Académique Documents

Professionnel Documents

Culture Documents

Hydraulic Cylinder

Transféré par

michol2014Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Hydraulic Cylinder

Transféré par

michol2014Droits d'auteur :

Formats disponibles

Hydraulic cylinder

1

Hydraulic cylinder

The hydraulic cylinders on this excavator control the machine's linkages.

A Hydraulic cylinder (also called a

linear hydraulic motor) is a mechanical

actuator that is used to give a

unidirectional force through a

unidirectional stroke. It has many

applications, notably in engineering

vehicles.

Operation

Hydraulic cylinders get their power

from pressurized hydraulic fluid,

which is typically oil. The hydraulic

cylinder consists of a cylinder barrel,

in which a piston connected to a piston

rod moves back and forth. The barrel is

closed on each end by the cylinder bottom (also called the cap end) and by the cylinder head where the piston rod

comes out of the cylinder. The piston has sliding rings and seals. The piston divides the inside of the cylinder in two

chambers, the bottom chamber (cap end) and the piston rod side chamber (rod end). The hydraulic pressure acts on

the piston to do linear work and motion.

Flanges, trunnions, and/or clevisses are mounted to the cylinder body. The piston rod also has mounting attachments

to connect the cylinder to the object or machine component that it is pushing.

A hydraulic cylinder is the actuator or "motor" side of this system. The "generator" side of the hydraulic system is

the hydraulic pump which brings in a fixed or regulated flow of oil to the bottom side of the hydraulic cylinder, to

move the piston rod upwards. The piston pushes the oil in the other chamber back to the reservoir. If we assume that

the oil pressure in the piston rod chamber is approximately zero, the force F on the piston rod equals the pressure P

in the cylinder times the piston area A:

.

The piston moves instead downwards if oil is pumped into the piston rod side chamber and the oil from the piston

area flows back to the reservoir without pressure. The pressure in the piston rod area chamber is (Pull Force) /

(piston area - piston rod area).

Parts of a hydraulic cylinder

A hydraulic cylinder consists of the following parts:

Cylinder barrel

The cylinder barrel is mostly a seamless thick walled forged pipe that must be machined internally. The cylinder

barrel is ground and/or honed internally.

Cylinder Bottom or Cap

In most hydraulic cylinders, the barrel and the bottom portion are welded together. This can damage the inside of the

barrel if done poorly. Therefore some cylinder designs have a screwed or flanged connection from the cylinder end

Hydraulic cylinder

2

cap to the barrel. (See "Tie Rod Cylinders" below) In this type the barrel can be disassembled and repaired in future.

Cylinder Head

The cylinder head is sometimes connected to the barrel with a sort of a simple lock (for simple cylinders). In general

however the connection is screwed or flanged. Flange connections are the best, but also the most expensive. A flange

has to be welded to the pipe before machining. The advantage is that the connection is bolted and always simple to

remove. For larger cylinder sizes, the disconnection of a screw with a diameter of 300 to 600mm is a huge problem

as well as the alignment during mounting.

Piston

The piston is a short, cylinder-shaped metal component that separates the two sides of the cylinder barrel internally.

The piston is usually machined with grooves to fit elastomeric or metal seals. These seals are often O-rings, U-cups

or cast iron rings. They prevent the pressurized hydraulic oil from passing by the piston to the chamber on the

opposite side. This difference in pressure between the two sides of the piston causes the cylinder to extend and

retract. Piston seals vary in design and material according to the pressure and temperature requirements that the

cylinder will see in service. Generally speaking, elastomeric seals made from nitrile rubber or other materials are

best in lower temperature environments while seals made of Viton are better for higher temperatures. The best seals

for high temperature are cast iron piston rings.

Piston Rod

The piston rod is typically a hard chrome-plated piece of cold-rolled steel which attaches to the piston and extends

from the cylinder through the rod-end head. In double rod-end cylinders, the actuator has a rod extending from both

sides of the piston and out both ends of the barrel. The piston rod connects the hydraulic actuator to the machine

component doing the work. This connection can be in the form of a machine thread or a mounting attachment such

as a rod-clevis or rod-eye. These mounting attachments can be threaded or welded to the piston rod or, in some

cases, they are a machined part of the rod-end.

