Académique Documents

Professionnel Documents

Culture Documents

TECHNICAL NOTE 007 Structural Steel Sub-Grades JR, J0 and J2 Does It Matter

Transféré par

OM PRAKASH PALCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

TECHNICAL NOTE 007 Structural Steel Sub-Grades JR, J0 and J2 Does It Matter

Transféré par

OM PRAKASH PALDroits d'auteur :

Formats disponibles

TECHNICALNOTE007

Version02,Jul2013

KMS/TECHNICALDEPARTMENT

TECHNICALNOTE007

StructuralSteelSub-Grades

JR,J0&J2

DoesItMatter?

We excel through experience and learning Version02,Jul2013

Version01,Mar2011

01

Keywords

Brittle fracture, sub-grades, JR, J0, J2

Synopsis

After the replacement of BS 4360 by EN 10025 and EN 10113,

structural steel grades and sub-grades are specified using a

different system to designate different steel quality. In general

engineering design works, the steel grades and sub-grades are

specified by the Responsible Engineer, and all we have to do is

to procure the steel grades and sub-grades specified. However,

in Contractors design, we should understand in greater detail

the design implication of different steel sub-grades, noting

over-specified steel sub-grades by Contractors Designers might

lead to difficulty in timely procurement.

1.0 Introduction

A steel of high strength and low ductility is brittle.

Brittle fracture (see figures below) can occur in steel

components/structures subject to tensile stresses in low

temperature. In certain situations where inappropriate

fabrication conditions or low toughness weld materials are used,

brittle fracture can also occur at normal temperature. The

problem is mitigated by specifying steel and welded joints with

appropriate grades of facture toughness (or steel quality).

Brittle fracture at steel plates Brittle fracture at heavy welding

The following tables show the most common steel grades and

sub-grades with their former grade designation in BS 4360 for

reference.

EN 10025 BS 4360 EN 10025 BS 4360

S275 JR Grade 43B S355 JR Grade 50B

S275 J0 Grade 43C S355 J0 Grade 50C

S275 J2 Grade 43D S355 J2 Grade 50D

2.0 Sub-Grades JR, J0, J2

Steel sub-grades indicate the Charpy impact value

required to prevent brittle fracture.

JR Longitudinal Charpy V-notch impacts 27J at Room temp

J0 Longitudinal Charpy V-notch impacts 27J at 0C

J2 Longitudinal Charpy V-notch impacts 27J at -20C

Comparing to JR, J0 & J2 quality steels are able to exhibit the

same level of ductility (ie, absorbing 27J impact energy) at

lower temperatures (ie, 0C & -20C). It means that these

steels are of better quality against brittle fracture, and hence

more expensive. The following tables give an indication of the

percentage increase in material cost relative to S275 JR.

Steel Grade % Extra Steel Grade % Extra

S275 JR 0 S355 JR 3 %

S275 J0 3.5 % S355 J0 4 %

S275 J2 4 % S355 J2 10 %

In very general terms, JR steel material is most readily available

from stock and mill. It is also the lowest priced sub-grade and

so for maximum economy and availability, JR quality material

should be used whenever possible. Higher quality materials, J0

and J2, are not normally held in stock and might need ordering

directly from the mill. Time allowance for this should be made

in the procurement programme.

- End -

This technical note is for internal circulation only.

For enquiry, please contact

Gary Chou

KMS / Technical Manager

Technical Department

Chun Wo Construction & Engineering Co Ltd

E gary.chou@chunwo.com

T 3758 8379

F 2744 6937

Vous aimerez peut-être aussi

- Deflection Continuous Beams - Two Equal Spans With UDLDocument2 pagesDeflection Continuous Beams - Two Equal Spans With UDLAnamaria SuzanaPas encore d'évaluation

- 06 Eurocodes Steel Workshop WALDDocument136 pages06 Eurocodes Steel Workshop WALDFrancisco RojasPas encore d'évaluation

