Académique Documents

Professionnel Documents

Culture Documents

Dry Well Regrease

Transféré par

shahin_bTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Dry Well Regrease

Transféré par

shahin_bDroits d'auteur :

Formats disponibles

Paramax 9000 Series 30

Paramax 9000 Speed Reducers

Paramax

Lubrication Addendum

Drywell and Drop Bearing Grease Procedure

1. Introduction

Drywells are designed for applications that cannot have any oil leaking down the low speed shaft. Applications range from treatment plant

agitators to food mixers.

Drywell assemblies consist of a drywell baffle that is designed to keep the oil out of the

bottom low speed bearing chamber. There is a grease V-ring seal between the bearing

and the drywell baffle. This is to prevent the bearing grease from entering the main

housing. The low speed bearing is packed with grease, which is replenished by

pumping grease through the grease nipple, and the excessive supply is purged out.

See Fig. A-2. The drop bearing/drywell is the same as the drywell except the low speed

bearing has been lowered to increase the lateral load capacity of the unit.

2. Procedure

Follow these instructions to maintain the lubricating grease for the bottom low

speed bearing:

a. The lowspeed bearing is packed with NLGI #2EP grease prior to shipping

(unless otherwise specified). It is not required to add grease to the low speed

bearing chamber before startup.

b. Add grease to the low speed bearing every 2500 hours of operation.

~ Refer to Table A-3 for approximate quantity.

~ Refer to Table A-4 for recommended mineral greases.

c. Remove the grease relief piping and clean out any excess grease every 5000 hours, or 1

year, which ever comes first. Old, unused grease will dry out and harden over time.

This process is required to prevent the purge line from clogging.

d. Units may be equipped with either a spring loaded grease relief fitting, or a plug in the grease purge port.

~ If your unit has a plug, begin by removing the plug.

~ While rotating the reducer shafts to ensure even grease distribution, slowly add the recommended amount of the grease. Do not

over grease.

~ After 30 minutes of continuous operation, reinstall plug, if necessary, cleanup, and dispose of all purged grease.

e. It is not uncommon for grease to continue to purge from the unit for a period of time after adding new grease. If this happens, do not

add additional grease to the unit.

Table A-3. Recommended Approximate Grease Quantity

Unit

Size

9030

9035

9040

9045 9050

9055

9060

9065 9070

9075

9080

9085

9090

9095 9100

9105

9110

9115 9118 9121

Grams 79 144 173 194 278 524 407 494 632 778 943 1184 1465 2025 2549

Ounces 2.8 5.1 6.1 6.8 9.8 18.5 14.4 17.4 22.3 27.4 33.3 41.8 51.7 71.4 89.9

Table A-4. Recommended NLGI #2 Mineral Greases

Grease BP Castrol Chevron/Texaco Exxon/Mobil Shell Total

Mineral

Ener-

Grease

LS EP2

Spheerol

AP3

Olista

Longtime

3EP

Tribol

3020/

1000-2

Dualith

Grease

EP2

Multifak

EP2

Beacon

EP2

Mobilux

EP2

Alvania

EP2

Multis

EP2

Food grade FM EP2

Fig. A-2 Drywell/Drop Bearing Assembly

25.01

Low Speed Shaft

36.01

Low Speed

Helical Gear

86.22

Drywell

60.01

Low Speed

Bearing

86.42

V-Ring Seal

36.02

Low Speed

Bearing

65.22

65.02

Low Speed Seal

76.02

O-Ring

Vous aimerez peut-être aussi

- ATURIA Sub PumpsDocument1 pageATURIA Sub Pumpsshahin_bPas encore d'évaluation

- Selection: How To Select A Submersible PumpsetDocument1 pageSelection: How To Select A Submersible Pumpsetshahin_bPas encore d'évaluation

- Production Includes: Performances RangeDocument1 pageProduction Includes: Performances Rangeshahin_bPas encore d'évaluation

- Installation: 3-Horizontal Installation As Booster PumpDocument1 pageInstallation: 3-Horizontal Installation As Booster Pumpshahin_bPas encore d'évaluation

- Submersible Electric Pumps: 3-Horizontal Installation As Booster PumpDocument6 pagesSubmersible Electric Pumps: 3-Horizontal Installation As Booster Pumpshahin_bPas encore d'évaluation

- Submersible Electric Pumps: 3-Horizontal Installation As Booster PumpDocument6 pagesSubmersible Electric Pumps: 3-Horizontal Installation As Booster Pumpshahin_bPas encore d'évaluation

- Siemens SPPA P3000Document2 pagesSiemens SPPA P3000shahin_bPas encore d'évaluation

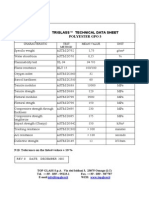

- Triglass™ Technical Data Sheet Polyester Gpo 3: Characteristic Test Method Mean-Value UnitDocument1 pageTriglass™ Technical Data Sheet Polyester Gpo 3: Characteristic Test Method Mean-Value Unitshahin_bPas encore d'évaluation

