Académique Documents

Professionnel Documents

Culture Documents

Prediction of Available Rotation Capacity and Ductility of Wide-Flange Beams PDF

Transféré par

Skerdi MucoDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Prediction of Available Rotation Capacity and Ductility of Wide-Flange Beams PDF

Transféré par

Skerdi MucoDroits d'auteur :

Formats disponibles

Prediction of available rotation capacity and ductility of wide-ange beams: Part 1:

DUCTROT-M computer program

Victor Gioncu

a,

, Marius Mosoarca

a

, Anthimos Anastasiadis

b

a

Politehnica University of Timisoara, Timisoara, Romania

b

ASA Structural Consultants, Thessaloniki, Greece

a b s t r a c t a r t i c l e i n f o

Article history:

Received 12 January 2011

Accepted 29 June 2011

Available online 9 September 2011

Keywords:

Ductility

Rotation capacity

Local plastic mechanism

In-plane mechanism

Out-of-plane mechanism

Gradient moment

Quasi-constant moment

This paper is a development of the [1], presenting the newimprovements in determining the rotation capacity

of wide-ange beams. It deals with the available rotation capacity of steel beams, using the local plastic

mechanism methodology. For these purposes, a more advanced software was elaborated at the Politehnica

University of Timisoara, namely DUCTROT-M, substituting the old DUCTROT-96 computer program presented

in [1]. The new version considers two different forms the in-plane and out-of-plane plastic mechanisms, as

well as the application of gradient or quasi-constant moments. A CD-ROM containing the free DUCTROT-M

computer program can be nding in Appendix of [2] or free on the site [3]. Thus, the present paper is focused

on the phenomenological aspects of the utilized plastic collapse mechanisms, while the companion paper [41]

is devoted to applications in design practice exploiting the new capabilities of the aforementioned current

software version.

2011 Elsevier Ltd. All rights reserved.

1. Introduction

Today's challenge, for a proper seismic design, is to solve the

balance between seismic demand and structural capacity. Seismic

demand corresponds to the earthquake effect on the structure and

depends on the ground motion characteristics. Structural capacity is

the ability of the structure to resist these effects without failure.

Looking to the development on topics of Engineering Seismology and

Earthquake Engineering, it is very clear that the major efforts of

researchers were directed toward the structural response analysis.

Therefore, the structural response can be predicted fairly condently,

but these achievements remain without real effects if the accurate

determination of the seismic actions is doubtful. In fact, the prediction

of ground motions is still far from a satisfactory level, due to the

complexity of the seismic phenomena [2,4].

Hence, in the design of earthquake-resistant structures, the

structural designer is confronted with many uncertainties. The checks,

which are required to assure a suitable behavior of a structure during

a seismic attack, must be examined in the light of three levels of

design approach namely; serviceability, damageability and ultimate

limit states. For the rst two limit states the exceeding of design

values as compared with seismic actions cannot produces important

effects. In exchange, in case of severe earthquakes when the structure

attains the ultimate limit state or the near collapse behavior, the great

uncertainty due to the variability, dispersion and scatter, in the

evaluation of seismic design forces seems to be the rule and not the

exception. The result can be the total or partial structure collapse,

which is not accepted by the Seismic Design Philosophy.

In order to consider this situation, the structure must be endowed

by design with corresponding ability to develop and maintain its

bearing capacity, even when the considered seismic action exceeds

the design limits. A measure of this ability, named robustness, is the

ductility, which is the structural performance to sustain these

exceeding by large deformations in plastic range without signicant

loss of resistance. The ductility could be dened as a function of

loading type acting on the structure (monotonic or cyclic ductility).

The capacity to predict the available ductility particularly under

seismic loads is a key-point in structural design. A measure of the

ductility is the plastic rotation capacity of a section. Unfortunately, in

present design specications, there are no provisions concerning the

determination of this rotation capacity. Furthermore, the difference

between monotonic and cyclic ductility is not recognized. The

Eurocode 3 (EN 19931:2005) [5] proposes the classication of

structural cross-section into four ductility classes: ductile, compact,

semi-compact and slender. The same classication is also specied to

the Eurocode 8. Evidently only the rst three classes can be

considered for seismic design. The main critics of this classication

refer to the sole use of cross-section characteristics to determine the

ductility. Therefore, the 2005 Italian code [6] introduces classication

criterion into three ductility classes, ductile, plastic and slender, using

Journal of Constructional Steel Research 69 (2012) 819

Corresponding author. Tel.: +40 740470642; fax: +40 256226277.

E-mail address: vgioncu@clicknet.ro (V. Gioncu).

0143-974X/$ see front matter 2011 Elsevier Ltd. All rights reserved.

doi:10.1016/j.jcsr.2011.06.014

Contents lists available at ScienceDirect

Journal of Constructional Steel Research

the characteristics of steel members and based on the over-strength

factor.

In the frame of performance-based design a structure, under a

specic ground motion, is sized in order to behave within code

prescribed bounds. To achieve these levels of verication, the seismic

design is laid out through required available formulation [2]:

REQUIRED CAPACITY < AVAILABLE CAPACITY

Currently, the required-available pairs of three mechanical

characteristics are considered in earthquake resistant design, namely

rigidity, strength and ductility:

REQUIRED RIGIDITY < AVAILABLE RIGIDITY

REQUIRED STRENGTH < AVAILABLE STRENGTH

REQUIRED DUCTILITY < AVAILABLE DUCTILITY

:

In a coherent earthquake design strategy, the structure must be

veried for rigidity at serviceability level, for strength at the

damageability level and for ductility at ultimate limit state.