- Breakout StrengthDocument3 pagesBreakout StrengthwaquarstrPas encore d'évaluation

- Section 6 - Torque - TensionDocument23 pagesSection 6 - Torque - TensionChris MedeirosPas encore d'évaluation

- Eccentrically Loaded Weld Group Analysis: Company Name Sample Calculations YP and Address 8/1/21 C-Shape WeldDocument9 pagesEccentrically Loaded Weld Group Analysis: Company Name Sample Calculations YP and Address 8/1/21 C-Shape WeldDesign explorer olomizanaPas encore d'évaluation

- Weldind Grup WeldsDocument30 pagesWeldind Grup WeldsEndryjiuPas encore d'évaluation

- Slab Design of Partially Fixed Circular SlabDocument4 pagesSlab Design of Partially Fixed Circular SlabBithika DattaPas encore d'évaluation

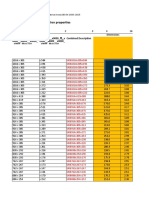

- Steel Section PropertiesDocument2 pagesSteel Section Propertiesman.drakePas encore d'évaluation

- Overall Buckling Behaviour and Design of High-Strength Steel Welded Section Columns, 2018 (Huiyong Ban)Document16 pagesOverall Buckling Behaviour and Design of High-Strength Steel Welded Section Columns, 2018 (Huiyong Ban)Phan Đào Hoàng HiệpPas encore d'évaluation

- Fire 7: Fire Resistance and Protection of Partially Encased Composite Column (Simple Calculation Models)Document50 pagesFire 7: Fire Resistance and Protection of Partially Encased Composite Column (Simple Calculation Models)vedranPas encore d'évaluation

- Steel ConnectionsDocument83 pagesSteel ConnectionsMEPPas encore d'évaluation

- Appendix - Ii: Principles of Construction, Material and Design of Ferrocement TankDocument5 pagesAppendix - Ii: Principles of Construction, Material and Design of Ferrocement TankbenzzenhdPas encore d'évaluation

- Example: Calculation of Effective Section Properties For A Cold-Formed Lipped Channel Section in BendingDocument10 pagesExample: Calculation of Effective Section Properties For A Cold-Formed Lipped Channel Section in BendingVarga ZoranPas encore d'évaluation

- Hilti-Fischer Anchor BoltDocument2 pagesHilti-Fischer Anchor Boltpavitrakedar100% (1)

- Is 1367 Part 7Document3 pagesIs 1367 Part 7Otavio1230% (1)

- Code Referenc E Calculations Outpu T Example 15 Design of Steel Column BaseplateDocument13 pagesCode Referenc E Calculations Outpu T Example 15 Design of Steel Column BaseplateMuriungi RicharsPas encore d'évaluation

- Composite Beam Design Intro Etabs PDFDocument6 pagesComposite Beam Design Intro Etabs PDFHumberto Estevez0% (1)

- Chun Wo - Technical Note 005Document3 pagesChun Wo - Technical Note 005Paul KwongPas encore d'évaluation

- Prestress End Block Design To CIRIADocument3 pagesPrestress End Block Design To CIRIAbalamurugan25011990Pas encore d'évaluation

- 5span Contineous BeamDocument22 pages5span Contineous BeamBilal Ahmed Barbhuiya100% (1)

- Fire 9: Fire Resistance and Protection of Totally Encased Composite ColumnDocument45 pagesFire 9: Fire Resistance and Protection of Totally Encased Composite ColumnvedranPas encore d'évaluation

- Exhibition Stand - REV 0Document12 pagesExhibition Stand - REV 0shibu4321Pas encore d'évaluation

- Danh Gia Lien Ket Ban de Chan Cot ThepDocument2 pagesDanh Gia Lien Ket Ban de Chan Cot ThepNguyen Duc CuongPas encore d'évaluation

- Screw TorquesDocument1 pageScrew Torquesaravindh1411Pas encore d'évaluation

- Corbel Design For Column : ProjectDocument2 pagesCorbel Design For Column : ProjectmayphyoPas encore d'évaluation

