Académique Documents

Professionnel Documents

Culture Documents

Furukawa Hydraulic Crawler Drill 1000 EDS11 PDF

Transféré par

Marco PezziniDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Furukawa Hydraulic Crawler Drill 1000 EDS11 PDF

Transféré par

Marco PezziniDroits d'auteur :

Formats disponibles

1

FRDFurukawa reserves right to change specifications without prior notice.

3-14, 2-chome, Nihonbashi Muromachi, Chuo-ku, Tokyo 103-0022, J apan

Phone+81-3-3231-6982 Fax+81-3-3231-6994

HCR1000-EDS-E0908-F2

Printed in J apan

Drilling Performer, HCR1000-EDS

Hi h d ti it & D bilit

Advanced drifter system

HD709 Dual-Damper System

High-productivity & Durability

Dual-Damper SystemDDS

Compact valve design

Newlydesigned piston

Dual-Damper

The Ultimate Combination of Performance and Economy The Ultimate Combination of Performance and Economy

Drill faster and straight with the patented HD709 drifter Drill faster and straight with the patented HD709 drifter

The Furukawa HD700 series drifter

is designed to minimize drill noise

and vibration without sacrificing

performance. Incorporating a new

piston design, the HD709 drifter

maximizes energy transmission and

drills effectively in a variety of rock

types.

FRD has developed the Dual-Damper System, a

first in the industry. For maximumenergy transfer,

active DDS minimizes returnof shock waves by

keepingthe bit firmlyagainst the rock at all times

during drilling. Active DDS minimizes percussion

energy loss and by optimizing the overall feedforce,

greatlyimproved the life of drilling accessories. An

additional benefit is greatly improvedlife of drilling

accessories.

Active DDS (U.S. Patent No.5,896,937)minimizes.

C l d i Compact valve design

A compact shuttle valve minimizes loss of oil

pressure and maintains total power output of the

drifter.

Reverse Percussion System

The Reverse Percussion System(RPS) makes it

easier to free a stuck rod. A substantial increase in

extractionforce allows the fieldproven RPS

(optional) to remove stuck rods quickly.

1 2

2

Easy handling rod changer

The all hydro-mechanical In-Line design is field

proven. Rod change speed is improvedover previous

design. J oystick operated rodchanger assures fast

High capacity compressor &

Dust collector

High-output compressor increases flushingair,

provides faster drilling and decreases bit wear.

Maximizes operator performance with Maximizes operator performance with

the ultimate in drilling technology the ultimate in drilling technology rodchanging.

p g

The upgraded dust collector has a suction capacity

higher than previous models. The dust collector

includes an effectivepre-cleaner to reduce the escape

of drilling dust. An optional dust suppression systemis

available for difficult drilling conditions.

the ultimate in drilling technology. the ultimate in drilling technology.

Dust collector

Lowemission engine

Powerful CAT

engine is fully compliant withTier

3/ Euro stage-3emission control.

Advanced hydraulic & Pneumatic

system

Thanks to advanced hydraulic and pneumatic

technology, output energy canbe transferredto each

t ith i i l Th t

J oystick rod changer

Extension boom

Extensionboomincreases

drilling pattern flexibility.

Slidingsuctioncap

Hydraulic centralizer

Pre-cleaner (optional)

Sliding suctioncap can be raisedto allowa fast visual

check of operation

Caterpillar and Cat are registered trademarks of Caterpillar Inc.

Power saving selector

component with minimumpower loss. These systems

support high productivity.

Heavy duty undercarriage

Stable chassiscombininga lowcenter of gravity,

highground clearance and protectedundercarriage

enhances stabilityand confidence when tramming

anddrilling on rough terrain.

Heavy-duty undercarriage

check of operation.

3

Power-saving selector

Byusingpower-saving selector, fuel consumption

rate is reduced during light work condition.

Standard :2,200min

-1

Power-saving:2,000min

-1

y y g

featuringa pentagonal

sectiondesign to reduce dirt

build-up and track wear

ensures strengthand

durability.

4

Meter panel Right side control box

J oystick drillingcontrol

Feel speedadjust dial

Feedpressure adjust dial

S i h

Combining performance and economy. Combining performance and economy.

