Académique Documents

Professionnel Documents

Culture Documents

UK (Euro) Air Burner Brochure

Transféré par

GIAN CARLO MAMANI GILES.Description originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

UK (Euro) Air Burner Brochure

Transféré par

GIAN CARLO MAMANI GILES.Droits d'auteur :

Formats disponibles

Air Curtain Burners

T TH HE E G GR RE EE EN N W WO OO OD D P PR RO OC CE ES SS SI IN NG G M MA AC CH HI IN NE ES S

Applications: (Subject to permit) Demolition - Forestry - Construction - Agriculture - Waste

Management - Manufacturing - Conservation - Disaster Relief - Disease Outbreak -

Military - Noxious Plants - Remote Location Waste Disposal - Oil Exploration

EUROPEAN & UK SPECIFIC MACHINES

enquiries@kingwell-holdings.co.uk www.kingwell-holdings.co.uk

UK, Ireland, Europe & Africa

Kingwell Holdings Ltd.

Cordons Farm Depot

Long Green

Cressing

Braintree

Essex

CM77 8DL

Phone 01376 550989

Fax 01376 551455

USA Headquarters:

Air Burners, LLC

4390 Cargo Way

Palm City, FL 34990

Phone 772-220-7303 or 888-566-3900

FAX 772-220-7302

E- mail

info@airburners.com Web

www.airburners.com

1998-2008, Air Burners, LLC.

The words Air Burners and the Air Burners Logo are Registered Trademarks of Air Burners, LLC.

All Rights Reserved. Subject to change without notice.

AIR BURNERS, LLC & KINGWELL HOLDINGS INFORMATION

Air Burners, LLC is the largest manufacturer of Air Curtain Burners in the world. The Com-

pany holds many patents on this system and for more than thirty years has been building

the most efficient and durable machines in the industry.

Reducing waste wood volume in landfill sites eliminates methane production from decompo-

sition, which is a major contributor to global warming. Landfill Tax is increasing year on year

and all other processing, handling and transport costs are rising. Air Burners provide an af-

fordable and environmentally sound alternative to disposal of wood waste into landfill.

Air Burner uses: (Subject to permit): Civil engineering & construction site clearance, Japa-

nese Knotweed and Rhododendron destruction, demolition wood waste processing, forestry

clearance, heathland creation, waste transfer & landfill sites. They are particularly suitable

for timber that is heavily contaminated with foreign objects as they are impervious to dam-

age from them.

They play an important role in many worldwide national contingency plans for dealing with

bio-security and catastrophic emergencies, storm or flood damage and to dispose of dis-

eased animal carcasses from outbreaks of BSE, FMD, H5N1 & CWD.

Our Air Curtain Systems have been engineered and manufactured to help reduce the envi-

ronmental impact of all types of waste timber and vegetation by volume reduction without

the need to shred, compost, chip or transport material to end-user or landfill.

They are environmentally friendly, have a low impact and low carbon footprint.

Air Burners are built to last, and incorporate state-of-the-art design and engineering con-

cepts to achieve maximum performance, reliability and return on investment, with minimum

running costs, maintenance, servicing and repair. They are over-engineered and all of the

machines have a modular design with every component made to be easily repaired or re-

placed in the field if damaged during use. There are no expensive electronics and very few

moving parts and they do not require specialist servicing or maintenance.

Air Burners have a design life of over 10 years and over 80% of all machines ever made are

still at work.

The Air Burners, LLC manufacturing facility is located in Palm City, Florida. Our engineering

staff use the latest 3D CAD software for our equipment designs and we constantly receive

feedback from both customers and our dealers so that we can quickly accommodate

changes to support our customers particular requirements and new developments.

The employees of Air Burners, LLC and Kingwell Holdings Ltd. are dedicated to maintaining

the high standard of customer service, design and manufacturing that has made us the rec-

ognised leader in air curtain burner equipment.

Our service quality, technical knowledge & customer support is your peace of mind.

