Académique Documents

Professionnel Documents

Culture Documents

Din1688 1 PDF

Transféré par

pericolinDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Din1688 1 PDF

Transféré par

pericolinDroits d'auteur :

Formats disponibles

ICS 77.150.10; 77.150.

20

Descriptors: General tolerances, machining allowances, castings,

light metal alloys.

Gurohteile aus Leichtmetallegierungen Sandgu

Allgemeintoleranzen, Bearbeitungszugaben (Nicht fr

Neukonstruktionen)

In keeping with current practice in standards published by the International Organization for Standardization

(ISO), a comma has been used throughout as the decimal marker.

Ref. No. DIN 1688-1 : 1998-08

English price group 06 Sales No. 0106

11.98

DEUTSCHE NORM August 1998

1688-1

{

Continued on pages 2 to 4.

No part of this translation may be reproduced without the prior permission of

DIN Deutsches Institut fr Normung e. V., Berlin.

Beuth Verlag GmbH, D-10772 Berlin, has the exclusive right of sale for German Standards (DIN-Normen).

Translation by DIN-Sprachendienst.

In case of doubt, the German-language original should be consulted as the authoritative text.

Rough castings of light metal alloys produced

by sand casting

General tolerances and machining allowances

(For replacement purposes only)

Supersedes

October 1980 edition.

Dimensions in mm

1 Scope and field of application

This standard specifies general tolerances and machining allowances for rough castings of aluminium and

magnesium alloys produced by sand casting, which are subject to the technical delivery conditions laid

down in DIN 1725-2 and DIN 1729-2.

Users of this standard should note that it now only applies to castings used for repair and replacement

purposes. New designs are covered by ISO 8062 : 1994.

Owing to the lack of empirical data, general tolerances have not been specified here for angular dimensions.

If angles are to meet accuracy requirements, these shall be indicated as individual tolerances.

2 Normative references

This standard incorporates, by dated or undated reference, provisions from other publications. These

normative references are cited at the appropriate places in the text, and the titles of the publications are

listed below. For dated references, subsequent amendments to or revisions of any of these publications

apply to this standard only when incorporated in it by amendment or revision. For undated references, the

latest edition of the publication referred to applies.

DIN 1680-1 Rough castings General tolerances and machining allowances General

DIN 1680-2 Rough castings System of general tolerances

DIN 1725-2 Aluminium casting alloys Sand casting, gravity die casting, pressure die casting and

investment casting

DIN 1729-2 Magnesium casting alloys Sand casting, gravity die casting, pressure die casting

DIN 7182-1 Sizes, deviations, tolerances and fits Basic concepts

ISO 8062 : 1994 Castings System of dimensional tolerances and machining allowances

3 Concepts

See DIN 7182-1 and DIN 1680-1 for the terms general tolerances and tolerance grade, and DIN 1680-1

for a definition of machining allowance.

Page 2

DIN 1688-1 : 1998-08

4 Tolerance grades

4.1 Dimensional deviations

For rough castings of light metal alloys produced by sand casting, dimensional deviations are largely dependent

on

a) the dimensional accuracy of the pattern, the care taken during moulding and casting, and the moulding

and casting equipment used based on the batch size;

b) the location of the parting line (i.e. dimensions are or are not influenced by the mould; cf. DIN 1680-1);

c) the nominal sizes.

4.2 Application of tolerance grades

Limit deviations shall be specified on the basis of the tolerance grades given in tables 1 and 2. Linear dimensions

and thickness shall be specified for the same grade; for exceptions see DIN 1680-1.

4.3 Nominal size ranges

The nominal size ranges shown in tables 1 and 2 for each tolerance grade have been selected on the basis of

reliable measurement data.

5 Machining allowances

The machining allowance, BZ, is a function of the largest external dimension of the casting and is the same for

all tolerance grades (cf. table 3); see DIN 1680-1 for exceptions.

For sizes up to 500 mm, machining allowances may be reduced to approximately half the values specified in

table 3 if the pattern equipment, casting procedure and machining procedure with regard to clamping surfaces

and datum surfaces have been optimized, for example, for series production, as agreed between the customer

and the foundry. These reduced values are shown in table 4.