According to these verications, one can remark that, in the rst

two ones there are no difculties to perform these verications, but

for the last one, referring to ductility, the verication is far to be

satisfactory. The main reason is the difculty to dene the required

and available ductility which are based on the very vague codes

provisions [2]. In addition, the new design philosophy considers that

the required ductility must by dened in function of earthquake

characteristics [4]:

(i) Reduced ductility but high strength (reduced q factor) for

earthquakes with short duration and reduced number of cycles.

(ii) Moderate ductility and moderate strength (medium q factor)

for earthquakes with moderate duration and number of cycles;

(iii) High ductility but reduced strength (high q factor) for

earthquakes with long duration and large number of cycles.

where q is the behavior factor.

This classication, characterized by the reduced or large number of

cycles, is given in function of the structural capacity to dissipate

seismic energy. In this way, a comprehensive methodology is required

that takes into account the possibility to calculate the structural

ductility (reduced, moderate or high) depending on earthquake

characteristics. The aforementioned target is not allowed by the

existing code rules until now.

A solution to improve this situation is to dene the ductility using

the rotation capacity of structural members. Therefore, analytical or

numerical methodologies for determining the available rotation

capacity of steel members are of crucial importance for seismic

design. Among the existing methodologies (experimental, theoretical

and empirical), it was proved that the most efcient for design

purposes is the local plastic mechanism model based on yield lines

and plastic zones [1,2].

2. Investigations in local plastic mechanism models

During the experimental tests on the steel wide-ange beams one

can observe that the plastic deformations are produced only in a

limited zone. The rest part of the beam remains in elastic eld. In this

plastic zone large rotations are concentrated, working as plastic

hinges. The inelastic rotations are amplied if in these zones plastic

buckling of ange and web occurs. Two main buckling types were

distinguished during the experimental tests, the in-plane and out-of-

plane buckling modes [7] (Fig. 1).

After these rst experimental results, a series of tests, presented in

[1,2], were performed, conrming the obtained results. Two types of

beam specimens were used, with one or two transversal forces, also

having different moment variations in zones were plastic hinges are

considered to be formed. The rst loading systemmodels the moment

gradient while the second one, the constant moment. Important

differences between the obtained results are observed, indicating that

moment variation is an important factor in determining the beam

ductility.

Following this experimental results, a series of studies involved in

analytical expression of momentrotation curves in plastic range,

were performed. The rst application of the plastic mechanism

method can be considered the paper of Climenhaga and Johnson [8],

which considers the plastic hinge formed by ange and web. The

proposed model is in good correspondence with experimental tests.

The most important aspect of this paper is the fact that the both in-

plane and out-of-plane are considered. An important progress in

application of this methodology was performed by Ivanyi [9], based

on the principle of the virtual work in order to analyze the local plastic

mechanism. Kuhlmann [10] and Feldmann [11] proposed a plastic

mechanism for in-plane plastic buckling, in which the interaction of

ange and web is considered.

An intensive research work was started in Timisoara from 1989 to

determine the ductility of wide-ange members using the local plastic

Fig. 1. Plastic buckling types for standard beam SB 1 [1]: (a) In-plane buckling; (b) Out-of-plane buckling.

9 V. Gioncu et al. / Journal of Constructional Steel Research 69 (2012) 819

mechanism methodology, for both in-plane and out-of-plane plastic

buckling modes. The rst results, including the development of

computer programs POSTEL and DUCTROT 93, were published in

[12,13]. The research was continued and further results were

published [1], while a new improved version of computer program,

the DUCTROT-96, was elaborated. The proposed methodology allows

determining the rotation capacity and ductility in function of all

geometrical and mechanical parameters.

The main conclusion of these studies is that the plastic buckling

operates as a lter against large strains in tension ange, reducing the

danger of cracking. A synthesis of these research works and some

applications of this methodology were published in [1416].

Another step in research works performed at Timisoara University

was devoted to modify the collapse mechanism, mainly for improving

the dimensions of plastic zone of ange local mechanism and the

shape of web local mechanism. On the basis of these optimized local

plastic mechanisms, an evolution of the abovementioned software

was made with the elaboration in 2002 of DUCTROT-M computer

program [17]. With the aid of this one new series of studies were

performed and the results were published in [2,18]. A very good

correspondence between numerical results and experimental tests

was obtained further validating the accuracy of the DUCTROT-M.

Details concerning the new shape of plastic mechanisms for in-plane

and out-of-plane mechanisms can be found in [2]. Additionally, more

in depth investigations regarding the evaluation of the rotation

capacity of steel members were published in [1921].

In the last period, based on the development presented in [8], local

plastic mechanisms were proposed to study the behavior of steel

members under low-cycle fatigue [22,23], or re conditions [24].

3. DUCTROT-M computer program

3.1. Modeling the member behavior

The available rotation capacity must be determined taking into

account that the member belongs to a structure with a complex

behavior. But this is a very difcult task, due to the great number of

factors inuencing the behavior of the actual member. Thus, it is

important to simplify the analysis by using for the actual member a

simple substitute element with a very similar behavior. This member

is so named standard beam, used for the rst time in [1] to determine

the rotation capacity.

Fig. 2a shows the behavior of a framed structure, where the

inection points divide the beams into two portions, with positive and

negative bending moments. The rotation capacity of the beam ends

must be determined in different conditions. For positive moments, the

plastic hinge works in a zone with quasi-constant gradient, while for

negative moments, under important moment gradient (Fig. 2b).

