Académique Documents

Professionnel Documents

Culture Documents

Metal Formulation

Transféré par

MrprambaCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Metal Formulation

Transféré par

MrprambaDroits d'auteur :

Formats disponibles

NATIONAL NETWORKED PROJECT

ON

STANDARDIZATION, SAFETY & EFFICACY

OF

METAL BASED FORMULATIONS

Department of Science & Technology (DST)

Technology Bhawan

New Mehrauli Road

New Delhi -110 016

October 2008

BhasmaProjectSeptember2008 1

CONTENTS

Background

2

Objectives of the Project

3

Identification of Bhasmas and Formulations

5

R& D Investigations to be carried out on identified bhasmas

6

Recommendations of the Working Groups

-Criteria for Networking

-Mode of Initiation & Operation

7

8

9

List of Institutions / Industry for Networking

10

Areas of Activities for inviting Expression of interest for participation in

the Project

11

APPENDICES

Appendix-I (Panel of Experts )

Appendix-II (Members of the Three Working Groups)

Appendix-III( Diagrammatic Presentation of Action Plan)

12

16

17

BhasmaProjectSeptember2008 2

I. BACKGROUND

Ayurvedic formulations usually consist of ingredients of herbal, mineral, metals and animal origin.

Recently there have been some scientific publications questioning the safety of Ayurvedic metallic/herbo

mineral products. Following this, several developed countries have prohibited the use of not only herbo-

mineral products but also some of the herbal products reported to be contaminated with heavy metals.

The herbal products are gaining more and more popularity through out the world and lot of work is

being done not only in developed countries, like US and European countries but also in developing

countries. These researches are heavily funded by organizations like NCCAM (National Centre for

Complimentary and Alternate Medicine) of US FDA. Indian research institutes/industries/organizations

are also investing in research on the herbal products but these research results have yet to be

translated into practice.

It is a fact that while whole world is working on the herbals almost no country is working on the metallic

products, which is very important strength area of Ayurvedic system of medicine. One of the reasons is

that, probably barring India, this knowledge does not exist anywhere else. Recently this important area

has drawn the attention of Indian researchers realizing the fact that millions of Indians are still

consuming these products with significant health benefits and little known side effects. The realization

that probably it is one area where Indian can make original contribution to the world has necessitated

the need of validation of claim of metallic products.

Keeping in view the fact that it is our heritage and needs to be subjected through well planned research

in order to bring it to international fora as Indias unique contribution, Dept of Science and Technology

has taken an initiative to tap this opportunity and is willing to push forward the R&D efforts in this thus

far highly neglected but very important area of Ayurvedic therapeutics.

For achieving the above objective , DST constituted a panel of experts to identify various areas requiring

inputs and way forward for all of them (APPENDIX-I) This project has been prepared on the basis of

their recommendations.

BhasmaProjectSeptember2008 3

II .OBJECTIVES OF THE PROJECT AND WORKING GROUPS:-

Broad Objectives are:

Identification of Bhasmas and formulations for carrying out scientific studies with regard to the

standardization of raw materials, processes & finished products, and chemical transformation,

safety, efficacy evaluation, and validation through networking of the various

institutions/industries/individuals having expertise in this area.

Develop validated methods of preparation with standardization parameters of identified bhasmas

and formulations

Specific Objectives

1. To authenticate herbal ingredients used in various process.

2. To evolve standards for basic raw materials as well as the raw materials used for Shodan and

Maran processes after analysis of at least three lots of each raw material procured from different

natural sources.

3. To evolve standards of Shodhit materials before and after carrying out Shodhanvidhi of three

lots of materials.

4. To develop validated Standard Operating Procedure (SOP) for Shodhan, maran ,etc. processes

involved in preparing the bhasmas.

5. To evolve standards for bhasmas including at different stages of Jaran and Maran based on at

least three lots of bhasma.

6. To establish validated Standard Operating Procedure (SOP) for Jaran and Maran.

7. Determination of chemical transformation during the above processes.

8. Development of physico chemical & bio assays for standardization of bhasmas.

9. To identify modern technology that can be applied to manufacture and testing of bhasmas.

BhasmaProjectSeptember2008 4

Working groups for Identification of Bhasmas formulations, and R&D Thrust Areas Research

In the first meeting of the Panel on Bhasmas , three Working Groups were formed as appended

(Appendix-II) . These working groups were entrusted with the responsibility of providing detailed

inputs on items 1 to 9 of the specific objectives. Defined jobs delegated to the three respective groups

are as follows:

Working Group I

Areas/Issues to be resolved

1. Selection of bhasmas for study on criteria considering

Successful therapeutic application.,

Clinical usefulness,

General acceptance., and

Availability of Manufacturing facilities.

