Académique Documents

Professionnel Documents

Culture Documents

Seminar Report DESIGN AND COMPARISION OF FLAT SLAB USING IS 456-2000 AND ACI 318-08

Transféré par

Mukesh MandeDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Seminar Report DESIGN AND COMPARISION OF FLAT SLAB USING IS 456-2000 AND ACI 318-08

Transféré par

Mukesh MandeDroits d'auteur :

Formats disponibles

A

SEMINAR REPORT ON

DESIGN AND COMPARISION OF FLAT SLAB USING IS 456-2000

AND ACI 318-08

BY

TUSHAR M. MADAMWAR

(ID-11001063)

GUIDED BY

Dr. K. N. KADAM

Department of Applied Mechanics

Government College of Engineering, Amravati.

(An Autonomous Institute of Government of Maharashtra)

2014-2015

CERTIFICATE

This is to certify that the seminar Report entitled DESIGN AND

COMPARISION OF FLAT SLAB USING IS 456-2000 AND ACI 318-08 submitted

by TUSHAR MANOJ MADAMWAR under my supervision and guidance as a record of

the work carried outrby him, is accepted as the seminar report submission. It is submitted in

the partial fulfillment of the prescribed syllabus of Final Year Civil Engineering in

Government College of Engineering, Amravati For the academic year 2014 - 2015

Date :

DR. K. N. KADAM PROF. D. J. CHAUDHARI

Guide Head of Department

Applied Mechanics Department Applied Mechanics Department

Government College of Engineering, Government College of Engineering,

Amravati Amravati

DECLARATION

I hereby declare that the seminar entitled DESIGN AND COMPARISION OF

FLAT SLAB USING IS 456-2000 AND ACI 318-08 has been exclusively carried out

and written by me under the guidance of Dr. K. N. Kadam , Assistant Professor, Department

of Applied Mechanics, Government College Of Engineering, Amravati for the course

Seminar. This work has not been previously formed the basis for the award of any degree or

diploma or certificate nor has been submitted elsewhere for the award of any degree or

diploma.

Place: Amravati TUSHAR MANOJ MADAMWAR

Date: (11001063)

ACKNOWLEDGEMENT

It gives me great pleasure in bringing out the seminar entitled " DESIGN AND

COMPARISION OF FLAT SLAB USING IS 456-2000 AND ACI 318-08". I express

my deep sense of gratitude and sincere regards to my respected guide Dr. K. N. Kadam.

Her timely guidance and friendly discussion had helped me immensely in selecting this

topic and completing the seminar work.

I would like to thank our Head of Department Prof. D. J. Chaudhari for

providing all facilities at the right period of time and for allowing me to deliver this

seminar.

I would also like to thank Dr. W. Z. Gandhare Principal, Government College

of Engineering, Amravati for providing all the facilities.

Last but not least, this acknowledgement would be incomplete without any

rendering impartial gratitude to all those person who have helped me directly or

indirectly in preparing this seminar report.

TUSHAR MANOJ MADAMWAR

(11001063)

TABLE OF CONTENTS

Chapter No. Title of Content Page No

Certificate

Declaration

Acknowledgement

Table of contents

List of figures and tables

1 INTRODUCTION

1.1 Basic definition of flat slab

1.2 Components of flat slab

2 Advantages of flat slab

3 DESIGN OF FLAT SLAB USING IS 456-2000

3.1 components of flat slab design

3.2 Division into column and middle strip

along:

3.3 Drops

3.4 column Heads

3.5 Depth of flat slab

3.6 Estimation of load acting on slab

3.7 Total design moment on span

3.8 Negative and positive design moments

3.9 Effective depth of slab

3.10 Thickness of drop from maximum ve

moment consideration

3.11 Shear in Flat Slab

4 DESIGN OF FLAT SLAB USING ACI 318-08

4.1 Drop of flat slabs

4.2 Thickness of the slab

4.3 Design strips

4.4 column head

4.5 Total factored static moment for a span

4.6 Shear provisions

4.7 Numerical Example

5 RESULTS-CODAL COMPARISIONS

6 CONCLUSIONS

REFERENCES

LIST OF FIGURES

Fig. No Name of figure Page No

1.1

Flat slab with drop panel & column head

1.2

conventional and beam free slab

LIST OF TABLES

Table

No

Name of table Page No

3.1 Drop dimensions

3.2 Column head dimensions

3.3 Depth consideration

3.4 Total design load

3.5 Sum of ve and +ve moments

4.1 Minimum thickness of slab

4.2 Factored moment in column strip

4.3 Factored moment in column strip

ABSTRACT

Flat slabs system of construction is one in which the beams used in the

conventional methods of constructions are done away with. The slab directly rests on the

column and load from the slab is directly transferred to the columns and then to the

foundation. To support heavy loads the thickness of slab near the support with the

column is increased and these are called drops, or columns are generally provided with

enlarged heads called column heads or capitals. Absence of beam gives a plain ceiling,

thus giving better architectural appearance and also less vulnerability in case of fire than

in usual cases where beams are used.

Plain ceiling diffuses light better, easier to construct and requires cheaper form

work. As per local conditions and availability of materials different countries have

adopted different methods for design of flat slabs and given their guidelines in their

respective codes. The aim of this seminar is to try and illustrate the methods used for flat

slab design using ACI-318 and IS: 456 design codes.

For carrying out this project an interior panel of a flat slab with dimensions 6.6 x 5.6 m

and super imposed load 7.75 kN /m

2

was designed using the codes given above.

