Académique Documents

Professionnel Documents

Culture Documents

Bootstrap Nitrogen Boosters PDF

Transféré par

mecambDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Bootstrap Nitrogen Boosters PDF

Transféré par

mecambDroits d'auteur :

Formats disponibles

H O W T H E Y W O R K

A P P L I C A T I O N S

M O D E L S E L E C T I O N

These units are simple area ratio

piston type boosters that

automatically reciprocate when gas

pressure, up to 150 psi, is applied to

the large low pressure drive piston.

This piston is directly connected to

small high pressure pistons inside

the booting sections of both ends

of the drive. Each boost section

contains integral inlet and outlet

check valves thereby producing a

pumping action. Unregulated

Nitrogen or Helium from a supply

cylinder(s) is directly connected at

maximum pressure to the boost sections.

Nitrogen to the drive section is regulated to 115-

120 psi by the integral drive control system

Wearing parts are low cost elastomers and self

lubricating engineering plastics, all available in

seal kits, are feld replaceable with simple

instructions and conventional hand tools.

Both units are lightweight, 1-man-portable,

weather resistant and operate in any position.

Both models have been designed for operators of

helicopters and/or small aircraft where a portable

self-powered booster is needed for ground support.

The primary application is to service the high

pressure on-board Nitrogen or Helium bottles on

helicopters equipped with emergency infatable

Pop Type foats. However, using either model to

service other components needing high pressure

Nitrogen such as shock struts and precharging

hydraulic accumulators is also common.

Model 17934-1 is the original low cost single

stage Nitrogen unit designed specifcally for the

2,800 to 3,000 psi fight bottles still used on many

commercial helicopters. The 55390 is a 2 stage

unit, suitable for all applications including the newer

high pressure fight bottles (up to 5,500 psi) charged

with nitrogen or Helium. It includes adjustable

automatic air pilot switch to stop at a preselected

output pressure and integral adjustable output

safety relief with 0-7,500 psi gauge.

Required by F.A.A. under F.A.R. regulation 135.183 if fying over water

beyond the point where landing would be possible if engine failed.

B O O T S T R A P N I T R O G E N B O O S T E R S f o r C h a r g i n g O n - B o a r d H e l i c o p t e r P o p F l o a t I n f l a t i o n B o t t l e s

BOOTSTRAP NITROGEN BOOSTERS

Bootstrap Booster Unit

f o r C h a r g i n g O n - B o a r d H e l i c o p t e r

P o p F l o a t I n f l a t i o n B o t t l e s

Model 55390 Nitrogen or Helium up to 5,500 psi.

Model 17934-1 Nitrogen only up to 3,000 psi.

BOOTSRAP NI TROGEN BOOSTERS f or Char gi ng On- Boar d Hel i copt er Pop Fl oat I nf l at i on Bot t l es

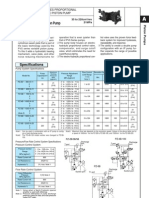

SCHEMATIC

(Abbreviated)

DRIVE

CONTROL

SYSTEM

GAS OUTLET

CONTROLS

AND

ACCESSORIES

GAS INLET

CONTROLS

AND

ACCESSORIES

TARE

WEIGHT

PERFORMANCE

Model 55390 Model 17934-1

Manual valve for start/stop

Automatic stop when gas INLET drops to 300 psi

Gas regulator with relief valve limiting drive section to

115 psi

Drive pressure gauge 0-160 psi

Vent valve

6 ft. x

1

/4" I.D. hose assembly 5,000 psi maximum

working pressure but limited to 3,000 psi with the

Schrader No. 556 connector provided (To fit MS28889

2 type aircraft charge valve)

Gauge 0-3,000 psi

6 ft. x 3/8" I.D. hose assembly, 4,000 psi maximum

working pressure with CGA 580 bottle connector

43 lbs.

Charge two 425 cu. In. flight bottles to 3,000 psi within

20 minutes from one standard D.O.T. 2,200 psi nitrogen

cylinder (226 SCF).