2. Raw-material selection and quality criteria: (APC monograph supposedly lays down certain

specifications for input materials).

3. Identification of institutions/researchers/ manufacturers for R&D work on the spelt out

problems

Working Group II

Issues to be Resolved

o Comparison of traditional and modern methods processes of Bhasmas preparation

o Analytical testing and verification of products during the processes of Shodhana, Maran

& Amritakaran by physical, chemical and geochemical methods.

o Types of chemical changes undergone during these traditional processes

o Selection of appropriate equipment for various processes / Studies/ Quality Control

parameters of Bhasmas

BhasmaProjectSeptember2008 5

Working Group-III

Issues to be resolved

A. Pre-clinical Studies

Pharmacological evaluation

Toxicity studies

Pharmacodynamic studies

Tissue distribution studies

B. Clinical Studies

This document has been prepared based on the inputs given by all the above three working groups

III. IDENTIFICATION OF BHASMAS AND FORMULATIONS

Selection of Bhasmas and their Formulations for Research

The following criteria were laid down for identification of Bhasmas & formulations, having these as

ingredients, for which detailed studies need to be carried out.

1. Successful therapeutic application,

2. Clinical usefulness,

3. General acceptance,

4. Availability of manufacturing facilities

The following Bhasmas/ compounds and their formulations have been selected based on the above

criteria:

1. Kajjali Rasatarrangini Paribhasha Prakaran

2. Abhrak Bhasma Rasa Ratna Samuchhay 2/43-44

3. Naag Bhasma Rasatarangini - 19

4. Vang Bhasma Rasatarangini - 18

5. Jasad Bhasma Rasatarangini - 19

6. Tamra Bhasma Rasa Ratna Samuchhay - 5

7. Mandoor Bhasma Rasa Ratna Samuchhay 5/150-151

8. Swarnamakshik Bhasma Rasa Chandanshu

9. Rasa Sindoor Rasa Yoga Sagar

10.Makardhwaj Rasendra Saar Sangraha 5/67-76

11. Lauha Bhasma Rasatantra Saar avem SiddhaPrayog Sangrah part-1

BhasmaProjectSeptember2008 6

Three most important prescribed formulations, identified for this project are:

1. Rasa Manikya Rasatarangini 11/83-89

2. Arogyawardhani Bharat Bhaishajya Ratnakar - 1/448

3. Punarnava Mandoor Bharat Bhaishjya Ratnakar

IV. DETAILED STUDIES (R&D) TO BE CARRIED OUT ON THE IDENTIFIED BHASMAS AND

RELEVANT FIELDS FOR NETWORKING

The detailed studies to be conducted on identified Bhasmas / compounds and their formulations are

given below :

1. Finalization of the process to be used for the preparation of a particular Bhasma.

2. Identification & Authentication of the raw materials.

3 Standarisation of the raw materials preferably using pharmacopoeial methods, alternatively using in

house specifications.

4. Process validation of shodhan, maran, amritikaran (if applicable)

5. Manufacturing of Bhasmas by both traditional as well as using modern tools like computerised

furnaces

6. Chemical transformations to be determined after every stage i.e. after shodhan, Maran/Jaran &

Amritikaran (if applicable)

7. Methods of standardization - their specifications along with the analytical methods used at every

stage to be given.

8. Development of process technologies for faster commercial production of Bhasmas.

9. Toxicity studies and safety pharmacology to be carried out.

10. Development of suitable bio-assays for biological standardization.

11. Efficacy evaluation through experimental pharmacology including pharmacodynamics.

12. Clinical studies on formulations

13. Any other relevant development activity

In order to carry out the above activities an interdisciplinary approach is of paramount

importance and would involve networking of manufacturing units, academic institutions research

Institutions & individuals having expertise in related fields.