CHAPTER 1

INTRODUCTION

1.1 Basic definition of flat slab:

In general, normal frame construction utilizes columns, slabs & beams. However it

may be possible to undertake construction without providing beams, in such a case the

frame system would consist of slab and column without beams. These types of slabs are

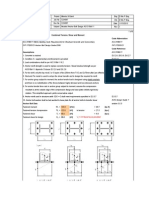

called flat slab, since their behavior resembles the bending of flat plates.(Fig 1.1 shows a

typical flat slab with its components)

1.2 Components of flat slabs:

i. Drops: Drops increases the shear strength of slab against punching shear failure.It

increases the negative moment carrying capacity of slab and stiffens it reducing the

defections.

ii. Column heads: Certain amount of negative moment is transferred from the slab to the

column at the support. To resist this negative moment the area at the support needs to be

increased .This is facilitated by providing column capital/heads. column heads increase

shear strength of slab.

Fig. 1.1 Flat slab with drop panel & column head

CHAPTER 2

ADVANTAGES OF FLAT SLAB

Flat slab has a number of advantages as compared to convenient slab beam

system. These advantages are listed below.

i. Flexibility in room layout: Flat slabs allows to introduce partition walls anywhere

required, it allows the choice of omittion of false ceiling and finished soffit of slab

with skim coating.It also allows the owner to change the size of room layout.

ii. Saving in building height: Lower storey height will reduce building weight due to

lower partitions and cladding resulting in reduction of foundation load.

Approximately saves 10% in vertical members. (refer Fig no 1.2)

Fig, 1.2 conventional and beam free slab

iii. Shorter construction time: Flat plates design facilitates the use of the big table

formwork to increase productivity.

iv. Ease of installation of M & E services: All M & E services can be mounted

directly on the underside of the slab instead of bending them to avoid the beams.

Avoid hacking through beams

v. Pre-fabricated welded mesh: Pre-fabricated welded mesh are available in standard

sizes, these mesh minimizes the installation time & helps in better quality control.

Chapter 3

Literature review

CHAPTER 3

DESIGN OF FLAT SLABS USING IS 456-2000

The term flat slab means a reinforced concrete slab with or without drops,

supported generally without beams, by columns with or without flared column heads (see

Fig. 1.1). A flat slab may be solid slab or may have recesses formed on the soffit so that

the soffit comprises a series of ribs in two directions. The recesses may be formed by

removable or permanent filler blocks.

3.1 Components of flat slab design:

a) Column strip : Column strip means a design strip having a width of 0.25 l

2

, but not

greater than 0.25l

1

, on each side of the column centre-line, where l

2

is the span in the

direction moments are being determined, measured centre to centre of supports and l

1

is

the span transverse to l

2

, measured centre to centre of supports.

b) Middle strip :Middle strip means a design strip bounded on each of its opposite sides

by the column strip.

c) Panel: Panel means that part of a slab bounded on-each of its four sides by the centre -

line of a column or centre-lines of adjacent-spans.

Table No Division into column and middle strip

Longer span Shorter span

L

1

=6.6 m , L

2

=5.6 m

( i ) column strip

= 0.25 L

2

= 1.4 m

But not greater than 0.25 L

1

= 1.65 m

(ii) Middle strip

= 5.6 (1.4+1.4) = 2.8 m

L

1

=5.6 m , L

2

=6.6 m

( i ) column strip

= 0.25 L

2

= 1.65 m

But not greater than 0.25 L

1

= 1.4 m

(ii) Middle strip

= 6.6 (1.4+1.4) = 3.8 m

Fig no.Dimensions of slab along longer and shorter span

3.3 Drops

As per clause 31.2.2 of IS 456-2000, the drops when provided shall be rectangular in plan

and have a length in each direction not less than one- third of the panel length in that

direction. For exterior panels, the width of drops at right angles to the non- continuous

edge and measured from the centre -line of the columns shall be equal to one half the

width of drop for interior panels.

Since the span is large it is desirable to provide drop

Table 3.1 Drop dimensions

Large span Short span

L

1

=6.6 m , L

2

=5.6 m

Not less than L

1

/3 = 2.2 m

L

1

=5.6 m , L

2

=6.6 m

Not less than L

1

/3 = 1.866 m

provide drop of size 2.2 x 2.2 m i.e. in column strip width.

3.4 Column Head

As per clause 31.2.3 of IS 456-2000, where column heads are provided, that portion of a

column head which lies within the largest right circular cone or pyramid that has a vertex

angle of

and can be included entirely within the outlines of the column and the

column head, shall be considered for design purposes.

1.4 m

C.S

3.8 m

M.S

C.S 1.4 m

C>S

2.8 m

M.S

1.4 m

1.4 m M.S

5.6 m 6.6 m

Table 3.2 Column head dimension along:

Longer span Shorter span

L

1

=6.6 m , L

2

=5.6 m

Not greater than L

1

/4 = 1.65 m

L

1

=5.6 m , L

2

=6.6 m

Not greater than L

1

/4 = 1.4 m

Adopting the diameter of column head = 1.30 m =1300 mm

3.5 Depth of Flat Slab

As per clause 23.2.1 of IS 456-2000, the thickness of the flat slab up to spans of 10 m

shall be generally controlled by considerations of span ( L ) to effective depth ( d ) ratios

given as below

Cantilever 7; simply supported 20; Continuous 26

For slabs with drops, span to effective depth ratios given above shall be applied directly;

otherwise the span to effective depth ratios in accordance with above shall be multiplied

by 0.9. For this purpose, the longer span of the panel shall be considered. The minimum

thickness of slab shall be 125 mm.

Table 3.3 Depth consideration

Longer span Shorter span

L =6.6 m , L

2

=5.6 m

Say 260 mm

L =5.6 m , L

2

=6.6 m

Say 220 mm

Taking effective depth of 25mm

Overall depth D = 260 +25 = 285 mm 125 mm (minimum slab thickness as per IS: 456)

It is safe to provide depth of 285 mm.