- Lattice TowerDocument15 pagesLattice TowerAmlan DasPas encore d'évaluation

- SX011a en GB Example Unrestrained Beam With End MomentsDocument9 pagesSX011a en GB Example Unrestrained Beam With End MomentsBenediktas DervinisPas encore d'évaluation

- App12 - ACI Meshed Slab and Wall DesignDocument51 pagesApp12 - ACI Meshed Slab and Wall DesignDario Manrique GamarraPas encore d'évaluation

- Jis 3193Document3 pagesJis 3193Angga KurniawanPas encore d'évaluation

- Deflections PortalsDocument9 pagesDeflections PortalsJim SpsPas encore d'évaluation

- BS 5276-2-2003Document20 pagesBS 5276-2-2003anoopkumarPas encore d'évaluation

- Spreadsheets To Ec2Document25 pagesSpreadsheets To Ec2mustafurade1Pas encore d'évaluation

- MAURER Spherical BearingsDocument9 pagesMAURER Spherical BearingsTiago Carvalho100% (1)

- Weld Strengths To BS5950 01.01.03Document1 pageWeld Strengths To BS5950 01.01.03Pallavi DalviPas encore d'évaluation

- Roof TrussDocument4 pagesRoof TrussShamie Dela Cruz CaldeaPas encore d'évaluation

- As Combined Stress Ratio Is Below 1 So Anchor Bolt Is OKDocument1 pageAs Combined Stress Ratio Is Below 1 So Anchor Bolt Is OKNaresh KumarPas encore d'évaluation

- Composite Beam Secondary: Construction StageDocument8 pagesComposite Beam Secondary: Construction StageSimon LsmPas encore d'évaluation

- Structural Sections SpreadsheetDocument74 pagesStructural Sections Spreadsheetpiper1985Pas encore d'évaluation

- Purlins Technical PDFDocument8 pagesPurlins Technical PDFРостислав ВасилевPas encore d'évaluation

- !! Stability Assessments According To Eurocode 3 PDFDocument106 pages!! Stability Assessments According To Eurocode 3 PDFAnonymous hprsT3WlPPas encore d'évaluation

- Lateral-Torsional Buckling of Cold-Formed Zed-Purlins Partial-Laterally Restrained by Metal SheetingDocument11 pagesLateral-Torsional Buckling of Cold-Formed Zed-Purlins Partial-Laterally Restrained by Metal SheetingReaditReaditPas encore d'évaluation

- Retrofitting Guideline Final 25 8 19Document86 pagesRetrofitting Guideline Final 25 8 19indranigogoiPas encore d'évaluation

- SX010a-En-EU-Example - Continuous Column in A Multi-Storey Building Using An H-Section or RHSDocument9 pagesSX010a-En-EU-Example - Continuous Column in A Multi-Storey Building Using An H-Section or RHSWPas encore d'évaluation

- Bolted Slip Resistant Connection EC3Document2 pagesBolted Slip Resistant Connection EC3cretz2Pas encore d'évaluation

- Steel Section WeightDocument25 pagesSteel Section WeightRoshan de Silva100% (1)

- Reinforced Concrete Column by Zinab EC2Document15 pagesReinforced Concrete Column by Zinab EC2berto2008Pas encore d'évaluation

- Sample Bolt CalculationDocument8 pagesSample Bolt CalculationEdmond ChowPas encore d'évaluation

- Bending of R.C BeamsDocument23 pagesBending of R.C BeamsHarold Jackson MtyanaPas encore d'évaluation

- Structural Steel Sub-Grades JR, J0 and J2 Does It Matter PDFDocument1 pageStructural Steel Sub-Grades JR, J0 and J2 Does It Matter PDFJafarPas encore d'évaluation

- Structural Steel Sub-Grades JR, J0 and J2 Does It MatterDocument1 pageStructural Steel Sub-Grades JR, J0 and J2 Does It MatterJafarPas encore d'évaluation

