Académique Documents

Professionnel Documents

Culture Documents

EPA Value Engineering Study Process Saves Millions

Transféré par

allan0 évaluation0% ont trouvé ce document utile (0 vote)

152 vues23 pagesThe document discusses the value engineering study process used at EPA fund lead sites for remedial design and remedial action projects. It provides an overview of the relevant policy directives and outlines the planning process, value engineering study team requirements, the value engineering study process, and examples of study results. Value engineering studies have identified significant cost savings for remedial action projects while validating current design approaches and incorporating best practices.

Description originale:

Titre original

value engineering process.pdf

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentThe document discusses the value engineering study process used at EPA fund lead sites for remedial design and remedial action projects. It provides an overview of the relevant policy directives and outlines the planning process, value engineering study team requirements, the value engineering study process, and examples of study results. Value engineering studies have identified significant cost savings for remedial action projects while validating current design approaches and incorporating best practices.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

152 vues23 pagesEPA Value Engineering Study Process Saves Millions

Transféré par

allanThe document discusses the value engineering study process used at EPA fund lead sites for remedial design and remedial action projects. It provides an overview of the relevant policy directives and outlines the planning process, value engineering study team requirements, the value engineering study process, and examples of study results. Value engineering studies have identified significant cost savings for remedial action projects while validating current design approaches and incorporating best practices.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 23

The Value Engineering Study Process at

EPA Fund Lead Sites

Lindsey K. Lien, PE

USACE NORTHWESTERN DIVISION

2009 Engineering Forum

Wednesday Business Session

January 28, 2008

San Diego, CA

VE at EPA Fund Lead Sites

Policy

Planning

VE Process

Results

Policy Directives

Federal OMB Circular 131 1988, rev 1993

Public Law 104-106 (1996) Section 4306

FAR 48.101 RD; 48.102 RA

OSWER Directive OSWER 9335.5-24

Value Engineering for Fund Financed

Remedial Design and Remedial Action

Projects April 14, 2006

VE at EPA Fund Lead Sites

VE at EPA Fund Lead Sites

OSWER 9335.5-24 APRIL 14, 2006

For a given project (or phase of a project) to

qualify for initial RA funding, the RD for that

project should undergo the VE process in

accordance with the table. As a prerequisite to

approval of the project for initial RA funding, the

priority panel for RA funding should confirm

that the appropriate Regional Branch Chief has

certified that the project is (or will be) in

compliance with the VE requirements for RD.

http://www.environmental.usace.army.mil/guide_process.htm

VE at EPA Fund Lead Sites

OSWER 9335.5-24 APRIL 14, 2006

VE at EPA Fund Lead Sites

Funding:

EPA HQ funded VE Studies during 2007 and scheduled for 2008

New requests, EPA regions are responsible for funding the VE Study

using the USACE Team.

If funding can not be provided by the region, EPA Regional staff

and/or USACE staff should contact EPA HQs (Emily Johnson/

Katherine Garufi) to see if EPA HQs funds may be made available to

fund the project.

USACE Staff Capacity:

For any new project requests, coordinate with Dave Jaros - USACE

EMCX to ensure the VE Team is available to conduct the study within

the schedule requested by the EPA Region.

Planning

A Fund Lead Site is Identified

VE Coordinator Contacts the RPM

Schedule Developed

PDT is Assembled and Funded

PDT Document Review

Conference Call (RPM/Team)

VE at EPA Fund Lead Sites

Value Engineering Study Team

Independent of the design team, with appropriate

experience and expertise

Members preferably have 40 hours of training

sponsored by the Society of American Value

Engineering (SAVE);

Team facilitator should have completed the

requirements for a Certified Value Specialist

(CVS) IAW SAVE (Society of American Value

Engineering)

Role of the RPM in the VE Study

A resource for information on the ROD,

policy, and the reasoning behind decisions

driving the design

Provides advice to help VE team avoid

studying parts of the design that cannot be

changed

Prepares written response to VE Report

with reasons for accepting or rejecting each

VE recommendation

VE at EPA Fund Lead Sites

Value Engineering is a function oriented,

systematic, dynamic TEAMapproach to

enhance the value of a project by increasing

benefit and/or reducing unnecessary

resource utilization

Definition

VE at EPA Fund Lead Sites

VE Study is conducted to:

validate current design approach

identify opportunities to reduce cost

ensure design incorporates best design and

construction practices

VE should be done (at the end of preliminary

design) for all fund lead remedial designs

What is Value?