Rod Gland

The cylinder head is fitted with seals to prevent the pressurized oil from leaking past the interface between the rod

and the head. This area is called the rod gland. It often has another seal called a rod wiper which prevents

contaminants from entering the cylinder when the extended rod retracts back into the cylinder. The rod gland also

has a rod bearing. This bearing supports the weight of the piston rod and guides it as it passes back and forth through

the rod gland. In some cases, especially in small hydraulic cylinders, the rod gland and the rod bearing are made

from a single integral machined part.

Other parts

Cylinder bottom connection

Seals

Cushions

A hydraulic cylinder should be used for pushing and pulling only. No bending moments or side loads should be

transmitted to the piston rod or the cylinder. For this reason, the ideal connection of a hydraulic cylinder is a single

clevis with a spherical ball bearing. This allows the hydraulic actuator to move and allow for any misalignment

between the actuator and the load it is pushing.

Hydraulic cylinder

3

Hydraulic Cylinder Designs

There are primarily two styles of hydraulic cylinder construction used in industry: tie rod style cylinders and welded

body style cylinders.

Tie Rod Cylinders

Tie rod style hydraulic cylinders use high strength threaded steel rods to hold the two end caps to the cylinder barrel.

This method of construction is most often seen in industrial factory applications. Small bore cylinders usually have 4

tie rods, while large bore cylinders may require as many as 16 or 20 tie rods in order to retain the end caps under the

tremendous forces produced. Tie rod style cylinders can be completely disassembled for service and repair.

The National Fluid Power Association (NFPA) has standardized the dimensions of hydraulic tie rod cylinders. This

enables cylinders from different manufacturers to interchange within the same mountings.

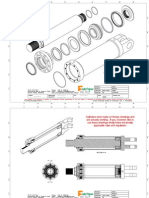

Welded Body Cylinders

Welded body cylinders have no tie rods. The barrel is welded directly to the end caps. The ports are welded to the

barrel. The front rod gland is usually threaded into or bolted to the cylinder barrel. This allows the piston rod

assembly and the rod seals to be removed for service.

A Cut Away of a Welded Body Hydraulic

Cylinder showing the internal components

Welded body cylinders have a number of advantages over tie rod style cylinders. Welded cylinders have a narrower

body and often a shorter overall length enabling them to fit better into the tight confines of machinery. Welded

cylinders do not suffer from failure due to tie rod stretch at high pressures and long strokes. The welded design also

lends itself to customization. Special features are easily added to the cylinder body. These may include special ports,

custom mounts, valve manifolds, and so on.

The smooth outer body of welded cylinders also enables the design of multi-stage telescopic cylinders.

Welded body hydraulic cylinders dominate the mobile hydraulic equipment market such as construction equipment

(excavators, bulldozers, and road graders) and material handling equipment (forklift trucks, telehandlers, and

lift-gates). They are also used in heavy industry such as cranes, oil rigs, and large off-road vehicles in above-ground

mining.

Piston Rod construction

The piston rod of a hydraulic cylinder operates both inside and outside the barrel, and consequently both in and out

of the hydraulic fluid and surrounding atmosphere.

Metallic coatings

Smooth and hard surfaces are desirable on the outer diameter of the piston rod and slide rings for proper sealing.

Corrosion resistance is also advantageous. A chromium layer may often be applied on the outer surfaces of these

parts. However, chromium layers may be porous, thereby attracting moisture and eventually causing oxidation. In

harsh marine environments, the steel is often treated with both a nickel layer and a chromium layer. Often 40 to 150

micrometer thick layers are applied. Sometimes solid stainless steel rods are used. High quality stainless steel such as

AISI 316 may be used for low stress applications. Other stainless steels such as AISI 431 may also be used where

there are higher stresses, but lower corrosion concerns.

Hydraulic cylinder

4

Ceramic coatings

Due to shortcomings of metallic materials, ceramic coatings were developed. Initially ceramic protection schemes

seemed ideal, but porosity was higher than projected. Recently the corrosion resistant semi ceramic Lunac 2+

coatings were introduced. These hard coatings are non porous and do not suffer from high brittleness.

Lengths

Piston rods are generally available in lengths which are cut to suit the application. As the common rods have a soft or

mild steel core, their ends can be welded or machined for a screw thread.

Special hydraulic cylinders

Telescopic cylinder

Telescopic cylinder (ISO 1219 symbol)

The length of a hydraulic cylinder is the total of the stroke, the thickness of

the piston, the thickness of bottom and head and the length of the

connections. Often this length does not fit in the machine. In that case the

piston rod is also used as a piston barrel and a second piston rod is used.

