Académique Documents

Professionnel Documents

Culture Documents

Paint Booth Design Review Checklist

Transféré par

ARC Electrical Safety ConsultingCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Paint Booth Design Review Checklist

Transféré par

ARC Electrical Safety ConsultingDroits d'auteur :

Formats disponibles

Page 1 of 6

Paint Booth

Design Review Checklist

ACGIH Industrial Ventilation Manual, 27

th

Edition

UFC 3-410-04N, Industrial Ventilation, 25 October 2004

ANSI Z9.3-2007, Spray Finishing Operations Safety Code for Design,

Construction, and Ventilation

29 CFR 1926.57, Ventilation

29 CFR 1910.94, Ventilation

29 CFR 1910.107, Spray finishing using flammable and combustible materials

NFPA 33-2011, Spray Application Using Flammable or Combustible Materials

National Guard Design Guides, 2009

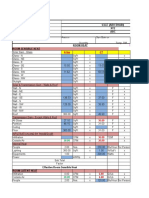

Means of Egress

1. Emergency Exits provided?

2. Walkway of 6.5 feet high and 3 feet wide provides access to exit(s)

(1910.94, ANSI Z9.3)?

3. Personnel doors open outward from the booth (1910.94)?

4. In booths where the open front is the only exit, is the exit not less than 3 feet wide

(1910.94)?

5. If there are multiple exits is each exit at least 2 feet wide (1910.94)?

6. Is the maximum distance to an exit less than or equal to 25 feet (1910.94)?

Fire Protection

1. Industrial occupancy in which the painting booth is located is separated from other

occupancies (2 hours from business; 3 hours from educational; 2 hours from

assembly)? Reduce by 1 hour if sprinkled. Spray areas separated from other areas of

the building by 1 hour fire barrier? Separated from other operations by 3 feet or a 1

hour fire barrier? (NFPA 33; 1910.94)

2. Is the area sprinkled? (required by NFPA 33)

a. Exhaust ductwork sprinkled?

b. Exhaust plenum sprinkled?

c. Particulate filters sprinkled, if applicable?

d. Recirculation air supply units, if applicable?

e. Mixing room sprinkled, if applicable?

3. Are fire extinguishers provided and located for instant use in emergency

(NFPA 33, 1910.107)?

Page 2 of 6

4. Fire alarm provided (NFPA 101)?

5. Will sprinklers be protected against overspray residue (NFPA 33)?

6. Ducts do not penetrate fire barriers (NFPA 33)? Penetrations through combustible

walls are protected with an appropriate fire resistant assembly (1910.94)?

Construction

1. Noncombustible/Limited combustible construction (NFPA 33)?

2. No aluminum used for structural support (NFPA 33)?

3. Interior surfaces are designed to prevent accumulation of residue (dead air pockets)

(NFPA 33)?

4. Acoustical treatment provided if noise levels exceed 85 dB for room where booth is

located? Must be noncombustible if provided. (NCB<60 for NGB)

5. Noncombustible fire doors and shutters (1910.94)? Noncombustible supports for air

filters, baffles, etc. (NFPA 33, 1910.107)?

6. Observation window of safety glass (heat-treated) (NFPA 33)?

7. No smoking signs for paint area, paint storage, mixing rooms (1910.107)?

8. Is a clear space of 3 feet maintained on all sides and above the booth (NFPA 33,

1910.107)? If no, is the booth located adjacent to a noncombustible exterior wall or roof

or an interior partition with a 1 hour fire rating?

HVAC

1. Space heating appliances located away from spray area (1910.107)?

2. Is makeup air provided if temperature is less than 55

o

F for an appreciable period of

time during booth operation (1910.94)? Is make-up air is heated to at least 65

o

F

(1910.94)? No means of heating make-up air inside booth (1910.94)?

3. Air velocity at doors, dampers or louvers into the booth is 200 fpm or less (1910.94)?

All are noncombustible?

4. Spray area is provided mechanical ventilation (NFPA 33)?

5. Exhaust system runs continuously while operations are in progress and as long as

necessary afterwards (1910.107)?

6. Air exhausted from spray operations is not recirculated and is directed outdoors to

the exhaust fan and away from intake openings (NFPA 33, 1910.107)?

Page 3 of 6

7. Ductwork does not connect to any other process (1910.94)?

8. Make up air system provided in same quantity as exhaust air (UFC)? Plenum

provided to distribute air evenly across the booth (UFC)?

9. Air intake openings are located to minimize dead air pockets and are adequate for

the efficient operation of exhaust fans (1910.107)? Air intake openings are fully open

during spray operations (1910.94)? Velocity through air intake openings does not

exceed 200 fpm unless exhaust system can accommodate higher velocities (1910.94)?