For further information on

Haskel products, visit our

website at: www.haskel.com

Printed in USA

GAS INLET HOSE

ASSEMBLY A

(HELIUM OR NITROGEN)

2,700 PSI MAXIMUM

For NITROGEN boost and drive, connect supply gas to

"A"; open valve "C": (Hose "B" can be removed)

For HELIUM boost with nitrogen drive, connect helium

supply to "A"; nitrogen supply to "B"; close valve "C"

Manual valve for start/stop

Automatic stop when gas INLET ("A") drops to 150 psi;

or gas OUTLET increases to user adjusted setting

(5,500 psi maximum)

Gas regulator with relief valve limiting drive section to 115 psi

Drive pressure gauge 0-160 psi

Safety relief valve, user adjusted

Vent valve

Gauge 0-7,500 psi

6 ft. x 3/16" I.D. hose assembly 5,500 psi maximum

working pressure with Schrader No. 5007 connector (To

fit MS28889 2 type aircraft charge valve)

Gauge 0- 3,000 psi

2 each 6 ft. x 3/8" I.D. hose assembly, 4,000 psi maximum

working pressure with CGA 580 bottle connector

Manual stop valve "C" (turn off if pumping helium)

48 lbs.

Charge two 425 cu. in. flight bottles to 3,000 psi within

20 minutes from less than two standard D.O.T. 2,200 psi

nitrogen cylinders (226 SCF each); or one 7.93 litre

bottle to 4,500 psi N

2 from approximately 2-1/2 D.O.T.

cylinders; or Helium from 2,200 psi, 215 SCF cylinder

using less than two N2

cylinders for drive.

2031137 Hask_NitroBooster2 UPDATED_2031137 Hask_NitroBooster2.qxd 8/1/14 9:32 AM Page 2

BOOTSTRAP NI TROGEN BOOSTERS f or Char gi ng On- Boar d Hel i copt er Pop Fl oat I nf l at i on Bot t l es

8

For further information on

Haskel products, visit our

website at: www.haskel.com

Printed in USA BST REV 08/14

Haskel International, LLC.

818.843.4000

Email: sales@haskel.com

www.haskel.com

Vous aimerez peut-être aussi

- HANDBOOK Blanket Gas Regulators PDFDocument8 pagesHANDBOOK Blanket Gas Regulators PDFfrankz89Pas encore d'évaluation

- Series 5100Document12 pagesSeries 5100HectorMaldonadoPas encore d'évaluation

- Type 1805P Pilot-Operated Relief ValveDocument8 pagesType 1805P Pilot-Operated Relief ValveJOMAGUESPas encore d'évaluation

- Pumps Spec Series5100!8!09Document12 pagesPumps Spec Series5100!8!09Carlos David Lopez TorresPas encore d'évaluation

- Dynex PF 1300 SpecsDocument7 pagesDynex PF 1300 SpecsAdeel HassanPas encore d'évaluation

- Dynex PF 500 SpecsDocument7 pagesDynex PF 500 SpecsWaseem WaqarPas encore d'évaluation

- Haskel Liquid Pump SpecsDocument30 pagesHaskel Liquid Pump SpecsMarcos Rodrigues Dos SantosPas encore d'évaluation

- 205 Drag Valves For Boiler Feedpump RecirculationDocument6 pages205 Drag Valves For Boiler Feedpump Recirculationesakkiraj1590Pas encore d'évaluation

- ComapDocument44 pagesComapfabianoal50% (2)

- Unloading Pressure Hk66j102Document12 pagesUnloading Pressure Hk66j102seaqu3stPas encore d'évaluation

- 501 007Document4 pages501 007burckhardt83Pas encore d'évaluation

- Self-Contained Hydraulic Control UnitDocument7 pagesSelf-Contained Hydraulic Control UnitPacco HmPas encore d'évaluation

- Reg RedQ Specialy Regulators PDFDocument20 pagesReg RedQ Specialy Regulators PDFDavid SaldarriagaPas encore d'évaluation