To achieve this objective, an interdisciplinary team of the institutions / experts having the following

expertise need to be evolved:

BhasmaProjectSeptember2008 7

i) Rasa Shastra

ii) Manufacturing Operations ( for MOPs/SOPs)

iii) Pharmaceutics

iv) Material Science ( including Metallurgy)

v) Inorganic/Organic Chemistry

vi) Geology (Minerolgy and geochemistry).

vii) Pharmacology

viii) Toxicology

ix) Biochemistry( for biological studies)

x) Biotechnology ( for cell based Assays) and

xi) Analytical Chemistry

V. RECOMMENDATIONS:

It is essential to understand the chemical nature of the complexation taking place with

metallic ions and organic phyto-constituents present in medicinal plants with which the metals are

treated. Unless we understand the nature of the complex compounds formed during the processing of

metals/minerals and medicinal plant material, it is not possible to evolve the quality parameters and

understand the mechanism of action of such important, potent & unique drugs of Ayurveda / Siddha.

There is strong need to understand the complex nature of such drugs otherwise they would continue to

remain out of the mainstream of therapeutic utility. Such a study needs to be taken up on priority.

Broad areas of study on such drugs need to be based on the following:

a) Proper identification/authentication of pure raw material and understanding the scientific basis of

process technology, involved in-process changes taking place in the selection of material.

b) Identification of organo-mineral-metallic complexes formed and their complete characterization.

c) Development of quality parameters of the finished product with a view to make pharmacopoeial

monographs,

d) Safety evaluation of these products by generating toxicity data (including acute, chronic toxicity,

genotoxicity, immunotoxicity, and teratogenicity, if applicable) and data of safety pharmacology.

e) efficacy studies covering pre-clinical studies (in vitro and in vivo Pharmacological models) and clinical

trials following proper protocols.

f) Search for new mineral raw materials in addition to traditional minerals as alternative.

BhasmaProjectSeptember2008 8

To achieve this networking of expertise in inter disciplinary areas is required

1. CRITERIA FOR NETWORKING:

(a) Academic Institutions

1. Experience / Expertise in R&D in Minerals( Bhasmas)/Metallic Products.

2. Availability of Infrastructure.

3. Expertise in the area of Material science/Metallurgical sciences/Geochemistry.

4. Expertise in the area of toxicity, pharmacology (both in vitro & in vivo studies), including

Molecular Biology

5. Publications in the related area (preferably on R&D in Mineral/Metallic products).

6. Expertise in the area of Rasa-Shastra.

7. Expertise in the area of Clinical Trials

(b) Research Institutions.

1. Experience in R&D in Bhasmas/Metallic Products.

2. Availability of Infrastructure.

3. Expertise in the area of material science/metallurgical sciences/geochemistry

4. Expertise/experience in the area of Toxicity and Pharmacology (Both in Vitro and In Vivo

Studies.) & Molecular Biology.

5. Expertise in the area of clinical trials, preferably on metallic products along with exposure of

clinical trial methodologies.

(c) Industry.

1. R&D Center of the Industry recognized by DSIR.

2. Expertise and experience in manufacturing classical Mineral/Metallic Products using/ willing to

adopt modern technologies/Technological Interventions in manufacturing Mineral / Metallic

Products.

3. Willingness to meet the requirements of the project.

4. GMP Certification

BhasmaProjectSeptember2008 9

2.MODE OF INITIATION

DST should issue an advertisement in the leading newspapers of India and on its website inviting

Expression of interest from various stake holders meeting the above eligibility criteria.

Participants (Project Investigators) in this networked programme will consist of the academic

Institutions, Research Institutes and Industries .

The Expert Committee constituted by DST for this purpose would evaluate the applications on the

basis of the procedure it decides to adopt . R&D Studies related to Bhasmas / Compounds/

formulations will involve :

i) Stage I

a) Standardisation and Validation of Products / Process

b) R&D Chemistry or Chemical Analysis.

c) Availability of Product at a scale appropriate for conducting research

d) Safety and Efficacy ( Pharmacological and Biological Evaluation)

ii)Stage II

Clinical Studies

3. MODE OF OPERATION

DST would constitute a Steering Committee consisting of experts in different disciplines for

R&D project with the purpose of overseeing , evaluating and mentoring. Monitoring

Committees will be constituted on project to project basis .