Therefore, the actual behavior of a member in a structure can be

replaced with the similar behavior of two standard beamtypes: the SB

1, with a central concentrated load for the zone under quasi-linear

moment gradient, and the SB2, with a distributed load for the zone

with weak moment gradient (Fig. 2c). Considering that the inection

point is situated at (0.20.3) Lb, the relation between standard beam

span, L, and real beam in a structure, Lb, is:

Standard beam span, mm Beam span, mm

2000 35005000

3000 50007500

4000 650010,000

5000 800012,500

3.2. Computer performances

However, the present paper is focusedonly tothe phenomenological

aspects of the utilized collapse mechanisms which are considered as

a basis for the development of the aforementioned software. The

characteristics of DUCTROT-M computer program are published in

[2,18], where mainly all mathematical aspects are discussed.

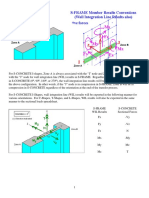

Fig. 3. DUCTROT-M computer program [2,18]: Analysis algorithm.

a)

b)

SB 2 SB 1

c)

Fig. 2. Using standard beams to determine rotation capacity [1,2]; (a) Structure

scheme; (b) Inuence of moment gradient; (c) Standard beam types.

10 V. Gioncu et al. / Journal of Constructional Steel Research 69 (2012) 819

The algorithm is presented in Fig. 3. The computer program

determines the following characteristics for wide ange members:

(i) General characteristics:

material characteristics considering the randomvariability of

superior limits for yield stress;

cross-section characteristics with the limits to prevent elastic

buckling and brittle fracture;

member characteristics considering loading systems (SB1

and SB2 standard beams), member span and axial force.

(ii) Ductility characteristics for monotonic loads:

two main curves of plastic buckling which determines in-

plane and out-of-plane plastic mechanisms;

momentrotation curves for the two mechanism types and

for gradient or quasi-constant moments;

determination of ultimate rotation and rotation capacity for

the dened level related to fully plastic moment (1.0 or 0.9);

main geometrical dimensions of plastic mechanism shape;

inuence of the beamcolumn connection details;

selectionbetweenin-planeandout-of-planeplastic mechanism;

Fig. 4. Evolution of local plastic mechanism shapes [2].

11 V. Gioncu et al. / Journal of Constructional Steel Research 69 (2012) 819

inuence of fabrication type: rolled or welded (let or

penetrated welds).

(iii) Ductility for seismic loads:

inuence of pulse loading, in function of strain-rate level and

exterior temperature;

inuence of cyclic loading, in function of cycle type

(increasing, constant or decreasing) and cycles number.

The present paper deals with the ductility dened under monotonic

loads. The principle that the results from monotonic actions can be also

used for seismic actions is accepted in the Eurocode 8 (earthquake

resistant design) by applying the same ductility classes prescribed in

Eurocode 3 (static design). In any case for exceptional seismic actions

with specic features, as pulse or multi-cycle characteristics, the

monotonic values must be corrected. The abovementioned topic

constitutes an open issue currently under investigation. However,

details for seismic effects on the available ductility can be found in [2].

The computer program DUCTROT-M is now free available on CD-

ROM as an appendix of the book [2] or free on the site [3].

4. Local plastic mechanisms for gradient moment

4.1. In-plane local plastic mechanism

This local plastic mechanism is characterized by deformation

situated in the beam plan, without lateral displacements of anges

(Fig. 1a). The shape of collapse mechanisms observed during the

experimental tests is composed by yield lines (true mechanism) or by

combination of yield lines and plastic zones (quasi-mechanism). The

last mechanism type involves a large amount of energy than the rst

type, due to the membrane yielding of plastic zone [2].

A progress in function of the attempt to transform the experi-

mental mechanisminto analytical and numerical models can be noted

(Fig. 4).

The Climenhaga and Johnson [8] as well as Ivanyi's [9] collapse

model is based on a perfect symmetry in relation with vertical axis,

and considers the length of ange and web plastic zone equal with the

ange width. The POSTEL [10] and DUCTROT 93 [13] computer

programs are based on these considerations.

Kuhlmann's model [10] is based only on yield lines, for symmetric

local plastic mechanisms, formed by plastic buckling of compressed

ange and compressed part of web. Feldmann's model [11] considers

only the collapse mechanism formed in compressed ange.

The version of DUCTROT-96 computer program was based on an

improved mechanism, implementing a more suitable shape for the

local plastic deformations of ange and web. However, examining

more careful the experimental tests [25] one can observe that the

opposite is true, namely the width of web plastic zone is different in

comparison with the ange one (Fig. 5a).

Therefore, the rst improvement in DUCTROT-M computer

program was to take into account this difference in the dimensions

of plastic zones of the ange and web.

The second improvement refers to the rotation point of web plastic

mechanism. The following cases are studied, considering the beam

column connection details:

- The mechanism type corresponding to the case when the shape of

mechanism is limited to the presence of the column ange or

vertical ribs (Fig. 5b).

- The formation of web shape plastic deformation is free, having no

imposed rotation point (Fig. 5c), in case of plastic hinge formed far

from column (cover plates or dog-bone solutions for beam

column connection).

The nal version of computer program, DUCTROT-M [2,3,17,18],

takes into consideration both of the above cases.

Making use of such shapes, some parametrical studies are

performed and the results were published in [1921].

For the standard beam SB 1 (Fig. 6a), the global plastic mechanism

is presented in Fig. 6b. It is composed by two local plastic mechanisms.