3.6 Estimation of Load Acting on The Slab:

Dead load acting on the slab = 0.285 x 25 = 6.25 KN /m

2

=W

d1

Floor finishes etc. load on slab = 1.45 KN /m

2

= W

d2

The Live load on slab = 7.75 KN /m

2

= W

1

Total dead load = W

d1

+ W

d2

=7.7 KN /m

2

= W

d

Design live load shall not exceed three times the design dead load.

Check=:

OK

Total design load = Wl

l

+ Wd= 15.45 KN/m

2

3.7 Total Design Moment On Span (31.3.1)

As per clause 31.3.1 of IS 456-2000, the absolute sum of the positive and average and is

given by negative bending moments in each direction shall be taken as

M

o

=

M

o

=total moment

W = design load on an area l

1

l

2

l

n

= clear span extending from face to face of columns, capitals, brackets or walls, but not

less than 0.65 l

1

l

1

= length of span in the direction of M

o

.

l

2

= length of span transverse to l

1

.

Circular supports shall be treated as square supports having the same area.

Equivalent side of the column head having the same area:

A=

)

Clear span along long span =l

n

=6.6-

(1.152)-

(1.152)=5.448 >4.29

(Should not be less than 0.65 l

1

) ok

Clear span along long span =l

n =

5.6-

(1.152)-

(1.152)=4.44 >3.64

(Should not be less than 0.65 l

1

) ok

Table 3.4 Total design load

Longer span Shorter span

l

n

=5.448 m , l

2

=5.6 m

W w l

2

l

n

W 15.45 5.6 5.448 471.36kN

l

n

=4.44 m , l

2

=6.6 m

W w l

2

l

n

W 1 5 . 4 5 6 . 6 4 . 4 4 452.74k N

Table 3.5 The absolute sum of negative and positive moment in a panel

Longer span Shorter span

l

n

=5.448 m , l

2

=5.6 m

M

o

=

l

n

=4.44 m , l

2

=6.6 m

M

o

=

3.8 Negative and Positive Design Moments

As per clause 31.4.3 of IS 456-2000 ,the negative design moment shall be at the

face of rectangular supports, circular supports being treated as square supports having the

same columns built integrally with the slab system area. Shall be designed to-resist

moments arising from loads.

In an interior span, the total design moment M

o

shall be distributed in the following

proportions

Negative design moment 0.65

Positive design moment 0.35

In an end span, the total design moment M

o

shall be distributed in the following

proportions

Interior negative design moment:

Positive design moment:

Exterior negative design moment:

a

c

Is the ratio of flexural stiffness of the exterior columns to the flexural stiffness of the

slab at a joint taken in the direction moments are being determined and is given by:

a

c

=

K

c

=sum of the flexural stiffness of the columns meeting at the joint.

K

s

=flexural stiffness of the slab, expressed as moment per unit rotation.

It shall be permissible to modify these design moments by up to 10 percent, so long as the

total design moment M

o

for the panel in the direction considered is not less than that

required by:

M

o

=

The negative moment section shall be designed to resist the larger of the two interior

negative design moments determined for the spans framing into a common support unless

an analysis is made to distribute the unbalanced moment in accordance with the stiffness

of the adjoining parts.

Moments In Column Strip

As per clause 31.4.5 of IS 456-2000,

1.Negative moment at an interior support: At an interior support, the column strip shall

be designed to resist 75 percent of the total negative moment in the panel at that support.

2.Negative moment at an exterior support:

a) At an exterior support, the column strip shall be designed to resist the total negative

moment in the panel at that support.

b) Where the exterior support consists of a column or a wall extending for a distance

equal to or greater than three-quarters of the value of l

2

. The length of span transverse to

the direction moments are being determined, the exterior negative moment shall be

considered to be uniformly distributed across the length l

2

.

3.Positive moment for each span: For each span, the column strip shall be designed to

resist 60 percent of the total positive moment in the panel.

Moments in The Middle Strip

a)That portion of-the design moment not resisted by the column strip shall be assigned to

the adjacent middle strips.

b) Each middle strip shall be proportioned to resist the sum of the moments assigned to

its two half middle strips. The middle strip adjacent and parallel to an edge supported by

a wall shall be proportioned, to resist twice the moment assigned to half the middle strip

corresponding to the first row of interior columns.

Stiffness Calculation

As per clause 31.5.2.1 of IS 456-2000,

let the height of the floor = 4.0 m

clear height of the column = height of floor depth of drop thickness of slab thickness

of head.

= 4000 140 285 300 = 3275 mm

Effective height of column = 0.8 x 3275 = 2620 mm

(Assuming one end hinged and other end fixed)

stiffness coefficient= a

c

=

1.longer span

k

c

=(

)

bottom

+(

)

top

(

)=2 (

) (

)=

(

k

s

, a

c

From table 17 of IS: 456-2000

&

a

cmin

a

c

a

cmin

o k

Hence the correction for pattern loading in the direction of short span is not required.

3.9 Distrubution Of Bending Moment Across The Panel Width

As per clause 31.4.3.3 of IS 456-2000,

In an exterior panel.

Longer span

1.column strip

Negative B.M at exterior support =[

] [

]

Positive span BM =[

]

Negative span BM at interior support = [

] -166.5 kNm

2.Middle Strip

Negative BM at exterior support =[

]

Positive span BM =[

]

Negative BM at interior support =

[

]

3.10 Effective depth of the slab

Thickness of the slab, from consideration of maximum positive moment any where in the

slab.