Value

=

Benefits

Resources

Where:

Value is derived from a product, project, or service

Benefits provided by product, project, or service

Resources are what is needed to produce it

The Value Expression

Value =

Function + Quality + Performance

Cost + Time

Relate Functions to Each Other

Collect/Identify Required Functions

Link functions by determining

relationship using how/why logic

Function A Function B Function C

High Order

Basic Function Low Order

How?

Why?

American Brass Inc., Function Model

Item Aspects of Item Function

Transportation Haul Soil/Debris Remove Contaminants

Excavation Ecosystem

Human Health

Water

0-1 feet

1-10 feet

10-GW

GW to max depth

Remove Contaminants

Disposal TSCA, RCRA C/D

EPA Facility Approval

Waste Acceptance

Criteria

Isolate Waste

Confirmation Sampling Field Screen

Fixed Lab

Test Frequency

Verify Removal

The VE Process

Information Phase

Functional Phase

Speculation Phase

Analytical Phase

Development Phase

Presentation Phase

Implementation

Presentation Phase

Each Recommendation Stands Alone

Present Concept and Increased Value

Potential

Each Recommendation is Presented for

Complete Understanding

Final Written Report

VE at EPA Fund Lead Sites

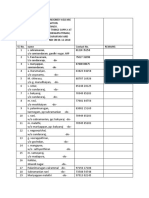

Results of Pilot Program

Site Region VE Study

Cost

RA Cost

Estimate

VE Identified

Savings

VE Savings

Identified

White Chemical, NJ 2 $40,000 $7.7 M $500,000 $500,000

Horseshoe Road, NJ 2 $50,000 $52.5 M $12,000,000 $10,600,000

Bountiful Woods OU1,

UT

8 $20,000 $1.8 M $65,000 NR

Upper Ten Mile, MT 8 $43,000 $7.7 M $935,000 NR

Bountiful Woods OU 2,

UT

8 $43,000 $16.4 M >$2,000,000* NR

Jasper/Hart (2 Sites), TX 6 $42,000 $13 M $397,000 $360,000

Cornell Dubilier, NJ 2 $61,500 $77.4 M $6,570,000 $4,967,000

Outboard Marine Corp,

IL

5 $35,000 $35.3 M $5,308,000 $4,820,000

American Brass

Headland, AL

4 $37,100 $5.8 M $2,520,000 NR

Elizabeth Mine, VT 1 $53,000 $16 M $2,800,000 NR

Libby Asbestos, MT 8 $46,000 $20 M $5,500,000 NR

Totals for Completed

Work:

$429,200

*499,000

$253.6 $38,595,000

($24,775,000)

$21,247,000

Example Projects

Bountiful Woods, UT

American Brass, AL

Upper Ten Mile Creek, MT

Issues and Follow-up Efforts

RPMs need to prepare written response to VE

Report with reasons for accepting or rejecting each

VE recommendation

Data on recommendations and actual cost savings

Identification of, and funding for, future studies

Value Engineering Study Team

Lessons Learned - Fund Lead Sites

Up Front Planning, Communication, and RD

review is Vital

Define Boundaries (ROD)

Designer/RPM/Stakeholder Participation is

Necessary

Initial Skepticism is not as Prevalent

The Site Visit is Extremely Helpful

Team Members need Advance Notice

Value Engineering Study Team

Links

OSWER Directive 9335.5-24 and OSWER 9335.5-24FS

http://www.environmental.usace.army.mil/guide_process.htm

OMB Circular A-131

http://www.whitehouse.gov/omb/circulars/a131/a131.html

Public Law104 106, 1996 (4306)

http://www.nist.gov/director/ocla/Public_Laws/PL104-106.pdf

Vous aimerez peut-être aussi

- Codes For All PhonesDocument54 pagesCodes For All Phonesapi-369654365% (31)