The mechanisms rotate around the rotation center O. An experimental

momentrotation curve is presented in Fig. 6c. There are some

important characteristic points which mark some signicant changes

regarding beambehavior. The rst point A refers to the reaching of the

ange yielding; the second one B is dened by the occurrence of fully

plastic moment. Moreover, in order to be developed the plastic hinge,

the rotation should be increased. At this stage an important

observation is that the increasing of bending moment over the fully

plastic moment is due to the strain-hardening behavior. The

maximum value for moment is reached in point C, when plastic

buckling occurs in the yielding zone of the compression ange and

web. In this step, the local plastic mechanism is formed. After point C

the bending begins to decrease with the increasing of rotation and the

equilibrium of the beam becomes unstable. The ultimate rotation

Length of flange

buckled shape

Length of web

buckled shape

Points of

rotation

Points of

rotation

a)

b)

c)

Fig. 5. Experimental aspects of local in-plane plastic mechanisms (modied after [25]);

(a) Relation between ange and web lengths of buckled shape; (b) Position of rotation

point in case of vertical ribs; (c) Position of rotation point in case of free conditions.

12 V. Gioncu et al. / Journal of Constructional Steel Research 69 (2012) 819

capacity is determined in the lowering post-buckling curve at the

intersection with the theoretical fully plastic moment (point O).

The theoretical momentrotation curve included in computer

program must reproduce the above experimental curve. Fig. 7

presents this curve, for which the elastic and plastic behavior can be

described by analytical relationships without any problems. The

difculties to complete the momentrotation curve are related to the

plastic post-buckling curve, referring to the degradation of moment

capacity due to the plastic buckling. For this purpose, the use of local

plastic mechanisms proved to be very operative. The maximum

moment results at the intersection of plastic and post-critical curves,

eroded by local geometrical and mechanical imperfections. The

ultimate rotation results at the intersection of this curve with the

line corresponding to fully plastic moment.

The local plastic mechanism shape is shown in Fig. 8a, being

composed by plastic zones and yield lines in compression ange

(Fig. 8b), web (Fig. 8c) and tension ange (Fig. 8d). The work of a

plastic mechanism implies that a larger amount of energy is absorbed

in the small area of plastic hinges and zones, therefore the other parts

can be neglected. The rigid-plastic analysis is based on the principle of

the minimumof total potential energy. The result of this analysis, after

some mathematical operations presented in [2], is the post-critical

curve of local plastic mechanism, described by the relationship:

M= Mp = A

1

+ A

2

1=2

1

Rotation

a)

b)

c)

Fig. 6. Local plastic mechanism for gradient moment [2]; (a) SB 1 standard beam;

(b) Local plastic mechanism; (c) Actual momentrotation curve.

Ultimate Rotation

rotation u

Fig. 7. Theoretical post-critical curve of local plastic mechanism.

Fig. 8. In-plane plastic mechanism[2]: (a) General view; (b) Compression ange plastic

mechanism; (c) Web plastic mechanism; (d) Tension ange plastic mechanism.

13 V. Gioncu et al. / Journal of Constructional Steel Research 69 (2012) 819

The coefcients A

1

and A

2

contain the mechanical and geometrical

characteristics of beams and the shape of plastic mechanism. They are

given in [2,3,18].

The post-critical curve depends of geometrical parameters of local

plastic mechanism. The length of mechanismis examined in [1], based

on theoretical studies and experimental data. The current version of

computer program takes into consideration these studies, keeping

unmodied the length of plastic mechanism. The inuence of other

parameters dening the shape of plastic mechanism is presented in

Fig. 9. The conclusions of this analysis are:

- The main dimension is the one dening the plastic zones of

compression ange and web (Fig. 9a), which presents a minimum

in determining the rotation capacity.

- The parameter dening the position of rotation point of plastic

mechanism shows a minimum for the position in the tension

ange (Fig. 9b).

- The asymmetry of mechanism shape produces an increasing of

rotation capacity, the minimum being obtained for symmetric

shape (Fig. 9c).

While the minimizing of the post-critical curve in function of the

rst two parameters is included in software's capabilities, for the last

parameter, which depends on the position of rotation point

determined by constructional details (Fig. 10), the characteristic of

Fig. 9. Geometrical parametrical study [2]: (a) Inuence of ange plastic zone;

(b) Inuence of rotation position; (c) Inuence of asymmetry of web plastic shape.

Fig. 10. Asymmetry of plastic mechanism[2]: (a) Column without continuity plates; (b)

Column with continuity plates; (c) Beam with cover plates.

Fig. 11. Determination of ultimate rotation for in-plane plastic mechanism using

DUCTROT-M computer program.

Compression zones of flanges

Tension zones of flanges

b)

a)

Fig. 12. Experimental shape for out-of-plane plastic mechanism: (a) View of plastic

mechanism (modied after [26]); (b) Lateral rotation of beam (modied after [27]).

14 V. Gioncu et al. / Journal of Constructional Steel Research 69 (2012) 819

local plastic mechanism asymmetry must be introduced in perfor-

mance data.

Fig. 11 shows the determination of in-plane rotation capacity using

the DUCTROT-M computer program.

4.2. Out-of-plane local plastic mechanism

This plastic mechanismis characterized by lateral displacements of

anges (Fig. 1b). The experimental shapes of out-of-plane plastic

deformation, named S-mechanisms, are presented in Fig. 12 [26,27].

Theoretical studies are given in [1,8,9]. This mechanism type is

produced by a free lateral rotation around the vertical axis (Fig. 13).

The majority of research works do not take into account the fact that

the joint could be restrained by elements to prevent the rotation.

