Académique Documents

Professionnel Documents

Culture Documents

Bridge Estimate

Transféré par

Daljeet SidhuDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Bridge Estimate

Transféré par

Daljeet SidhuDroits d'auteur :

Formats disponibles

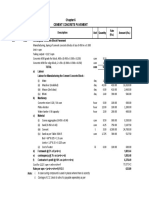

Item CSR No Particulars of item Quantity

1

21.1 Earth work in excavation of foundation of structures as per

drawing and technical specification, including setting out,

construction of shoring and bracing, removal of stumps and

other deleterious matter, dressing of sides and bottom and

backfilling with approved material.Depth upto 3 m in soil.

2

21.3 Sand Filling in Foundation Trenches as per Drawing & Technical

Specification.

3

21.4 Plain cement concrete 1:3:6 nominal mix in foundation with

crushed stone aggregate 40 mm nominal size mechanically

mixed, placed in foundation and compacted by vibration

including curing for 14 days.

4

21.5 Brick Masonry Work in Cement Mortar 1:3 in Foundation

complete excluding Pointing and Plastering, as per Drawing and

Technical Specifications.

5

21.7 Plain/Reinforced Cement Concrete in Open Foundation complete

as per Drawing and Technical Specifications.

5.1 Pain Conc M 15

5.2 RCC M20

6

21.27 Supplying, Fitting and Placing un coated HYSD bar Reinforcement

in Foundation complete as per Drawing and Technical

Specifications.

7

21.28 Brick masonry work in 1:3 in sub structure complete excluding

pointing and plastering, as per drawing and Technical

Specifications.

8

21.29 Pointing with cement mortar (1:3) on brick work in substructure

as per Technical Specifications.

9

21.3 Plastering with cement mortar (1:3) on brick work in sub-

structure as per Technical Specifications.

10

21.32 Plain/ Reinforced cement concrete in sub-structure complete as

per drawing and Technical Specifications

10.1 RCC M25 Height up to 5 m

10.2 RCC M30 Height up to 5 m

10.3 RCC M35 Height up to 5 m

11

21.35 Providing weep holes in Brick masonry/Plain/ Reinforced

concrete abutment, wing wall/ return wall with 100 mm dia PVC

pipe, extending through the full width of the structure with slope

of 1V :20H towards drawing face. Complete as per drawing and

Technical Specifications.

12

21.36 Back filling behind abutment, wing wall and return wall complete

as per drawing and Technical Specification.

12.1 Grannular material

13

21.37 Providing and laying of Filter media with granular

materials/stone crushed aggregates satisfying the requirements

laid down in clause 2504.2.2. of MoRTH specifications to a

thickness of not less than 600 mm with smaller size towards the

soil and bigger size towards the wall and provided over the entire

surface behind abutment, wing wall and return wall to the full

height compacted to a firm condition complete as per drawing

and Technical Specification.

14

21.4 Supplying, fitting and fixing in position true to line and level

sliding plate bearing with PTFE surface sliding on stainless steel

complete including all accessories as per drawing and Technical

Specifications and BS: 5400, section 9.1 & 9.2 (for PTFE) and

clause 2004 of MoRTH Specifications.

15

22.1 Furnishing and Placing Reinforced/Prestressed cement

concrete RCC Grade M20 as per drawing and Technical

Specification.

16

For Solid slab super-structure-including centering and shuttering

16.1 RCC M-25 upto a height of 5 m

16.2 RCC M-30 upto a height of 5 m

16.3 RCC M-35 upto a height of 5 m

17

22.2 Supplying, fitting and placing HYSD bar reinforcement in super-

structure complete as per drawing and technical specifications.

18

22.4 B Providing and laying 12 mm thick mastic asphalt wearing course

on top of deck slab excluding prime coat with paving grade

bitumen meeting the requirements given in table 500-29,

prepared by using mastic cooker and laid to required level and

slope after cleaning the surface, including providing antiskid

surface with bitumen precoated fine grained hard stone chipping

of 9.5 mm nominal size at the rate of 0.005cum per 10 sqm and

at an approximate spacing of 10 cm center to center in both

directions, pressed into surface when the temperature of

surfaces not less than 100 deg. C, protruding 1 mm to 4 mm over

mastic surface, all complete as per clause 515.