Starter switch

Enginethrottle adjust dial

Enginediagnostic lights

Pressurecontrol adjust dials

Air conditioner control panel

Horn

Ashtray

Operators Seat

Hi-back operators seat with

f b i h l t d

ROPS - FOPS cab

The standardROPS/FOPS cabprovides large

i d t th f t d th i ht id i i

IMS monitor

Enginecoolant temperature

gauge

Compressor discharge air

temperaturegauge

Hydraulic temperature gauge

Enginehour meter

Enginetachometer

2dimensional electric angle

indicator (optional)

(Intelligent Monitoring

S t )

Left side control box

J oystick rod changer

Air flushing

Greaselubricationswitch

Hoodandcentralizer switch

fabric upholstery and arm

rests holds the operator in an

optimumposition all day.

Joystick operation

A single muti-functionlever

controls all the drilling

windows at the front and on the right side maximize

operator visibility. Cab is air conditioned and

pressurized with filter air to keepout dust.

Control panel for air conditioner

System)

IMS is always monitoring

machine conditions and

supports trouble shoots

for operator and

mechanics. IMS supports

to reduce daily

maintenance time and

down time.

Pillar mounted gauges

Mode selector switch

Anti-jammingswitch

Compressor startingswitch

Hydraulic oil heatingswitch

Oscillatinglock switch

Safetylock lever

Cabdoor release lever

functions.

AM/FM radio Cabwindow

Pillar mounted gauges

Percussionpressure gauge

Feedforce pressure gauge

Rotationpressure gauge

Flushingair pressure gauge

Angle indicator

Tilt guide angle indicator Swingguide angle indicator

J oystick drillingcontrol

Boomslide lever

Oscillating/ guide slide lever

Guidetilt / guideswing lever

Boomlift / boomswing lever

Travel levers (with pedal)

AM/FMradio

Front, roof wiper andwasher switches

Front, rear floodlightswitches

ROPS:Roll-Over Protective Structures

FOPS:Falling-ObjectProtective Structures

5 6

g g gg g

(optional)

Angle indicator for quick and easydrilling alignment.

3

Accessibility

for

Maintenance

Walk-around, ground-level maintenance provides fast, easy upkeep

or repair. Hinged service doors provide easy access to required areas.

Maintenance & Safety Maintenance & Safety

Access to the right side cover

Fully opened access cover makes access to

the radiator, the grease can and the drilling

control valves easier.

Access to the left side cover

Service for the engine, the electric control

panel can be made fromthe left side access

cover.

Hydraulic locklever Cabheadguard Synthetic hose reel &Wear plate for carriage

Unlock

Lock

Access to the rear cover

Filters are within the reach.

The hydraulic lock lever is a

safetydevicewhich stops the

travelingfunction, andthe

functionof the rodchanger

control lever.

Roof is reinforcedand

overheadwindowis steel

gaugeprotected.

Extends hose life, ensures

longer service life and

reduces service load.

Synthetic wear plates for

carriage.

Fire extinguisher Fanguard Angle indicator Hose junctions

Unlock

Access to the upper cover

Locatedat rear-right-sideof

the cab.

Fanguards andbelt guards

are standard.

Angleindicator is standard. Longhoses are junction

connectedfor lifeandservice.