However, in practical cases the formation of plastic mechanism also

involves the participation of the adjacent column. The Fig. 14 presents

details of this deformational condition, in the case when the column

presence has no any inuence. On the contrary case, see the

discussion presented [41]. The plastic mechanism is composed by

two plastic zones and yielding lines. The post-critical curve is

described by the relationship [2]:

M= Mp = B

1

+ B

2

1= 2

+ B

3

3= 4

2

where the coefcients B

1

, B

2

and B

3

are given in [2,3,18]. One can

remark that, comparing the Eq. (1), for in-plane mechanism, with

Eq. (2), for out-of-plane mechanism, an additional term appears,

producing a supplementary degradation in the post-buckling range.

The Fig. 15 shows the determination of out-of-plane rotation capacity,

Fig. 13. Out-of-plane plastic mechanisms.

Fig. 14. S-shaped plastic mechanism [2]: (a) General view; (b) Compression ange plastic mechanism; (c) Web plastic mechanism; (d) Tension ange mechanism.

Fig. 15. Determination of ultimate rotation capacity for out-of-plane mechanism using

DUCTROT-M computer program.

15 V. Gioncu et al. / Journal of Constructional Steel Research 69 (2012) 819

for the same prole as the one of Fig. 11. Obviously the rotation

capacity for out-of-plane is larger than the in-plane one, but the

degradation is higher.

4.3. Interaction between in-plane and out-of-plane local plastic

mechanisms

The experimental evidences [7] show that in majority of tests the

rst formed mechanism is the in-plane one, and only in the post-

buckling range the beam buckles in out-of-plane, due to considerably

weakened of ange rigidity, caused by the plastic deformations. Two

cases of interaction were distinguished (Fig. 16):

(i) The intersection of two post-buckling curves takes place under

the line M/Mp=1, when the rotation capacity is dened by in-

plane mechanism.

(ii) The intersection occurs over this line, and the rotation capacity

must be determined taking into account the interaction of

these two buckling modes and the rotation capacity is dened

by out-of-plane mechanism.

It is very well known that the coupling of two buckling forms can

increase the inuence of imperfections [28]. But this form of coupling

belongs to the category of weak interaction in post-critical range. In

this case the interaction could be neglected, being covered from the

Fig. 16. Interaction between in-plane and out-of-plane local plastic mechanisms; 1-In-

plane mechanism, 2-Out-of-plane mechanism.

a)

b)

c)

Fig. 17. Experimental shape for plastic mechanism under constant moments:

(a) Experimental test; (b) Local plastic mechanisms (modied after [30]);

(c) Experimental momentrotation curve.

Fig. 18. Local plastic mechanism for quasi-constant moments: (a) SB 2 standard beam;

(b) Local plastic mechanism.

Fig. 19. Determination of ultimate rotation using DUCTROT-M computer program.

16 V. Gioncu et al. / Journal of Constructional Steel Research 69 (2012) 819

scatter caused by other factors with higher inuence on rotation

capacity than this interaction [29].

5. Local plastic mechanisms for quasi-constant moment

The experimental data for determination the quasi-constant

moment are obtained from beams loaded by two loads [9,30,31]

(Fig. 17a). The local plastic mechanisms are formed by two symmetric

in-plane shapes (Fig. 17b). The typical experimental moment

rotation curve is shown in Fig. 17c. The standard beam to evaluate

the rotation capacity is presented in Fig. 18a, while the local plastic

mechanism in Fig. 18b. The determination of rotation capacity

utilizing the DUCTROT-M is given in Fig. 19. Generally, the rotation

capacity for quasi-constant moments is larger than the moment

gradient.

6. Denition of rotation capacity

In order to decide if a structural member has or no sufcient

ductility and to ensure a suitable response under different loading

conditions, the practice requires to dene some indicators. As such

can be the ductility index or rotation capacity. Concerning these

indicators one must recognize that there is no standard denition

which is universally accepted by all the specialists. However the most

rational denition is related to ultimate rotation [1]. The member

ductility is based on the determination of rotation capacity parameter

Fig. 20. Correlation theoreticalexperimental values for rotation capacity; (a) Lukey-Adams [7] and Kulhmann [10] experimental values; (b) Spangemaher [32], Boerave et al. [33],

Kemp [34] and Suzuki [35] experimental values.

17 V. Gioncu et al. / Journal of Constructional Steel Research 69 (2012) 819

R, dened as the ratio between plastic rotation at collapse

p

and the

elastic limit one

y

(

p

=

u

y

):

R =

p

=

y

: 3

This denition requires the calculation of ultimate rotation. With

the aid of DUCTROT-Mit is possible to determine the ultimate rotation

at the intersection of post-critical curve with the theoretical fully

plastic moment. The software facilitates the evaluation of the

available ultimate rotation or alternatively the non-dimensional

available rotation capacity under various geometrical, mechanical

and loading conditions.

7. Reliability of DUCTROT-M computer program

After the development process of a software the main question

that arises is mainly associated to the reliability of the provided

results. Accordingly, a comparison between theoretical results and

experimental tests reported in the technical literature, is performed.

The most important experimental tests are selected in [1,2] ([7,12,32

35]), numbering 81 specimens. A very careful examination of related

experimental values was carried out, also considering the possibility

of existence of some errors in these results, connected with the

following aspects [36]:

(i) Determination of material properties in plastic and hardening

ranges are less supervised than the ones in the pre-yielding

eld.

(ii) Measurement of rotation for elastic and plastic deformations

may introduce some errors due to testing arrangements.

(iii) Determination of ultimate rotation at the intersection between

the post-yielding curve and horizontal straight line corre-

sponding to full plastic moment results for a very small angle

between the two curves. Therefore, the measured values can be

determined with important errors.