- Honda S2000 (00-03) Service ManualDocument0 pageHonda S2000 (00-03) Service Manualmcustom1Pas encore d'évaluation

- 2600: The Hacker Quarterly (Volume 2, Number 11, November 1985)Document8 pages2600: The Hacker Quarterly (Volume 2, Number 11, November 1985)Ranko Kohime100% (1)

- 2016 Front End SampleDocument12 pages2016 Front End SampleB GirishPas encore d'évaluation

- Model BOQDocument70 pagesModel BOQYasar Athif86% (7)

- Certificate of Employment and Compensation detailsDocument1 pageCertificate of Employment and Compensation detailsallanPas encore d'évaluation

- Work Breakdown Structure A Complete Guide - 2020 EditionD'EverandWork Breakdown Structure A Complete Guide - 2020 EditionPas encore d'évaluation

- Septic TANK DesignDocument4 pagesSeptic TANK Designadnan88% (8)

- Prepared For: Puan Khair Shakira Bustamam Prepared By: Anis Shahireen Effah Atiqah Fatinah Husna Nur FatinDocument9 pagesPrepared For: Puan Khair Shakira Bustamam Prepared By: Anis Shahireen Effah Atiqah Fatinah Husna Nur FatinFatinah Husna100% (2)

- Seaweeds ProductionDocument66 pagesSeaweeds ProductionallanPas encore d'évaluation

- Coping Against El NinoDocument226 pagesCoping Against El Ninoallan0% (1)

- Building MaterialsDocument13 pagesBuilding MaterialsPriyanka BasuPas encore d'évaluation

- Increase value through lower costs with value engineering (VEDocument8 pagesIncrease value through lower costs with value engineering (VEparag_mitPas encore d'évaluation

- Self PublishingDocument84 pagesSelf PublishingFrancesco CusumanoPas encore d'évaluation

- Reinforcement DetailingDocument47 pagesReinforcement DetailingMuhammad Saqib Abrar94% (16)

- Reinforcement DetailingDocument47 pagesReinforcement DetailingMuhammad Saqib Abrar94% (16)

- Value Engineering: SAVE InternationalDocument7 pagesValue Engineering: SAVE InternationalSadaf NazPas encore d'évaluation

- نوتة حسابية كاملة لمبنى فيلاDocument87 pagesنوتة حسابية كاملة لمبنى فيلاWalif Dababat95% (22)

- Rice Husk Gas Stove Handbook - Alexis T.BelonioDocument155 pagesRice Husk Gas Stove Handbook - Alexis T.BelonioAris TrihandokoPas encore d'évaluation

- 4183-2007 Australian Standard Value ManagementDocument10 pages4183-2007 Australian Standard Value Managementsenzo scholarPas encore d'évaluation

- Value Engineering: Akhand Anish Avaneesh Gajendra HimanshuDocument27 pagesValue Engineering: Akhand Anish Avaneesh Gajendra HimanshuAkhand Pratap Singh PariharPas encore d'évaluation

- Value Methodology Glossary PDFDocument4 pagesValue Methodology Glossary PDFCalPas encore d'évaluation

- CVS Certification ManualDocument32 pagesCVS Certification Manual황상훈Pas encore d'évaluation

- Value Management in Construction ProjectsDocument6 pagesValue Management in Construction ProjectsNurali MamenPas encore d'évaluation

- F-510-S04-0004 Specification For Tank Foundation and Earthen Bund WallsDocument12 pagesF-510-S04-0004 Specification For Tank Foundation and Earthen Bund WallssurPas encore d'évaluation

- DC PT Contractors Role Responsibilities PTIA IEAust NewcastleDocument30 pagesDC PT Contractors Role Responsibilities PTIA IEAust NewcastleSree NivasPas encore d'évaluation

- OPTIMIZING VALUE THROUGH FUNCTION ANALYSISDocument28 pagesOPTIMIZING VALUE THROUGH FUNCTION ANALYSISTrizzhaynah AbejarPas encore d'évaluation

- Lec. 3 - VE Job PlanDocument42 pagesLec. 3 - VE Job PlanMohamed Salem0% (1)