These kind of cylinders are called telescopic cylinders. If we call a normal rod

cylinder single stage, telescopic cylinders are multi-stage units of two, three,

four, five and even six stages. In general telescopic cylinders are much more

expensive than normal cylinders. Most telescopic cylinders are single acting (push). Double acting telescopic

cylinders must be specially designed and manufactured.

Plunger cylinder

Plunger cylinder

A hydraulic cylinder without a piston or with a piston without seals is

called a plunger cylinder. A plunger cylinder can only be used as a

pushing cylinder; the maximum force is piston rod area multiplied by

pressure. This means that a plunger cylinder in general has a relatively

thick piston rod.

Differential cylinder

Differential cylinder (ISO 1219 symbol)

A differential cylinder acts like a normal cylinder when pulling. If the

cylinder however has to push, the oil from the piston rod side of the cylinder

is not returned to the reservoir, but goes to the bottom side of the cylinder. In

such a way, the cylinder goes much faster, but the maximum force the

cylinder can give is like a plunger cylinder. A differential cylinder can be

manufactured like a normal cylinder, and only a special control is added.

Hydraulic cylinder

5

Rephasing cylinder

Rephasing cylinders are two or more cylinders plumbed in series or parallel, with the bores and rods sized such that

all rods extend and/or retract equally when flow is directed to the first, or last, cylinder within the system.

In "parallel" applications, the bore and rod sizes are always the same, and the cylinders are always used in pairs. In

"series" applications, the bore and rod sizes are always different, and two or more cylinders may be used. In these

applications, the bores and rods are sized such that all rods extend or retract equally when flow is applied to the first

or last cylinder within the system.

This hydraulic synchronization of rod positions eliminates the need for a flow divider in the hydraulic system, or any

type of mechanical connection between the cylinder rods to achieve synchronization.

[1]

Position sensing "smart" hydraulic cylinder

Position sensing hydraulic cylinders eliminate the need for a hollow cylinder rod. Instead, an external sensing bar

utilizing Hall-Effect technology senses the position of the cylinders piston. This is accomplished by the placement

of a permanent magnet within the piston. The magnet propagates a magnetic field through the steel wall of the

cylinder, providing a locating signal to the sensor.

[2]

[3]

A note about popular terminology

At least in the USA, popular usage sometimes refers to the whole assembly of cylinder, piston, and piston rod (or

more) collectively as a "piston", which is incorrect. See, for instance, "Hydraulic piston raises the table from 19 (in.)

to 26 (in.)" Marine Tables, Inc.

[4]

(Select item 3 of 8, near the bottom.)

References

[1] Energy Manufacturing Explanation of Rephasing Cylinder (http:/ / www. energymfg. com/ products/ rephasing-hydraulic-cylinders. html)

[2] Energy Definition of Position Sensing Hydraulic Cylinder (http:/ / www. energymfg. com/ products/

position-sensing-smart-hydraulic-cylinders. html)

[3] Position Sensing Hydraulic Cylinders

[4] http:/ / marinetablesinc. com/ collections/ category/ high-lows/

Article Sources and Contributors

6

Article Sources and Contributors

Hydraulic cylinder Source: http://en.wikipedia.org/w/index.php?oldid=391706310 Contributors: A More Perfect Onion, Aboalbiss, Amalas, Andy Dingley, Animagi1981, Ash, Bhgtrog,

Biscuittin, Catsquisher, Celerystick009, Clockworkis, Daderot, Ddunkel, Dhollm, Dmercurio1, Drmies, Duk, Dulciana, EdJogg, Edison, Editore99, Edwarle, Ency, Fosnez, Graham87, Grstain,

HenkvD, Hillel, Hotdogcartman, J12629, Jamclaassen, Joef101, Jusdafax, Kamarton, Ke6gwf, L Kensington, Lazylaces, LeaveSleaves, Louisville Hydraulics, Luna Santin, Mannafredo, MarcRY,

Mdresser, Mebden, Mikiemike, Nate9112, Nick Michael, Nikevich, Pinethicket, Quadell, RadioFan, Rexroth-Hydraulics, Rickjpelleg, Rjwilmsi, S, Seamusd, Skier Dude, Sotojenerpac, Thparkth,

Tiptoety, Trekphiler, VBGFscJUn3, Vanjka-ivanych, Wizard191, Wuhwuzdat, Xqt, Yendificer, 75 anonymous edits

