Addison Diehl-IT Training ModelL_Addison_DiehlPas encore d'évaluation

- CP 1Document22 pagesCP 1api-3757791100% (1)

- Powerful Communication Tools For Successful Acupuncture PracticeDocument4 pagesPowerful Communication Tools For Successful Acupuncture Practicebinglei chenPas encore d'évaluation

- Chapter 8 - Lipids and Proteins Are Associated in Biological Membranes - Part 1Document44 pagesChapter 8 - Lipids and Proteins Are Associated in Biological Membranes - Part 1Tommy RamazzottoPas encore d'évaluation

- OKRA Standards For UKDocument8 pagesOKRA Standards For UKabc111007100% (2)

- Hamraki Rag April 2010 IssueDocument20 pagesHamraki Rag April 2010 IssueHamraki RagPas encore d'évaluation

- Inked CultureDocument90 pagesInked Culturemar phisPas encore d'évaluation

- E-Kabin - O Series - Monoblock Enclosure - ENGDocument12 pagesE-Kabin - O Series - Monoblock Enclosure - ENGCatalina CocoşPas encore d'évaluation

- NTJN, Full Conference Program - FINALDocument60 pagesNTJN, Full Conference Program - FINALtjprogramsPas encore d'évaluation

- DR Hoon Park III - Indigenous Microorganism (IMO)Document33 pagesDR Hoon Park III - Indigenous Microorganism (IMO)neofrieda79100% (1)

- CASE DIGEST GAISANO CAGAYAN vs. INSURANCE COMPANY OF NORTH AMERICADocument3 pagesCASE DIGEST GAISANO CAGAYAN vs. INSURANCE COMPANY OF NORTH AMERICAclairePas encore d'évaluation

- Olivares VsDocument2 pagesOlivares VsDebbie YrreverrePas encore d'évaluation

- Intentions and Results ASFA and Incarcerated ParentsDocument10 pagesIntentions and Results ASFA and Incarcerated Parentsaflee123Pas encore d'évaluation

- BHP Billiton Petroleum Contract Letter For ABDUL SATTARDocument5 pagesBHP Billiton Petroleum Contract Letter For ABDUL SATTARAbdul SattarPas encore d'évaluation

- Microsoft Security Intelligence Report Volume 21 EnglishDocument180 pagesMicrosoft Security Intelligence Report Volume 21 EnglishAlejandro CadarsoPas encore d'évaluation

- Hmo Details November 2022 1Document6 pagesHmo Details November 2022 1Saad BelloPas encore d'évaluation

- Frequency Inverter: User's ManualDocument117 pagesFrequency Inverter: User's ManualCristiano SilvaPas encore d'évaluation

- Standerdised Tools of EducationDocument25 pagesStanderdised Tools of Educationeskays30100% (11)

- Electric Field Summary NotesDocument11 pagesElectric Field Summary NotesVoyce Xavier PehPas encore d'évaluation

- Amul Amul AmulDocument7 pagesAmul Amul Amulravikumarverma28Pas encore d'évaluation

- Varioklav Steam Sterilizer 75 S - 135 S Technical SpecificationsDocument10 pagesVarioklav Steam Sterilizer 75 S - 135 S Technical Specificationssagor sagorPas encore d'évaluation

- E10b MERCHANT NAVY CODE OF CONDUCTDocument1 pageE10b MERCHANT NAVY CODE OF CONDUCTssabih75Pas encore d'évaluation

- Maya Mendez ResumeDocument2 pagesMaya Mendez Resumeapi-520985654Pas encore d'évaluation

- Disorders of The Reproductive SystemDocument10 pagesDisorders of The Reproductive SystemRose Kathreen Quintans AuxteroPas encore d'évaluation

- Nfpa 502 Critical Velocity Vs Fffs EffectsDocument5 pagesNfpa 502 Critical Velocity Vs Fffs Effectsamir shokrPas encore d'évaluation

- Assignment On Inservice Education Sub: Community Health NursingDocument17 pagesAssignment On Inservice Education Sub: Community Health NursingPrity DeviPas encore d'évaluation

- Distress Manual PDFDocument51 pagesDistress Manual PDFEIRINI ZIGKIRIADOUPas encore d'évaluation

- Mobrey CLT PDFDocument18 pagesMobrey CLT PDFAnonymous Oydnu9Pas encore d'évaluation