7 8

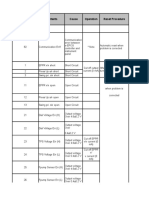

Dimensions mm

Model HCR1000-EDS

Drifter

HD709 standard

Dual-Damper system standard

Reverse percussion Optional

Guide shell

Hydraulic centralizer Standard

Slidingsuction cap Standard

Standard & Optional equipments Drilling coverage

Horizontal drilling coverage

Specifications

Synthetic hose reel Standard

Synthetic wear plate for carriage Optional

Rod changer

Length of rod

10ft Select

12ft Select

Rodsize

32H, 38R (T38) Select

38H, 45R (T45) Select

MM/ MF rod Select

Rotator Standard

Boom

Extendable boom Standard

Undercarriage

Tripleshoe Optional

Singleshoe Standard

Liftingeyes for transportation Optional

Weight&

Dimensions

Operating weight with ROPS/FOPS cab 11,990 kg

Overall length 9,215 mm

Overall width 2,930 mm

Overall width (transportation) 2,400 mm

Overall height 3,086 mm

Overall height (transportation) 2,950 mm

Drifter

Model HD709

Weight 185 kg

Number of percussion 2,250 - 2,500 min-1

Number of rotation 0- 250 min-1

Undercarriage

Track length 2,825 mm

Ground contact length 2,175 mm

Widthof shoe 300 mm

Grand clearance 550 mm

Oscillatingangle 10

g y p p

Dust collector

Pre-cleaner Optional

Foldingbracket for pre-cleaner Optional

Exhaust shutter Optional

Sinter-lamellar filter Optional

Cab

ROPS/FOPS cab Standard

High-backedseat Standard

Suspensionseat Optional

AM/FMradio Standard

Intelligent Monitoring System Standard

Intellligent Monitoring System2 Optional

Sidedoor mirror Optional

Air conditioner Standard

RotatinglightYellow Optional

Vertical drilling coverage

Oscillatingangle 10

Travelingspeed 0- 3.8 km/h

Gradability 57.7%( 30)

Engine

Make &Model CATERPILLAR C7

Type

Water-cooled, direct injection, 6-cylinders,

air to air after cooled, turbo-charged, diesel

Output / speed 168 kW/ 2,200 min-1

Fuel tank capacity 320 L

Hydraulic pump

Variable displacement piston pump 2

Gear pump 3

Hydraulic oil tank capacity 170 L

Compressor

Model PDS265-S35A (AIRMAN)

Type Screw1-stage forced oil lubrication

Free air delivery 6.1 m3/min

Workingair pressure 1.03 Mpa

M d l J E326

Optional equipment

g g p

Leveler Standard

Seat belt Standard

Rear viewmonitoring cameraBlack / White) Optional

Rear viewmonitoring cameraColor) Optional

Additional lights70 W x 2 Optional

Catwalk Standard

Foldingcatwalk Optional

Fireextinguisher Standard

Evacuationhammer Optional

Control

Boomcontrol Standard

J oystick control for percussion, feed and rotation Standard

Integrated DrillingSystemIDS-2 Optional

ActiveDual-Damper Standard

Anti-jammingsystemfor air flow Standard

Boom

Model J E326

Type Extension boom

Boomlift angle Up40 Down28

Boomswing angle Right35 Left10

Boomslide length 1,200 mm

Guide shell

Model GH831-31

Length 7,675 mm

Feed length with R/P 10ft. : Option 4,227 mm(4,052mm)

Feed length with R/P 12ft. : Standard 4,727 mm(4,552mm)

Guide slide length 1,500 mm

Guide swing Right30 Left90

Guide tilt angle 180

Max. rod pull force 24.5 kN

Feed type Hydraulically operated chain drive

Dust collector

Suction capacity 20 m3/min

ReversePercussion Foldingcatwalk

Anti-jammingsystemfor air pressure Standard

Anti-jammingsystemfor rotationpressure Standard

J oystick controlledrod changer Standard

Manual over-ride for rod changer Standard

Automatic oscillationlock Standard

Engine throttle dial Standard

Back-up buzzer Standard

Auto throttle control for percussion and air flow Standard

Others

Tiltguide angle indicator Standard

Swingguide angle indicator Optional

2Dimensional electric angle indicator Optional

Water tank for water injectionsystem Optional

Emergency shut down system Optional

Hour meter for engine Standard

10

Dust collector

Number of filter 4

Rodarrangement

Type Rodchanger

Number of rod 5

Control lever 1

Bit &Rod

Recommended bit diameter 65 - 90 mm

Type of bit Cross, Button, Ballistic, Conical

Size of rod 32H,38R,45R,(38H)

Length of rod 3,050 mm(10 ft.) or 3,660 mm(12 ft.)

Starter rod (Max) 4,000 mm(14 ft.)

Caterpillar and Cat are registeredtrademarks of Caterpillar Inc. The contents of this specifications are subject to change without notice inthe

future.

9

Additional lights70Wx2 Heavyduty under cover

Hour meter for drifter Optional

Tool box Optional

Heavyduty under cover Optional

Water separator for engine Standard

Auto air release valve for compressor Optional

Winter package Optional

Highcapacity battery Optional

Power saving mode selector Standard

Vous aimerez peut-être aussi

- Hydraulics and Pneumatics: A Technician's and Engineer's GuideD'EverandHydraulics and Pneumatics: A Technician's and Engineer's GuideÉvaluation : 4 sur 5 étoiles4/5 (8)

- Cold Milling Machine W 1900: Efficient Milling in The 2-m ClassDocument16 pagesCold Milling Machine W 1900: Efficient Milling in The 2-m ClassAly Abdelhamed100% (2)