Maximum +ve BM occurs in the column strip (long span) = 90.91 kNm

factored moment = 1.50 x 90.91 = 136.36 kNm

M

o

0.138f

ck

( )

d=

( )

d=132.83 mm 140 mm

Using 12 mm (diameter) main bars.

Overall thickness of slab =14015+

161 mm 170 mm

Depth (along longitudinal direction) =170-15-

Depth (along longitudinal direction) = 150-12=138mm

3.11 Thickness of drop from maximum negative moment consideration

Thickness of drop from consideration of maximum ve moment anywhere in the panel.

Max negative BM occurs in the column strip = 166.6 KNm

M

u

=f

ck

bd

2

1.5

=0.138

d=254.3mm

Say 260 mm. Use 12 mm bars

Over all thickness of flat slab:D=260+15+

3.12 Shear in Flat Slab

As per clause 31.6 of IS 456-2000, the critical section for shear shall be at a distance d/2

from the periphery of the column/capital/ drop panel, perpendicular to the plane of the

slab where d is the effective depth of the section The shape in plan is geometrically

similar to the support immediately below the slab.

Check for shear stress developed in slab

The critical section for shear for the slab will be at a distance d/2 from the face of drop.

Perimeter of critical section =4 340=9340mm

V

o

=1.5 [

()()]=729.78kN

Nominal shear stress =T

v

=

shear strength of concrete =T

c

=0.25

= =1.1N/

Permissible shear stress =T

v

Ks=(0.5+

) ,

c

=0.848

K

s

=1.348

Tv<Tc safe Design OK

Check for shear in drop

b

o

=(D+

)=(1.3+0.26)=4.89 m

V=1.5 *

( )

+=812.27kN

T

v

=

=0.683N/mm

2

Nominal shear stress T

c

=0.25

=1.11N/mm

2

T

v

< T

C

safe in shear.

3.12 Reinforcement details

As per clause 31.7 of IS 456-2000

1.Longer span

Negative exterior reinforcement:

Mu=0.87 fyA

st

[

]

1.5

[ ]

Ast=4290mm

2

positive steel:-

1.5

Ast=3122mm

2

2. Shorter span

Column strip:

1.5

[ ]

Ast=3768.9mm

2

Middle strip:

1.5

[ ]

Ast=1182mm

2

CHAPTER 4

DESIGN OF FLAT SLAB USING ACI 318-08

4.1 Drop of flat slabs

As per clause 13.2.5 of ACI 318-08, where a drop panel is used to reduce

amount of negative moment reinforcement over the column of a flat slab, size of drop

panel shall be in accordance with the following:

Drop panel shall extend in each direction from centerline of support a distance not less

than one-sixth the span length measured from center -to center of supports in that

direction. Projection of drop panel below the slab shall be at least one -quarter the slab

thickness beyond the drop. In computing required slab reinforcement, thickness of drop

panel below the slab shall not be assumed greater than one-quarter the distance from edge

of drop panel to edge of column or column capital.

4.2 Thickness of the slab

As per clause 9.5.3 of ACI 318-08, for slabs without interior beams spanning

between the supports and having a ratio of long to short span not greater than 2, the

minimum thickness shall be in accordance with the provisions of Table below and shall

not be less than the following values:

(a) Slabs without drop panels as ......................... 5 in.

(b) Slabs with drop panels as defined.................. 4 in.

Table 4.1 Minimum Thickness of Slabs Without Interior Beams

consider the slab to be designed with drops

Depth of the slab from deflection criteria =

(the yield strees fyi=60,000psi,

4.3 Design strips: (13.2.1)

Column strip is a design strip with a width on each side of a column centerline equal to

0.25 l

2

or 0.25 l

1,

whichever is less.

Middle strip is a design strip bounded by two column strips.

A panel is bounded by column, beam, or wall centerlines on all sides.

4.4 Column head

The upper supporting part of a column is enlarged to form the column head. The diameter

or the column head is made 0.20 to 0.25 of the span length.

4.5 Total factored static moment for a span: (13.6.2)

Total factored static moment for a span shall be determined in a strip bounded laterally

by centerline of panel on each side of centerline of supports.

Absolute sum of positive and average negative factored moments in each direction shall

not be less than.

Mo=

W

u

=load per unit area acting on the slab panel

l

n

=Clear span l

n

shall extend from face to face of columns, capitals, brackets, or walls.

Value of l

n

shall not be less than 0.65 l

1

. Circular or regular polygon shaped supports

shall be treated as square supports with the same area.

l

2

=When the span adjacent and parallel to an edge is being considered, the distance from

edge to panel centerline shall be substituted for l

2

.

In an interior span, total static moment M

o

shall be distributed as follows:

Negative factored moment .................................0.65

Positive factored moment ...................................0.35

In an end span, total factored static moment 0 M shall be distributed as follows:

Negative moment sections shall be designed to resist the larger of the two interior

negative factored moments determined for spans framing into a common support unless

an analysis is made to distribute the unbalanced moment in accordance with stiff nesses

of adjoining elements. Edge beams or edges of slab shall be proportioned to resist in

torsion their share of exterior negative factored moments

Factored moments in middle strips:(13.6.6.3)

That portion of negative and positive factored moments not resisted by column

strips shall be proportionately assigned to corresponding half middle strips.

Each middle strip shall be proportioned to resist the sum of the moments assigned to its

two half middle strips.

A middle strip adjacent to and parallel with an edge supported by a wall shall be

proportioned to resist twice the moment assigned to the half middle strip corresponding

to the first row of interior supports.

