Académique Documents

Professionnel Documents

Culture Documents

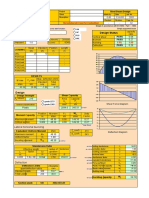

Calculation Sheet: Padeye Calculations Loads

Transféré par

shani5573Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Calculation Sheet: Padeye Calculations Loads

Transféré par

shani5573Droits d'auteur :

Formats disponibles

2

Padeye calculations

Loads

Max. Unfactored lifting Load, P kN

Dynamic Amplification factor, DAF

Consequence Factor, g

c

Maximum design vertical load, V kN

Maximum design horizontal load, 50% of vertical load, H kN

Maximum design lateral load, 5% of vertical load, L

T kN

L

T

Shackle Selection : Bow Shackle - Refer EN:13889:2003(E)

Static load for shackle selection kN

Working load limit as per EN:13889:2003(E) kN

Shackle pin diameter, D

pin

( D in fig) mm

Inside width of shackle (w, in fig) mm

Inside length of shackle (s, in fig) mm

Padeye geometry

Radius of the main plate, r

mp

mm

Thickness of the main plate, t

mp

mm

Width of main plate, W

mp

mm

Diameter of padeye hole, D

hole

mm

Diameter of sling, D

sling

mm

MT

MT

9.375 MT

5 MT

9.38 MT

60

10

9.38 MT

5

6.5

18

=

150

=

=

=

=

14.18

75

=

= 7.565

= 9.8

7.565

1.5

14.2

14.2

1.25

=

=

=

=

= 45.5

= 85

= 34

=

CALCULATION SHEET

Project

VALHALL LQ MODULE

Title

HTCC Room - padeye calculations

Discipline

STRUCT

By

NKA

Date

24/03/09

Page

001

Chkd. Date

Job No.

7020

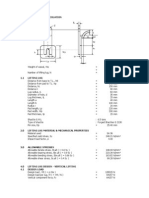

V

H

A A

2

Check for adequacy

Dia. of the padeye hole should be more than shackle pin dia.by 3mm mm

Thk. of main plate should be between 0.6 to 0.8times inside width of shackle, - mm

Minimum Clearance inside the shackle to be 0.5 times sling dia. mm

Padeye Design

Young's Modulus, E N/mm

2

Material Factor, g

M

Yield Strength, f

y

N/mm

2

Design Criteria, as per EC3

Axial Tension, 0.6 f

y N/mm

2

Compression, 0.6 f

y N/mm

2

Bending, 0.66f

y

N/mm

2

Shear, 0.4f

y

N/mm

2

Bearing, F

b

= 0.9f

y

N/mm

2

Combined, 0.66 f

y

N/mm

2

Equivalent stress, 0.75 f

y

N/mm

2

Check for Bearing stress

Factored vertical load, V kN

Bearing Thickness, T

bearing

mm

Bearing Area, A

bearing

= D

pin

X T

bearing

mm

2

Calculated Bearing Stress, f

b

N/mm

2

Unity Check ratio

Check for Shackle-pin shear pull out

Factored vertical load, V kN

Area under shear-pull out, A

s

= (2xr

mp

- D

hole)

x t

mp

mm

2

Calculated Shear Stress, f

v

N/mm

2

Unity Check ratio

Check for tension and combined stress at section A-A

Factored vertical load, V kN

Tensile area , A

t

= (2xr

mp

- D

hole)

x t

mp

mm

2

Calculated Shear Stress, F

t

N/mm

2

Unity Check ratio

Shear stress at section A-A

The horizontal component of vertical load, H kN

Shear area, A

shear

(same as tensile area)

mm

2

Calculated Shear stress at section A-A, t

v

N/mm

2

Unity Check ratio

Ok

= 14.2

Ok

540.0

26.30

0.2

23.2

=

=

0.1 =

=

= 2E+06

18.0

= 612.0

=

= 355

1.15

14.2

8

Ok

Ok

Ok

27.3 36.4

37

= 204

= 232

204

= 185

= 185

=

=

=

=

=

=

=

=

=

540.0

26.30

0.1

= 123

= 278

14.2

=

0.2 Ok =

Ok

14.2

540.0

26.30

=

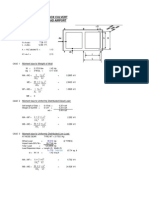

CALCULATION SHEET

Project

VALHALL LQ MODULE

Title

HTCC Room - padeye calculations

Discipline

STRUCT

By

NKA

Date

24/03/09

Page

001

Chkd.