4. SUGGESTED LIST OF THE INSTITUTIONS/ INDUSTRY WHO MAY BE

CONSIDERED FOR NETWORKING

(A) List of Academic Institutions

1. Department of Ras Shastra, Banaras Hindu University, Varanasi.

2. Department of Ras Shastra, Jamnagar, Gujarat.

3. Indian Institute of Technology, Mumbai.

BhasmaProjectSeptember2008 10

4. Institute of Technology, Banaras Hindu University, Varanasi.

5. All India Institute of Medical Sciences( AIIMS) , Ansari Nagar, New Delhi.

6. Anna University , Chennai

7. SASTRA University . Thanjavur , Tamil Nadu

8. Jadavpur University , Raja Subodh Mallick Square , Kolkata

9. Department of Earth Sciences, Indian Institute of Technology ( IIT) , Roorkee

10. Department of Metallurgy,IIT,Delhi

11. JAMIA HAMDARD (Hamdard University)

12. B.V.Patel PERD Centre, Ahmedabad

13. Seth G.S.Medical College & KEM Hospital , Mumbai

14. BYL Nair Hospital and Medical College, Mumbai.

15. Guru Kul kangri University, Haridwar

(B) List of Research Institutions .

1. National Chemical Laboratory (NCL), Pune.

2. Indian Institute of Chemical Technology( IICT) , Hyderabad.

3. Indian Institute of Chemical Biology (IICB) , Kolkata.

4. Central Drug Research Institute (CDRI) , Lucknow

5. Indian Toxicology Research Centre ( ITRC) , Lucknow

6. Regional Research Laboratory , Jorhat

7. Amrita Institute of Medical Sciences and Research Centre, Kochi, Kerala.

8. Amala Cancer Research Institute, Kerala.

9. Bharatiya Vidyapeeth University College of Ayurveda (BVUCOA), Pune

10. Bhide Foundation , SP College Campus , Sadashiv Peth , Pune-411030

11. VCP Cancer Research Foundation , Dehradun

12. Shriram Institute for Industrial Research (SIIR) , 19, University Road, Delhi-110007

13. National Institute of Ayurveda ( NIA) , JAIPUR

14. CCRAS, 61-65, Institutional Area , Janakpuri , New Delhi 110058

15. CCRUM, 61-65, Institutional Area , Janakpuri , New Delhi -110058

(C) List of Industries

1. Dhootpapeshwar Ltd., Mumbai.

2. Dabur India Ltd , Ghaziabad (UP)

3. Arya Vaidya Sala, Kottakal,

4. Zandu Pharmaceuticals Ltd , Mumbai

5. Sree Baidyanath Ayurved, Kolkatta.

BhasmaProjectSeptember2008 11

6. Gurukul Kangri.Pharmacy, Haridwar.

7. Maharashi Ayurveda Ltd , Noida

8. IPCA Traditional Remedies Ltd , Mumbai

9. Divya Yoga Pharmacy , Hardwar

10. The Indian Medical Practitioners Co-operative Pharmacy & Stores Ltd (IMCOPS),

Chennai- 600 041.

11. Charaka Pharma Pvt Ltd, Mumbai Varanasi.

12. Hamdard (Wakf) Industries, Ghaziabad.

5. AREAS OF ACTIVITIES FOR INVITING EXPRESSION OF INTEREST FOR

PARTICIPATION IN THIS PROJECT

Process/Studies

Raw Material Identification and standardization (Metal , Mineral & Herb)

Process validation (Shodhana, Marana, etc.)

Evaluation of physicochemical changes at different stages of bhasma

perparations

Safety Evaluation

1. Toxicity

2 Safety pharmacology

Efficacy Evaluation for

1.Pharmacological studies, in vitro & in vivo

2.Clinical Trials

6. Flow Sheet of Procurement Testing - Physical, geochemical etc

(Appendix-III)

Recommendations were made that suitable steps to be taken to get supply centers established for

having the right kind of minerals / mineral substances and central testing facility if any.

BhasmaProjectSeptember2008 12

APPENDIX-I

( Panel of Experts on Bhasmas ORDER )

No : VII-DPRP/01/06-07/TDT

Department of Science & Technology

(Technology Development & Transfer Division)

New Delhi

Office Order

Dated 20

th

June 2006

SUBJECT : Constitution of a panel of Experts on Bhasmas

In order to standardize the process of preparation of some Bhasmas with inputs of

modern techniques the following panel of experts has been constituted :

1. Dr.J.S.Yadav , Chairman

Director ,

Indian Institute of Chemical Technology (IICT),

Uppal Road, Hyderabad-500 007

2. Dr.Laxman Prasad , Member

Adviser & Head , TDT Divn,

DST, Technology Bhawan, New Delhi-110 016

3. Dr.G.S.Lavekar , Director Member

Central Council for Research in Ayurveda & Siddha ( CCRAS)

Department of AYUSH , ( Ministry of Health & Family Welfare)