Factored moments in column strips: (13.6.4)

Column strips shall be proportioned to resist the following portions in percent of

exterior negative factored moments:

Table 4.2

Column strips shall be proportioned to resist the following portions in percent of exterior

negative factored moments:

Tables 4.3

Modification of factored moment:

Modification of negative and positive factored moments by 10 percent shall be

permitted ,provided the total static moment for a panel in the direction considered is not

less than that required by M

o

=

4.6 Shear provision(punching shear): (13.6.8)

Two-way action where each of the critical sections to be investigated shall be

located so that its perimeter b

o

is a minimum but need not approach closer than d / 2 to

(a) Edges or corners of columns, concentrated loads, or reaction areas, or

(b) Changes in slab thickness such as edges of capitals or drop panels.

Nominal shear strength of concrete:

For flat slabs V

c

=nominal shear strength of concrete V

c

Shall be smallest of the

following: [Where

c

is the ratio of long side to short side of the column, concentrated

load or reaction area and where a

s

is 40 for interior columns, 30 for edge columns,20 for

corner columns]

V

c

==(

V

c

==(

V

c

=4

4.7 Numerical example:

consider the slab to be designed with drops

Depth of the slab from deflection criteria =

Minimum depth of slab

=max(

)

=max(5.58in,4.74in)

=5.58in

6 in > 4 in (for slabs with drop panels)

Providing a slab of thickness 6 in or 152.4 mm.

Density of concrete =150 lb/

Dead load on the slab =

Live load on the slab = 161.80 psf = 7.75 kN /m

2

Design load on the slab = (1.2 x 7.5 + 1.6 x 161.80)

= 348.88 350 psf

= 16. 765 kN /m

2

For short span direction, the total static design moment :

M

o

=

ft-kips=201.04kNm

This is distributed as follows :

Negative design moment = 148.06 x 0.65 = 96.24 ft -kips = 130.50 kNm

Positive design moment = 148.06 x 0.35 = 51.891 ft -kips = 70.36 kNm

The column strip has a width of 2 x2

With

=0 (no beams)

Bending moment for column strip:

Negative moment for column strip = 75 % of total negative moment in the panel

= 0.75 x 96.24 = 72.18 ft -kips = 97.88 kNm

Positive moment for column strip = 60 % of total positive moment in the panel.

= 0.60 x 51.891 = 31.135 ft -kips = 42.21 kNm

Static moment along longer direction

M

o

=

This is distributed as follows:

Negative design moment = 237 x 0. 65 = 154 ft-kips = 208.89 kNm

Positive design moment = 237 x 0.35 = 83.00 ft -kips = 113.22 kNm

The column strip has a width of 2

With

Bending moment for column strip

Negative moment for column strip = 75 % of total negative moment in the pannel

= 0.75 x 154.00 = 115.50 ft -kips = 157.66 kNm

Positive moment for column strip = 60 % of total positive moment in the panel.

= 0.60 x 83.00 = 49.8 ft -kips = 67.977 kNm

Bending moment for middle strip along shorter span

Negative moment for middle strip = 0.25 x 96.24

= 24.06 ft-kips

= 32.84 kNm

positive moment for middle strip = 0.40 x 51.891

= 20.7564 ft-kips

= 28.33 kNm

Bending moment for middle strip along longer span

Negative moment for middle strip = 0.25 x 154 = 38.5 ft -kip

= 52.55 kNm

Positive moment for middle strip = 0.40 x 83.00 = 33.2 ft kips

= 45.318 kNm

Max moment (+ve or ve ) along shorter span = 72.18 ft -kips

Max moment (+ve or ve) along longer span = 115.50 ft kips

P

max

= maximum permitted reinforcement ratio

M

u

=P

)

M

u

=* (

)+

()

=3.07in=77.79mm

provide a slab of thickness 6 in.

Drop in flat slabs:

Span of panel in longer direction = 16.76 ft

length of drop panel

=

=5.58ft

With half width on either side of th e centre line of support = 0.85 m

Thickness of drop =

Check for punching shear:

V

u

= factored shear, acting at distance d/2 from face of the support.

(assuming column of size 400 mm by 400 mm)

V

u

=350[( ) ( )( )]

=350[

]=82265.365 lb=365.91kN

= ( )

The nominal stress of concrete will be smallest of the following :

(a) V

c

==(

)

(b) V

c

==(

)

(c) V

c

=4

V

c

> V

u

section safe in punching shear safe.

Reinforcement detail

Depth=6 ft,Width=16.76 ft

Minimum area of steel required = 0.0018 x gross area of concrete

(for control of temperature & shrinkage cracking)

=0.0018

In 14.22 ft direction,P

min

=

In 16.76 ft direction,P

min

=

R=pf

y

(

)psi or R=

()

1. Calculation of area of steel along shorter span:

For negative moment in column strip:

R=

=150.933

Reinforcement ratio = 0.0040

Area of reinforcement = 0.0040 x 14.76 x 6 x 12 = 4.250 in

2

/ft

For positive moment in column strip :

R=

()

=65

Reinforcement ratio = 0.0017

Area of reinforcement = 0.0017x 14.76 x 6 x 12 =1.8066 in

2

/ft

For negative moment in middle strip:R=

=50.311

Reinforcement ratio = 0.0013

Area of reinforcement = 0.0013x 14.76 x 6 x 12 = 1.38 in

2

/ft

For positive moment in middle strip:

R=

=43.40

Reinforcement ratio = 0.00075

Area of reinforcement = 0.00075x 14.76 x 6 x 12 = 0.79 in

2

/ft

2. Calculation of area of steel along longer span:

For negative moment in column strip:

R=

()

=219.77

Reinforcement ratio = 0.00375

Area of reinforcement = 0.00375 x 16.22 x 6 x 12 = 4.38 in

2

/ft

For positive moment in column strip :