Job No.

7020

Not OK

001

Date

7020

2

Check for bending

At section AA only bending load is due to lateral load, L

T

Bending moment

Max. bending stress occurs at outer fibre of main plate, t

mp

/3

Moment of inertia at section A-A, (2xrmpx(tmp)

3

)/12

L

T

A A

Maximum bending stress, F

b

Allowable Bending stress, 0.66f

y

N/mm

2

Unity Check ratio

Check for Equivalent Stress, s

e

Allowable Equivalent stress, 0.75f

y

Unity Check ratio

Tensile and Combined stress at the attachment of padeye to the structure

Tensile stress check

Factored vertical load, V

Tensile area, A

ten

= Wmp X Tmp

Tensile stress, F

t1

= V/A

ten

Shear stress check

The horizontal component of vertical load, H

Shear area, A

shear

= Wmp X Tmp

Shear stress, t

v1

= H/A

shear

N/mm

2

2320 =

6 =

= 232 N/mm

2

0.1 Ok

= 25.5 N/mm

2

Equivalent Stres, s

e

= ( F

t

2

+

F

b

2

+ 3 t

v

2

)

Distance taken conservatively from center of pin to the

inside length of shackle, (Dpin/2+S)

10

= 119375

=

=

kN

mm

2

kN

mm

2

N/mm

2

= 12

N-mm

0.1 Ok

= 204

= 15.44

mm

77333

kN

= 88.50 mm

= 1.35

mm

4

N/mm

2

13.5 =

2320 =

= 27.0

CALCULATION SHEET

Project

VALHALL LQ MODULE

Title

HTCC Room - padeye calculations

Discipline

STRUCT

By

NKA

Date

24/03/09

Page

001

Chkd. Date

Job No.

7020

V

H

B

2

Check for In-Plane Bending

Inplane bending caused by horizontal component, H acting at the padeye hole

Inplane Bending Moment, M

ipb

Moment of inertia at section A-A, (2xrmp)^3x(tmp))/12

H

mm

C C

Maximum bending stress, F

b

Check for Out-of-Plane Bending

The out-of-plane is due to the lateral component of vertical load and it is to be checked at point E

Lateral load, L

T

Lateral load acting at the distance from center of padeye hole,

Bending moment,

Moments of inertia about minor axis

L

T

Bending stress at point E, F

b

Check for Equivalent Stress, s

e

Allowable Equivalent stress, 0.75f

y

Unity Check ratio

Result

= 3E+06 mm

4

20

Hence Padeye passess all the design calculation checks

mm

= 539550 N-mm

Maximum Bending stress acts at the outer extremity of padeye plate, point B in the figure

116

Ok

= 1.35

53955

=

=

N/mm

2

kN

N-mm

6.98 mm

4

232 N/mm

2

0.1

= 12.0

=

= 40

Equivalent Stres, s

e

= ( F

t

2

+

F

b

2

+ 3 t

v

2

) = 20.7 N/mm

2

= 77333 mm

4

CALCULATION SHEET

Project

VALHALL LQ MODULE

Title

HTCC Room - padeye calculations

Discipline

STRUCT

By

NKA

Date

24/03/09

Page

001

Chkd. Date

Job No.