Image Sources, Licenses and Contributors

Image:Blmexcavsm.jpg Source: http://en.wikipedia.org/w/index.php?title=File:Blmexcavsm.jpg License: unknown Contributors: High Contrast, LosHawlos, WernerHerdecke

Image:cutawayweldedcylinder544x123.jpg Source: http://en.wikipedia.org/w/index.php?title=File:Cutawayweldedcylinder544x123.jpg License: Public Domain Contributors: Hotdogcartman

Image:Double acting telescopic cylinder (symbol,ISO1219).svg Source: http://en.wikipedia.org/w/index.php?title=File:Double_acting_telescopic_cylinder_(symbol,ISO1219).svg License:

Creative Commons Attribution-Sharealike 3.0 Contributors: Marton Kiss-Albert

Image:Plungercylinder.jpg Source: http://en.wikipedia.org/w/index.php?title=File:Plungercylinder.jpg License: GNU Free Documentation License Contributors: Jamclaassen

Image:Double acting cylinder (symbol,differential,ISO1219).svg Source: http://en.wikipedia.org/w/index.php?title=File:Double_acting_cylinder_(symbol,differential,ISO1219).svg License:

Creative Commons Attribution-Sharealike 3.0 Contributors: Marton Kiss-Albert

License

Creative Commons Attribution-Share Alike 3.0 Unported

http:/ / creativecommons. org/ licenses/ by-sa/ 3. 0/

Vous aimerez peut-être aussi

- CylindersDocument36 pagesCylindersNellai Vpr100% (1)

- Hydraulic CylindersDocument7 pagesHydraulic Cylinderspacopil34Pas encore d'évaluation

- Hydraulic Cylinders: Faculty of Engineering Cairo University Mechanical Design & Prod. DepartmentDocument21 pagesHydraulic Cylinders: Faculty of Engineering Cairo University Mechanical Design & Prod. DepartmentengmomoPas encore d'évaluation

- Hydraulic Cylinder: Guided By:-Dr. Pankaj Sahlot Presented By: - Kishan Savaliya (15Bme149D) Viken Patel (14BME072)Document15 pagesHydraulic Cylinder: Guided By:-Dr. Pankaj Sahlot Presented By: - Kishan Savaliya (15Bme149D) Viken Patel (14BME072)SK MagnetxPas encore d'évaluation

- Hydraulic Cylinder EnotesDocument8 pagesHydraulic Cylinder Enotesapi-3723357100% (3)

- Axial Piston Pump Lecture 8Document12 pagesAxial Piston Pump Lecture 8ssbudzPas encore d'évaluation

- Hydraulic Motors: What Is A Hydraulic Motor and Why Do You Need It?Document7 pagesHydraulic Motors: What Is A Hydraulic Motor and Why Do You Need It?Anil NairPas encore d'évaluation

- 5-778-93 Hydraulic CylindersDocument8 pages5-778-93 Hydraulic CylindersJerry ZhangPas encore d'évaluation

- Basic Hydraulics - JR - L&TDocument188 pagesBasic Hydraulics - JR - L&TArul SankaranPas encore d'évaluation

- Instruction Manual: AH-250H Automatic Hitch Feed Metal Cutting Band Saw (415V) 280 X 250mm (W X H) RectangleDocument134 pagesInstruction Manual: AH-250H Automatic Hitch Feed Metal Cutting Band Saw (415V) 280 X 250mm (W X H) Rectanglemaicon sulivanPas encore d'évaluation

- Hydraulics Training - KemapcoDocument77 pagesHydraulics Training - Kemapcoapi-3806314100% (2)

- Chapter 4 ValvesDocument55 pagesChapter 4 ValvesNor HidayahPas encore d'évaluation

- Hydraulic Circuits and ApplicationsDocument20 pagesHydraulic Circuits and ApplicationsLalola HahohaPas encore d'évaluation

- Hydraulic Power Units Vertical Mount Fixed DisplacementDocument32 pagesHydraulic Power Units Vertical Mount Fixed DisplacementSujata Roy100% (1)

- Hydraulic Cylinder - ReferenceDocument95 pagesHydraulic Cylinder - ReferenceWarren RiveraPas encore d'évaluation

- Hydraulic Pumps and MotorsDocument1 pageHydraulic Pumps and MotorsChumporn SaraphatmarkyingPas encore d'évaluation