61-65 , Institutional Area , Opp D Block , Janakpuri ,

New Delhi- 110 058

4. Dr.Narendra S Bhatt , Chief Executive Officer, Member

Zandu Pharmaceuticals Ltd, 15 Bachubai Building (Ist Floor),

J Bhatnagar Marg , Parel , Mumbai 400 012

5. Dr.C.K.Katiyar , Director, Herbal Drug Research Member

Ranbaxy Research Labs , R&D II, Plot 20 , Sector 18,

Udyog Vihar Industrial Area , Gurgaon

6.Dr.N.V.RamaRao, Managing Director , Member

M/s Indian Medicine Pharmaceuticals Corporation Ltd ,(IMPCL)

Mohan Distt , Almorah , Uttraanchal, Via Ram Nagar-244715

7.Dr.S.K.Dixit , Professor of Ras Shastra , Member

Department of Medicinal Chemistry , Institute of Medical Sciences,

Banaras Hindu University ( BHU) , Varanasi- 221 005

8. Dr A Mitra, Deptt of Kayachikitsa, Member

Institute of Post Graduate Ayurvedic Education and Research,

Kolkata 700 009.

BhasmaProjectSeptember2008 13

9. Prof VA Dole, Head, Deptt of Rasashastra, Member

2/2, Manoj Housing Society, Opp Market Yard,

Pune 411 037

10. Dr M Rajani , Assistant Director & Head Member

Pharmacognosy & Phytochemical Deptt,

BV Patel Pharmaceutical Education & Research Development Centre,

PERD Centre, Thaltej, Ahmedabad 380 054

11.Prof O P Varma, Member

Formerly: Head App Geol. &

Professor of Mining Geology, ISM,

35 A, Civil Lines, Roorkee 247 667.

12.Prof. J.K.Ojha, Member

Ex.Dean Ayurveda Faculty,

Institute of Medical Sciences ( IMS)

BHU, Gurudham Colony,Varanasi-221 005

13. Prof. V. Tripathi , Member

MD Surya Pharmaceutical,

7, Krishna Bhagh,Varansi-221 005

14. Dr. T.S.Murali , R&D Manager, Member

Arya Vaidya Sala,

Kottackal-675503 (Kerala)

15. Prof. Y.K.Gupta , Member

Head , Department of Pharmacology,

AIIMS, Ansari Nagar, New Delhi-110029

16. Dr SK Sharma, Member

Adviser, Department of AYUSH,

Indian Red Cross Building, New Delhi- 110 001.

17. Dr. R.K.Khandal , Member

Director, Shriram Institute for Industrial Research(SIIR),

19, University Road , Delhi-110 007

18. Dr. Vasantha Muthuswamy , Member

Sr.Deputy Director General ,

Indian Council of Medical Research (ICMR),

Ansari Nagar, New Delhi-110029

19. Dr S.B. Vohora, Member

Ex Head, Department of Elementology

Faculty of Science, JAMIA HAMDARD

114, Kailash Hills, New Delhi 110 065

20. Prof G.P. Dubey , Member

Former Dean , Faculty of Ayurveda,

B-29/10, Nandigram Lanka,

Varanasi-221 005

21. Prof. Asmita Wele , Member

HOD of RSBKV, BVDU College of Ayurveda ,

404, Govind gaurav B Apts , Swanand Society ,

Sahakarnagar 2 , Pune 411 009

BhasmaProjectSeptember2008 14

22. Prof. Dhananjay Pandey Member

Co-ordinator School of Material Sciences,

Institute of Technology (IT) , BHU,

Varanasi-221 005

23. Dr ( Mrs) S.N.Khan , Member Secretary

Scientist F , TDT Division,

DST, Technology Bhawan ,

New Delhi-110016

BhasmaProjectSeptember2008 15

Terms of reference and other conditions :

I). To recommend:

(i) Conference of Identification of Bhasmas on which work related to Scientific validation etc

should be initiated

(ii) Identification of Institutes, which could undertake R&D work on identified Bhasmas

(iii) The manufacturing industries, which could possibly participate in scientific validation

(iv) The kind of state-of-the art facilities which are required for testing etc ; &

(v) Any other relevant aspect, like training in specific field .

II) The non-official members of the Committee will be eligible to TA/DA as per Government

of India rules for attending the meetings of the said panel of experts .

III.) The members , as per rule , will be paid honorarium @ Rs 250/- for attending

the meeting

III) Payments for air- travel will be made only on production of original air

tickets along with the claim and on certification that no claim from any

other source has been / will be made for the visit during the period

of meetings of the panel .