7020

116

20

E

E

40

100

150X75 PFC

2

Check for Weld

Type 1 : Connecting padeye to the 150X75 PFC facia channel

The welds need to be checked for all three forces acting on the padeye

Steel Tensile strength (Ft) = N/mm^2

EC3 Material Factor weld =

EC3 Correlation Factor weld =

assume throat weld = 6

no

1

2

3

Centroid

X = mm = mm

4

Ip = mm

4

Y = mm = mm

4

r = mm

= = kN kN

MT* = reaction moment

H

V = kN

Force due to vertical load, V/2 = kN

Moment due to horizontal load, MT = kN-mm

Force on weld due to reaction moment = kN

Maximum reaction on weld =

Shear stress on weld due to max reaction force, t

v

=

N/mm

2

Allowable shear stress on weld =

Max weld utilization ratio =

13.5

13.5

28.9

2E+06

Iyy

27

500000 1800

500000

58

Ixx

x Ay

######

104 1872 562432

1824 105792 1E+06 566032

66.1

kN 26

2E+06 ######

120528

4E+06

13.5 H=

6 624 58 97 36192 60528

###### 1800

6 100 600

113 50 67800 30000 8E+06

Iyy

6 100 600

3 50 1800 30000 5400

width depth Area

y

0.15

1.25

0.9

V/2 13.5 V/2 13

100

104

Ok

1431

62.46

Ax Ay

2

Ax

2

460

N/mm

2

13

6E+06

123

13

409

1431

Ixx

CALCULATION SHEET

Project

VALHALL LQ MODULE

Title

HTCC Room - padeye calculations

Discipline

STRUCT

By

NKA

Date

24/03/09

Page

001

Chkd. Date

Job No.

7020

1 2

3

X

X

Y

Y

MT *

r

V

H

LT

2

Check for Weld

MT* = reaction moment

Force due to lateral load, L

T

= kN

Moment due to horizontal load, MT = kN-mm

Max force on weld due to reaction moment = kN

Resultant force on the weld =

Shear stress on weld due to max reaction force, t

v

=

N/mm

2

Hence Resultant shear stress =

EC3 Allowable shear stress on weld =

Max weld utilization ratio =

Type 2 : Connecting padeye to the 254UB146 beam

Weld Length, W

L

=

Force due to Vertical load, V/2 = kN

Shear stress on weld due to vertical force, t

v

=

N/mm

2

1.3

54

4.72

14 kN

13.5

27.41

409

0.17

116

68.88 N/mm

2

116

29.04

N/mm

2

Ok

mm

CALCULATION SHEET

Project

VALHALL LQ MODULE

Title

HTCC Room - padeye calculations

Discipline

STRUCT

By

NKA

Date

24/03/09

Page

001

Chkd. Date

Job No.

7020

E

40

100

150X75 PFC

LT

MT*

H

H

due to LT

Resultant

V

H LT

V

H

LT

Vous aimerez peut-être aussi

- Torsion Validation ShayanDocument10 pagesTorsion Validation ShayanGicuPas encore d'évaluation

- Wind Load Calculation NZS PDFDocument1 pageWind Load Calculation NZS PDFSantoshPas encore d'évaluation

- Pad Eye Connected To Bottom PieceDocument7 pagesPad Eye Connected To Bottom PieceAsaru Deen0% (1)

- DG Consulting EngineersDocument8 pagesDG Consulting EngineersThakshayani SellavelPas encore d'évaluation

- Corbel and NibDocument17 pagesCorbel and NibCatherine Mohanji GeraPas encore d'évaluation

- Aisc Asd Gusset Plate Aisc341 16Document12 pagesAisc Asd Gusset Plate Aisc341 16Zarna Modi100% (1)

- 21.65 Kips/bolt Shear Strength Controls: Section at ADocument3 pages21.65 Kips/bolt Shear Strength Controls: Section at ASuneesh PPas encore d'évaluation

- A23.3-04 CorbelsDocument3 pagesA23.3-04 CorbelsDivyesh MistryPas encore d'évaluation

- BS code-Base-Plate-DesignDocument38 pagesBS code-Base-Plate-Designrajasekhar.cheruvu8635Pas encore d'évaluation

- Dimensional Solutions Mat3DDocument69 pagesDimensional Solutions Mat3DTimothy HancockPas encore d'évaluation

- Staad Analysis For StackDocument39 pagesStaad Analysis For StackABIDEEN BAMNEPas encore d'évaluation

- TQ-0305-R00 - Calculo Estrutura PDFDocument4 pagesTQ-0305-R00 - Calculo Estrutura PDFPeterson MagroPas encore d'évaluation