AIR BURNERS, LLC PRODUCT BROCHURE KHL Version: 05.11.2008

AIR BURNERS, LLC PRODUCT BROCHURE KHL Version: 05.11.2008

UK SPECIFICATION S-SERIES FIRE BOXES

Designed for un-treated timber and vegetation, UK (European) Specification S-Series

machines (S-10, S-20 Euroburner and S-40) are all rated at a maximum through-put of

950kg per hour or below.

Please contact our in-house waste consultant for further assistance or information regarding

permits.

Customers should always work under the correct permit, license or consent, as applicable,

prior to carrying out any operations.

Air Burners use very high temperatures that safely and efficiently reduce wood and other

vegetation waste to a residual ash and dramatically reduce emissions from the burning proc-

ess. This process generally reduces the waste material volume by approximately 95%.

The refractory-lined fire box is the central component of this equipment and enables the

burning of wood at extremely high temperatures and prevents the machine from destroying

itself. This lining is far stronger than a standard kiln or incinerator lining and has taken many

years to develop. It is a unique feature and can only be found on machines manufactured by

Air Burners, LLC and will withstand many years of use. Beware of un-tested cheap copies.

The system is a very simple means of controlling the emissions from an existing open fire

and making it burn at a far higher temperature than if it were in the open. The area inside the

refractory walls has no floor and the system needs no flue, cover or firebox lid.

The patented air manifold system is mounted on the top side of one of the firebox walls and

the blower fan is powered by a small Diesel engine. The principle of the air curtain concept

works when high velocity air is directed across the top and downwards at an angle into the

firebox, creating a moving air curtain or invisible cover on top of the fire and a rotational tur-

bulence within the fire itself. This also provides an oxygen-enriched environment within the

combustion zone, which forces the fire on and accelerates the burning by raising the tem-

peratures within the fire to approximately 1,000 C. It is this extreme heat and over-

oxygenation that breaks down the chemical compounds and reduces the emissions.

The moving air curtain over the fire traps the smoke and continuously returns it into the com-

bustion zone until it is virtually all destroyed. This achieves nearly 100% combustion with

minimal particulate. The refractory walls also aid in the process by retaining and reflecting

the high temperatures generated within the chamber, which then acts like an oven to raise

temperature levels still further. The volume of material that can be processed per hour de-

pends on the density, size and moisture content of the waste wood.

The burners are skid-mounted, self-contained, fully assembled and require no set-up. They

can either be used in a semi-permanent position or dragged around a site. The machines are

loaded over the top, by dropping material through the curtain of air that stops the emissions,

usually by an excavator and grapple. Ash removal is from the rear doors of the firebox, usu-

ally by excavator and bucket and is carried out daily.

Once cooled, metal and aggregate can be recovered from the ash and recycled to reduce

the volume still further and bring additional value to the recycling operation.

AIR BURNERS, LLC PRODUCT BROCHURE KHL Version: 05.11.2008

AIR BURNER ADVANTAGES & WORKING DIAGRAM

- Low purchase and running costs and a long working lifespan + high resale value.

- Safe to use, quick to set up and very reliable.

- Very strong construction for continuous site use and impervious to foreign objects.

- Easy to move for mobile operation - such as demolition or site clearance.

- Low fuel consumption and very quiet when operating.

- Low carbon emissions & low environmental impact. No methane emissions.

- Prevent waste wood from going to landfill.

- Reduce wood waste by 95% to inert ash.

- Recover and recycle metal from waste wood with little mechanical effort.

- Aggregate from the ash can be recovered and recycled.

- Ash from the burner can be recycled or tipped.

- Trucks used on wood transport to tip are now freed up for other work.

- Free up yard space - no need to stockpile waste timber.

- Scavenge free heat from the burner to heat water, dry waste, aggregate & soils.

- No need to shred or compact wood before processing.

- (Air Burners are Not suitable for woodchip, mulch or sawdust).

HOW DOES AN AIR BURNER WORK?