- Hy17 8523 UkDocument6 pagesHy17 8523 Ukexay40Pas encore d'évaluation

- SS-AEPF Goodman Air ConditionerDocument8 pagesSS-AEPF Goodman Air ConditionerArmando EnriquezPas encore d'évaluation

- Valvulas XT PDFDocument4 pagesValvulas XT PDFIsidro Gomez GarciaPas encore d'évaluation

- HP Regulators v2Document9 pagesHP Regulators v2Danny SánchezPas encore d'évaluation

- PSI PumpsDocument12 pagesPSI PumpsagiacomuzoPas encore d'évaluation

- Catalogos BombasDocument12 pagesCatalogos BombasJose NavarretePas encore d'évaluation

- PRH09 PDFDocument4 pagesPRH09 PDFengp3077Pas encore d'évaluation

- SIT630 Installation InstructionsDocument2 pagesSIT630 Installation Instructionsmelisa63Pas encore d'évaluation

- CROWN Esd Brochure Usa 3 2Document4 pagesCROWN Esd Brochure Usa 3 2Ahmed Ayman Yassin100% (1)

- 6 HP Pump G Series Technical SpecsDocument25 pages6 HP Pump G Series Technical SpecsEduardo CramerPas encore d'évaluation

- DRESSER Regulators FlowgridDocument12 pagesDRESSER Regulators Flowgridzalziza100% (1)

- 133 RegulatorDocument16 pages133 Regulatorgre294Pas encore d'évaluation

- C72H NorgrenDocument4 pagesC72H NorgrenHernando HerreraPas encore d'évaluation

- Hi-Force Hydrostatic PDFDocument6 pagesHi-Force Hydrostatic PDFWong Chung MengPas encore d'évaluation

- Valv Y AscoDocument12 pagesValv Y Ascojoticamario123Pas encore d'évaluation

- Ruelco Self Contained Product Manual Rev 4Document11 pagesRuelco Self Contained Product Manual Rev 4DDani3214Pas encore d'évaluation

- Tools MaunalDocument86 pagesTools MaunalAbrar HussainPas encore d'évaluation

- 50B4KGDocument2 pages50B4KGonin007Pas encore d'évaluation

- Mallard IOM Series 5600Document13 pagesMallard IOM Series 5600Nacho.pPas encore d'évaluation

- PRH04-300 FLG PDFDocument5 pagesPRH04-300 FLG PDFengp3077Pas encore d'évaluation

- FunctionalSafety V7666Document12 pagesFunctionalSafety V7666rufino.perea.2Pas encore d'évaluation

- Peco Gas Scrubber Fs 85 SL 01Document4 pagesPeco Gas Scrubber Fs 85 SL 01Rigoberto LozanoPas encore d'évaluation

- 6-552-1 (PS10-34)Document2 pages6-552-1 (PS10-34)Ânderson Silva BrasilPas encore d'évaluation

- SPM Full Bore Emergency Unloading Valve Manual PDFDocument9 pagesSPM Full Bore Emergency Unloading Valve Manual PDFPablo SotoPas encore d'évaluation

- FEPA Gas-over-oil ActuatorsDocument4 pagesFEPA Gas-over-oil Actuatorstoader56Pas encore d'évaluation

- Proportional Electro-Hydraulic ControlsDocument31 pagesProportional Electro-Hydraulic ControlshassanHyro43100% (3)

- SB 8540.3 - 1800 and 2000 Industrial RegDocument12 pagesSB 8540.3 - 1800 and 2000 Industrial RegImam BuchairiPas encore d'évaluation

- All About HidrolicDocument7 pagesAll About Hidrolicpiteng1945100% (3)

- PL 2Document2 pagesPL 2dagomezooPas encore d'évaluation

- E 55L 60Document2 pagesE 55L 60Gustavo Acosta MorenoPas encore d'évaluation

- Bomba Pistao Dynex MorlinaDocument6 pagesBomba Pistao Dynex MorlinaoperariopantaleaoPas encore d'évaluation