- Isoloated Footing DesignDocument7 pagesIsoloated Footing Designvijay morePas encore d'évaluation

- HSS Flange Plate Moment Connection - Temporary SteelDocument9 pagesHSS Flange Plate Moment Connection - Temporary SteelrajedmaglintePas encore d'évaluation

- Design Calculations For Primary Beam Connections As Welded Connections R2Document6 pagesDesign Calculations For Primary Beam Connections As Welded Connections R2Rajesh PorePas encore d'évaluation

- Embedded PlateDocument2 pagesEmbedded PlateAlma M. LaraPas encore d'évaluation

- HDT & Atu Unit-Iocl Digboi 4580.09-VP1-30005-CV-3022 4580.09 0Document8 pagesHDT & Atu Unit-Iocl Digboi 4580.09-VP1-30005-CV-3022 4580.09 0Mohammad Shadab AliPas encore d'évaluation

- Sfex Pad Eyes Calculations 35T - 32MMDocument1 pageSfex Pad Eyes Calculations 35T - 32MMJohn Rom CabadonggaPas encore d'évaluation

- Cdo CalcDocument3 pagesCdo CalcJeric FarinPas encore d'évaluation

- Four Bolt Moment Connection DesignDocument12 pagesFour Bolt Moment Connection DesignDarshan Panchal0% (1)

- Padeye - 01Document9 pagesPadeye - 01ramPas encore d'évaluation

- Fdocuments - in Insert Plate Design LugsDocument8 pagesFdocuments - in Insert Plate Design Lugsarchetype designPas encore d'évaluation

- Calculation For Beam Connection AISC 14th Edition 2011: LRFD Method Material and Load PropertiesDocument7 pagesCalculation For Beam Connection AISC 14th Edition 2011: LRFD Method Material and Load PropertiesYunizar Putra MahardikaPas encore d'évaluation

- Steel Column Base Plate Analysis: Blue Cells Are Input DataDocument1 pageSteel Column Base Plate Analysis: Blue Cells Are Input DataHansal Soni0% (1)

- Simple Bracing ConnectionDocument33 pagesSimple Bracing ConnectionRohit SinghPas encore d'évaluation

- Design of Brace Connection PlateDocument6 pagesDesign of Brace Connection PlateJonatas PrandiniPas encore d'évaluation

- Base Plate DesignDocument19 pagesBase Plate DesignLeah Ann ManuelPas encore d'évaluation

- Wind Load Calculation For Multiple Framed Open Structures Design Wind PressureDocument2 pagesWind Load Calculation For Multiple Framed Open Structures Design Wind Pressurechirag01020% (1)

- PadeyeDocument14 pagesPadeyeMarshall Minggat AmpiPas encore d'évaluation

- Wind CalculatorDocument12 pagesWind Calculatorilyasmd7Pas encore d'évaluation

- CHS Base Plate DesignDocument1 pageCHS Base Plate DesignOlusegun S. AjibolaPas encore d'évaluation

- Setting Bolt CalculationDocument1 pageSetting Bolt Calculationrina2393Pas encore d'évaluation

- Petrofac Spreadsheet ValidationDocument33 pagesPetrofac Spreadsheet ValidationALBERTPas encore d'évaluation

- Insert Plate DesignDocument8 pagesInsert Plate DesignPiyushPas encore d'évaluation

- Lashing FormulaDocument1 pageLashing FormulaMuhammad FitrahPas encore d'évaluation

- Design of Laterally Supported Beams As Per Is 800:2007Document12 pagesDesign of Laterally Supported Beams As Per Is 800:2007Divyanshu ShekharPas encore d'évaluation

- Capacity of Bolts in Bearing Connection Based On AISC-ASD 9th EditionDocument1 pageCapacity of Bolts in Bearing Connection Based On AISC-ASD 9th EditionThiha KyawPas encore d'évaluation

- RAM Connection Input With CommentsDocument6 pagesRAM Connection Input With CommentsAhmed Saeed OokaPas encore d'évaluation

- Multi Lift Point CalcsDocument3 pagesMulti Lift Point CalcsLuis LuperdiPas encore d'évaluation