Generally, in the stability problems, variation of results is very

large. For instance, in studies of Nakashima [37] referring to statistical

evaluation of steel strength, the coefcient of variation is 0.010.13,

while for ductility capacity, this coefcient is 0.541.35. Consequently,

a special methodology for validation of theoretical results must be

employed. The correlation between experimental data and numerical

results were performed. Applying a step by step analysis the

experimental data are processed considering rough, systematic or

aleatory errors of measurements [38]. Therefore, making use of this

methodology [39], in the rst step, the 6 experimental values obvious

wrong were eliminated. They are out of rational eld, from a group of

specimens having the same characteristics they have had values very

different from the other ones. For the remaining 75 data (with a

variation coefcient of 0.379), there are also some errors which can be

connected to the above difculties in measurements. Based on

probabilistic considerations and adopted a relevant trust levels

some the errors are recognized and eliminated. Furthermore, the

mean value, standard deviation and coefcient of variation are

determined. The elimination of wrong values is performed in two

steps, rstly 15 and secondly 5 data are excluded until a proper trust

level of P=0.95 as well as a coefcient of variation 0.185 was

obtained. The remaining 55 data offer a high level of correspondence

between experimental and theoretical results.

The correlation between the available experimental results, RE,

and the calculated rotation capacity, RC (using the DUCTROT-M

computer program) in given in Fig. 20a (for [7,10] experimental data)

and 20b (for [3235] experimental data). A distinction between in

plane and out-of plane mechanisms as reported form experimental

evidence is considered in statistical processing. It is remarked that, in

spite of a scatter area specic for the stability experimental data, the

correlation is good, giving condence in the developed local plastic

mechanism as a methodology for determining the available rotation

capacity.

With respect to the type of local plastic mechanism it should be

underline that the great majority of experiments (especially for rolled

sections) showan out-of-plane mechanism. This fact is also conrmed

by the numerical tests performed in [40], where the results came by

FEM analysis revealing that the dominant type of plastic buckling for

rolled standard beams is the out-of-plane collapse mechanism. This is

mainly due to the presence of a simple reinforcement situated under

the force, which has very weak torsional rigidity, allowing the lateral

displacements of buckled anges in report with the beamvertical axis.

8. Conclusions

The paper presents the progress of some issues developed in [1]

concerning the plastic collapse mechanism approach in determining

the available rotation capacity for wide-ange beams. It is described

the phenomenological inelastic behavior of the steel elements as

observed in experiments. Based on buckled shapes which are formed

by plastic zones and yielding lines some collapse mechanisms are

discussed. By a continuing improvement of those mechanism shapes

and after a long evolution a more advanced computer program the

DUCTROT-M is developed taking into account geometrical, mechan-

ical and loading parameters. In this way the paper is devoted to the

interpretation and modeling of the buckled shapes captured from

experimental evidence and furthermore investigated the improve-

ments as well as revalidated the models presented in [1]. Based on

those mechanisms in the companion paper [41] the application in

practical aspects of the DUCTROT-M will be presented. Through

parametrical studies on welded and rolled wide-ange steel beams

the available ductility under monotonic conditions were investigated

demonstrating the capabilities of the software to quantify the inelastic

capacity of such elements.

References

[1] Gioncu V, Petcu D. Available rotation capacity of wide-ange beams and beam

columns. Part1, Theoretical approaches, Part 2, Experimental and numerical tests. J

Constr Steel Res 1997;43(16118):21944.

[2] Gioncu V, Mazzolani FM. Ductility of seismic resistant steel structures. London:

Spon Press; 2002.

[3] D. Petcu, V. Gioncu. DUCTROT-M. Rotation capacity of steel members. INCERC

Timisoara. Politechnica University Timisoara, West University Timisoara;

20022011 http://web.info.uvt.ro/petcu/software.html#ductrot.

[4] Gioncu V, Mazzolani FM. Earthquake engineering for structural design. London:

Spon Press; 2011.

[5] EN 1993-1-1. Design of steel structures. Part 11: general rules and rules for

buildings. Rue de Stassart 36, B-1050: CEN Central Secretariat; 2005.

[6] OPCM 3431. First elements in the matter of general criteria for seismic

classication of the national territory and of technical codes for structures in

seismic zones. Ofcial Gazette of the Italian Republic; 2005.

[7] Lukey AF, Adams PF. Rotation capacity of beams under moment gradient. J Struct

Div 1969;95(ST 6):117388.

[8] Climenhaga JJ, Johnson RP. Momentrotation curves for locally buckling beams. J

Struct Div 1972;50(ST 9):123954.

[9] Ivanyi M. Moment rotation characteristics of locally buckling beams. Period

Polytech Civil Eng 1979;23(3/4):21730.

[10] Kuhlmann U. Rotationskapazitat biegebeanspruchter I-Prole unter Berucksichti-

gung des plastischen Beulens. Technical Report, No. 855. Bochum University,

Mitteilung; 1986.

[11] M. Feldmann. Zur Rotationskapazitat von I-Prolen statisch and dynamisch

belastung Trager. Doctoral dissertation. Aachen: RWTH University, 1994.

[12] Gioncu V, Mateescu G, Orasteanu O. Theoretical and experimental research

regarding the ductility of welded I-sections subjected to bending. Proceedings of

Stability of Metal Structures, SSRC Conference; 1989. p. 28998.

[13] Gioncu V, Mateescu G, Iuhas A. Contributions to the study of plastic rotational

capacity of I-steel sections. Proceedings of Behaviour of Steel Structures in Seismic

Areas; 1994. p. 16981.

[14] Gioncu V, Mateescu G, Petcu D, Anastasiadis A. Prediction of available ductility by

means of local plastic mechanism method: DUCTROT computer program. In:

Mazzolani FM, editor. Moment Resistant Connections of Steel Frames in Seismic

Areas. London: E & FN Spon; 2000. p. 95146.