6 Designation

Where both the tolerance grade and the machining allowance have been selected on the basis of this standard,

the designation of a grade GTA 16/5 tolerance (GTA 16/5) in conjunction with a machining allowance of 3,5

(BZ 3,5), for example, shall be designated as follows:

Tolerance and machining allowance DIN 1688 GTA 16/5 BZ 3,5

See DIN 1680-1 for other examples of designations.

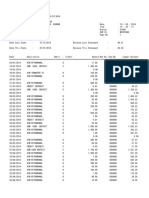

Table 1: Limit deviations for linear dimensions (length, width, height,

centreline distance, diameter, radius)*)

Tolerance

grade

Dimensions

influenced by

mould

Yes

No

Nominal size range

Yes

No

*) Irrespective of the values given in this table, the actual deviation of the linear dimensions of a casting shall in

no case be greater than t25 % of the nominal size, rounded to one decimal place. This restriction is of particular

relevance when applying the deviations in the boxes enclosed by thick lines.

Corresponds

to tolerance

grade... as in

DIN 1680-2

Over

up to

Over

up to

Up to

50

Over

up to

Over

up to

Over

up to

Over

up to

Over

up to

Over

up to

Over

up to

Over

up to

Over

up to

plus allowance

,

plus allowance

,

Page 3

DIN 1688-1 : 1998-08

7 Indicating general tolerances on existing drawings

If an existing drawing does NOT refer to the tolerance groups specified in the 1958 edition of this standard

(which is no longer valid), then the tolerance grades given in tables 1 and 2 do not apply. It is recommended

that a grade suitable for the casting in question be indicated on such drawings.

If an existing drawing DOES refer to the previously valid tolerance groups, it is recommended that these be

converted to the tolerance grades specified in tables 1 and 2 of the present standard. If this is not possible, the

permissible limit deviations are to be taken from tables 5 and 6 below.

Tables 5 and 6 do NOT apply to new drawings.

Table 2: Limit deviations for thicknesses (wall, web or rib thicknesses)*)

Tolerance

grade

Dimensions

influenced by

mould

Nominal size range

Over

up to

Up to

6

Over

10

Yes

No

Yes

No

*) Irrespective of the values given in this table, the actual deviation

of the linear dimensions of a casting shall in no case be greater

than t 25 % of the nominal size, rounded to one decimal place.

This restriction is of particular relevance when applying the

deviations in the boxes enclosed by thick lines.

The limit deviations specified in table 2 have not been derived from a specific tolerance series.

Table 3: Machining allowances, BZ

Table 4: Reduced machining allowances, BZ (see clause 5)

Nominal size range

(based on the largest

overall dimension of

casting)

Nominal size range

(based on the largest

overall dimension of

casting)

Machining allowance, BZ

Machining allowance, BZ

Over

up to

Over

up to

Up to

30

Over

up to

Over

up to

Over

up to

Over

up to

Over

up to

Over

up to

Over

up to

Up to

30

Over

up to

Over

up to

Over

up to

Over

up to

Over

up to

Over

up to

Page 4

DIN 1688-1 : 1998-08

Table 5: Limit deviations for linear dimensions on existing drawings

Table 6: Limit deviations for thicknesses on existing drawings

8 Indicating machining allowances on existing drawings

The machining allowances specified in this standard only apply to drawings on which general tolerances in

accordance with clause 4 and tables 1 and 2 of this standard are indicated.

Previous editions

DIN 1688-1: 1958-04, 1974-08, 1980-10.

Amendments

As compared with the October 1980 edition, the standard now applies only to castings used for replacement

purposes.

Other relevant standard

DIN 1690-1 Technical delivery conditions for castings of metallic materials General

Tolerance

group

Nominal size range

Over

up to

Tolerance

group

Nominal size range

Over

up to

Up to

50

Over

up to

Over

up to

Over

up to

Over

up to

Over

up to

Over

up to

Over

up to

Over

up to

Over

up to

Up to

6

Over

up to

Vous aimerez peut-être aussi

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Concrete For Water StructureDocument22 pagesConcrete For Water StructureIntan MadiaaPas encore d'évaluation

- Process Interactions PDFDocument1 pageProcess Interactions PDFXionPas encore d'évaluation