- Structural Steel Sub-Grades JR, J0 and J2 PDFDocument1 pageStructural Steel Sub-Grades JR, J0 and J2 PDFJafarPas encore d'évaluation

- Structural Steel Plate, Beams, Columns, Channels, Angles - S275, S355Document2 pagesStructural Steel Plate, Beams, Columns, Channels, Angles - S275, S355توفيق عبداللهPas encore d'évaluation

- Structural Steel Sub-Grades JR, J0 and J2 Does It MatterDocument1 pageStructural Steel Sub-Grades JR, J0 and J2 Does It MatterJafarPas encore d'évaluation

- Aar603 StructureDocument9 pagesAar603 StructureMUHAMMAD AQIL BIN RAMLIPas encore d'évaluation

- EN 10025 S355 SteelDocument3 pagesEN 10025 S355 SteelMuhsin KaharPas encore d'évaluation

- En 10025Document4 pagesEn 10025Jayesh83% (6)

- Section2 04Document16 pagesSection2 04swainpiyush123Pas encore d'évaluation

- 115-How To Specify SteelDocument2 pages115-How To Specify SteelTimmy VoPas encore d'évaluation

- EN10025 - Steel Grades SpecificationsDocument6 pagesEN10025 - Steel Grades SpecificationsFYPas encore d'évaluation

- Table of Material Properties For Structural Steel S235, S275, S355, S420Document4 pagesTable of Material Properties For Structural Steel S235, S275, S355, S420vodounnou0% (1)

- Ruukki Hot Rolled Steels Standard Steel Grades Comparison Designation and Codes1Document6 pagesRuukki Hot Rolled Steels Standard Steel Grades Comparison Designation and Codes1Cad AutocadPas encore d'évaluation

- En 10025Document16 pagesEn 10025Sorin Radu100% (1)

- Mpil RequirmentDocument1 pageMpil RequirmentOM PRAKASH PALPas encore d'évaluation

- Ever - Sendai C On Strtjction Pvt. LTD: Vtyvfi/1Document6 pagesEver - Sendai C On Strtjction Pvt. LTD: Vtyvfi/1OM PRAKASH PALPas encore d'évaluation

- En 10025Document4 pagesEn 10025Jayesh83% (6)

- Non-Alloy Structural Steels: Mechanical Properties Available DimensionsDocument1 pageNon-Alloy Structural Steels: Mechanical Properties Available DimensionsOM PRAKASH PALPas encore d'évaluation

- Material Grade Comparison Chart PDFDocument1 pageMaterial Grade Comparison Chart PDFHelen Kate Saccuan100% (1)

- Rework Report FabDocument1 pageRework Report FabOM PRAKASH PALPas encore d'évaluation

- Surface Finish TerminologyDocument30 pagesSurface Finish TerminologyXin YuPas encore d'évaluation

- Design Calculation of Spillway GateDocument11 pagesDesign Calculation of Spillway GateAnonymous sfkedkymPas encore d'évaluation

- Sprinkler Cabinets 3, 6, & 12 Sprinklers, 1/2 or 3/4 Inch NPT 6 ESFR Sprinklers, 3/4 or 1 Inch NPT General Description Technical DataDocument4 pagesSprinkler Cabinets 3, 6, & 12 Sprinklers, 1/2 or 3/4 Inch NPT 6 ESFR Sprinklers, 3/4 or 1 Inch NPT General Description Technical Datacarlos vegaPas encore d'évaluation

- Zinc-Coated Steel Strand For Messenger Support of Figure 8 CableDocument3 pagesZinc-Coated Steel Strand For Messenger Support of Figure 8 CableDarwin DarmawanPas encore d'évaluation

- 5231R 06Document13 pages5231R 06BddbvffffnhebrbbrPas encore d'évaluation

- Asphalt Mix ProductionDocument26 pagesAsphalt Mix ProductionRatih D Shima100% (1)