1. Air curtain manifold directs high velocity air across and into the firebox.

2. Hard refractory lined wall to contain fire and increase burn temperature.

3. Material being burned is agitated by the airflow.

4. Continuous airflow forms a high velocity curtain or cover over fire.

5. Continued air flow over-oxygenates fire to maintain high temperatures.

AIR BURNERS, LLC PRODUCT BROCHURE KHL Version: 05.11.2008

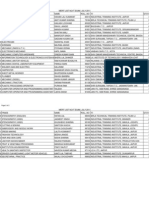

UK (EUROPEAN) SERIES AIR BURNER SPECIFICATIONS

1.

Fan Engine

Kubota V2003-TE Tier 2 (56 HP) or equivalent diesel engine. Full enclosure

with lockable control panel. 400 Hour service intervals

2.

Safety Features

Low oil pressure and low coolant shutdown. Over temperature shutdown. Anti-

slip deck floor. Lockable control panel

3.

Fan Drive Train

Engine mounted PTO with direct coupling drive and manual clutch to engage

4.

Fire Box

102 mm thick walls. Refractory panels with hard thermal ceramic lining

5.

Electric System

12 V DC with engine mounted alternator and battery isolation switch

6.

Instrument Panel

Key switch, tachometer, hour meter, fuel gauge, oil pressure and water tem-

perature indicators with safety shutdown features and adjustable locking throt-

tle

7.

Air Fan

Custom fan. Solid metal blades and guarded air intake

8.

Manifold

Minimum 3.2 mm steel, solid-weld assembly, with bash plate protection

9.

Skid Deck

12.7 mm steel plate, all solid-weld construction

10.

Fuel Tank

265 liters capacity

11.

Transportation & Set-

up

Ready for immediate use. Skid mounted for site movement and has no floor. 2

doors at rear for ash removal. Lifting points provided for crane lifting

12.

Options

Firebox safety mesh screen. Engine deck security enclosure. Transport skid for

hook-lift equipment. Heat recovery.

13.

Maximum Through-put

S-10: 650kg per hr. S-20 Euroburner: 650kg per hr. S-40: 950kg per hr

14.

Overall Weight

S-10: 9,300 kg. S-20 Euroburner 11,800 kg. S-40: 13,600kg

15.

Dimensions - Overall

L W H

S-10: 5.7m 2.2m 2.3m. S-20 Euroburner: 8.3m 2.2m 2.3m.

S-40: 8.2m x 2.6m x 2.6m

16.

Dimensions - Fire Box

L W H

S-10: 3.3m 1.5m 1.8m. S-20 Euroburner: 4.9m 1.5m 1.8m.

S-40: 5m x 1.9m x 2.2m

Note: All weights and dimensions are approximate. Subject to change without notice.

AIR BURNERS, LLC PRODUCT BROCHURE KHL Version: 05.11.2008

Purchase or Hire an Air Burner - UK Operations

Please contact us if you wish to hire a burner on long or short term contract or if you

wish to purchase.

We can advise you on the correct model and application to exactly suit your needs.

With many Air Burner, LLC machines operating in the UK, our strength and experi-

ence is un-rivaled.

We have our own in-house waste consultant who can advise or take on permit

applications on behalf of clients and organisations where required.

We can provide loading equipment and highly trained staff to carry out operations.

Flexible transport systems are available - hook-lift, low-loader or crane to flat-bed.

Full training for your operators is always provided for purchase and hire.

Multiple machines are available on our hire fleet.

We usually have a selection of used equipment available for immediate sale.

Repairs, servicing and major overhaul work can always be undertaken.

For customers from outside the UK or concerning other issues such as emergency

relief or disease outbreak, we offer a confidential and rapid response to your enquiry.