- Proposal For Chemical Shed at Keraniganj - 15.04.21Document14 pagesProposal For Chemical Shed at Keraniganj - 15.04.21HabibPas encore d'évaluation

- Product Guide TrioDocument32 pagesProduct Guide Triomarcosandia1974Pas encore d'évaluation

- Delta PresentationDocument36 pagesDelta Presentationarch_ianPas encore d'évaluation

- Health Informatics SDocument4 pagesHealth Informatics SnourhanPas encore d'évaluation

- Milestone 9 For WebsiteDocument17 pagesMilestone 9 For Websiteapi-238992918Pas encore d'évaluation

- Entrep Q4 - Module 7Document5 pagesEntrep Q4 - Module 7Paula DT PelitoPas encore d'évaluation

- (ENG) Visual Logic Robot ProgrammingDocument261 pages(ENG) Visual Logic Robot ProgrammingAbel Chaiña Gonzales100% (1)

- Kayako Support Suite User Manual PDFDocument517 pagesKayako Support Suite User Manual PDFallQoo SEO BaiduPas encore d'évaluation

- Sangeetahealingtemples Com Tarot Card Reading Course in UsaDocument3 pagesSangeetahealingtemples Com Tarot Card Reading Course in UsaSangeetahealing templesPas encore d'évaluation

- Automatic Stair Climbing Wheelchair: Professional Trends in Industrial and Systems Engineering (PTISE)Document7 pagesAutomatic Stair Climbing Wheelchair: Professional Trends in Industrial and Systems Engineering (PTISE)Abdelrahman MahmoudPas encore d'évaluation

- The Concept of ElasticityDocument19 pagesThe Concept of ElasticityVienRiveraPas encore d'évaluation

- Bisleri 2.0Document59 pagesBisleri 2.0Dr Amit Rangnekar100% (4)

- Floor Paln ModelDocument15 pagesFloor Paln ModelSaurav RanjanPas encore d'évaluation

- Modulation and Frequency Synthesis X Digital Wireless RadioDocument233 pagesModulation and Frequency Synthesis X Digital Wireless Radiolcnblzr3877Pas encore d'évaluation

- Bank Statement SampleDocument6 pagesBank Statement SampleRovern Keith Oro CuencaPas encore d'évaluation

- Insurance Smart Sampoorna RakshaDocument10 pagesInsurance Smart Sampoorna RakshaRISHAB CHETRIPas encore d'évaluation

- MWG Installation 7.6.2 IG INSTALLATION 0516 en - PDDocument64 pagesMWG Installation 7.6.2 IG INSTALLATION 0516 en - PDjbondsrPas encore d'évaluation

- Danube Coin LaundryDocument29 pagesDanube Coin LaundrymjgosslerPas encore d'évaluation

- Between:-Mr. Pedro Jose de Vasconcelos, of Address 14 CrombieDocument2 pagesBetween:-Mr. Pedro Jose de Vasconcelos, of Address 14 Crombiednd offiPas encore d'évaluation

- Introduction Into Post Go-Live SizingsDocument26 pagesIntroduction Into Post Go-Live SizingsCiao BentosoPas encore d'évaluation

- 133 The Science and Understanding of TheDocument14 pages133 The Science and Understanding of TheCarlos RieraPas encore d'évaluation

- Unit 5 Andhra Pradesh.Document18 pagesUnit 5 Andhra Pradesh.Charu ModiPas encore d'évaluation

- Mounting BearingDocument4 pagesMounting Bearingoka100% (1)

- A Comparison of Pharmaceutical Promotional Tactics Between HK & ChinaDocument10 pagesA Comparison of Pharmaceutical Promotional Tactics Between HK & ChinaAlfred LeungPas encore d'évaluation

- CT018 3 1itcpDocument31 pagesCT018 3 1itcpraghav rajPas encore d'évaluation

- Writing Task The Strategy of Regional Economic DevelopementDocument4 pagesWriting Task The Strategy of Regional Economic DevelopementyosiPas encore d'évaluation

- Review of Accounting Process 1Document2 pagesReview of Accounting Process 1Stacy SmithPas encore d'évaluation

- The Finley ReportDocument46 pagesThe Finley ReportToronto StarPas encore d'évaluation