- Full Text 02Document112 pagesFull Text 02Như Nguyễn Trần ThảoPas encore d'évaluation

- Joints and Pains of Hydraulic CylindersDocument16 pagesJoints and Pains of Hydraulic CylindersVinaySeebaPas encore d'évaluation

- Hydroirma Catalog Gear PumpDocument104 pagesHydroirma Catalog Gear PumpEng-Mohammed Salem100% (1)

- 3 PTL MBD SimulationDocument8 pages3 PTL MBD SimulationSumit SheoranPas encore d'évaluation

- Buckling of Hydraulic Cylinder - ANSYSDocument11 pagesBuckling of Hydraulic Cylinder - ANSYSnavsidPas encore d'évaluation

- Basic HydraulicsDocument85 pagesBasic HydraulicsRamesh Babu K KPas encore d'évaluation

- 1.6 Hoses, Pipes & FittingsDocument17 pages1.6 Hoses, Pipes & FittingsAndikaPas encore d'évaluation

- Presentation by Mr. Kalu Charan Sia Sr. Maintenance Engineer The Supreme Industries Limited Kharagpur - PPDDocument54 pagesPresentation by Mr. Kalu Charan Sia Sr. Maintenance Engineer The Supreme Industries Limited Kharagpur - PPDAnimesh Jana100% (1)

- Hydraulics and PneumaticsDocument20 pagesHydraulics and Pneumaticsharishme028100% (2)

- 1 Fluid Power Devices CircuitsDocument20 pages1 Fluid Power Devices CircuitshamidouPas encore d'évaluation

- Service Instructions: Oilgear Type "PVV 540" Open Loop PumpsDocument14 pagesService Instructions: Oilgear Type "PVV 540" Open Loop PumpsAxel LetonaPas encore d'évaluation

- Fluid Power EngineeringDocument2 pagesFluid Power EngineeringBhavesh PipaliyaPas encore d'évaluation

- Kobelco Wet Type Clutch WinchDocument5 pagesKobelco Wet Type Clutch WinchPHÁT NGUYỄN THẾPas encore d'évaluation

- Basic HydraulicsDocument30 pagesBasic HydraulicsPremangshu SahaPas encore d'évaluation

- Coool Hydraulic System Design ThesisDocument235 pagesCoool Hydraulic System Design ThesisGirish Kasturi100% (1)

- Unit 24: Applications of Pneumatics and HydraulicsDocument15 pagesUnit 24: Applications of Pneumatics and HydraulicsEmad ElsaidPas encore d'évaluation

- HYdraulics Lab Manual - New1Document115 pagesHYdraulics Lab Manual - New1Fati Mah100% (2)

- Gear Pumps Amp Motors Failure Analysis Guide PDFDocument26 pagesGear Pumps Amp Motors Failure Analysis Guide PDFChristopher GarciaPas encore d'évaluation

- Lesson 3 - Hydraulic PumpDocument10 pagesLesson 3 - Hydraulic PumppowertrainlPas encore d'évaluation

- Hydraulic Basics KnowladgeDocument72 pagesHydraulic Basics KnowladgeVanHieu Luyen100% (1)

- Mobile Hydraulic Tips: Component Basics For Mobile Equipment HydraulicsDocument16 pagesMobile Hydraulic Tips: Component Basics For Mobile Equipment HydraulicsSamik MukherjeePas encore d'évaluation

- Linkage in Farm MachineryDocument4 pagesLinkage in Farm MachineryRehan RashidPas encore d'évaluation

- Basic HydraulicsDocument53 pagesBasic Hydraulicsabhinay02mePas encore d'évaluation

- Department of Mechanical Engineering Question Bank 2017 (Regulation) ME8694-Hydraulics and PneumaticsDocument15 pagesDepartment of Mechanical Engineering Question Bank 2017 (Regulation) ME8694-Hydraulics and PneumaticsSC 8D musicPas encore d'évaluation

- Hydraulic Cylinder Force & Speed CalculationDocument1 pageHydraulic Cylinder Force & Speed CalculationMani Maran0% (2)

- Fluid Power Applications ExampleDocument14 pagesFluid Power Applications Examplemskumar_554100% (1)

- EATON Vickers Vane Motor PDFDocument17 pagesEATON Vickers Vane Motor PDFAndri HermantoPas encore d'évaluation