19

22.5 Construction of precast RCC railing of M30 Grade , aggregate size

not exceeding 12 mm, true to line and grade, tolerance of

vertical RCC post not to exceed 1 in 500, centre to centre spacing

between vertical post not to exceed 2000 mm, leaving adequate

space between vertical post for expansion, complete as per

approved drawings and technical specifications. the rate is

inclusive of steel

20.21

22.7 Providing, fitting and fixing mild steel railing complete as per

drawing and Technical Specification

22

22.8 B Drainage Spouts complete as per drawing no. SD/205 and

Technical specification with 0.6 meter long GI 100 mm dia

drainage GI light grade pipe (For Bridges)

23

22.9 PCC M15 Grade, as leveling course below approach slab

complete as per drawing and Technical specification.

24

22.1 Reinforced cement concrete approach slab using M-30 grade

concrete using 380 kg/ cum cement, including reinforcement and

fomwork complete as per drawing and Technical specification

25

22.12 A Provision of Reinforced cement concrete crash barrier at the

edges of the bridge,road, approaches to bridge structures and

medians, constructed with M-40 grade concrete with HYSD

reinforcement confoming to IRC:21 and dowel bars 25 mm dia,

450 mm long at expansion joints filled with pre- moulded asphalt

filler board, keyed to the structure on which it is built and

installed as per design given in the enclosure to MOST circular

No. RW/NH - 33022/1/94-DO III dated 24 June 1994 as per

dimensions in the approved drawing and at locations directed by

the Engineer, all as specified

26

22.13 Providing and applying 2 coats of water based cement paint to

unplastered concrete surface after cleaning the surface of dirt,

dust, oil, grease, efflorescence and applying paint @ of 1 litre for

2 sqm.

27

22.19 Providing and laying of a strip seal expansion joint catering

to maximum horizontal movement upto 70 mm, complete as per

approved drawings and standard specifications to be installed by

the manufacturer/supplier or their authorised representative

ensuring compliance to the manufacturer's instructions for

installation.

28

22.22 Dismantling RCC work any part of bridge structure including

cutting, strengthening stacking of reinforcement and disposal of

dismantled material with all lifts and lead upto 1 km

BRIDGE TRAINING AND PROTECTION WORKS

29

22.25 Cement Concrete Blocks (size 0.5 x 0.5 x 0.5 m) Providing and

laying of apron with cement concrete blocks of size 0.5x0.5x0.5

m cast in-situ and made with nominal mix of M-15 grade cement

concrete with a minimum cement content of 275 kg/cum as per

IRC: 21-2000.

30

22.26 Providing and laying Pitching on slopes laid over prepared

filter media including boulder apron laid dry in front of toe of

embankment complete as per drawing and Technical

specifications. Stone/Boulder more than 18 Kg

31

22.27 Providing and laying Filter material underneath pitching in

slopes complete as per drawing and Technical specification

Includes Mazdoor required for trimming of slope to proper

profile and preparation of bed.

32

22.28 Providing and laying Flooring complete as per drawing and

Technical specifications laid over cement concert

bedding.Includes cement mortar for laying and filling of joints.

Rubble stone laid in cement mortar 1:3.

Approach Roads to Bridge 30 M both side 12 M wide

33 Providing an laying Grannular Sub Base

34 Providing an laying Wet Mix Macadam

35 Providing and laying pavement quality concrete M30

Unit Rate Premium Total Rate Amount

Vous aimerez peut-être aussi

- Specification For Gas Fired Boiler PDFDocument7 pagesSpecification For Gas Fired Boiler PDFmjmehta81Pas encore d'évaluation

- Bill of QuantitiesDocument10 pagesBill of Quantitieskresimir.mikoc9765100% (1)

- 400 MW Power Plant Civil WorksDocument62 pages400 MW Power Plant Civil WorkskrmcharigdcPas encore d'évaluation