[15] A. Anastasiadis. Ductility problems of steel moment resisting frames (in

Romanian), Doctoral dissertation. Timisoara: Faculty of Civil Engineering,

Politehnica University of Timisoara, 1999.

18 V. Gioncu et al. / Journal of Constructional Steel Research 69 (2012) 819

[16] Anastasiadis A, Gioncu V. Ductility of IPE and HEA beams and beamcolumns.

Proceedings of 6th International Colloquium on Stability and Ductility of Steel

Structures; 1999. p. 24957.

[17] Gioncu V, Petcu D. Improvement of shape of local plastic mechanism (in

Romanian). Report: INCERC; 2001.

[18] Petcu D, Gioncu V. Computer program for available ductility analysis of steel

structures. Compos Struct 2003;81:214964.

[19] Gioncu V. Inuence of constructional details on plastic buckling and ductility of

steel members. Proceedings of 8th International Colloquium on Stability and

Ductility of Steel Structures; 2006. p. 895901.

[20] Gioncu V. Parametrical studies on steel member ductility. Proceedings of

Conference Steel: A New and Traditional Material for Buildings; 2006. p. 5117.

[21] Gioncu V, Mosoarca M, Anastasiadis A. Proposal for increasing the ductility of steel

structures. Proceedings of Behaviour of Steel Structures in Seismic Areas; 2009.

p. 67984.

[22] Lee K, Stojadinovic B. Seismic rotation capacity and lateral bracing for US steel

moment connections. Proceedings of Behaviour of Steel Structures in Seismic

Areas; 2003. p. 33542.

[23] Lee K, Stojadinovic B. A plastic collapse method for evaluating rotation capacity of

full-restrained steel moment connections. Theor Appl Mech 2008;35:191214.

[24] Tan KH, Huang ZF, Dharma RB. Behaviour and modelling of composite columns

and beams under re conditions. Urban Habitat Constructions under Catastrophic

Events; 2007. p. 1724.

[25] SAC. Connection test summaries. Report No. SAC-96-02, SAC Joint Venture,

Sacramento, California; 1996 http://www.sacsteel.org/design/test-summaries.html.

[26] Mateescu G, Gioncu V. Member response to strong pulse seismic loading.

Behaviour of Steel Structures in Seismic Areas; 2000. p. 5562.

[27] Smith RJ, Adams PF. Experiments on wide-ange beams under moment gradient.

Structural Engineering Report no. 13. Alberta (CA): Department of Civil

Engineering, University of Alberta; 1968.

[28] Gioncu V. Phenomenological and mathematical modeling of coupled instabilities.

In: Rondal J, editor. Coupled Instabilities in Steel Structures, CIMS Courses Udine.

Wien: Spinger Verlag; 1998. p. 85149.

[29] Gioncu V, Tirca L, Petcu D. Interaction between in-plane and out-of-plane plastic

buckling of wide-ange section members. Proceedings of Coupled Instabilities in

Metal Structures; 1996. p. 27381.

[30] Hoglund T, Nylander H. Maximiforhallnde B/t for tryckt ans hos valsad I-balk vid

dimensionering med graslastruetod. Repoert 83/1970. Technical University of

Stockholm; 1970.

[31] Haaijer G, Thurlimann B. On inelastic buckling in steel. J Eng Mech Div, 84; 1958.

p. 147. no EM 2.

[32] R. Spangemacher, Zum rotationsnachweis von stahlkonstruktion, die nach dem

traglastverfahren berechnet werden. Doctoral dissertetion. Aachen: RWTH

University, 1991.

[33] Boerave Ph, Lognard B, Janss J, Gerardy JC, Schleich JB. Elastoplastic behaviour of

steel frameworks. J Constr Steel Res 1993;27:321.

[34] Kemp AR, Dekker NW. Available rotation capacity in steel and composite beams.

Struct Eng 1991;69:8897.

[35] Susuki T, Ogawa T, Ikaraski K. A study on local buckling behaviour of hybrid beams.

Thin Walled Struct 1994;19:33751.

[36] Gioncu V, Tirca L. Improved correlation between experimental data and numerical

results in ductility of steel members. Buletinul Stiintic al Universitatii Politehnica

din Timisoara 1996:619 Tom 41.

[37] Nakashima M. Variation of ductility capacity of steel beamcolumns. J Struct Eng

1994;120:194159.

[38] Rumshiskii LI. Mathematical processing of experimental data (in Romanian).

Bucuresti (Ro): Editura Tehnica Bucuresti; 1978.

[39] Gioncu V, Tirca L. Correlation between experimental data and numerical results in

ductility of steel members. Proceedings of Conference on Material Engineering;

1996. p. 93100.

[40] Espiga F. Numerical simulation on RWTH tests. Labein Technological Research

Center Report; 1997.

[41] Anastasiadis A, Mosoarca M, Gioncu V. Prediction of available rotation capacity

and ductility of wide-ange beams. Part 2: Applications. J Constr Steel Res

2012;69:819.