- Project Management Office Complete Self-Assessment GuideD'EverandProject Management Office Complete Self-Assessment GuidePas encore d'évaluation

- Philippines Tilapia EconomicsDocument268 pagesPhilippines Tilapia EconomicsallanPas encore d'évaluation

- Owner S Project RequirementsDocument1 pageOwner S Project RequirementsHumaid ShaikhPas encore d'évaluation

- Astm Peel TestDocument2 pagesAstm Peel TestIvander GultomPas encore d'évaluation

- IPC No 10-Rev 1 (Check)Document80 pagesIPC No 10-Rev 1 (Check)Nguyen Hoành QuảngPas encore d'évaluation

- CSI Code Guide for Mechanical, Electrical and Plumbing ProjectsDocument15 pagesCSI Code Guide for Mechanical, Electrical and Plumbing Projectsdelmar02Pas encore d'évaluation

- VM MhabDocument39 pagesVM MhabSaiful Muzamir IsmailPas encore d'évaluation

- Complete VM StudyDocument38 pagesComplete VM StudyChungHuiPingPas encore d'évaluation

- Minimum Technical Requirements (Indice Delle Norme Da Applicare in KSA)Document183 pagesMinimum Technical Requirements (Indice Delle Norme Da Applicare in KSA)senkum279342100% (1)

- Delay Analysis in EPC Projects Using Ishikawa DiagramDocument6 pagesDelay Analysis in EPC Projects Using Ishikawa DiagramIjaems JournalPas encore d'évaluation

- 01-Battery Room Ceramic Floor TilesDocument1 page01-Battery Room Ceramic Floor TilesJoey RomeroPas encore d'évaluation

- Code for Construction Quality Acceptance and Evaluation of Boiler UnitDocument836 pagesCode for Construction Quality Acceptance and Evaluation of Boiler UnitecsuperalPas encore d'évaluation

- Curtain Wall ProblemsDocument4 pagesCurtain Wall ProblemsMohammad Reza NateghPas encore d'évaluation

- Checklist For Finishing Activities: Room AreaDocument4 pagesChecklist For Finishing Activities: Room AreaAdnanPas encore d'évaluation

- WV DOT Value Engineering ManualDocument193 pagesWV DOT Value Engineering ManualTAHER AMMARPas encore d'évaluation

- 2.1 VMBOK - VM Study Process - BLP - Ogos - 2015 PDFDocument43 pages2.1 VMBOK - VM Study Process - BLP - Ogos - 2015 PDFfarahazuraPas encore d'évaluation

- 17 July 2009 VE Conference Pre-RegistrationDocument1 page17 July 2009 VE Conference Pre-RegistrationallanPas encore d'évaluation

- Acknowledgement: Value Engineering / Management Theory and Application Cost StudiesDocument15 pagesAcknowledgement: Value Engineering / Management Theory and Application Cost StudiesMuhammad SageerPas encore d'évaluation

- The Mitigation HierarchyDocument2 pagesThe Mitigation HierarchyCarlos Ferreira100% (1)

- Ve Workshop Final ReportDocument133 pagesVe Workshop Final ReportbocevskiPas encore d'évaluation

- Process Flowchart and Guidelines For RF ClaimsDocument8 pagesProcess Flowchart and Guidelines For RF ClaimsanildipPas encore d'évaluation

- MEP Project Engineer Role at Maryland Construction FirmDocument1 pageMEP Project Engineer Role at Maryland Construction FirmSonny CorreaPas encore d'évaluation

- Value Engineering Analysis in The Construction of Box Girder Bridge PDFDocument8 pagesValue Engineering Analysis in The Construction of Box Girder Bridge PDFDudi MustofaPas encore d'évaluation

- Improve Site ConstructabilityDocument4 pagesImprove Site ConstructabilitylizaPas encore d'évaluation

- Change Management FinalDocument33 pagesChange Management FinalMihan MarocPas encore d'évaluation

- Part A Memorandum of ProcedureDocument24 pagesPart A Memorandum of ProcedureSyed Umair HashmiPas encore d'évaluation