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Manual Pajero 4x4 Service BrakesDocument70 pagesManual Pajero 4x4 Service BrakesGIAN CARLO MAMANI GILES.Pas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Testing SoftwareDocument54 pagesTesting SoftwareGIAN CARLO MAMANI GILES.Pas encore d'évaluation

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Manual Pajero 4x4 Engine and Emision ControlDocument48 pagesManual Pajero 4x4 Engine and Emision ControlGIAN CARLO MAMANI GILES.Pas encore d'évaluation

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Manual Pajero 4x4 Front SuspentionDocument16 pagesManual Pajero 4x4 Front SuspentionGIAN CARLO MAMANI GILES.Pas encore d'évaluation

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Manual Mitsubishi Pajero 4x4 Propeler ShaftDocument8 pagesManual Mitsubishi Pajero 4x4 Propeler ShaftGIAN CARLO MAMANI GILES.Pas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Manual Mitsubishi Pajero 4x4 Engine CoolingDocument18 pagesManual Mitsubishi Pajero 4x4 Engine CoolingGIAN CARLO MAMANI GILES.100% (1)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Manual Mitsubishi Pajero 4x4 Interior and SuplyDocument62 pagesManual Mitsubishi Pajero 4x4 Interior and SuplyGIAN CARLO MAMANI GILES.Pas encore d'évaluation

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Manual Pajero 4x4 Rear AxleDocument32 pagesManual Pajero 4x4 Rear AxleGIAN CARLO MAMANI GILES.Pas encore d'évaluation

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Manual - Pajero4x4rear SuspentionsDocument8 pagesManual - Pajero4x4rear SuspentionsGIAN CARLO MAMANI GILES.Pas encore d'évaluation

- Manual Pajero 4x4 ExteriorDocument32 pagesManual Pajero 4x4 ExteriorGIAN CARLO MAMANI GILES.Pas encore d'évaluation

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Manual Pajero 4x4 ClutchDocument8 pagesManual Pajero 4x4 ClutchGIAN CARLO MAMANI GILES.Pas encore d'évaluation

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- Manual Pajero 4x4 Intake and ExhaustDocument20 pagesManual Pajero 4x4 Intake and ExhaustGIAN CARLO MAMANI GILES.Pas encore d'évaluation

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Manual Pajero 4x4 Power PlantDocument10 pagesManual Pajero 4x4 Power PlantGIAN CARLO MAMANI GILES.Pas encore d'évaluation

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- Manual Pajero 4x4 Rear AxleDocument32 pagesManual Pajero 4x4 Rear AxleGIAN CARLO MAMANI GILES.Pas encore d'évaluation

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Manual - Pajero4x4wheel and TyreDocument6 pagesManual - Pajero4x4wheel and TyreGIAN CARLO MAMANI GILES.Pas encore d'évaluation

- Manual Pajero4x4steereingDocument42 pagesManual Pajero4x4steereingGIAN CARLO MAMANI GILES.Pas encore d'évaluation

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- Manual Pajero 4x4 BodyDocument58 pagesManual Pajero 4x4 BodyGIAN CARLO MAMANI GILES.Pas encore d'évaluation

- Manual Pajero 4x4 GeneralDocument30 pagesManual Pajero 4x4 GeneralGIAN CARLO MAMANI GILES.Pas encore d'évaluation

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Instructions For Chemical Kinetics SimulatorDocument11 pagesInstructions For Chemical Kinetics SimulatorGIAN CARLO MAMANI GILES.Pas encore d'évaluation

- Paket B Listening Ujian Sekolah Bahasa Inggris SMK Tahun Pelajaran 2022-2023Document3 pagesPaket B Listening Ujian Sekolah Bahasa Inggris SMK Tahun Pelajaran 2022-2023Nadiah PutriPas encore d'évaluation

- Fi̇z 137-CH 1-Measurement PDFDocument27 pagesFi̇z 137-CH 1-Measurement PDFkaskoskasPas encore d'évaluation

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Recent Advances in Second Generation Bioethanol Production An Insight To Pretreatment, Saccharification and Fermentation ProcessesDocument11 pagesRecent Advances in Second Generation Bioethanol Production An Insight To Pretreatment, Saccharification and Fermentation ProcessesBryant CoolPas encore d'évaluation

- 6.4L - Power Stroke EngineDocument16 pages6.4L - Power Stroke EngineRuben Michel100% (2)