- Hamon CatalogDocument16 pagesHamon Catalogshahin_bPas encore d'évaluation

- Khan NanaDocument4 pagesKhan Nanashahin_bPas encore d'évaluation

- Selecting A Vertical Turbine Pump: (Information Required From Client)Document6 pagesSelecting A Vertical Turbine Pump: (Information Required From Client)shahin_bPas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5795)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Sd-1-Parts-Book Manual Propietario SpreaderDocument30 pagesSd-1-Parts-Book Manual Propietario Spreadergabriel sanchezPas encore d'évaluation

- Programmable Safety Systems PSS-Range: Service Tool PSS SW QLD, From Version 4.2 Operating Manual Item No. 19 461Document18 pagesProgrammable Safety Systems PSS-Range: Service Tool PSS SW QLD, From Version 4.2 Operating Manual Item No. 19 461MAICK_ITSPas encore d'évaluation

- Notes Mechanism of Methanol Synthesis From Carbon Monoxide and Hydrogen On Copper CatalystsDocument4 pagesNotes Mechanism of Methanol Synthesis From Carbon Monoxide and Hydrogen On Copper CatalystsArif HidayatPas encore d'évaluation

- Features: 833H - 1A - F - CDocument3 pagesFeatures: 833H - 1A - F - CDaniboy1994Pas encore d'évaluation

- F4 Search Help To Select More Than One Column ValueDocument4 pagesF4 Search Help To Select More Than One Column ValueRicky DasPas encore d'évaluation

- Wrights Mushroom ColumnDocument33 pagesWrights Mushroom ColumnKeithy GandhiPas encore d'évaluation

- 3 3 1 Material Sorter Design ChallengeDocument3 pages3 3 1 Material Sorter Design Challengeapi-343534512Pas encore d'évaluation

- 2011 TH 18205 Awad Nassib PdfaDocument95 pages2011 TH 18205 Awad Nassib PdfahafosaamrPas encore d'évaluation

- 2009 PMI CatalogueDocument124 pages2009 PMI Cataloguedesbennett004Pas encore d'évaluation

- En 12604 (2000) (E)Document7 pagesEn 12604 (2000) (E)Carlos LanzillottoPas encore d'évaluation

- The Effects of Crankshaft Offset On The Engine FrictionDocument15 pagesThe Effects of Crankshaft Offset On The Engine Frictionqingcaohe100% (1)

- Compressed Air Treatment EquipmentDocument12 pagesCompressed Air Treatment EquipmentSAUL OSPINOPas encore d'évaluation

- Iso 9974-2Document4 pagesIso 9974-2willianPas encore d'évaluation

- Api 682Document132 pagesApi 682Raul Gonzalez FernandezPas encore d'évaluation

- 9-Energy Resources Properties of Steam PDFDocument67 pages9-Energy Resources Properties of Steam PDFS.m. ChandrashekarPas encore d'évaluation

- Interfacing Seven Segment Display With LPC1769Document18 pagesInterfacing Seven Segment Display With LPC1769Gurudatta Palankar0% (1)

- An Overview of Subspace Identification: S. Joe QinDocument12 pagesAn Overview of Subspace Identification: S. Joe QinGodofredoPas encore d'évaluation

- CTLG MINI08engDocument48 pagesCTLG MINI08enggadacz111Pas encore d'évaluation

- REE Copy PDFDocument9 pagesREE Copy PDFJake ZozobradoPas encore d'évaluation

- Fundamentals of Fluid Mechanics (5th Edition) - Munson, OkiishiDocument818 pagesFundamentals of Fluid Mechanics (5th Edition) - Munson, OkiishiMohit Verma85% (20)

- Tda - 2002 PDFDocument19 pagesTda - 2002 PDFJose M PeresPas encore d'évaluation

- Bloomberg - Transport - SecurityDocument13 pagesBloomberg - Transport - SecurityFernandoPas encore d'évaluation

- Cadence Short CommandsDocument1 pageCadence Short Commandsgetme_samPas encore d'évaluation

- CPS 800 12 900 10 Parts List 2012 02 ENG 2205 6006 51 PDFDocument51 pagesCPS 800 12 900 10 Parts List 2012 02 ENG 2205 6006 51 PDFMar SolPas encore d'évaluation

- APP157 CoP For Site Supervision 2009 202109Document92 pagesAPP157 CoP For Site Supervision 2009 202109Alex LeungPas encore d'évaluation

- Cyclic Redundancy CheckDocument3 pagesCyclic Redundancy CheckmeerashekarPas encore d'évaluation

- Us06-106 850 01 01 02 PDFDocument6 pagesUs06-106 850 01 01 02 PDFF2CANALESPas encore d'évaluation

- Practice Exam 1Document7 pagesPractice Exam 1425Pas encore d'évaluation

- Kaltreparatur-Textil WT2332 enDocument20 pagesKaltreparatur-Textil WT2332 enFerAK47aPas encore d'évaluation

- Dex Stainless Steel Undermount Kitchen Sinks: Installation ManualDocument18 pagesDex Stainless Steel Undermount Kitchen Sinks: Installation ManualRrsc RamsPas encore d'évaluation