Académique Documents

Professionnel Documents

Culture Documents

Bioplastic Market Summary

Transféré par

vmshanes0 évaluation0% ont trouvé ce document utile (0 vote)

13 vues2 pagesenvironmental issues

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentenvironmental issues

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

13 vues2 pagesBioplastic Market Summary

Transféré par

vmshanesenvironmental issues

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 2

This report provides an analysis and evaluation of the current and

prospective opportunities surrounding engineer-grade bioplastics, specifically those

opportunities associated with Eugene Chens technology enabling the rapid

production of acrylic bioplastics by organic catalysts.

The global use of bioplastics was 0.64 million metric tons in 2010 and 0.85

million metric tons in 2011. Analysts expect that the use of bioplastics will increase

up to 3.7 million metric tons by 2016, a compound annual growth rate (CAGR) of

34.3%. The European market segment accounted for around 34% of the global

market in 2010 and was nearly 0.21 million metric tons. This segment increased to

0.3 million metric tons in 2011 and will further grow to 1.2 million metric tons in

2016, a CAGR of 32.1%. The American market accounted for around 37.5% of the

total market in 2010 and was 0.24 million metric tons. Analysts have forecasted

that the American market will increase from 0.3 million metric tons in 2011 to 1.2

million metric tons by 2016, a CAGR of 33%.

Interest in making best use of natural resourcesas a means to reduce

society's reliance on synthetic petroleum-based chemicalsis increasing due to the

general interest in a low-carbon economy. In some cases, the driver for using more

bio-based chemicals will be the needs of these consumers. However, in many cases,

the benefits will be primarily for producers of chemicals and materials, or the end-

product OEMs (specifically the transportation and construction & utilities

industries), through benefits such as sourcing flexibility.

The current desire within the chemical industry to move to more bio-based

feedstocks is a clear trend; however, the reasons behind it are complex. A recent

survey of senior managers of miscellaneous chemical companies suggests there are

four key mega trends driving this change in the chemical industry

1

:

1. Development of a low-carbon economy

2. The need to enhance functionality and performance

3. Improvements in health and wellness

4. Globalization of people, products, and processes

The auto industry has been identified as a potential primary consumer of

end-products similar to that created by this technology specifically thermoplastics.

The auto industry is unique in that, although it represents a relatively small

1

Balmer, B. A Bio-based Future for the Chemicals and Materials Market. Frost and Sullivan. December 2011.

proportion of total usage of chemicals such as thermoplastics, it is one that chemical

companies are most keen to promote as a market that their products are used in.

Fabrication of plastics from naturally renewable feedstocks offers the

potential for a cost effective and sustainable alternative to petroleum-based plastics.

Biomass-derived polymers based on butyrolactone have been recognized as a

potential substitute for plastics derived from petroleum-based polyacrylics, but

systems suitable for large-scale production have not yet been developed.

Researchers at Colorado State University have addressed this problem by

developing a method to synthesize polymers from a class of renewable compounds.

The sustainability and advantageous properties exhibited by this technology make it

an excellent candidate to displace petroleum-based alternatives.

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (120)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Arc Basics - FA 2009 ISO 14175 Revised StandardDocument10 pagesArc Basics - FA 2009 ISO 14175 Revised StandardCatalinPas encore d'évaluation

- Operating CostingDocument7 pagesOperating CostingImnonePas encore d'évaluation

- GeneDocument4 pagesGenevmshanesPas encore d'évaluation

- Tetras Educare Study Notes Vol 22 PTC Part 1Document27 pagesTetras Educare Study Notes Vol 22 PTC Part 1vmshanesPas encore d'évaluation

- Lysosomes and Peroxisomes and GlyoxysomesDocument2 pagesLysosomes and Peroxisomes and Glyoxysomesalphabetagama713085100% (1)

- Lysosomes and Peroxisomes and GlyoxysomesDocument2 pagesLysosomes and Peroxisomes and Glyoxysomesalphabetagama713085100% (1)

- LysosomeDocument15 pagesLysosomevmshanesPas encore d'évaluation

- TETRAS Educare Study Notes Vol 30 CentrifugationDocument14 pagesTETRAS Educare Study Notes Vol 30 CentrifugationvmshanesPas encore d'évaluation

- RNA TypesDocument7 pagesRNA TypesvmshanesPas encore d'évaluation

- ChromosomesDocument1 pageChromosomesvmshanesPas encore d'évaluation

- Presentation 1Document3 pagesPresentation 1vmshanesPas encore d'évaluation

- 2Document2 pages2vmshanesPas encore d'évaluation

- DNA SequencingDocument7 pagesDNA SequencingvmshanesPas encore d'évaluation

- The Operon ModelDocument7 pagesThe Operon ModelvmshanesPas encore d'évaluation

- Characteristic and Exceptions of Genetic CodeDocument4 pagesCharacteristic and Exceptions of Genetic CodevmshanesPas encore d'évaluation

- Interactions Between Antigen and AntibodyDocument25 pagesInteractions Between Antigen and AntibodyvmshanesPas encore d'évaluation

- RibosomesDocument2 pagesRibosomesvmshanesPas encore d'évaluation

- Cloning VectorsDocument19 pagesCloning VectorsvmshanesPas encore d'évaluation

- Protein TransportDocument13 pagesProtein TransportvmshanesPas encore d'évaluation