- 40kgm max torque air clutchDocument4 pages40kgm max torque air clutchRio de MarioPas encore d'évaluation

- Portable NItrogen Booster Rev 2Document2 pagesPortable NItrogen Booster Rev 2Samy MaxPas encore d'évaluation

- HPB Brochure 0708Document12 pagesHPB Brochure 0708musaluddinPas encore d'évaluation

- 7000 Flow Control ValvesDocument51 pages7000 Flow Control Valvesadyro12100% (1)

- RegO 2014 Product GuideDocument8 pagesRegO 2014 Product GuideJason D ClarkPas encore d'évaluation

- E 0054Document1 pageE 0054PuLung SambadhaPas encore d'évaluation

- Variable Vane Pumps: 1 P V 2 V 3 - / RA01MC A 1Document8 pagesVariable Vane Pumps: 1 P V 2 V 3 - / RA01MC A 1Dias EliPas encore d'évaluation

- Air Preparation ProductsDocument6 pagesAir Preparation ProductssenamotoPas encore d'évaluation

- Dongguan Suncenter Fluid Control Equipment Co., LTDDocument10 pagesDongguan Suncenter Fluid Control Equipment Co., LTDJeisson DazaPas encore d'évaluation

- R431002626 AventicsH 3Controlair®ValveswithRollerDocument2 pagesR431002626 AventicsH 3Controlair®ValveswithRollerHamza ChenakerPas encore d'évaluation

- NLB Back Pressure Valves Brochure 032613Document9 pagesNLB Back Pressure Valves Brochure 032613EquilibarPas encore d'évaluation

- SKF Lagg 50A or LAGG 180A: Air-Driven Grease PumpsDocument8 pagesSKF Lagg 50A or LAGG 180A: Air-Driven Grease PumpsEdgar CanelasPas encore d'évaluation

- Tank BlankettingDocument6 pagesTank BlankettingBaskar KannaiahPas encore d'évaluation

- Marvel Carbureter and Heat Control As Used on Series 691 Nash Sixes Booklet SD'EverandMarvel Carbureter and Heat Control As Used on Series 691 Nash Sixes Booklet SPas encore d'évaluation

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitD'EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitPas encore d'évaluation

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsD'EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsPas encore d'évaluation

- Jack HydraulicDocument1 pageJack HydraulicmecambPas encore d'évaluation

- Fligth Control SystemDocument4 pagesFligth Control SystemmecambPas encore d'évaluation

- Engineering Symbology - Prints and Drawings 1Document120 pagesEngineering Symbology - Prints and Drawings 1Zander_Pas encore d'évaluation

- Engineering Symbology - Prints and Drawings 2 PDFDocument96 pagesEngineering Symbology - Prints and Drawings 2 PDFNelson Aguirre BravoPas encore d'évaluation

- Servo ValveDocument7 pagesServo ValvemecambPas encore d'évaluation

- Service N ValveDocument30 pagesService N ValvemecambPas encore d'évaluation

- Owner's Manual Talon LC Hydraulic Cargo Hook Kit Airbus Helicopters AS350Document49 pagesOwner's Manual Talon LC Hydraulic Cargo Hook Kit Airbus Helicopters AS350이영모Pas encore d'évaluation

- Cargo Hook 120-044-00Document52 pagesCargo Hook 120-044-00mecambPas encore d'évaluation

- 120-099-01 Cargo HookDocument61 pages120-099-01 Cargo HookmecambPas encore d'évaluation

- Air Amplifiers and Systems R13 June 2021Document12 pagesAir Amplifiers and Systems R13 June 2021mecambPas encore d'évaluation

- Parker Chomerics Conductive Elastomer Engineering HandbookDocument152 pagesParker Chomerics Conductive Elastomer Engineering HandbookBarPas encore d'évaluation

- Repair Parts Sheet MIC-100, MIC-200/MC-75, MC-77: Mobile Crane UnitsDocument8 pagesRepair Parts Sheet MIC-100, MIC-200/MC-75, MC-77: Mobile Crane UnitsmecambPas encore d'évaluation