- V A35d A40d Lowp 211 4170 0304Document8 pagesV A35d A40d Lowp 211 4170 0304ahmad fikriPas encore d'évaluation

- C6 RS6 Engine Wiring DiagramsDocument30 pagesC6 RS6 Engine Wiring DiagramsArtur Arturowski100% (3)

- HCR 1200 IIDocument4 pagesHCR 1200 IIRolando Vera100% (2)

- 900-DSII - 910-DS - 1200-DSIII - Hydraulic and Pneumatic System AdjustmentDocument115 pages900-DSII - 910-DS - 1200-DSIII - Hydraulic and Pneumatic System Adjustmentphuocloi82100% (3)

- Mu 14055Document413 pagesMu 14055oleg-spb100% (2)

- D275A-5 - KomatsuDocument6 pagesD275A-5 - KomatsuRoean NaudePas encore d'évaluation

- Doosan DX300LC excavator specs & dimensionsDocument8 pagesDoosan DX300LC excavator specs & dimensionsMega Indra PermanaPas encore d'évaluation

- 950G Wheel Loader: - Electro-Hydraulic Implement SystemDocument24 pages950G Wheel Loader: - Electro-Hydraulic Implement Systempuput utomoPas encore d'évaluation

- Hue Truch of DenoDocument136 pagesHue Truch of DenoKhincho ayePas encore d'évaluation

- RANGER 500 Technical SpecsDocument4 pagesRANGER 500 Technical SpecsWilman CFPas encore d'évaluation

- Doosan DX225LCA Workshop ManualDocument792 pagesDoosan DX225LCA Workshop ManualPhomma Khinphommavong100% (1)

- Sysmex Xs-800i1000i Instructions For Use User's ManualDocument210 pagesSysmex Xs-800i1000i Instructions For Use User's ManualSean Chen67% (6)

- ZX 350Document28 pagesZX 350Adi Gug100% (2)

- Iq TestDocument9 pagesIq TestAbu-Abdullah SameerPas encore d'évaluation

- The ultimate HCR1200 drilling machineDocument8 pagesThe ultimate HCR1200 drilling machineJorge Velarde LatorrePas encore d'évaluation

- A25F, A30F: Volvo Articulated HaulersDocument24 pagesA25F, A30F: Volvo Articulated HaulersSanPas encore d'évaluation

- Full Air Brake SystemDocument81 pagesFull Air Brake SystemMuhamad RifkyPas encore d'évaluation

- Oracle Learning ManagementDocument168 pagesOracle Learning ManagementAbhishek Singh TomarPas encore d'évaluation

- Rounded Scoodie Bobwilson123 PDFDocument3 pagesRounded Scoodie Bobwilson123 PDFStefania MoldoveanuPas encore d'évaluation

- DX300LC PDFDocument20 pagesDX300LC PDFAugusto OliveiraPas encore d'évaluation

- 01B Regla - Dynapac V6000TVEDocument152 pages01B Regla - Dynapac V6000TVERodrigo DíazPas encore d'évaluation

- HCR900ES Spec SheetDocument4 pagesHCR900ES Spec SheetDinh Phu LePas encore d'évaluation

- DX300LCDocument20 pagesDX300LCjohnmichph_95611836Pas encore d'évaluation

- Kawasaki 90zv BrochureDocument12 pagesKawasaki 90zv Brochuretraingheo300100% (1)

- Catalogue and Specifications For HCR910DSDocument8 pagesCatalogue and Specifications For HCR910DSAung Naing Oo100% (1)

- IR ECM 720HydraulicCrawlerDrill PDFDocument8 pagesIR ECM 720HydraulicCrawlerDrill PDFELMER100% (1)

- Hitachi ZX 190 W-3 PDFDocument28 pagesHitachi ZX 190 W-3 PDFjayPas encore d'évaluation

- Hcr1200 II SpecsDocument8 pagesHcr1200 II Specserica kPas encore d'évaluation

- Polyol polyether+NCO Isupur PDFDocument27 pagesPolyol polyether+NCO Isupur PDFswapon kumar shillPas encore d'évaluation

- RCS Rig Control System OverviewDocument17 pagesRCS Rig Control System Overviewrigoberto otinianoPas encore d'évaluation

- Xcentric Ripper Series Instruction Manual English (109E) PDFDocument85 pagesXcentric Ripper Series Instruction Manual English (109E) PDFwidiantoro7100% (1)