- Lead Estimator for Oil & Gas Operator in DubaiDocument2 pagesLead Estimator for Oil & Gas Operator in DubaiManoj SinghPas encore d'évaluation

- 3 ValueengineeringvalueanalysisandvaluemanagementofverticalslipformconstructionsystemDocument11 pages3 Valueengineeringvalueanalysisandvaluemanagementofverticalslipformconstructionsystemmuhammad aliPas encore d'évaluation

- AR6901 SE Unit 3 NotesDocument4 pagesAR6901 SE Unit 3 Notessarath sarathPas encore d'évaluation

- Application Handbook VMVE001 Offshore Onshore Expansion Project Oil Gas Value Management Value EngineeringDocument15 pagesApplication Handbook VMVE001 Offshore Onshore Expansion Project Oil Gas Value Management Value EngineeringIbrahim SalahudinPas encore d'évaluation

- Execution Phase ReviewsDocument14 pagesExecution Phase ReviewsMiguel InfantesPas encore d'évaluation

- Value Engineering in Construction IndustryDocument4 pagesValue Engineering in Construction Industryz_artist95Pas encore d'évaluation

- ASTM E1155 ReportDocument2 pagesASTM E1155 ReportChân QuêPas encore d'évaluation

- Project Closeout TemplateDocument6 pagesProject Closeout Templatejeyn100% (1)

- Lecture 6 OptimizationDocument41 pagesLecture 6 Optimizationaku_la100% (2)

- VM StandardDocument24 pagesVM StandardJosé Alberto Gonzales OchoaPas encore d'évaluation

- Applying VE ConceptDocument164 pagesApplying VE ConceptzainabcomPas encore d'évaluation

- VM Awareness CourseDocument41 pagesVM Awareness CoursefarahazuraPas encore d'évaluation

- Thought Starters For Preparing Engineering Competency Claims in EcharteredDocument5 pagesThought Starters For Preparing Engineering Competency Claims in EcharteredSiji AntonyPas encore d'évaluation

- Gaja Puyal ListDocument9 pagesGaja Puyal ListVijayssc SivaPas encore d'évaluation

- Value Engineering in ERPDocument24 pagesValue Engineering in ERPhemal0% (2)

- Service Quality Gap ModelDocument43 pagesService Quality Gap Modelvikasgaurkanpur100% (1)

- Individual Performance Contract ReviewDocument1 pageIndividual Performance Contract ReviewSarah Jane Ali100% (1)

- Webinar Value Engineering March 28 2019Document48 pagesWebinar Value Engineering March 28 2019Dhanushka WijesekaraPas encore d'évaluation

- Means and Methods Term 2 PDFDocument8 pagesMeans and Methods Term 2 PDFJefferson WidodoPas encore d'évaluation

- CH 2 Project CycleDocument16 pagesCH 2 Project CycleMebratu SimaPas encore d'évaluation

- Pre Construction Services A Complete Guide - 2020 EditionD'EverandPre Construction Services A Complete Guide - 2020 EditionPas encore d'évaluation

- Record of Asian AlgaeDocument18 pagesRecord of Asian AlgaeallanPas encore d'évaluation

- Assessing The Headwaters of Layawan RiverDocument72 pagesAssessing The Headwaters of Layawan Riverallan100% (1)

- Mapping Philippines Agro-Ecologizal ZonesDocument59 pagesMapping Philippines Agro-Ecologizal ZonesamgvinelesPas encore d'évaluation

- Survival For EarthquakeDocument3 pagesSurvival For EarthquakeallanPas encore d'évaluation

- Streetlight DrawingsDocument5 pagesStreetlight DrawingsallanPas encore d'évaluation

- 616 PDFDocument1 page616 PDFAnonymous qMToncPas encore d'évaluation

- Study For Dam SafetyDocument41 pagesStudy For Dam SafetyallanPas encore d'évaluation

- Section 5-Street Light Design DrawingsDocument29 pagesSection 5-Street Light Design DrawingsallanPas encore d'évaluation

- Street Light ManualDocument14 pagesStreet Light ManualallanPas encore d'évaluation