R=

()

=94.76

Reinforcement ratio = 0.00175

Area of reinforcement = 0.00175 x 16.22 x 6 x 12 = 2.04 in

2

/ ft

For negative moment in middle strip:

R=

()

=73.25

Reinforcement ratio = 0.00125

Area of reinforcement = 0.00125x 16.22 x 6 x 12 = 1.4598 in

2

/ ft

For positive moment in middle strip:

R=

()

=63.17

Reinforcement ratio = 0.00115

Area of reinforcement = 0.00115x 16.22 x 6 x 12 = 1.34 in

2

/ ft

CHAPTER 5

RESULTS-CODAL COMPARISIONS

CODE IS 456 -2000 ACI 318-08

Shape of test specimen

for concrete strength

(mm)

Cube

150x150x150

Cylinder

152.4x304.8

Grade of

concrete(N/mm)

20 20

Grade of steel (N/mm) 415 413.7

Negative moment

(KN-m)

188.5 208.89

Positive moments

(KN-m)

90 113.22

Area of

reinforcement(mm)

4290 2829

Thickness of slab for

Serviceability

criteria(mm)

170 150

Punching shear Safe Safe

CHAPTER 6

CONCLUSIONS

1. By comparing with different codes we concluded that ACI 318 code

is more effective in designing of flat slabs.

2. As per Indian code we are using cube strength but in international

standards cylindered are used which gives higher strength than cube.

3. Drops are important criteria in increasing the shear strength of the

slab.

4. Enhance resistance to punching failure at the junction of concrete

slab & column.

5. By incorporating heads in slab, we are increasing rigidity of slab.

6. In the interior span, the total design moments (Mo) are same for IS

456-2000 & ACI 318-08.

7. The negative moments section shall be designed to resist the larger

of the two interior negative design moments for the span framing into

common supports.

8. According to Indian standard (IS 456) for RCC code has

recommended characteristic strength of concrete as 20, 25, and 30

and above 30 for high strength concrete. For design purpose strength

of concrete is taken as 2/3 of actual strength this is to compensate the

difference between cube strength and actual strength of concrete in

structure. After that we apply factor of safety of 1.5. So in practice

Indian standard actually uses 46% of total concrete characteristic

strength. While in International practice is to take 85% of total

strength achieved by test and then apply factor of safety which is

same as Indian standard. So in actual they use 57% of total strength.

9. Pre fabricated sections to be integrated into the design for ease of

construction.

CHAPTER 7

REFERENCES

1. Bureau of Indian Standards, New Delhi, IS 456:2000, Plain and Reinforced

Concrete - Code of Practice, Fourth Revision, July (2000).

2. American Concrete Institute, ACI 318-08, Building Code Requirements for

Structural Concrete and Commentary, January (2008).

3. Dr. V. L. Shaha & Dr. S. R. Karve Limit State Theory and Design of

Reinforced Concrete Sixth edition

4. Amit A. Sathwane , R. S. Deoalate (IJERA)Analysis and Design of Flat Slab and

Grid Slab and Their cost omparision

Vous aimerez peut-être aussi

- Stability Analysis of Pipe Rack in Petrochemical Facilities-IJAERDV04I0264348Document11 pagesStability Analysis of Pipe Rack in Petrochemical Facilities-IJAERDV04I0264348Editor IJAERDPas encore d'évaluation

- Design of One-Way SlabDocument34 pagesDesign of One-Way SlabAbdelqader ShurrabPas encore d'évaluation

- ACI 437 R - 91 American Concrete InstituteDocument24 pagesACI 437 R - 91 American Concrete Instituteabdulrehman731Pas encore d'évaluation

- 330 1-03 PDFDocument6 pages330 1-03 PDFsaeidcivil89Pas encore d'évaluation

- Seismic Design Criteria For Slab-Column ConnectionsDocument12 pagesSeismic Design Criteria For Slab-Column ConnectionsIvan Jansen S.Pas encore d'évaluation

- Dynamic Analysis of Heavy Equipment Mounted On Steel Skid FoundationsDocument11 pagesDynamic Analysis of Heavy Equipment Mounted On Steel Skid FoundationsSagar M JadhavPas encore d'évaluation

- 313 97Document19 pages313 97Adrian DiezPas encore d'évaluation

- Aisc Dam GuideDocument12 pagesAisc Dam GuideScribdmarificPas encore d'évaluation

- ACI 303.1-97 Standard Specification For Cast-In-Place Architectural ConcreteDocument10 pagesACI 303.1-97 Standard Specification For Cast-In-Place Architectural ConcreteZaki 'Eki' MuliawanPas encore d'évaluation

- Case-1 (Actual Load+tension With Anchor Bar)Document16 pagesCase-1 (Actual Load+tension With Anchor Bar)userhiePas encore d'évaluation

- Design For DCM ColumnsDocument2 pagesDesign For DCM ColumnsTruong Phuoc TriPas encore d'évaluation

- Engineering Calculation Sheet Consulting EngineersDocument17 pagesEngineering Calculation Sheet Consulting EngineersParthiban ArivazhaganPas encore d'évaluation

- Bolted Field Splices For Steel Bridge Flexural MembersDocument76 pagesBolted Field Splices For Steel Bridge Flexural MembersMario Guevara Ubidia- IngenieroCivilPas encore d'évaluation

- Design of Reinforced Concrete Floor Systems: Professional Development SeriesDocument7 pagesDesign of Reinforced Concrete Floor Systems: Professional Development SeriesJCS100% (1)

- Site Specific Ground Response Analysis PDFDocument9 pagesSite Specific Ground Response Analysis PDFSudan ShresthaPas encore d'évaluation