- Code Cause Operation Reset ProcedureDocument3 pagesCode Cause Operation Reset ProcedureAdi M100% (1)

- Doosan Trauble ShootingDocument7 pagesDoosan Trauble Shootingjacklyn ade putra100% (1)

- 345 Modo de ServicioDocument8 pages345 Modo de ServicioJordan RaveloPas encore d'évaluation

- Unit Injector - Install: Disassembly and AssemblyDocument13 pagesUnit Injector - Install: Disassembly and AssemblyAnung Nugroho100% (1)

- Quantification of Dell S Competitive AdvantageDocument3 pagesQuantification of Dell S Competitive AdvantageSandeep Yadav50% (2)

- 70ziv2 BrochureDocument12 pages70ziv2 Brochurekiko100% (1)

- TheEconomist 2023 04 01Document297 pagesTheEconomist 2023 04 01Sh FPas encore d'évaluation

- General InfoDocument78 pagesGeneral Infoibnu100% (2)

- Spec EC460B INT EN 30E4351646Document16 pagesSpec EC460B INT EN 30E4351646Stroia Constantin MariusPas encore d'évaluation

- HCR 900 EsiiDocument7 pagesHCR 900 Esiinyoman bennyPas encore d'évaluation

- Omm - Wa380z-6 PDFDocument297 pagesOmm - Wa380z-6 PDFVirginia D. Tortal100% (1)

- Single Drum Soil Compactor: JCB 116DDocument2 pagesSingle Drum Soil Compactor: JCB 116DMuhammad ShofaPas encore d'évaluation

- Hydraulic Attachments for ExcavatorsDocument20 pagesHydraulic Attachments for Excavatorspraghuprasad3861Pas encore d'évaluation

- Bomag bw219Document2 pagesBomag bw219ZabdyRA YT0% (1)

- Hitachi EX270LC-5 Excavator Service Repair Manual PDFDocument12 pagesHitachi EX270LC-5 Excavator Service Repair Manual PDFfhjskemmdmPas encore d'évaluation

- Hitachi Zaxis 330CLDocument5 pagesHitachi Zaxis 330CL111111100% (1)

- A35DContainerHauler EnglishDocument6 pagesA35DContainerHauler Englishandreika1970Pas encore d'évaluation

- Product Brochure Volvo A35E, A40EDocument28 pagesProduct Brochure Volvo A35E, A40EmnowaqPas encore d'évaluation

- 02 zx-6 Isuzu Engine En-08Document76 pages02 zx-6 Isuzu Engine En-08Srdjan NikolicPas encore d'évaluation

- TR-500EX: Tadano LTDDocument6 pagesTR-500EX: Tadano LTDMuhammadFaridPas encore d'évaluation

- DX700 Product SpecDocument4 pagesDX700 Product SpecshPas encore d'évaluation

- Wa470 5 PDFDocument12 pagesWa470 5 PDFDino Oporto PrudencioPas encore d'évaluation

- ROC LS and ROC LS: Master of Productivity and FlexibllityDocument7 pagesROC LS and ROC LS: Master of Productivity and FlexibllityenricoPas encore d'évaluation

- Roc F7Cr & Roc F9Cr: Atlas Copco Surface Drill RigsDocument8 pagesRoc F7Cr & Roc F9Cr: Atlas Copco Surface Drill RigsVenerable DezzyPas encore d'évaluation

- Spek ZX350Document2 pagesSpek ZX350Sigit Adi P100% (1)

- Ether Injection Control SolenoidDocument3 pagesEther Injection Control SolenoidBlowby HighPas encore d'évaluation

- Cat 320 D LLRDocument16 pagesCat 320 D LLRLuis Dilan QE AY100% (1)

- Wiring Diagram SCH10: Valid For Serial Numbers Model Production Site Serial Number Start Serial Number StopDocument3 pagesWiring Diagram SCH10: Valid For Serial Numbers Model Production Site Serial Number Start Serial Number StopKorneliusPas encore d'évaluation

- Doosan DX520LC Hydraulic ExcavatorDocument3 pagesDoosan DX520LC Hydraulic ExcavatorDidik HartadiPas encore d'évaluation

- FX 1000 User S Manual 2Document328 pagesFX 1000 User S Manual 2jacobbritto100% (1)