- MDD SoilDocument4 pagesMDD SoilDaljeet SidhuPas encore d'évaluation

- MDD SoilDocument4 pagesMDD SoilDaljeet SidhuPas encore d'évaluation

- Sharp SJ-P58M-GY Fridge Service ManualDocument44 pagesSharp SJ-P58M-GY Fridge Service ManualAnonymous 2iQ1B59Pas encore d'évaluation

- All Item RateDocument104 pagesAll Item RateDharmendra SharmaPas encore d'évaluation

- BOQ Box Culvert FinalDocument19 pagesBOQ Box Culvert FinalManoj AhirwarPas encore d'évaluation

- Major Bridge Estimate (Well Found.)Document12 pagesMajor Bridge Estimate (Well Found.)Mohammed Faiz100% (1)

- Bill of Quantity For RCC BuildingsDocument16 pagesBill of Quantity For RCC BuildingsAaron SolisPas encore d'évaluation

- BOQ - TaramaniDocument46 pagesBOQ - Taramanismith0% (1)

- Boq of BridgeDocument6 pagesBoq of BridgeMuzamil Rather100% (1)

- AMS-2249-Chemical Check Analysis LimitsDocument6 pagesAMS-2249-Chemical Check Analysis LimitsSinan Yıldız100% (1)

- Summary of BR - Quantity (Original Estimate)Document10 pagesSummary of BR - Quantity (Original Estimate)Bilal Ahmed BarbhuiyaPas encore d'évaluation

- Construction Cost Estimate for Road UpgradationDocument22 pagesConstruction Cost Estimate for Road UpgradationShane RodriguezPas encore d'évaluation

- BOQ For Batching Plant Area1Document10 pagesBOQ For Batching Plant Area1sh2705_877839042Pas encore d'évaluation

- Excel QuantityDocument234 pagesExcel Quantityviveik_mudgalPas encore d'évaluation

- QAQC EvaluationDocument22 pagesQAQC EvaluationsaifasadPas encore d'évaluation

- Steel ConstructionDocument46 pagesSteel ConstructionKhadeeja AslamPas encore d'évaluation

- Tank Analysis and Design by STAAD PRODocument3 pagesTank Analysis and Design by STAAD PROnour100% (4)

- Boq Road+project-NhaiDocument10 pagesBoq Road+project-NhaidhwaniPas encore d'évaluation

- Boq of Box CulvertDocument10 pagesBoq of Box Culvertparkashmishra0% (1)

- Adeka Introduction Portfolio GeneralDocument19 pagesAdeka Introduction Portfolio Generalladislav_hipolPas encore d'évaluation

- (381611313) BOQ EarthworkDocument39 pages(381611313) BOQ EarthworkAshish SadaPas encore d'évaluation

- JHELL SIDING HOWRAH Concrete Road WorksDocument6 pagesJHELL SIDING HOWRAH Concrete Road Workskartick adhikaryPas encore d'évaluation

- Mosque BOQDocument17 pagesMosque BOQHossam Al-Dein Mostafa HelmyPas encore d'évaluation

- Box Estimate.Document254 pagesBox Estimate.rahul sumanPas encore d'évaluation

- Concrete in Highway Engineering: International Series of Monographs in Civil EngineeringD'EverandConcrete in Highway Engineering: International Series of Monographs in Civil EngineeringÉvaluation : 4 sur 5 étoiles4/5 (5)

- 400 MW Power Plant Civil WorksDocument274 pages400 MW Power Plant Civil WorkskrmcharigdcPas encore d'évaluation

- Estimate For Construction of R.C.C. Bridge Over River Buribalason, at Jalasnijamtara, Phansidewa, SiliguriDocument15 pagesEstimate For Construction of R.C.C. Bridge Over River Buribalason, at Jalasnijamtara, Phansidewa, SiliguriRio HandokoPas encore d'évaluation

- Reinforced Concrete Buildings: Behavior and DesignD'EverandReinforced Concrete Buildings: Behavior and DesignÉvaluation : 5 sur 5 étoiles5/5 (1)

- SOP For Boiler Light Up ChecklistDocument9 pagesSOP For Boiler Light Up Checklistpradeep.selvarajan100% (1)