- PayrollDocument3 pagesPayrollallanPas encore d'évaluation

- At Char ADocument1 pageAt Char AallanPas encore d'évaluation

- 17 July 2009 VE Conference Pre-RegistrationDocument1 page17 July 2009 VE Conference Pre-RegistrationallanPas encore d'évaluation

- AutoCAD Tutorial - 3DDocument17 pagesAutoCAD Tutorial - 3DAnghel AdrianPas encore d'évaluation

- Introducing Microsoft Project 2007Document205 pagesIntroducing Microsoft Project 2007Prof. Dr. Abdalla ElDaoushy100% (3)

- Sharp Lc-46d65u & Lc-52d65u Final LCD TV SMDocument56 pagesSharp Lc-46d65u & Lc-52d65u Final LCD TV SMDan PrewittPas encore d'évaluation

- 08 CastingDocument6 pages08 CastinguzairmetallurgistPas encore d'évaluation

- Lobbying Vacations For CongressDocument54 pagesLobbying Vacations For CongressBigMamaTEAPas encore d'évaluation

- Techrite Siemens Siemens Qra Uv Flame Detection 013060323409Document14 pagesTechrite Siemens Siemens Qra Uv Flame Detection 013060323409Ali Hadi100% (1)

- Data Visualization Nanodegree Program Syllabus PDFDocument4 pagesData Visualization Nanodegree Program Syllabus PDFsergio paredesPas encore d'évaluation

- RemoteDocument16 pagesRemotetok222222Pas encore d'évaluation

- Red Ocean Vs Blue OceanDocument8 pagesRed Ocean Vs Blue Oceanbadshahkhn110Pas encore d'évaluation

- Ale For Abapers - Day3Document15 pagesAle For Abapers - Day3Supratim RayPas encore d'évaluation

- Position: Chapter-9 Flow Past Through BodyDocument3 pagesPosition: Chapter-9 Flow Past Through BodyAbishek AdhikariPas encore d'évaluation

- Osaka City Waste Management Collections and TransportationDocument5 pagesOsaka City Waste Management Collections and TransportationRatna 'ica' ChoirunnisaPas encore d'évaluation

- SB07 Decorative Effects 04Document14 pagesSB07 Decorative Effects 04Mohamed AliPas encore d'évaluation

- 01 Rude DoctypeDocument215 pages01 Rude DoctypeChristal Rae Tac-anPas encore d'évaluation

- O & M Manual For JHVR 6000X PDFDocument234 pagesO & M Manual For JHVR 6000X PDFvenkatesh100% (2)

- B2-Embedded System DesignDocument20 pagesB2-Embedded System DesignSailesh KhandelwalPas encore d'évaluation

- Vet. Medicine Companies in PakistanDocument6 pagesVet. Medicine Companies in PakistanRAO NABEEL AKRAM100% (1)

- Sileo Katalog S12 enDocument2 pagesSileo Katalog S12 enMirceaPas encore d'évaluation

- Devops Training in Bangalore - Devops Training in Bangalore MarathahalliDocument8 pagesDevops Training in Bangalore - Devops Training in Bangalore MarathahalliitrainPas encore d'évaluation

- CircuitsDocument26 pagesCircuitsDarian ShiPas encore d'évaluation

- Oracle® Database: 2 Day + Security Guide 11g Release 1 (11.1)Document130 pagesOracle® Database: 2 Day + Security Guide 11g Release 1 (11.1)arwahannanPas encore d'évaluation

- Gate Study MaterialDocument89 pagesGate Study MaterialMansoor CompanywalaPas encore d'évaluation

- A Real-Time Face Recognition System Using Eigenfaces: Daniel GeorgescuDocument12 pagesA Real-Time Face Recognition System Using Eigenfaces: Daniel GeorgescuAlex SisuPas encore d'évaluation

- Lumascape Lightings CatalogueDocument265 pagesLumascape Lightings CatalogueajlounicPas encore d'évaluation

- Airfoil Surface Pressure and Wake Velocity ExperimentDocument24 pagesAirfoil Surface Pressure and Wake Velocity ExperimentAh WenPas encore d'évaluation

- IoT Workshop Tutorial PDFDocument10 pagesIoT Workshop Tutorial PDFSrikanth SriPas encore d'évaluation