- Aa2fm Rexroth PDFDocument36 pagesAa2fm Rexroth PDFComassur SA de CVPas encore d'évaluation

- SealsDocument143 pagesSealsMd ArifullahPas encore d'évaluation

- Calculation of Hydraulic Cylinder Design - HänchenDocument1 pageCalculation of Hydraulic Cylinder Design - Hänchenkumardas das100% (1)

- Cylinders FullDocument110 pagesCylinders FulltnvishPas encore d'évaluation

- Earth-Moving Machinery - Hydraulic Excavator and Backhoe Loader Boom-Lowering Control Device - Requirements and TestsDocument25 pagesEarth-Moving Machinery - Hydraulic Excavator and Backhoe Loader Boom-Lowering Control Device - Requirements and TestsVictor MedinaPas encore d'évaluation

- Hydraulic Power PacksDocument44 pagesHydraulic Power PacksHarsh Thakkar100% (1)

- Session 12 en Logic Element-Cartridge Valve NoRestrictionDocument5 pagesSession 12 en Logic Element-Cartridge Valve NoRestrictionahmed elkhoulyPas encore d'évaluation

- HYDAC Understanding Hydraulics1 MAR 2015Document5 pagesHYDAC Understanding Hydraulics1 MAR 2015marc271986Pas encore d'évaluation

- NAHAD Hydraulic Hose Assembly GuidelinesDocument65 pagesNAHAD Hydraulic Hose Assembly GuidelinesLuhur BudiPas encore d'évaluation

- Hydraulic Cylinder CalculationsDocument5 pagesHydraulic Cylinder CalculationsManoj Thomas100% (3)

- Hydraulic Cylinder: The Hydraulic Cylinders On This Control The Machine'sDocument9 pagesHydraulic Cylinder: The Hydraulic Cylinders On This Control The Machine'smanojpro21_9131911970% (1)

- ME080 Section 8 - Other Hydraulic ComponentsDocument101 pagesME080 Section 8 - Other Hydraulic ComponentsAhmed FaragPas encore d'évaluation

- Parts of A Hydraulic CylinderDocument2 pagesParts of A Hydraulic CylinderSamma Noor GujjarPas encore d'évaluation

- Hydraulic Cylinder by Syed Jaffer PDFDocument39 pagesHydraulic Cylinder by Syed Jaffer PDFSiraj Busse100% (7)

- Hydraulic Cylinder AppDocument5 pagesHydraulic Cylinder AppwanradhiahPas encore d'évaluation

- Hydrolic Pipe Bending MachineDocument59 pagesHydrolic Pipe Bending MachineNilesh Maheshwari67% (3)

- Engine Construction 1Document11 pagesEngine Construction 1collins arogoPas encore d'évaluation

- Lifetime (Guitar Tab) - Ben & BenDocument4 pagesLifetime (Guitar Tab) - Ben & Benmichol2014Pas encore d'évaluation

- Kks-Kraftwerk KennzeichensystemDocument53 pagesKks-Kraftwerk KennzeichensystemDuncan_McLeod_8911Pas encore d'évaluation

- IsolatorsDocument12 pagesIsolatorsmichol2014Pas encore d'évaluation

- Instruments TransformersDocument15 pagesInstruments Transformersmichol2014Pas encore d'évaluation

- Surge ArresterDocument10 pagesSurge Arrestermichol2014Pas encore d'évaluation

- En Engineering Basic Vocational KnowledgeDocument172 pagesEn Engineering Basic Vocational KnowledgeAdisu ShumbelayPas encore d'évaluation

- Control PanelDocument12 pagesControl Panelmichol20140% (1)

- BeerDocument21 pagesBeermichol20140% (1)

- Piping and Plumbing Fittings PDFDocument5 pagesPiping and Plumbing Fittings PDFmichol201450% (4)

- Pipe Network Analysis PDFDocument3 pagesPipe Network Analysis PDFmichol2014100% (2)

- Ice Rink: Name OriginsDocument6 pagesIce Rink: Name Originsmichol2014Pas encore d'évaluation

- Cheesemaker: ProcessDocument4 pagesCheesemaker: Processmichol2014Pas encore d'évaluation

- Prener-Lc Preamp User'S Manual: FunctionsDocument3 pagesPrener-Lc Preamp User'S Manual: Functionsmichol2014Pas encore d'évaluation