- CE 632 Shallow Foundations Part-1Document39 pagesCE 632 Shallow Foundations Part-1Abdul KabasyPas encore d'évaluation

- Culvert BOQ - Pipe CulvertsDocument15 pagesCulvert BOQ - Pipe Culvertsrrajdeep54100% (2)

- RamDocument8 pagesRamsunaifctmPas encore d'évaluation

- NPCC P-4Document3 pagesNPCC P-4soumodip SahaPas encore d'évaluation

- Improvements of Road NH-748 From KM 26.130 To KM 69.480 of Goa Border To Belagavi Section of NH-748AA in The State of Karnataka On EPC ModeDocument14 pagesImprovements of Road NH-748 From KM 26.130 To KM 69.480 of Goa Border To Belagavi Section of NH-748AA in The State of Karnataka On EPC ModeAVD CONSTRUCTIONSPas encore d'évaluation

- Boq 51483Document4 pagesBoq 51483saorabh13Pas encore d'évaluation

- Rate CardsDocument32 pagesRate CardsSasanka SekharPas encore d'évaluation

- Shephard College Construction ProjectDocument12 pagesShephard College Construction Projectsurendra_pangaPas encore d'évaluation

- Annex A - BOQDocument11 pagesAnnex A - BOQyaseen90azizPas encore d'évaluation

- Construction of 55 RCC Bridges in Bankura DistrictDocument2 pagesConstruction of 55 RCC Bridges in Bankura Districtsoumodip SahaPas encore d'évaluation

- 17.02.2024-BSCPL Boq Vibhutipura Civil R00Document24 pages17.02.2024-BSCPL Boq Vibhutipura Civil R00Darshit VyasPas encore d'évaluation

- Construction of Primary Hospital ExcelDocument58 pagesConstruction of Primary Hospital ExcelDipesh BasnetPas encore d'évaluation

- Construction of Four Lanning NH-1Document39 pagesConstruction of Four Lanning NH-1Pankaj JagtapPas encore d'évaluation

- July Ipp Addtional JobDocument9 pagesJuly Ipp Addtional JobSasanka SekharPas encore d'évaluation

- Road:-Samakhiali-Gandgidham-NH8A Quantity Summary For UnderpassDocument4 pagesRoad:-Samakhiali-Gandgidham-NH8A Quantity Summary For UnderpassGirinathPas encore d'évaluation

- Abstract of CostDocument4 pagesAbstract of Costcomedy INSHAAN. 12.2MPas encore d'évaluation

- Re Civil BOQ Format For Electrical Works - Manfo - BengaluruDocument25 pagesRe Civil BOQ Format For Electrical Works - Manfo - BengaluruDarshit VyasPas encore d'évaluation

- HB 12350Document21 pagesHB 12350Pawan Kumar PrajapatPas encore d'évaluation

- GSL SilicaDocument4 pagesGSL SilicaprasadmvkPas encore d'évaluation

- Musikot Final To SumbitDocument117 pagesMusikot Final To SumbitAsan GajurelPas encore d'évaluation

- CL10 (May 2012)Document22 pagesCL10 (May 2012)uddinnadeemPas encore d'évaluation

- BO-BoQ For Balance Civil & FinishingDocument16 pagesBO-BoQ For Balance Civil & FinishingcubadesignstudPas encore d'évaluation

- SampleDocument186 pagesSampleSANDESHPas encore d'évaluation

- Sub-structure Section OverviewDocument3 pagesSub-structure Section Overviewaalignup arc & const. pvt ltdPas encore d'évaluation

- CEOMA HBL Comletion Certificate DraftDocument7 pagesCEOMA HBL Comletion Certificate DraftNihal AhmadPas encore d'évaluation

- RateDocument51 pagesRatemukesh kumarPas encore d'évaluation

- Boq PDFDocument12 pagesBoq PDFChandeshwor Shah0% (1)

- Construction Variation StatementDocument31 pagesConstruction Variation StatementJithesh GowdaPas encore d'évaluation

- Da AnnxDocument103 pagesDa AnnxPratik GuptaPas encore d'évaluation

- BOQ_CIVIL_FOR SHED (1)Document8 pagesBOQ_CIVIL_FOR SHED (1)MariPas encore d'évaluation