- Strong Suit of Midas Civil For Malaysian Bridge Engineers: MIDAS Technical Support SystemDocument2 pagesStrong Suit of Midas Civil For Malaysian Bridge Engineers: MIDAS Technical Support SystemjunjiangPas encore d'évaluation

- Renold SMX Gearbox PDFDocument24 pagesRenold SMX Gearbox PDFAnonymous T7zEN6iLHPas encore d'évaluation

- Bored Pile Construction - ChrisDocument38 pagesBored Pile Construction - ChrisTerry Choi100% (2)

- Dale Sinclair (Author) - Guide To Using The RIBA Plan of Work 2013-RIBA Publishing (2019) PDFDocument121 pagesDale Sinclair (Author) - Guide To Using The RIBA Plan of Work 2013-RIBA Publishing (2019) PDFPalaPas encore d'évaluation

- Stress Assessment of Skew Composite Steel I-Girder Bridge: Kapil Kumar Gupta, Shashivendra DulawatDocument9 pagesStress Assessment of Skew Composite Steel I-Girder Bridge: Kapil Kumar Gupta, Shashivendra DulawatkapilshwetaPas encore d'évaluation

- 547315-En 1.0.0Document160 pages547315-En 1.0.0Jose MustienesPas encore d'évaluation

- Damp Prevention in BuildingsDocument43 pagesDamp Prevention in Buildingswaterproofing_best100% (3)

- Dolebury End: Dolberrow, Churchill, BS25 5NSDocument4 pagesDolebury End: Dolberrow, Churchill, BS25 5NSFace shePas encore d'évaluation

- A Study On Creep and Drying Shrinkage of High Performance ConcreteDocument4 pagesA Study On Creep and Drying Shrinkage of High Performance Concreteit does not exist for the [mpossiblePas encore d'évaluation

- Welding Olet As ASME B31.3Document1 pageWelding Olet As ASME B31.3Mohd Effiezool YaserPas encore d'évaluation

- 5.1 Site Description and LocationDocument14 pages5.1 Site Description and LocationSigfred FabellonPas encore d'évaluation

- Lincoln Weld Directory C2.10Document32 pagesLincoln Weld Directory C2.10edgarpato100% (1)

- IRC Clauses For Retaining WallsDocument2 pagesIRC Clauses For Retaining WallsAvnish raiPas encore d'évaluation

- Chapter 6 Lateral Torsional Buckling: 6.2 Elastic Beams 6.2.1 Buckling of Elastic BeamsDocument51 pagesChapter 6 Lateral Torsional Buckling: 6.2 Elastic Beams 6.2.1 Buckling of Elastic BeamsabadittadessePas encore d'évaluation

- 03 Monthly Progress Report May 2022 Rev 00Document38 pages03 Monthly Progress Report May 2022 Rev 00Raj KamatPas encore d'évaluation

- Forest EngineeringDocument78 pagesForest EngineeringPrakash KanivePas encore d'évaluation

- BP (Method Statement) - 2Document5 pagesBP (Method Statement) - 2khraieric16Pas encore d'évaluation

- FormulaeDocument10 pagesFormulaeCisum ErupPas encore d'évaluation

- Kitz Stainless Steel Catalog New PDFDocument58 pagesKitz Stainless Steel Catalog New PDFel_apache10Pas encore d'évaluation

- Detailed Project ReportDocument117 pagesDetailed Project ReportShrikant BudholiaPas encore d'évaluation

- Cost in House ConstructionDocument32 pagesCost in House ConstructionSj interiorPas encore d'évaluation

- Toilet: Layout Toilet With Tanggulan Layout Accesible Toilet With TanggulanDocument1 pageToilet: Layout Toilet With Tanggulan Layout Accesible Toilet With TanggulanhendriPas encore d'évaluation

- Chapter 11Document12 pagesChapter 11Erika Rose LaronPas encore d'évaluation

- ELECT-TIC-2.1 - (Material Receiving Inspection For MV Power Cables & Accessories)Document2 pagesELECT-TIC-2.1 - (Material Receiving Inspection For MV Power Cables & Accessories)Muhammad IrfanPas encore d'évaluation