This issues with the approval of Secretary DST vide his Dy.No 4313 dated 2

nd

June 2006 and concurrence of Integrated finance division vide Dy.No 460/JSF/2006

dated 9

th

June 2006

(Dr.(Mrs) S.N.Khan)

Scientist F

BhasmaProjectSeptember2008 16

APPENDIX-II

(Members of the Three Working Groups)

Working Group I

Name of Members

1. Dr. Narendra Bhatt, Zandu Pharmaceuticals, Mumbai

2. Dr. S.K.Sharma, Adviser(Ay.), Dept. of AYUSH, New Delhi

3. Dr. C.K.Katiyar, Ranbaxy, Gurgaon

Working Group II

Name of Members

1. Dr. C.K Katiyar, Ranbaxy, Gurgaon

2. Dr. Asmita Wele, BVDU College, Pune

3. Vaid Nadkarni, Dhoot Papeshwar, Mumbai

4. Prof .Dhananjay Pandey, BHU

Working Group-III

Name of Members

1. Dr. V.Rama Rao, VIMTA Labs Ltd , Hyderabad

2. Dr. Chako, Sriram Institute of Industrial Research (SRIIR) , Delhi

3. Prof. Y.K.Gupta, Deptt of PharmacologyAIIMS, New Delhi

4. Dr.V. Tripathy, B.H.U, Varanasi

5. Dr.Vinay Bansal, Ranbaxy, Gurgaon

wrt shodhan /maran process etc in-vitro and cell based assays to develop not

Standardization of RM to be used for the Identification of right equipments to e.g.: Shodhan acute toxicity only efficacy data but also quick method of

Contemporary method identification of metals in free form. Develop appropriate assays to be

used for screening and for their

of identified bhasmas/formulations

for the identified disease.

of Bhasmas/compounds/formulations suitable pharmacological method

required for evaluating the efficacy

APPENDIX-III

(ACTION PLAN)

Preparation of Product Validation of chemical changes Safety evaluation Efficacy studies

Finalize the process of shodhan/ maran Chemical transformation taken place Guidelines for toxicity studies In-vitro experiments: Develop suitable

suitable to meet the requirement) like shodhan, maran &amritakaran

Preparation of bhasma/compounds/ evaluate the chemical changes Maran 4 to 6 weeks toxicity & biological standardization at every

Clinical studies: Develop Integrated

Protocols to conduct clinical trials

on the identified bhasmas and their

formulations using both Ayurvedic

expertise as well as clinical

Pharmacology expertise besides

the expertise of modern medicine in

the related field.

formulations (if need be to Develop new equipments Final Product-3-6 months toxicity stage of preparation of bhasmas

Physiochemical parameters for standardization In-vivo experiments: Develop

Maran process with in-process controls mechanism of action

and SOPs

& SOPs comparison of Traditional & e.g.: non-destructive method of

Shodhan process with in-process controls

Vous aimerez peut-être aussi

- Pharmaceutical Research Methodology and Bio-statistics: Theory and PracticeD'EverandPharmaceutical Research Methodology and Bio-statistics: Theory and PracticePas encore d'évaluation

- Aoac 2014 Presentation PDFDocument39 pagesAoac 2014 Presentation PDFAbu RaihanPas encore d'évaluation

- 260 Ijar-8550 3Document13 pages260 Ijar-8550 3esraa asemPas encore d'évaluation

- HACCP Generic Mod11Document3 pagesHACCP Generic Mod11GABRIELA BARCENAPas encore d'évaluation

- M.Pharm PharmaceuticsDocument13 pagesM.Pharm PharmaceuticsBilla NPas encore d'évaluation

- Research Methodology and Biostatistics Introductory Course WorkshopDocument37 pagesResearch Methodology and Biostatistics Introductory Course Workshoppharma000Pas encore d'évaluation

- How to Design and Implement Powder-to-Tablet Continuous Manufacturing SystemsD'EverandHow to Design and Implement Powder-to-Tablet Continuous Manufacturing SystemsFernando MuzzioPas encore d'évaluation

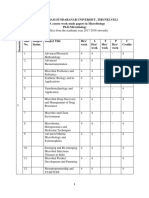

- Gujarat Technological University: W.E.F. AY 2017-18Document2 pagesGujarat Technological University: W.E.F. AY 2017-18raj royel100% (1)

- Validationof Analytical MethodsDocument6 pagesValidationof Analytical MethodsdiegoPas encore d'évaluation