- Canteen and Dress Changing RoomDocument43 pagesCanteen and Dress Changing RoomJeevitha DeivasigamaniPas encore d'évaluation

- AbcDocument7 pagesAbcsunaifctmPas encore d'évaluation

- S.N. Description of Works Quantity Unit Rate Total Amount RemarksDocument11 pagesS.N. Description of Works Quantity Unit Rate Total Amount RemarksSagar AcharyaPas encore d'évaluation

- Item Rate BOQ for Package No: AS-11-721Document3 pagesItem Rate BOQ for Package No: AS-11-721Rubai GangulyPas encore d'évaluation

- Dismantling Hume Pipe From Culverts, Syphons, Aqueducts, Superpassage, Sluice BarrelsDocument12 pagesDismantling Hume Pipe From Culverts, Syphons, Aqueducts, Superpassage, Sluice Barrelsaibhavkumarjain8108Pas encore d'évaluation

- Bituminous Works & CulvertsDocument22 pagesBituminous Works & CulvertsDheeraj ThakurPas encore d'évaluation

- TNT Construction PLC - Tender 3Document42 pagesTNT Construction PLC - Tender 3berekajimma100% (1)

- AOR Conc Blocks 450x300x150 M30Document1 pageAOR Conc Blocks 450x300x150 M30Daljeet SidhuPas encore d'évaluation

- Apprehensions About Use of PPCDocument2 pagesApprehensions About Use of PPCDaljeet SidhuPas encore d'évaluation

- Schedule of Rates: Items Description Unit Quantity Rate Amount Sub Head 1: Earth WorkDocument99 pagesSchedule of Rates: Items Description Unit Quantity Rate Amount Sub Head 1: Earth WorkDaljeet SidhuPas encore d'évaluation

- Importance of BM LayerDocument1 pageImportance of BM LayerDaljeet SidhuPas encore d'évaluation

- Published Paper PDFDocument6 pagesPublished Paper PDFDaljeet SidhuPas encore d'évaluation

- Transient WalkDocument26 pagesTransient WalkDaljeet SidhuPas encore d'évaluation

- Kasiana Lang 18ftDocument5 pagesKasiana Lang 18ftDaljeet SidhuPas encore d'évaluation

- Project Report Rurki Chanarthal CRFDocument7 pagesProject Report Rurki Chanarthal CRFDaljeet SidhuPas encore d'évaluation

- 40 11-20Document10 pages40 11-20Daljeet SidhuPas encore d'évaluation

- Published Paper PDFDocument6 pagesPublished Paper PDFDaljeet SidhuPas encore d'évaluation

- Hydraulic Calculations RD179Document2 pagesHydraulic Calculations RD179Daljeet SidhuPas encore d'évaluation

- Stability of Canal EmbankmentDocument7 pagesStability of Canal EmbankmentDaljeet Sidhu100% (1)

- Published Paper PDFDocument6 pagesPublished Paper PDFDaljeet SidhuPas encore d'évaluation

- PB Sangrur TehDocument1 pagePB Sangrur TehDaljeet SidhuPas encore d'évaluation

- Travelling Allowance Bill of The Establishment of Department of Agb For The Month of February, 2015Document1 pageTravelling Allowance Bill of The Establishment of Department of Agb For The Month of February, 2015Daljeet SidhuPas encore d'évaluation

- Linearrailway Model PDFDocument1 pageLinearrailway Model PDFDaljeet SidhuPas encore d'évaluation

- Gurdaspur Sri Hargobindpur Road (Maintenance) 255 Days Tue 07-11-06 Tue 04-09-07Document4 pagesGurdaspur Sri Hargobindpur Road (Maintenance) 255 Days Tue 07-11-06 Tue 04-09-07Daljeet SidhuPas encore d'évaluation

- Use of The Light Weight DeflectometerDocument2 pagesUse of The Light Weight DeflectometerDaljeet SidhuPas encore d'évaluation

- Mix DesignDocument3 pagesMix DesignDaljeet SidhuPas encore d'évaluation

- Lime PavementsDocument2 pagesLime PavementsDaljeet SidhuPas encore d'évaluation