- Load calculation and wind analysis of temporary barricationDocument2 pagesLoad calculation and wind analysis of temporary barricationBrandon HalePas encore d'évaluation

- AISC 360-16 Check of Single Plate Shear ConnectionDocument9 pagesAISC 360-16 Check of Single Plate Shear ConnectionVietanh PhungPas encore d'évaluation

- Welded Moment Connection PDFDocument22 pagesWelded Moment Connection PDFRajasekar MeghanadhPas encore d'évaluation

- Moment Connection - Beam SpliceDocument3 pagesMoment Connection - Beam SpliceSh MNPas encore d'évaluation

- X Y and Partners: Steel Beam DesignDocument35 pagesX Y and Partners: Steel Beam DesignAndré SantosPas encore d'évaluation

- Pin Design AISCDocument3 pagesPin Design AISCFernando SimaPas encore d'évaluation

- #754 v-3103 Spreader & Lifting 60 DegreeDocument12 pages#754 v-3103 Spreader & Lifting 60 DegreeHafizi HZnumismatic100% (1)

- Cranebeam v1 2 AramadaDocument1 pageCranebeam v1 2 AramadaronyPas encore d'évaluation

- Ulitization Ratio:: Check Bolt Bearing CapacityDocument1 pageUlitization Ratio:: Check Bolt Bearing CapacitySkylerYuanPas encore d'évaluation

- 6952-4.T&Angle-Brace Connection (Knee Brace) (M Project) - 0618Document81 pages6952-4.T&Angle-Brace Connection (Knee Brace) (M Project) - 0618Omprakash KhodkePas encore d'évaluation

- AISC 13th Slip Critical Bolt Capacity ASDDocument1 pageAISC 13th Slip Critical Bolt Capacity ASDdantevariasPas encore d'évaluation

- Beam Column Web ConnectionsDocument9 pagesBeam Column Web Connectionsmsiddiq1Pas encore d'évaluation

- Monorail Design Lateral LoadDocument46 pagesMonorail Design Lateral Loadshangz1511Pas encore d'évaluation

- End Plate Moment Connection DesignDocument16 pagesEnd Plate Moment Connection DesignAbdul HameedPas encore d'évaluation

- Calculation Sheet: Padeye Calculations LoadsDocument14 pagesCalculation Sheet: Padeye Calculations Loadsandi_nu0% (1)

- Final Design of Angle Members For 4leged Single Angle TowersDocument65 pagesFinal Design of Angle Members For 4leged Single Angle Towersks_raghuveerPas encore d'évaluation

- Bottom Trunnion (-) 45m - With Shear Plate Extension (0 Deg)Document10 pagesBottom Trunnion (-) 45m - With Shear Plate Extension (0 Deg)nallay1705Pas encore d'évaluation

- Weld Design CalculationsDocument7 pagesWeld Design CalculationsanwarPas encore d'évaluation

- Lifting LugDocument8 pagesLifting LugAzwan ShahPas encore d'évaluation

- Fixed Base Plate-ACI CodeDocument5 pagesFixed Base Plate-ACI CodeMuthukumaran Sivalingam100% (1)

- Weld strength calculation guide for fillet weldsDocument20 pagesWeld strength calculation guide for fillet weldsVikash Yadav100% (1)

- Currency Rate Calculator1Document1 pageCurrency Rate Calculator1shani5573Pas encore d'évaluation

- Year-End Tax Planning Calculator1Document18 pagesYear-End Tax Planning Calculator1shani5573Pas encore d'évaluation

- Conveyor Belt Installtion SplicingDocument71 pagesConveyor Belt Installtion SplicingMatthew Butler75% (4)

- A4-P 1.0 enDocument4 pagesA4-P 1.0 enshani5573Pas encore d'évaluation

- 1UIADocument7 pages1UIAshani5573Pas encore d'évaluation

- MT French Vocabulary Course PDFDocument48 pagesMT French Vocabulary Course PDFsuigeneris11Pas encore d'évaluation

- Pile Load Test: (Source: Pile Design and Construction by M.J. Tomlinson, 1994)Document4 pagesPile Load Test: (Source: Pile Design and Construction by M.J. Tomlinson, 1994)Arvin BhurtunPas encore d'évaluation