- Caterpillar Excabadora 246d Diagrama HydraDocument11 pagesCaterpillar Excabadora 246d Diagrama Hydrahitler morales gavidia100% (1)

- TB A944CHD-U enGB 10-03 7426-0Document14 pagesTB A944CHD-U enGB 10-03 7426-0Roger TrujilloPas encore d'évaluation

- The New Generation ZAXIS-3 Series Hydraulic ExcavatorDocument24 pagesThe New Generation ZAXIS-3 Series Hydraulic ExcavatorElvis Justo Choquegonza GomezPas encore d'évaluation

- v400 Operator's Manual PDFDocument120 pagesv400 Operator's Manual PDFEpure Gabriel100% (3)

- 2018 - sh330 6 sh330lc 6 sh350hd 6 sh350lhd 6 t3Document14 pages2018 - sh330 6 sh330lc 6 sh350hd 6 sh350lhd 6 t3Ralf Maurer50% (2)

- Kami Export - BuildingtheTranscontinentalRailroadWEBQUESTUsesQRCodes-1Document3 pagesKami Export - BuildingtheTranscontinentalRailroadWEBQUESTUsesQRCodes-1Anna HattenPas encore d'évaluation

- Software Requirements Specification: Chaitanya Bharathi Institute of TechnologyDocument20 pagesSoftware Requirements Specification: Chaitanya Bharathi Institute of TechnologyHima Bindhu BusireddyPas encore d'évaluation

- Zelev 1Document2 pagesZelev 1evansparrowPas encore d'évaluation

- BPL Millipacs 2mm Hardmetrics RarDocument3 pagesBPL Millipacs 2mm Hardmetrics RarGunter BragaPas encore d'évaluation

- Rtsa 2012Document7 pagesRtsa 2012Justin RobinsonPas encore d'évaluation

- HCW22 PDFDocument4 pagesHCW22 PDFJerryPPas encore d'évaluation

- Radio Frequency Transmitter Type 1: System OperationDocument2 pagesRadio Frequency Transmitter Type 1: System OperationAnonymous qjoKrp0oPas encore d'évaluation

- Family Service and Progress Record: Daughter SeptemberDocument29 pagesFamily Service and Progress Record: Daughter SeptemberKathleen Kae Carmona TanPas encore d'évaluation

- SEG Newsletter 65 2006 AprilDocument48 pagesSEG Newsletter 65 2006 AprilMilton Agustin GonzagaPas encore d'évaluation

- DECA IMP GuidelinesDocument6 pagesDECA IMP GuidelinesVuNguyen313Pas encore d'évaluation

- PRODUCTDocument82 pagesPRODUCTSrishti AggarwalPas encore d'évaluation

- Clark DietrichDocument110 pagesClark Dietrichikirby77Pas encore d'évaluation

- Neuropsychological Deficits in Disordered Screen Use Behaviours - A Systematic Review and Meta-AnalysisDocument32 pagesNeuropsychological Deficits in Disordered Screen Use Behaviours - A Systematic Review and Meta-AnalysisBang Pedro HattrickmerchPas encore d'évaluation

- To Introduce BgjgjgmyselfDocument2 pagesTo Introduce Bgjgjgmyselflikith333Pas encore d'évaluation

- GlastonburyDocument4 pagesGlastonburyfatimazahrarahmani02Pas encore d'évaluation

- Survey Course OverviewDocument3 pagesSurvey Course OverviewAnil MarsaniPas encore d'évaluation

- Planning A Real Estate ProjectDocument81 pagesPlanning A Real Estate ProjectHaile SilasiePas encore d'évaluation

- Google Dorks For PentestingDocument11 pagesGoogle Dorks For PentestingClara Elizabeth Ochoa VicentePas encore d'évaluation

- RUJUKANDocument3 pagesRUJUKANMaryTibanPas encore d'évaluation

- GMWIN SoftwareDocument1 pageGMWIN SoftwareĐào Đình NamPas encore d'évaluation

- GROSS DOMESTIC PRODUCT STATISTICS (Report) - Powerpoint PresentationDocument37 pagesGROSS DOMESTIC PRODUCT STATISTICS (Report) - Powerpoint PresentationCyryhl GutlayPas encore d'évaluation

- Surgery Lecture - 01 Asepsis, Antisepsis & OperationDocument60 pagesSurgery Lecture - 01 Asepsis, Antisepsis & OperationChris QueiklinPas encore d'évaluation