10. Overspray collection filters are Class 1 or 2 iaw ANSI/UL 900 (NFPA 33)? Filters

maintain average velocity greater than or equal to 100 fpm over open face of booth

(1910.107)? Filters sized for 100-500 fpm (IV Manual)? Filters have interlocks with

ventilation system or are on effective inspection program

(NFPA 33)?

11. Booths equipped with overspray collection filters have visible gauges, audible

alarms or inspection program to ensure adequate airflow velocity (1910.107)? Filters

are accessible for cleaning/replacement?

12. Differential pressure gauges across replacement air filters (1910.107)?

13. Multiple booths, if provided, each have a dedicated exhaust system

(NFPA 33, 1910.107)?

14. Exhaust ducts are equipped with access panels every 9-12 feet for ducts up to 12

inches diameter, greater distances for larger ducts (NFPA 33, 1910.94)?

15. Exhaust ducts constructed of steel (no aluminum) (NFPA 33)? Exhaust ducts have

at least 18 inches clearance from combustible construction (1910.107)? Exhaust ducts

protected from damage (1910.107)? Exhaust ducts correctly supported (SMACNA)

(NFPA 33)?

16. Exhaust does not discharge within 25 feet of combustible construction or

unprotected opening and within 6 feet of an exterior wall or roof (NFPA 33, 1910.107)?

17. Exhaust fan is non-ferrous with explosion proof motor and electrical fixtures (NFPA

33, 1910.107)? Is the fan belt sealed and not inside the spray area? Exhaust fan static

pressure accommodates dirty filter conditions (1910.94)?

18. Static pressure sensor at exhaust fan inlet (UFC)?

19. Exhaust remains functional during fire alarm condition or fire protection system is

designed to shut off ventilation (NFPA 33)?

20. Equipment used to monitor exhaust streams, if required, are listed for this purpose,

trigger and alarm, shut down spray operations if vapor concentrations in exhaust stream

exceed 25% LFL (NFPA 33)?

Page 4 of 6

21. Ductwork has a transport velocity of 2000 fpm (IV Manual)?

22. Booth is downdraft type (UFC, 1910.94)?

a. Exhaust plenums no wider than 8 feet?

b. Exhaust plenum velocity does not exceed 1000 fpm?

c. Supply air provided by a plenum which evenly distributes air across the cross-

section of the booth above the object being sprayed?

d. Supply air plenum velocity does not exceed 500 fpm?

e. Supply air plenum has openings designed for 1000 fpm?

f. Exhaust air removed via plenum which runs evenly across the cross-section of

the booth?

23. Booth is crossdraft type (UFC, 1910.94)?

a. Exhaust plenums no wider than 8 feet?

b. Exhaust plenum velocity does not exceed 1000 fpm?

c. Supply air provided by a plenum which evenly distributes air across the cross-

section of the booth upstream of object being sprayed?

d. Supply air plenum velocity does not exceed 500 fpm?

e. Supply air plenum has openings designed for 2000 fpm

f. Exhaust air removed via plenum which runs evenly across the cross-section of

the booth?

24. Air volumes are designed to meet the following (IV Manual)?

a. Q = 200 cfm per sq. ft. of booth open cross section for small booth with face

area up to 4 square feet

b. Q = 150 cfm per sq. ft. of booth open cross section for small booth with face

area over 4 square feet

c. Q = 100 cfm per square foot booth c-s area for large walk-in booths

d. Q = 75 cfm per square foot booth c-s area for large deep walk-in booths

e. Q = 50 cfm per square foot booth c-s area for booths where W x H > 150 sq. ft.

f. Q = 60 cfm per square foot booth c-s area for HVLP or airless electrostatic

spraying in large walk-in or drive-in booths

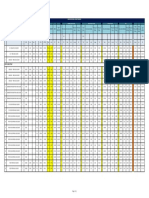

25. Air velocities meet the requirements below (1910.94)?

Operating Conditions

for Objects inside

Booth

Crossdrafts (feet per

minute, fpm)

Airflow Velocities, fpm

Design Range

Electrostatic and

Automatic Airless

operation contained in

booth without operator

Negligible 50, large booth 50-75

Page 5 of 6

Air-operated guns,

manual or automatic

Up to 50 100 small

booth, 100

large booth

75-125

Air-operated guns,

manual or automatic

Up to 100 150 small

booth, 150

large booth

125-175

200 small

booth

150-250

Plumbing

1. Compressed air provided for painting tools? Breathing air provided for respirators

(UFC)?

2. Shut-off valve on hose or flexible connections from containers or piping (1910.107)?

3. Pumping system, if used for delivery, is sufficient to accommodate system pressures

(1910.107)?