- MitochondriaDocument21 pagesMitochondriavmshanesPas encore d'évaluation

- Golgi ComplexDocument8 pagesGolgi ComplexvmshanesPas encore d'évaluation

- LysosomeDocument15 pagesLysosomevmshanesPas encore d'évaluation

- The Central DogmaDocument8 pagesThe Central Dogmaalphabetagama713085Pas encore d'évaluation

- BioplasticsDocument8 pagesBioplasticsvmshanesPas encore d'évaluation

- Nucleosomes and TelomeresDocument5 pagesNucleosomes and TelomeresvmshanesPas encore d'évaluation

- Movement Across Plasma MembraneDocument3 pagesMovement Across Plasma MembranevmshanesPas encore d'évaluation

- NucleusDocument25 pagesNucleusvmshanesPas encore d'évaluation

- Cell OrganellesDocument16 pagesCell OrganellesvmshanesPas encore d'évaluation

- TETRAS Educare Study Notes Vol 28 CarbohydratesDocument36 pagesTETRAS Educare Study Notes Vol 28 CarbohydratesvmshanesPas encore d'évaluation

- MCQ in BiochemistryDocument6 pagesMCQ in Biochemistryvmshanes100% (1)

- BioplasticsDocument8 pagesBioplasticsvmshanesPas encore d'évaluation

- Sdpi-Renewable Energy Report-2022Document108 pagesSdpi-Renewable Energy Report-2022zeeshan aliPas encore d'évaluation

- Lend Lease Americas Fact Sheet March 2015Document2 pagesLend Lease Americas Fact Sheet March 2015Music ObsessedPas encore d'évaluation

- Tata Power HistoryDocument14 pagesTata Power Historyvinit2801Pas encore d'évaluation

- UPSCPORTAL Magazine Vol 17 September 2010 WWW - UpscportalDocument80 pagesUPSCPORTAL Magazine Vol 17 September 2010 WWW - UpscportalNishat AhmadPas encore d'évaluation

- APTRANSCO Technical Reference Book 2011 Vol IIDocument381 pagesAPTRANSCO Technical Reference Book 2011 Vol IIChandra SekharPas encore d'évaluation

- ES Audit CheckpointsDocument12 pagesES Audit CheckpointsAnonymous j5apk2AumPas encore d'évaluation

- ESPC GuideDocument223 pagesESPC GuidejoechengshPas encore d'évaluation

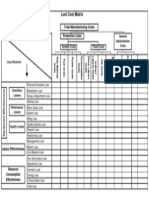

- Lost Cost Matrix: Total Manufacturing CostsDocument1 pageLost Cost Matrix: Total Manufacturing CostsMadhan KumarPas encore d'évaluation

- Orbit Article Molecular Sieve Dehydration Switching ValvesDocument12 pagesOrbit Article Molecular Sieve Dehydration Switching ValvesPasquale Sessa0% (1)

- GE Renewable Energy: Strategic ImplementationDocument12 pagesGE Renewable Energy: Strategic ImplementationApoorva SomaniPas encore d'évaluation

- Pema News 2004 enDocument8 pagesPema News 2004 enkorky1Pas encore d'évaluation

- Hyd Actua Device070110 1Document6 pagesHyd Actua Device070110 1Ashish SinglaPas encore d'évaluation

- Training Attendence SheetDocument34 pagesTraining Attendence SheetPrakash kumarTripathiPas encore d'évaluation

- Degree of ProtectionDocument3 pagesDegree of ProtectionSanjeewa HemaratnePas encore d'évaluation

- Каталог Remeza - 2015 Ганновер 2015 PDFDocument32 pagesКаталог Remeza - 2015 Ганновер 2015 PDFbinhleduc36Pas encore d'évaluation

- Qualification of ERW HFIDocument17 pagesQualification of ERW HFIovermach100% (1)

- Smart Grid Rational Read AheadDocument12 pagesSmart Grid Rational Read AheadJudkerrPas encore d'évaluation

- 2012 Flyer A5 SP en ES Sans PrixDocument48 pages2012 Flyer A5 SP en ES Sans PrixJose SantosPas encore d'évaluation

- Invitation Letter Petrolida 2021Document91 pagesInvitation Letter Petrolida 2021Stephen ZhengPas encore d'évaluation

- Cost Data 2024 Dated 08022024 - 240209 - 144302Document78 pagesCost Data 2024 Dated 08022024 - 240209 - 144302sreejitvpPas encore d'évaluation

- UNIDO Methodologies, Tools And: Networks For Partnership PromotionDocument19 pagesUNIDO Methodologies, Tools And: Networks For Partnership PromotionMauro MLRPas encore d'évaluation

- Oil & Gas AccountingDocument4 pagesOil & Gas AccountingFolakemi OgunyemiPas encore d'évaluation

- Irfan Khan ResumeDocument3 pagesIrfan Khan Resumemanisha guptaPas encore d'évaluation

- PLTGDocument20 pagesPLTGbeacon-docs100% (1)

- Rapport Annuel Cosumar 2019 Web en - ReduceDocument58 pagesRapport Annuel Cosumar 2019 Web en - ReduceVyrax FalconPas encore d'évaluation

- Safety Clearance For Transformer - Electrical Notes & ArticlesDocument5 pagesSafety Clearance For Transformer - Electrical Notes & ArticlessankhaginPas encore d'évaluation

- QAPDocument6 pagesQAPRahul ChandanPas encore d'évaluation

- Neptune Price List 7 August 2020Document11 pagesNeptune Price List 7 August 2020SUNILABHI_APPas encore d'évaluation