- Mustafa Kamal Pasha: Calender For 2011Document4 pagesMustafa Kamal Pasha: Calender For 2011shani5573Pas encore d'évaluation

- Pile LOad Test AADocument1 pagePile LOad Test AAshani5573Pas encore d'évaluation

- Gear BoxDocument4 pagesGear Boxshani5573Pas encore d'évaluation

- Process Systems Process System - Introduction: System Levels in Ore / Minerals ProcessingDocument12 pagesProcess Systems Process System - Introduction: System Levels in Ore / Minerals ProcessingepaccoyPas encore d'évaluation

- On 17Document2 pagesOn 17shani5573Pas encore d'évaluation

- A4-P 1.0 enDocument4 pagesA4-P 1.0 enshani5573Pas encore d'évaluation

- MT French AdvancedDocument64 pagesMT French AdvancedperacPas encore d'évaluation

- Marvelous FishesDocument51 pagesMarvelous FishesMushtaq M.ChinoyPas encore d'évaluation

- Design Calculations For Pressure VesselsDocument73 pagesDesign Calculations For Pressure Vesselsshani5573Pas encore d'évaluation

- Blue Book Cor Us 20041011Document960 pagesBlue Book Cor Us 20041011ccbserialk100% (1)

- MD20.12 Gear Units Fast Track en Es ItDocument22 pagesMD20.12 Gear Units Fast Track en Es ItJosueNorrisPas encore d'évaluation

- Alternative Mixed: Cost /ton $ Cost /ton $ Cost /ton $ Cost /ton $Document3 pagesAlternative Mixed: Cost /ton $ Cost /ton $ Cost /ton $ Cost /ton $shani5573Pas encore d'évaluation

- Knowledge ManagementDocument298 pagesKnowledge Managementshani5573Pas encore d'évaluation

- Arrangement of EquipmentDocument4 pagesArrangement of Equipmentshani5573Pas encore d'évaluation

- SHUTDODocument13 pagesSHUTDOshani5573Pas encore d'évaluation

- Square FootingDocument9 pagesSquare Footingshani5573Pas encore d'évaluation

- Virus Signature DatabaseDocument1 pageVirus Signature Databaseshani5573Pas encore d'évaluation

- Equipment - Elect Kiln 2Document26 pagesEquipment - Elect Kiln 2shani5573Pas encore d'évaluation

- 2nd Line Presentation Dated 12-07-2003Document5 pages2nd Line Presentation Dated 12-07-2003shani5573Pas encore d'évaluation

- Vibration Analysis On BearingsDocument67 pagesVibration Analysis On BearingsronfrendPas encore d'évaluation

- Army Welfare Trust Nizampur Cement Plant: Electrical DepartmentDocument18 pagesArmy Welfare Trust Nizampur Cement Plant: Electrical Departmentshani5573Pas encore d'évaluation

- Lucky Cement Limited Karachi Project: SR No. Date LINE Equipments Defect/Deficiencies/ProblemsDocument4 pagesLucky Cement Limited Karachi Project: SR No. Date LINE Equipments Defect/Deficiencies/Problemsshani5573Pas encore d'évaluation

- The New Environmental Office Building Research EstablishmentDocument2 pagesThe New Environmental Office Building Research EstablishmentAnthony QuinnPas encore d'évaluation

- AIA PA Contract Document Listing and Prices 1Document7 pagesAIA PA Contract Document Listing and Prices 1Pin VongphaiPas encore d'évaluation

- JNTUK II B.Tech II Sem Revised Time TableDocument2 pagesJNTUK II B.Tech II Sem Revised Time TableJayanth KanumuriPas encore d'évaluation

- Opening and Closing Rank IIT CSE GENDocument1 pageOpening and Closing Rank IIT CSE GENramchanderPas encore d'évaluation

- Wide Module Pan Skip Joist Spandrel Torsion Concrete Floor Design Detailing PDFDocument92 pagesWide Module Pan Skip Joist Spandrel Torsion Concrete Floor Design Detailing PDFGonzalo Gomez CastilloPas encore d'évaluation