- Statistics Geothermal FieldsDocument3 pagesStatistics Geothermal Fieldsmichol2014Pas encore d'évaluation

- MRBR ATR 72 Rev18Document424 pagesMRBR ATR 72 Rev18Juan Forero OrtizPas encore d'évaluation

- Azimuth Steueung - EngDocument13 pagesAzimuth Steueung - EnglacothPas encore d'évaluation

- Harper Independent Distributor Tri FoldDocument2 pagesHarper Independent Distributor Tri FoldYipper ShnipperPas encore d'évaluation

- Laboratory Manual (CIV 210) Engineering Surveying (2018-19) (For Private Circulation Only)Document76 pagesLaboratory Manual (CIV 210) Engineering Surveying (2018-19) (For Private Circulation Only)gyanendraPas encore d'évaluation

- Organization and Management Module 3: Quarter 1 - Week 3Document15 pagesOrganization and Management Module 3: Quarter 1 - Week 3juvelyn luegoPas encore d'évaluation

- GT-N7100-Full Schematic PDFDocument67 pagesGT-N7100-Full Schematic PDFprncha86% (7)

- CEE Annual Report 2018Document100 pagesCEE Annual Report 2018BusinessTech100% (1)

- Waterstop TechnologyDocument69 pagesWaterstop TechnologygertjaniPas encore d'évaluation

- TIMO Final 2020-2021 P3Document5 pagesTIMO Final 2020-2021 P3An Nguyen100% (2)

- Networker Performance Tuning PDFDocument49 pagesNetworker Performance Tuning PDFHarry SharmaPas encore d'évaluation

- Business Plan 3.3Document2 pagesBusiness Plan 3.3Rojin TingabngabPas encore d'évaluation

- LTE Networks Engineering Track Syllabus Overview - 23 - 24Document4 pagesLTE Networks Engineering Track Syllabus Overview - 23 - 24Mohamed SamiPas encore d'évaluation

- Gemini Dollar WhitepaperDocument7 pagesGemini Dollar WhitepaperdazeeePas encore d'évaluation

- Proceeding of Rasce 2015Document245 pagesProceeding of Rasce 2015Alex ChristopherPas encore d'évaluation

- Working With Difficult People Online WorksheetDocument4 pagesWorking With Difficult People Online WorksheetHugh Fox IIIPas encore d'évaluation

- Hdfs Default XML ParametersDocument14 pagesHdfs Default XML ParametersVinod BihalPas encore d'évaluation

- Nama: Yossi Tiara Pratiwi Kelas: X Mis 1 Mata Pelajaran: Bahasa InggrisDocument2 pagesNama: Yossi Tiara Pratiwi Kelas: X Mis 1 Mata Pelajaran: Bahasa InggrisOrionj jrPas encore d'évaluation

- Richardson Heidegger PDFDocument18 pagesRichardson Heidegger PDFweltfremdheitPas encore d'évaluation

- Mcom Sem 4 Project FinalDocument70 pagesMcom Sem 4 Project Finallaxmi iyer75% (4)

- Role of Personal Finance Towards Managing of Money - DraftaDocument35 pagesRole of Personal Finance Towards Managing of Money - DraftaAndrea Denise Lion100% (1)

- Golf Croquet Refereeing Manual - Croquet AustraliaDocument78 pagesGolf Croquet Refereeing Manual - Croquet AustraliaSenorSushi100% (1)

- Test ScienceDocument2 pagesTest Sciencejam syPas encore d'évaluation

- FAMOUS PP Past TenseDocument21 pagesFAMOUS PP Past Tenseme me kyawPas encore d'évaluation

- Parliament of India: Rajya SabhaDocument64 pagesParliament of India: Rajya SabhaSivapothuraju KonathalaPas encore d'évaluation

- Global Geo Reviewer MidtermDocument29 pagesGlobal Geo Reviewer Midtermbusinesslangto5Pas encore d'évaluation

- Pavement Design1Document57 pagesPavement Design1Mobin AhmadPas encore d'évaluation

- Financial Accounting 2 SummaryDocument10 pagesFinancial Accounting 2 SummaryChoong Xin WeiPas encore d'évaluation

- PLC Laboratory Activity 2Document3 pagesPLC Laboratory Activity 2Kate AlindajaoPas encore d'évaluation

- All You Need To Know About Egg YolkDocument7 pagesAll You Need To Know About Egg YolkGolden Era BookwormPas encore d'évaluation