- Pump Jack/Ladder Jack Scaffold Photo Compliance GuideDocument33 pagesPump Jack/Ladder Jack Scaffold Photo Compliance GuideDharmendra RajanPas encore d'évaluation

- Advanced Modelling Techniques in Structural DesignD'EverandAdvanced Modelling Techniques in Structural DesignÉvaluation : 5 sur 5 étoiles5/5 (3)

- A Welder’s Handbook to Robotic ProgrammingD'EverandA Welder’s Handbook to Robotic ProgrammingÉvaluation : 5 sur 5 étoiles5/5 (3)

- Arduino: The complete guide to Arduino for beginners, including projects, tips, tricks, and programming!D'EverandArduino: The complete guide to Arduino for beginners, including projects, tips, tricks, and programming!Évaluation : 4 sur 5 étoiles4/5 (3)

- Pocket Guide to Flanges, Fittings, and Piping DataD'EverandPocket Guide to Flanges, Fittings, and Piping DataÉvaluation : 3.5 sur 5 étoiles3.5/5 (22)

- To Engineer Is Human: The Role of Failure in Successful DesignD'EverandTo Engineer Is Human: The Role of Failure in Successful DesignÉvaluation : 4 sur 5 étoiles4/5 (138)

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindD'EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindPas encore d'évaluation

- Marine Structural Design CalculationsD'EverandMarine Structural Design CalculationsÉvaluation : 4.5 sur 5 étoiles4.5/5 (13)

- Structural Cross Sections: Analysis and DesignD'EverandStructural Cross Sections: Analysis and DesignÉvaluation : 4.5 sur 5 étoiles4.5/5 (19)

- Carpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresD'EverandCarpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresÉvaluation : 1 sur 5 étoiles1/5 (2)

- Artificial Intelligence: From Medieval Robots to Neural NetworksD'EverandArtificial Intelligence: From Medieval Robots to Neural NetworksÉvaluation : 4 sur 5 étoiles4/5 (3)

- Green Roofs, Facades, and Vegetative Systems: Safety Aspects in the StandardsD'EverandGreen Roofs, Facades, and Vegetative Systems: Safety Aspects in the StandardsPas encore d'évaluation

- Structural Steel Design to Eurocode 3 and AISC SpecificationsD'EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsPas encore d'évaluation

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureD'EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureÉvaluation : 4.5 sur 5 étoiles4.5/5 (2)

- Artificial Intelligence: The Complete Beginner’s Guide to the Future of A.I.D'EverandArtificial Intelligence: The Complete Beginner’s Guide to the Future of A.I.Évaluation : 4 sur 5 étoiles4/5 (5)

- Flow-Induced Vibrations: Classifications and Lessons from Practical ExperiencesD'EverandFlow-Induced Vibrations: Classifications and Lessons from Practical ExperiencesTomomichi NakamuraÉvaluation : 4.5 sur 5 étoiles4.5/5 (4)

- Dark Aeon: Transhumanism and the War Against HumanityD'EverandDark Aeon: Transhumanism and the War Against HumanityÉvaluation : 5 sur 5 étoiles5/5 (1)

- Artificial Intelligence: Learning about Chatbots, Robotics, and Other Business ApplicationsD'EverandArtificial Intelligence: Learning about Chatbots, Robotics, and Other Business ApplicationsÉvaluation : 5 sur 5 étoiles5/5 (3)

- Pile Design and Construction Rules of ThumbD'EverandPile Design and Construction Rules of ThumbÉvaluation : 4.5 sur 5 étoiles4.5/5 (15)

- How to Survive a Robot Uprising: Tips on Defending Yourself Against the Coming RebellionD'EverandHow to Survive a Robot Uprising: Tips on Defending Yourself Against the Coming RebellionÉvaluation : 3.5 sur 5 étoiles3.5/5 (129)