- Id Number Title Year OrganizationDocument12 pagesId Number Title Year OrganizationrabeemhPas encore d'évaluation

- Luxfer SCI Composite Cylinder Manual English 032317Document33 pagesLuxfer SCI Composite Cylinder Manual English 032317mecambPas encore d'évaluation

- Air PreparationDocument500 pagesAir PreparationmecambPas encore d'évaluation

- Utility Helicopter Newsletter Stabilator Pin Jul-Aug Pages 6-7Document2 pagesUtility Helicopter Newsletter Stabilator Pin Jul-Aug Pages 6-7mecambPas encore d'évaluation

- Hydraulic Technology Worldwide: Instruction Sheet Hydraulic Load Cells Compression & Tension (2-300 Ton Models)Document8 pagesHydraulic Technology Worldwide: Instruction Sheet Hydraulic Load Cells Compression & Tension (2-300 Ton Models)mecambPas encore d'évaluation

- USCG ME Exam - Motor Knowledge IllustrationsDocument111 pagesUSCG ME Exam - Motor Knowledge IllustrationsSatyabrat GaanPas encore d'évaluation

- Specification Sheet Load Cell: L665 Rev O. 05/98Document2 pagesSpecification Sheet Load Cell: L665 Rev O. 05/98mecambPas encore d'évaluation

- Instruction Sheet Digital Gauges (P) DGB - (P) DGP - (P) DGL: 1.0 Important Receiving Instructions L1095 Rev. O 09/99Document8 pagesInstruction Sheet Digital Gauges (P) DGB - (P) DGP - (P) DGL: 1.0 Important Receiving Instructions L1095 Rev. O 09/99mecambPas encore d'évaluation

- L1205 oDocument4 pagesL1205 omecambPas encore d'évaluation

- Patent ActuatorDocument5 pagesPatent ActuatormecambPas encore d'évaluation

- Repair Parts Sheet MIC-100, MIC-200/MC-75, MC-77: Mobile Crane UnitsDocument8 pagesRepair Parts Sheet MIC-100, MIC-200/MC-75, MC-77: Mobile Crane UnitsmecambPas encore d'évaluation

- NSTM 551 Compressed AirDocument238 pagesNSTM 551 Compressed AirmecambPas encore d'évaluation

- GD30 Series: Inlet & Outlet 0-3,600 Psig Dome-Loaded Pressure RegulatorsDocument2 pagesGD30 Series: Inlet & Outlet 0-3,600 Psig Dome-Loaded Pressure RegulatorsmecambPas encore d'évaluation

- Definitions: Back Pressure: Burst PressureDocument15 pagesDefinitions: Back Pressure: Burst PressuremecambPas encore d'évaluation

- GD30 Series: Inlet & Outlet 0-3,600 Psig Dome-Loaded Pressure RegulatorsDocument2 pagesGD30 Series: Inlet & Outlet 0-3,600 Psig Dome-Loaded Pressure RegulatorsmecambPas encore d'évaluation

- Gas Booster Brochure R9Document12 pagesGas Booster Brochure R9mecambPas encore d'évaluation

- Liquid Flow C Equation: LegendDocument3 pagesLiquid Flow C Equation: LegendHusseinPas encore d'évaluation

- Gas Turbines A Manual PDFDocument74 pagesGas Turbines A Manual PDFHenry Pannell100% (1)

- Assignment #3Document2 pagesAssignment #3Choa Pei ShuangPas encore d'évaluation

- Generator Diesel Chicago Pneumatic CPSG 9Document2 pagesGenerator Diesel Chicago Pneumatic CPSG 9diconPas encore d'évaluation

- RC SLAB1 SoftwareDocument14 pagesRC SLAB1 Softwaresofianina05Pas encore d'évaluation

- 7 - In. Posiset Thru-Tubing Plug (2 / - In. Od) : Description FeaturesDocument1 page7 - In. Posiset Thru-Tubing Plug (2 / - In. Od) : Description Featureshamed1725Pas encore d'évaluation