- Poor Drainage Leads to Road FailureDocument3 pagesPoor Drainage Leads to Road FailureDaljeet SidhuPas encore d'évaluation

- DPR Template For Road ProjecDocument62 pagesDPR Template For Road ProjecDaljeet SidhuPas encore d'évaluation

- Lime PavementsDocument2 pagesLime PavementsDaljeet SidhuPas encore d'évaluation

- KSB OmegaDocument2 pagesKSB OmegaAnne 90Pas encore d'évaluation

- Plastic AnalysisDocument23 pagesPlastic AnalysisPraveen Kumar R100% (1)

- Summary of Procedure For ASTM D 698Document2 pagesSummary of Procedure For ASTM D 698Miller De Leon Cutora100% (1)

- Multi Zone Completion OptionsDocument6 pagesMulti Zone Completion OptionsTong ChaipanyakulPas encore d'évaluation

- Celda de Carga Tipo Z Sensortronics - 60050 (Molinos de Pasta)Document1 pageCelda de Carga Tipo Z Sensortronics - 60050 (Molinos de Pasta)Schiraldi BonillaPas encore d'évaluation

- Site Plan 02 Puerto Baru Rev.04Document1 pageSite Plan 02 Puerto Baru Rev.04TaihimyPas encore d'évaluation

- Aci 318R 08Document1 pageAci 318R 08Sayed Diab AlsayedPas encore d'évaluation

- Kobe Works eDocument13 pagesKobe Works eJagdish ShresthaPas encore d'évaluation

- The Rheology Degradation Processing and Characterization of ReDocument261 pagesThe Rheology Degradation Processing and Characterization of ReDeidra CadePas encore d'évaluation

- Civil Engineering Materials UOL Lahore: ConcreteDocument119 pagesCivil Engineering Materials UOL Lahore: ConcreteNawab Zada ManekaPas encore d'évaluation

- Adokapı Technical PresentationDocument32 pagesAdokapı Technical PresentationHussain BagasrawalaPas encore d'évaluation

- CIC Total Product List 2016Document1 pageCIC Total Product List 2016RAMI HAMADPas encore d'évaluation

- CH - Mass Transfer and Transport Phenomenon PDFDocument29 pagesCH - Mass Transfer and Transport Phenomenon PDFRaghul RockPas encore d'évaluation

- Integrated LabDocument36 pagesIntegrated LabBeki WalkerPas encore d'évaluation

- Calculating Expansion TanksDocument4 pagesCalculating Expansion TanksanescuveronicaPas encore d'évaluation

- Solcourse - Polythene DPM DatasheetDocument2 pagesSolcourse - Polythene DPM DatasheetkibzeamPas encore d'évaluation

- Heat Load Calculation IIDocument2 pagesHeat Load Calculation IIsiruslara6491Pas encore d'évaluation

- FN Steel Datasheet Spring Steels ENG-V2Document2 pagesFN Steel Datasheet Spring Steels ENG-V2ariPas encore d'évaluation

- MEC E 563 Assignment 4Document8 pagesMEC E 563 Assignment 4JasonPas encore d'évaluation

- Chemistry ProjectDocument16 pagesChemistry Projectgaganshishodia2Pas encore d'évaluation

- Utilization of Waste Plastic in Manufacturing of Paver BlocksDocument4 pagesUtilization of Waste Plastic in Manufacturing of Paver BlocksAragorn RingsPas encore d'évaluation

- Pavement Materials: Highway and Transportation Engineering (Faculty of Engineering)Document38 pagesPavement Materials: Highway and Transportation Engineering (Faculty of Engineering)atharPas encore d'évaluation

- Objective: Experiment 2: Determination of Ash ContentDocument2 pagesObjective: Experiment 2: Determination of Ash ContentRaj Kumar Purkayastha100% (2)

- Manufacturer'S Test Certificate: National Builtech Trading and Contracting CoDocument1 pageManufacturer'S Test Certificate: National Builtech Trading and Contracting CoNBTC Tubes & PipesPas encore d'évaluation