19 V. Gioncu et al. / Journal of Constructional Steel Research 69 (2012) 819

Vous aimerez peut-être aussi

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Builders Guide To CementDocument52 pagesBuilders Guide To CementSkerdi MucoPas encore d'évaluation

- Designers' Guide To Eurocode 2: Design of Concrete StructuresDocument242 pagesDesigners' Guide To Eurocode 2: Design of Concrete StructuresEmina LjubijankicPas encore d'évaluation

- Sika AnchorFix 1 PDSDocument8 pagesSika AnchorFix 1 PDSSkerdi MucoPas encore d'évaluation

- Analysis and Design of Bridge Using STAAD ProDocument156 pagesAnalysis and Design of Bridge Using STAAD Prorctorresh100% (2)

- Foundation Box and Walls FAEDocument9 pagesFoundation Box and Walls FAESkerdi MucoPas encore d'évaluation

- Three Dimensional Static and Dynamic Analysis of StructuresDocument423 pagesThree Dimensional Static and Dynamic Analysis of StructuresUsman SiddiquiPas encore d'évaluation

- Pushover Analysis of RC Frame Structure Using ETABS 9.7.1Document9 pagesPushover Analysis of RC Frame Structure Using ETABS 9.7.1Skerdi MucoPas encore d'évaluation

- CBR Pavement Design MethodDocument10 pagesCBR Pavement Design MethodSkerdi MucoPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Acomodacion y VergenciasDocument1 pageAcomodacion y VergenciasJeferson Alexander Pabon RodriguezPas encore d'évaluation

- Theil Index DecompositionDocument2 pagesTheil Index DecompositionshareevPas encore d'évaluation

- Wall Integration Conventions S-CONCRETE R11 S-FRAMEDocument3 pagesWall Integration Conventions S-CONCRETE R11 S-FRAMESyed RaziuddinPas encore d'évaluation

- William D. Penny - Signal Processing CourseDocument178 pagesWilliam D. Penny - Signal Processing Coursejomasool100% (1)

- PhysicsDocument396 pagesPhysicsGreeny34Pas encore d'évaluation

- Governing 11Document35 pagesGoverning 11rahul100% (2)

- DIL 805 Quenching Dilatometer BrochureDocument14 pagesDIL 805 Quenching Dilatometer BrochureDeniz ShenPas encore d'évaluation

- Che 0411 Steam Heat Exchangers Are UnderworkedDocument5 pagesChe 0411 Steam Heat Exchangers Are UnderworkedXpizmonPas encore d'évaluation

- Flow Conditioning PLatesDocument8 pagesFlow Conditioning PLatesGeethaPas encore d'évaluation

- A True Global Presence: Manual ClampingDocument346 pagesA True Global Presence: Manual ClampingIsaías AguilarPas encore d'évaluation

- Description and Use of LSODE, The Livermore Solver For Ordinary Differential EquationsDocument124 pagesDescription and Use of LSODE, The Livermore Solver For Ordinary Differential EquationsChristian CândidoPas encore d'évaluation

- RRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRDocument14 pagesRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRPranay GoswamiPas encore d'évaluation

- Comparacion Ansys CFX y TelemacDocument8 pagesComparacion Ansys CFX y TelemacOscar Choque JaqquehuaPas encore d'évaluation

- Chemical Reaction and Diffusion in A Spherical Onon-Isothermal Catalyst PelletDocument6 pagesChemical Reaction and Diffusion in A Spherical Onon-Isothermal Catalyst PelletMaximiliano Valenzuela LamPas encore d'évaluation

- ENGINEERING GRAPHICS (ENGINEERING DRAWING) by P.H.JainDocument8 pagesENGINEERING GRAPHICS (ENGINEERING DRAWING) by P.H.JainProf. P. H. Jain78% (9)

- Uv Disinfectant Storage Cabinet PDFDocument1 pageUv Disinfectant Storage Cabinet PDFnareshpaneruPas encore d'évaluation

- O3 Final ReportDocument109 pagesO3 Final ReportFaizan MirPas encore d'évaluation

- Evaluation of LS-DYNA Concrete Material Model 159Document209 pagesEvaluation of LS-DYNA Concrete Material Model 159SudathipTangwongchaiPas encore d'évaluation

- Noritake Value ShadeDocument4 pagesNoritake Value ShadeRobinson Vasquez Chavez100% (1)

- Psslope ManualDocument47 pagesPsslope ManualMed El Hadi AbidiPas encore d'évaluation

- Luke Diosiek Fun With Electricity and MagnetismDocument21 pagesLuke Diosiek Fun With Electricity and MagnetismseabluePas encore d'évaluation

- Process Control Servo SystemDocument16 pagesProcess Control Servo SystemCarlos RamirezPas encore d'évaluation

- Krasnov, Kiselev, Makarenko, Shikin - Mathematical Analysis For Engineers - Vol 2Document677 pagesKrasnov, Kiselev, Makarenko, Shikin - Mathematical Analysis For Engineers - Vol 2Lee TúPas encore d'évaluation

- Light and Shadow Quiz NameDocument4 pagesLight and Shadow Quiz Nameapi-490528795100% (1)

- EEG BCI For Dual Task Driving DetectionDocument9 pagesEEG BCI For Dual Task Driving DetectionBudi SetyawanPas encore d'évaluation

- tp5 Mixed Convection With 2 Movable WallsDocument6 pagestp5 Mixed Convection With 2 Movable WallsTahar ADJOUDJPas encore d'évaluation

- Science Matter Lesson PlanDocument2 pagesScience Matter Lesson Planapi-218287701100% (1)

- Analog Vs Digital DataDocument3 pagesAnalog Vs Digital Datanmuhunthan100% (1)

- Use of Fiber-Reinforced Soil For Blast ProtectionDocument16 pagesUse of Fiber-Reinforced Soil For Blast ProtectionSameer ShashwatPas encore d'évaluation

- 2012, AAG, Tachi - Interactive Freeform Design of TensegrityDocument10 pages2012, AAG, Tachi - Interactive Freeform Design of TensegrityPierre ClrPas encore d'évaluation