- ROV Inspection and Intervention VesselDocument2 pagesROV Inspection and Intervention VesselAhmad Reza AtefPas encore d'évaluation

- Management Information Systems and Corporate Decision - Making: A Literature ReviewDocument5 pagesManagement Information Systems and Corporate Decision - Making: A Literature Reviewvaaz205Pas encore d'évaluation

- Antennas and Wave Propagation - Nov - 2015Document8 pagesAntennas and Wave Propagation - Nov - 2015Jyothi SamanthulaPas encore d'évaluation

- Important Questions - BlockchainDocument1 pageImportant Questions - BlockchainHarsh Varshney100% (1)

- Anti FoundationalismDocument4 pagesAnti FoundationalismKostasBaliotisPas encore d'évaluation

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Lesson PlanDocument11 pagesLesson PlanKim Gabrielle Del PuertoPas encore d'évaluation

- Applied-Signed Product Cordial Labeling and - Santhi.mDocument6 pagesApplied-Signed Product Cordial Labeling and - Santhi.mImpact JournalsPas encore d'évaluation

- P2P L2 Asr9000Document88 pagesP2P L2 Asr9000ws_595Pas encore d'évaluation

- Purchasing Process Models Inspiration For Teac 2019 Journal of Purchasing ADocument11 pagesPurchasing Process Models Inspiration For Teac 2019 Journal of Purchasing ASunita ChayalPas encore d'évaluation

- Ass AsDocument2 pagesAss AsMukesh BishtPas encore d'évaluation

- Pdpa CraDocument3 pagesPdpa CraAdyrah RahmanPas encore d'évaluation

- Liter Ature - 4A: Start ThinkingDocument2 pagesLiter Ature - 4A: Start ThinkingNour AlkaloutiPas encore d'évaluation

- Is 800-2007 - Indian Code of Practice For Construction in SteelDocument41 pagesIs 800-2007 - Indian Code of Practice For Construction in SteelshiivendraPas encore d'évaluation

- Comparing Registers: MIPS vs. ARM AssemblyDocument12 pagesComparing Registers: MIPS vs. ARM Assemblyshruti chouhanPas encore d'évaluation

- Qüestionari KPSI.: ActivitiesDocument2 pagesQüestionari KPSI.: ActivitiesfrancisPas encore d'évaluation

- Bantilan Maureen Lhee RDocument8 pagesBantilan Maureen Lhee RAlexa Anne Louise BercillaPas encore d'évaluation

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Lesson4 1515Document14 pagesLesson4 1515gm hashPas encore d'évaluation

- Hydraulics Laboratory ManualDocument37 pagesHydraulics Laboratory ManualHarold Taylor100% (2)

- Cell Cycle Karyotyping Lab ReportDocument11 pagesCell Cycle Karyotyping Lab ReportRichie JustinPas encore d'évaluation

- JSREP Volume 38 Issue 181ج3 Page 361 512Document52 pagesJSREP Volume 38 Issue 181ج3 Page 361 512ahmed oudaPas encore d'évaluation

- CATEGORY - Green (III) Consent To EstablishDocument4 pagesCATEGORY - Green (III) Consent To EstablishROOPDIP MUKHOPADHYAYPas encore d'évaluation

- Resume MullinsDocument4 pagesResume Mullinsapi-236735643Pas encore d'évaluation

- Report - Roche Pharmaceuticals LTD (Human Resource Planning & Development) 222Document23 pagesReport - Roche Pharmaceuticals LTD (Human Resource Planning & Development) 222jawwadraja100% (1)

- STRUCTUREDocument26 pagesSTRUCTUREJulia RatihPas encore d'évaluation

- Data Analaysis and InterpretationDocument56 pagesData Analaysis and Interpretationporkodisvl100% (2)

- Guidelines for Auditing Process Safety Management SystemsD'EverandGuidelines for Auditing Process Safety Management SystemsPas encore d'évaluation

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsD'EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsPas encore d'évaluation

- Guidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisD'EverandGuidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisÉvaluation : 5 sur 5 étoiles5/5 (1)