- Books - 2509 - 0 HARBOUR ENGINEERING PDFDocument19 pagesBooks - 2509 - 0 HARBOUR ENGINEERING PDFMuhammad EMPas encore d'évaluation

- Earthquake Collapse PatternDocument16 pagesEarthquake Collapse Patterngaurav jagtap0% (1)

- TP02 Cornejo PDFDocument8 pagesTP02 Cornejo PDFJefreyMatuanMondranoPas encore d'évaluation

- ACI 318-Development and SplicesDocument4 pagesACI 318-Development and SplicesRafeeq WazirPas encore d'évaluation

- Design Documents Referenced: Api Pip 686 ACI 351.3R-04Document4 pagesDesign Documents Referenced: Api Pip 686 ACI 351.3R-04Dr RajeevPas encore d'évaluation

- As-11WI-6 Blast Resistant Design ConsiderationsDocument4 pagesAs-11WI-6 Blast Resistant Design ConsiderationsjausingchiPas encore d'évaluation

- Non-Shrink GroutDocument7 pagesNon-Shrink GroutIm ChinithPas encore d'évaluation

- Hilti HSL-3-GDocument8 pagesHilti HSL-3-GDaniel RabascallPas encore d'évaluation

- Aci 222.1-96Document43 pagesAci 222.1-96farhadamPas encore d'évaluation

- Mba Summer 2019Document2 pagesMba Summer 2019Deepak SolankiPas encore d'évaluation

- Fema 355 CDocument51 pagesFema 355 CWei ZhangPas encore d'évaluation

- BNCSReport5 2013 11Document69 pagesBNCSReport5 2013 11AlejandroPas encore d'évaluation

- İsrail Deprem Yönetmeliği EkiDocument18 pagesİsrail Deprem Yönetmeliği EkiErol Eylemci KaplanPas encore d'évaluation

- StandardiDocument4 pagesStandardinikolicjelenaPas encore d'évaluation

- ACI 307 - 1998 Chimney Design Commentary 307R - 98Document14 pagesACI 307 - 1998 Chimney Design Commentary 307R - 98aj2346Pas encore d'évaluation

- 546 Standard Asce/Sei 7-16Document11 pages546 Standard Asce/Sei 7-16Demi CalderonPas encore d'évaluation

- Bracing PDFDocument2 pagesBracing PDFmsn722005Pas encore d'évaluation

- Limit State Response of Composite Columns and Beam-Columns Part I, Roberto Leon PDFDocument18 pagesLimit State Response of Composite Columns and Beam-Columns Part I, Roberto Leon PDFHeriberto Bórquez UrquidyPas encore d'évaluation

- Relating Seismic Design Level and Seismic Performance: Fragility-Based Investigation of RC Moment-Resisting Frame Buildings in ChinaDocument13 pagesRelating Seismic Design Level and Seismic Performance: Fragility-Based Investigation of RC Moment-Resisting Frame Buildings in ChinaAniket DubePas encore d'évaluation

- Seismic Behavior of Steel Plate Shear WallDocument34 pagesSeismic Behavior of Steel Plate Shear WallSachin Pawar100% (1)

- AISC Shapes Database v14.0 - Metric - SI UnitDocument26 pagesAISC Shapes Database v14.0 - Metric - SI UnitDwiSulistyo09100% (1)

- Aci 224.3R - 2001 PDFDocument44 pagesAci 224.3R - 2001 PDFBhavanishankar ShettyPas encore d'évaluation

- One Way SlabDocument69 pagesOne Way Slabforlogin018Pas encore d'évaluation

- Double Tee Ridge BeamDocument3 pagesDouble Tee Ridge BeamhuyxpkissPas encore d'évaluation

- C StrucDesign Morgan Jun151 PDFDocument3 pagesC StrucDesign Morgan Jun151 PDFkylePas encore d'évaluation

- Guide To Shotcrete: by Lars BalckDocument4 pagesGuide To Shotcrete: by Lars BalcklijiabinbinPas encore d'évaluation

- Reinforcement For Slabs On GroundDocument7 pagesReinforcement For Slabs On GroundfordesignPas encore d'évaluation

- Analysis On Laterally Loaded Group PilesDocument5 pagesAnalysis On Laterally Loaded Group PileschenPas encore d'évaluation

- Detailed Composite Beam Design AISCDocument20 pagesDetailed Composite Beam Design AISCRaveendra Babu CherukuriPas encore d'évaluation

- Seismic Response Control Using Base Isolation Strategy, PDFDocument5 pagesSeismic Response Control Using Base Isolation Strategy, PDFAashiq MohammedPas encore d'évaluation

- Seismic Behavior and Design of Composite Steel Plate Shear Walls PDFDocument73 pagesSeismic Behavior and Design of Composite Steel Plate Shear Walls PDFmanpreetkhanujaPas encore d'évaluation

- Spancrete - CarbonCast - HP Insulated Wall PanelsDocument8 pagesSpancrete - CarbonCast - HP Insulated Wall PanelsMattSearsPas encore d'évaluation

- Cable Roofs HistoryDocument3 pagesCable Roofs HistorySparrow JackPas encore d'évaluation

- Retrofitting of BuildingPPTDocument52 pagesRetrofitting of BuildingPPTjithinaravind007100% (2)

- SP 17M (14) Student PreviewDocument12 pagesSP 17M (14) Student PreviewPrasanth B0% (1)

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionD'EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionPas encore d'évaluation

- Concrete-Filled Double-Skin Steel Tubular Columns: Behavior and DesignD'EverandConcrete-Filled Double-Skin Steel Tubular Columns: Behavior and DesignPas encore d'évaluation