- Fisher Control Valve Sourcebook - Power and Severe ServiceDocument220 pagesFisher Control Valve Sourcebook - Power and Severe Servicemtrj59Pas encore d'évaluation

- Properties of Natural Gas and Condensate SystemsDocument80 pagesProperties of Natural Gas and Condensate SystemsHashem HashemPas encore d'évaluation

- Thermal Physics - DPP 11 of (Lec 23) - Saakaar Batch For IIT JAM PhysicsDocument3 pagesThermal Physics - DPP 11 of (Lec 23) - Saakaar Batch For IIT JAM PhysicsAnkur TiwariPas encore d'évaluation

- Interlock, Protection & Permissive of BFPDocument15 pagesInterlock, Protection & Permissive of BFPShweta Srivastava100% (2)

- Cek Item SapDocument30 pagesCek Item Sapiduy emailsPas encore d'évaluation

- Catalog 40 Spare PartsDocument54 pagesCatalog 40 Spare PartsMiticaVladPas encore d'évaluation

- DT - Hardness TestDocument30 pagesDT - Hardness TestSamuel Christian GiovanniPas encore d'évaluation

- CVT PatriotDocument37 pagesCVT PatriotErnesto Rivas SoteloPas encore d'évaluation

- Kurt Pamvouxoglou KDE11 20SS Service - Manual PDFDocument111 pagesKurt Pamvouxoglou KDE11 20SS Service - Manual PDFرحمة هداية اللهPas encore d'évaluation

- Productdata 1LDocument23 pagesProductdata 1Lsharif_alPas encore d'évaluation

- Section 5 - Relief SystemsDocument22 pagesSection 5 - Relief Systemslulis171Pas encore d'évaluation

- Archimedes and BuoyancyDocument2 pagesArchimedes and Buoyancyromaehab201912Pas encore d'évaluation

- Strengthening Mechanisms ExplainedDocument74 pagesStrengthening Mechanisms ExplainedRyan TorresPas encore d'évaluation

- Stability Analysis of Columns With Variable Cross-Sections 1st Two Pages Placed LastDocument12 pagesStability Analysis of Columns With Variable Cross-Sections 1st Two Pages Placed LastIntishar RahmanPas encore d'évaluation

- Carbon-Carbon CompositesDocument12 pagesCarbon-Carbon CompositesSONU KUMARPas encore d'évaluation

- Inspection DT Scania 21633Document8 pagesInspection DT Scania 21633Sarohman RohmanPas encore d'évaluation

- OCH - Part1-Energy-Critica DepthDocument33 pagesOCH - Part1-Energy-Critica Depthtewodros getuPas encore d'évaluation

- Fluid and Fluid PropertiesDocument42 pagesFluid and Fluid PropertiesCIPETIPT Tool RoomPas encore d'évaluation

- Combination Tool WFTDocument11 pagesCombination Tool WFTCarlos HolguinPas encore d'évaluation

- Product CatalogDocument106 pagesProduct CatalogAri AzadPas encore d'évaluation

- B149.03 02-En PDFDocument4 pagesB149.03 02-En PDFIndra MishraPas encore d'évaluation

- CDM816DⅢ配件图册 (2015第1版第1次)Document188 pagesCDM816DⅢ配件图册 (2015第1版第1次)Mohammadazmy Sobursyakur0% (1)

- Low Pressure Pumps: Installation and Start-Up InstructionDocument12 pagesLow Pressure Pumps: Installation and Start-Up InstructionsmithworkPas encore d'évaluation

- Hydraulic Puller Operating InstructionsDocument5 pagesHydraulic Puller Operating InstructionsMasterrPas encore d'évaluation

- Edge Effects in Thin Film DelaminationDocument15 pagesEdge Effects in Thin Film DelaminationAdamRaczPas encore d'évaluation

- 1950 Kaman Servoflap US2695674Document23 pages1950 Kaman Servoflap US2695674jorge paezPas encore d'évaluation