- S0-1 Sood RameshDocument10 pagesS0-1 Sood RameshJaya AbrahamPas encore d'évaluation

- Project Report On Drug Regulatory Affairs: Submitted in Partial Fulfilment of Requirement For The Award of The Degree ofDocument64 pagesProject Report On Drug Regulatory Affairs: Submitted in Partial Fulfilment of Requirement For The Award of The Degree ofNatural agro100% (1)

- Essentials of Botanical Extraction: Principles and ApplicationsD'EverandEssentials of Botanical Extraction: Principles and ApplicationsÉvaluation : 5 sur 5 étoiles5/5 (5)

- Advances in Extraction and Applications of Bioactive PhytochemicalsD'EverandAdvances in Extraction and Applications of Bioactive PhytochemicalsPas encore d'évaluation

- Role of R&D in Regulatory Filing: Mr. Jayesh H. Jathar M. Pharm (Research Fellow)Document19 pagesRole of R&D in Regulatory Filing: Mr. Jayesh H. Jathar M. Pharm (Research Fellow)kajalPas encore d'évaluation

- Genetic Toxicology Testing: A Laboratory ManualD'EverandGenetic Toxicology Testing: A Laboratory ManualRay ProudlockPas encore d'évaluation

- Adult Sponsor Checklist for Student Research ProjectsDocument6 pagesAdult Sponsor Checklist for Student Research ProjectsErijah YapPas encore d'évaluation

- Analytical Method Development: April 2020Document14 pagesAnalytical Method Development: April 2020Chuyang ChenPas encore d'évaluation

- Multivariate Analysis in the Pharmaceutical IndustryD'EverandMultivariate Analysis in the Pharmaceutical IndustryAna Patricia FerreiraPas encore d'évaluation

- Nuclear Content Outline 2014Document4 pagesNuclear Content Outline 2014Yousab MKPas encore d'évaluation

- M Pharm Sem IIDocument25 pagesM Pharm Sem IIBhaven PatelPas encore d'évaluation

- Antioxidant Methods: A Guideline for Understanding and Determining Antioxidant CapacityD'EverandAntioxidant Methods: A Guideline for Understanding and Determining Antioxidant CapacityPas encore d'évaluation

- Food Analyst Exam Plan and SyllabusDocument11 pagesFood Analyst Exam Plan and SyllabusAmit KumarPas encore d'évaluation

- Are View Article On Analytical Method ValidationDocument12 pagesAre View Article On Analytical Method ValidationMelissa KadoumPas encore d'évaluation

- International Conference On HarmonizationDocument35 pagesInternational Conference On HarmonizationFarah Aman Khan100% (2)

- Industrial Process Scale-up: A Practical Innovation Guide from Idea to Commercial ImplementationD'EverandIndustrial Process Scale-up: A Practical Innovation Guide from Idea to Commercial ImplementationPas encore d'évaluation

- AReviewonStep by StepAnalyticalMethodValidationDocument14 pagesAReviewonStep by StepAnalyticalMethodValidationVENESYA SARAH MATULESSYPas encore d'évaluation

- Designing of Clinical Study DocumentsDocument16 pagesDesigning of Clinical Study DocumentsSaranya Smiley100% (1)

- 1628083193Document12 pages1628083193Harold fotsingPas encore d'évaluation

- Know How1 PDFDocument6 pagesKnow How1 PDFSunil DarjiPas encore d'évaluation

- Prof. P. R. Vavia ResumeDocument50 pagesProf. P. R. Vavia ResumeGwen WalkerPas encore d'évaluation

- Botanical Safety Assessment GuidelinesDocument11 pagesBotanical Safety Assessment GuidelinesRaida SiagianPas encore d'évaluation

- Inoculation of Culture Media: National Standard MethodDocument12 pagesInoculation of Culture Media: National Standard MethodPooran AppaduPas encore d'évaluation

- CIOMS ICHglossary V4 20jul2023Document205 pagesCIOMS ICHglossary V4 20jul2023rakshitha vPas encore d'évaluation

- Vara FINAL DOCUMENTATION NewDocument42 pagesVara FINAL DOCUMENTATION NewSiddhu FFPas encore d'évaluation

- Moi University: ISO 9001:2015 Certified InstitutionDocument33 pagesMoi University: ISO 9001:2015 Certified InstitutionANTONY MUNENEPas encore d'évaluation

- Comparison Bet. US FDA, USP & ICH GuidelinesDocument10 pagesComparison Bet. US FDA, USP & ICH GuidelinesRavi KantPas encore d'évaluation