- Design and Comparison of Flat Slab According To IS 456-2000 and ACI 318-08Document34 pagesDesign and Comparison of Flat Slab According To IS 456-2000 and ACI 318-08harishram123456Pas encore d'évaluation

- Enhanced Punching Shear MethodDocument4 pagesEnhanced Punching Shear Methodgks6043Pas encore d'évaluation

- Hospital Building ProjectDocument58 pagesHospital Building ProjectAnonymous yM5XLR694% (18)

- Design of Portal FramesDocument35 pagesDesign of Portal FramesPranav Prabhakar100% (2)

- 3 RD Sem StaddDocument35 pages3 RD Sem StaddPuneetkumar GargPas encore d'évaluation

- 3d PrintingDocument1 page3d PrintingMukesh MandePas encore d'évaluation

- Human Area Network: By: Vinayak NandikalDocument37 pagesHuman Area Network: By: Vinayak NandikalMukesh MandePas encore d'évaluation

- Virtual Reality (Artificial Reality)Document45 pagesVirtual Reality (Artificial Reality)Mukesh MandePas encore d'évaluation

- Design and Comparison of Flat Slab Using Is 456 - 2000Document26 pagesDesign and Comparison of Flat Slab Using Is 456 - 2000Mukesh Mande100% (6)

- Multifix All Mechanical Anchor - Design GuideDocument28 pagesMultifix All Mechanical Anchor - Design GuideConstantino L. Ramirez III0% (1)

- Section-VIII Bill of QtyDocument48 pagesSection-VIII Bill of Qtyinfra120Pas encore d'évaluation

- TEL-SRPD-EGD-CIV-001 Design Basis For Civil and Structural Rev B PDFDocument31 pagesTEL-SRPD-EGD-CIV-001 Design Basis For Civil and Structural Rev B PDFMuhammad LutfhiPas encore d'évaluation

- Masonry SuDocument32 pagesMasonry SuÔzØnè BęržëŕkPas encore d'évaluation

- ISA RP60 1 1990 Control Center FacilitiesDocument22 pagesISA RP60 1 1990 Control Center FacilitiesDaniel Arrieta DarrásPas encore d'évaluation

- Comparative Study On Behaviour of Hot and Cold Formed Steel Sections Under Flexure IJERTCONV5IS13158Document9 pagesComparative Study On Behaviour of Hot and Cold Formed Steel Sections Under Flexure IJERTCONV5IS13158samsurendran_mech4020Pas encore d'évaluation

- Storage Tank PDFDocument16 pagesStorage Tank PDFEngineering100% (1)

- Metro Rail Design Criteria Section 05 Structural-Geotechnical Rev 4Document163 pagesMetro Rail Design Criteria Section 05 Structural-Geotechnical Rev 4PS100% (1)

- A 485 - 03Document4 pagesA 485 - 03luis-12Pas encore d'évaluation

- AnchorDocument51 pagesAnchorrobiyullahPas encore d'évaluation

- 30.8 of VKT Road To Pannikkankuppam Road DPRDocument70 pages30.8 of VKT Road To Pannikkankuppam Road DPRveevimalPas encore d'évaluation

- Arc Welding of Specific Steels and Cast Irons: Fourth EditionDocument170 pagesArc Welding of Specific Steels and Cast Irons: Fourth EditionJose Luis ChapasPas encore d'évaluation

- Fpb1500c, D, e 500e or 1800a, B ManualDocument150 pagesFpb1500c, D, e 500e or 1800a, B ManualAzianCuz50% (2)

- Difference Between Moment Connection and Shear Connection in Steel StructuresDocument3 pagesDifference Between Moment Connection and Shear Connection in Steel StructuresThiha Kyaw100% (1)

- ASDO - EnglischDocument12 pagesASDO - EnglischCraciun PaulPas encore d'évaluation

- AWS Material Trace AbilityDocument2 pagesAWS Material Trace AbilitySanthosh NairPas encore d'évaluation

- Chapter 6Document36 pagesChapter 6dyanPas encore d'évaluation

- Aluminium AloyDocument2 pagesAluminium AloyGian GiovaniPas encore d'évaluation

- Design of Bunkers and SilosDocument15 pagesDesign of Bunkers and SilosSagarKasarla100% (1)

- Corus Jumbo Sections 2004Document20 pagesCorus Jumbo Sections 2004Collin NguPas encore d'évaluation

- UEP Bulletin 1724E-204Document55 pagesUEP Bulletin 1724E-204Edwin Medina TroncosPas encore d'évaluation

- Program of Work: Part A-Ofacilities For The EngineersDocument3 pagesProgram of Work: Part A-Ofacilities For The Engineersnught surPas encore d'évaluation

- Davit TestDocument6 pagesDavit TestOkondu ChieduPas encore d'évaluation

- Steel Weight CalculatorDocument26 pagesSteel Weight Calculatormakara ukthaunPas encore d'évaluation

- Astm A656Document2 pagesAstm A656josefonte50% (2)

- Sans 1431Document30 pagesSans 1431johndupPas encore d'évaluation

- Civil - Steel Structure Drawing ChecklistDocument4 pagesCivil - Steel Structure Drawing ChecklistZafar100% (2)

- Is 1200 15Document12 pagesIs 1200 15ramachandra_20012040Pas encore d'évaluation

- 7 3814 AX SG 000002 IS05 Structural Steel SpecificationDocument34 pages7 3814 AX SG 000002 IS05 Structural Steel Specificationgchaves504Pas encore d'évaluation

- Lincoln FC ElectrodesDocument44 pagesLincoln FC ElectrodeszmcgainPas encore d'évaluation