- ECE 4140 Embedded System Design Course SyllabusDocument2 pagesECE 4140 Embedded System Design Course SyllabusroderickvicentePas encore d'évaluation

- 46.innovative Congestion Control System For Ambulance Using ZigbeeDocument4 pages46.innovative Congestion Control System For Ambulance Using ZigbeebalabooksPas encore d'évaluation

- L T Hydrocarbon Engineering Limited Comparable M A TransactionsDocument16 pagesL T Hydrocarbon Engineering Limited Comparable M A TransactionsHarsimranSinghPas encore d'évaluation

- SAP EWM - Part+Entitled+to+Dispose,+Owner+and+CustodianDocument8 pagesSAP EWM - Part+Entitled+to+Dispose,+Owner+and+CustodianRajesh KumarPas encore d'évaluation

- Melbourne Business School Library Project Management BibliographyDocument8 pagesMelbourne Business School Library Project Management BibliographyAndre Joseph Fournier0% (1)

- Factor of SafetyDocument12 pagesFactor of SafetyRavi TarunPas encore d'évaluation

- College Course Code Data for Andhra PradeshDocument114 pagesCollege Course Code Data for Andhra Pradeshashok815Pas encore d'évaluation

- VIT Campus, Jaipur: Leading Engineering College of Rajasthan/ Best Infrastructure & PlacementDocument85 pagesVIT Campus, Jaipur: Leading Engineering College of Rajasthan/ Best Infrastructure & PlacementOnkar BagariaPas encore d'évaluation

- OEE Primer Understanding OverDocument483 pagesOEE Primer Understanding OverJorge Cuadros Blas100% (1)

- Final TT-End Sem - Spring Sem2022-23 - 13.04.2023Document4 pagesFinal TT-End Sem - Spring Sem2022-23 - 13.04.2023Ritwik NandiPas encore d'évaluation

- STATICS COURSE PLANDocument5 pagesSTATICS COURSE PLANPranksterz StarzPas encore d'évaluation

- Extended DIA - Ne XT - AccessDocument2 pagesExtended DIA - Ne XT - Accesslaiquz zaman33% (3)

- Est200 Design and Engineering, December 2021Document2 pagesEst200 Design and Engineering, December 2021publicuse2716Pas encore d'évaluation

- Two Cell Box CulvertDocument12 pagesTwo Cell Box CulvertAhmad Arslan Rafique71% (7)

- APFC Relays Catalogue 2 1Document12 pagesAPFC Relays Catalogue 2 1Maulik PatelPas encore d'évaluation

- Slab Girder BridgeDocument42 pagesSlab Girder BridgeAslam Saifi100% (2)

- Construction Materials and TestingDocument24 pagesConstruction Materials and TestingJames NeoPas encore d'évaluation

- Master of Professional EngineeringDocument1 pageMaster of Professional EngineeringEduardo Jose Tovar CamachoPas encore d'évaluation

- Site PlanDocument1 pageSite PlanARJUN PRASHANTHPas encore d'évaluation

- Direct-Drive Bi-Rotary Milling Head Variable Load PDFDocument7 pagesDirect-Drive Bi-Rotary Milling Head Variable Load PDFLeonardo CremoniPas encore d'évaluation

- 2-Ideal Pharmaceutical FactoryDocument22 pages2-Ideal Pharmaceutical FactorymariumPas encore d'évaluation

- ENGINEERING MANAGEMENT Part IDocument19 pagesENGINEERING MANAGEMENT Part Irtg.chrisPas encore d'évaluation

- IIT Madras Bolted Connections GuideDocument30 pagesIIT Madras Bolted Connections GuidepjuvvadiPas encore d'évaluation

- Teaching of ASME IX Code To Students of GTAW, GMAW/FCAW, SMAW and SAW Welding ProcessesDocument5 pagesTeaching of ASME IX Code To Students of GTAW, GMAW/FCAW, SMAW and SAW Welding ProcessesConnie RodriguezPas encore d'évaluation

- New EM Graduate ProgramDocument18 pagesNew EM Graduate ProgramabofahadPas encore d'évaluation