- UntitledDocument5 pagesUntitledNguyễn HiếuPas encore d'évaluation

- Process Analytical Technology Concepts and Principles PDFDocument8 pagesProcess Analytical Technology Concepts and Principles PDFhdmnauPas encore d'évaluation

- A Review On Step-by-Step Analytical Method ValidationDocument13 pagesA Review On Step-by-Step Analytical Method ValidationMd MoinulPas encore d'évaluation

- WHO and ICH Guidelines For The Assessment of Herbal DrugDocument11 pagesWHO and ICH Guidelines For The Assessment of Herbal DrugEditor IJTSRDPas encore d'évaluation

- Steps For Analytical Method Development - Pharmaceutical GuidelinesDocument1 pageSteps For Analytical Method Development - Pharmaceutical GuidelinesAnju NarraPas encore d'évaluation

- Adult Sponsor Checklist GuideDocument14 pagesAdult Sponsor Checklist GuideJordan HyattPas encore d'évaluation

- NOM 164 SSA1 2015 APIs GMPDocument45 pagesNOM 164 SSA1 2015 APIs GMPJota VinodPas encore d'évaluation

- Bio DataDocument2 pagesBio Dataameya_yadavPas encore d'évaluation

- Notice Comments Guidelines Sampling Microbiology 14-10-2021Document38 pagesNotice Comments Guidelines Sampling Microbiology 14-10-2021sheela bethapudiPas encore d'évaluation

- Ich Terms and DefinitionsDocument197 pagesIch Terms and Definitionsv9991 v9991Pas encore d'évaluation

- A Review On Step-by-Step Analytical Method ValidationDocument13 pagesA Review On Step-by-Step Analytical Method ValidationIOSR Journal of Pharmacy100% (1)

- Proposed Revision of USP General Chapter on PET RadiopharmaceuticalsDocument34 pagesProposed Revision of USP General Chapter on PET Radiopharmaceuticalsantoniob2bPas encore d'évaluation

- P&G Report ModifiedDocument81 pagesP&G Report ModifiedKaushik SharmaPas encore d'évaluation

- Syllabus08th 05thDocument11 pagesSyllabus08th 05thThirumalaiPas encore d'évaluation

- Guidelines For Single-Laboratory Validation of Methods of Analysis - IUPAC PDFDocument21 pagesGuidelines For Single-Laboratory Validation of Methods of Analysis - IUPAC PDFmraleman717Pas encore d'évaluation

- STABILITY GUIDANCE PROTOCOLDocument10 pagesSTABILITY GUIDANCE PROTOCOLManish shankarpure100% (1)

- Final ICH GuidelineDocument52 pagesFinal ICH Guidelineshiv kumarPas encore d'évaluation

- Project Report of RMDocument47 pagesProject Report of RMNaveen SinghalPas encore d'évaluation

- CR023 Module 6 - REV0Document28 pagesCR023 Module 6 - REV0Sony M NidhiryPas encore d'évaluation

- An Update On AOAC INTERNATIONAL New Program ActivitiesDocument4 pagesAn Update On AOAC INTERNATIONAL New Program ActivitieskarimPas encore d'évaluation

- Harmonised Guideline for Bioanalytical Method ValidationDocument3 pagesHarmonised Guideline for Bioanalytical Method ValidationfdfsdfdssfsfsPas encore d'évaluation

- Applied Microbiology and Bioengineering: An Interdisciplinary ApproachD'EverandApplied Microbiology and Bioengineering: An Interdisciplinary ApproachPratyoosh ShuklaPas encore d'évaluation

- Course Work Syllabus PDFDocument318 pagesCourse Work Syllabus PDFshivacrazzePas encore d'évaluation

- Valid Analytical Methods & ProceduresDocument85 pagesValid Analytical Methods & ProceduresJonathan SierraPas encore d'évaluation

- PT 22 (1104-1108)Document5 pagesPT 22 (1104-1108)Doyel RaiPas encore d'évaluation

- 1 s2.0 S0378517398001690 MainDocument38 pages1 s2.0 S0378517398001690 MainDoyel RaiPas encore d'évaluation

- 1 s2.0 S0176161708001715 MainDocument5 pages1 s2.0 S0176161708001715 MainDoyel RaiPas encore d'évaluation

- Asian Journal PaperDocument6 pagesAsian Journal PaperDoyel RaiPas encore d'évaluation