- Dtu Placement BrouchureDocument25 pagesDtu Placement BrouchureAbhishek KumarPas encore d'évaluation

- Fire on the Horizon: The Untold Story of the Gulf Oil DisasterD'EverandFire on the Horizon: The Untold Story of the Gulf Oil DisasterPas encore d'évaluation

- Electric Motors and Drives: Fundamentals, Types and ApplicationsD'EverandElectric Motors and Drives: Fundamentals, Types and ApplicationsÉvaluation : 4.5 sur 5 étoiles4.5/5 (12)

- Electric Motor Control: DC, AC, and BLDC MotorsD'EverandElectric Motor Control: DC, AC, and BLDC MotorsÉvaluation : 4.5 sur 5 étoiles4.5/5 (19)

- Well Integrity for Workovers and RecompletionsD'EverandWell Integrity for Workovers and RecompletionsÉvaluation : 5 sur 5 étoiles5/5 (3)

- Introduction to Power System ProtectionD'EverandIntroduction to Power System ProtectionÉvaluation : 5 sur 5 étoiles5/5 (1)

- Solar Energy: Survive Easily on Solar Power Off the GridD'EverandSolar Energy: Survive Easily on Solar Power Off the GridPas encore d'évaluation

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesD'EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesÉvaluation : 4.5 sur 5 étoiles4.5/5 (21)

- Idaho Falls: The Untold Story of America's First Nuclear AccidentD'EverandIdaho Falls: The Untold Story of America's First Nuclear AccidentÉvaluation : 4.5 sur 5 étoiles4.5/5 (21)

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialD'EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialPas encore d'évaluation

- VSC-FACTS-HVDC: Analysis, Modelling and Simulation in Power GridsD'EverandVSC-FACTS-HVDC: Analysis, Modelling and Simulation in Power GridsPas encore d'évaluation

- Offshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsD'EverandOffshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsPas encore d'évaluation

- Building Energy Management Systems and Techniques: Principles, Methods, and ModellingD'EverandBuilding Energy Management Systems and Techniques: Principles, Methods, and ModellingPas encore d'évaluation

- Handbook on Battery Energy Storage SystemD'EverandHandbook on Battery Energy Storage SystemÉvaluation : 4.5 sur 5 étoiles4.5/5 (2)

- Solar Power Demystified: The Beginners Guide To Solar Power, Energy Independence And Lower BillsD'EverandSolar Power Demystified: The Beginners Guide To Solar Power, Energy Independence And Lower BillsÉvaluation : 4.5 sur 5 étoiles4.5/5 (2)

- Well Control for Completions and InterventionsD'EverandWell Control for Completions and InterventionsÉvaluation : 4 sur 5 étoiles4/5 (10)

- Air Cooled Heat Exchanger Handbook: Fundamentals, Calculations, Design and Q&AD'EverandAir Cooled Heat Exchanger Handbook: Fundamentals, Calculations, Design and Q&APas encore d'évaluation

- Thermal Power Plant: Design and OperationD'EverandThermal Power Plant: Design and OperationÉvaluation : 4.5 sur 5 étoiles4.5/5 (23)

- Electrochemical Technologies for Energy Storage and Conversion, 2 Volume SetD'EverandElectrochemical Technologies for Energy Storage and Conversion, 2 Volume SetPas encore d'évaluation

- Photovoltaic Solar Energy: From Fundamentals to ApplicationsD'EverandPhotovoltaic Solar Energy: From Fundamentals to ApplicationsPas encore d'évaluation

- Pipeline and Energy Plant Piping: Design and TechnologyD'EverandPipeline and Energy Plant Piping: Design and TechnologyÉvaluation : 5 sur 5 étoiles5/5 (2)

- Shorting the Grid: The Hidden Fragility of Our Electric GridD'EverandShorting the Grid: The Hidden Fragility of Our Electric GridÉvaluation : 4.5 sur 5 étoiles4.5/5 (2)

- Practical Power Distribution for IndustryD'EverandPractical Power Distribution for IndustryÉvaluation : 2.5 sur 5 étoiles2.5/5 (2)

- Heat Transfer Engineering: Fundamentals and TechniquesD'EverandHeat Transfer Engineering: Fundamentals and TechniquesÉvaluation : 4 sur 5 étoiles4/5 (1)

- Asphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsD'EverandAsphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsPas encore d'évaluation