4. Piping is steel or heat/damage resistant (1910.107)?

5. Piping systems are bonded/grounded (1910.107, NFPA 33)?

6. Spray nozzles from positive displacement pumps have relief valve in the pump

discharge line or a device to stop it if safe operating pressure is exceeded (1910.107)?

Electrical

1. Explosion-proof lighting/wiring or lighting/wiring listed for use in spray area

(1910.107, NFPA 33)?

2. Light fixture panels of safety glass (heat treated) and listed for use in spray area

(NFPA 33)?

3. No open flame or spark producing equipment within 20 feet of spray area

(1910.107)? No electrical equipment in spraying area unless approved for that location

(1910.107)?

4. Electrically conductive parts, ducts or equipment are electrically bonded and

grounded to prevent sparks and static electricity (NFPA 33)?

5. Supply and exhaust systems are electrically interlocked (NFPA 33)?

6. Spray guns and electrical equipment are interlocked with ventilation system (NFPA

33)?

Page 6 of 6

7. Drying apparatus interlocked with spraying apparatus so spraying cannot occur

when drying is in process (NFPA 33)? Drying system interlocked to shut off in the event

of ventilation system failure (NFPA 33)?

Vous aimerez peut-être aussi

- Saudi Aramco LOTO GuideDocument8 pagesSaudi Aramco LOTO GuideMusharaf Shah100% (3)

- Saudi Aramco LOTO GuideDocument8 pagesSaudi Aramco LOTO GuideMusharaf Shah100% (3)

- Ventilation Design Sample For Locker Rooms and HACCPDocument10 pagesVentilation Design Sample For Locker Rooms and HACCPerickquinto100% (1)

- Ashrea Duct WorkDocument55 pagesAshrea Duct WorkHaja MydeenPas encore d'évaluation

- Heatloss in Industrial Plants Part 1 PDFDocument10 pagesHeatloss in Industrial Plants Part 1 PDFMuhammad HarisPas encore d'évaluation

- PEERLEES Fire Pump PDFDocument175 pagesPEERLEES Fire Pump PDFN. AndradePas encore d'évaluation

- Sprinkler System FormulasDocument2 pagesSprinkler System Formulasturbosri_mech100% (1)

- Domestic Water Pipe Sizing Ib P Pc2014 009Document20 pagesDomestic Water Pipe Sizing Ib P Pc2014 00963ragtopPas encore d'évaluation

- Battery Room Ventilation GuidelinesDocument5 pagesBattery Room Ventilation GuidelinesARC Electrical Safety ConsultingPas encore d'évaluation

- Fire Protection For Structural Steel in BuildingsDocument91 pagesFire Protection For Structural Steel in BuildingsHamada Shoukry MohammedPas encore d'évaluation

- Eight Dimensions of Product Quality ManagementDocument6 pagesEight Dimensions of Product Quality Managementusamaca1Pas encore d'évaluation

- Fire Flow Calculator Worksheet 2011Document7 pagesFire Flow Calculator Worksheet 2011walitedisonPas encore d'évaluation

- CPD/VRF PresentationDocument23 pagesCPD/VRF PresentationthibinPas encore d'évaluation

- Fresh Air Louver Selection - 11-10-2015Document1 pageFresh Air Louver Selection - 11-10-2015organicspolybondPas encore d'évaluation

- Industrial VentilationDocument8 pagesIndustrial VentilationECRD100% (1)

- Pharmaceutical Facility DesignDocument27 pagesPharmaceutical Facility Designmdalt9180Pas encore d'évaluation

- WA Booster System Work Sheet v2Document45 pagesWA Booster System Work Sheet v2Richard RajkumarPas encore d'évaluation

- Electrical Thumb Rules (Part 7)Document5 pagesElectrical Thumb Rules (Part 7)AriesFranandaPanjaitanPas encore d'évaluation

- Air Leakage Through Automatic DoorsDocument5 pagesAir Leakage Through Automatic DoorsstranfirPas encore d'évaluation

- AC FAN CalculationDocument6 pagesAC FAN CalculationSubramanyaPas encore d'évaluation

- Fire Protection-Sprinkler Sys (With Min Press 7psi) & Water Supply Sys (042114)Document2 pagesFire Protection-Sprinkler Sys (With Min Press 7psi) & Water Supply Sys (042114)Edwin TorilloPas encore d'évaluation

- Enclosure Cooling DesignDocument9 pagesEnclosure Cooling Designrajpre1213Pas encore d'évaluation

- FF BoqDocument14 pagesFF BoqSreenivasa Rahavan VPas encore d'évaluation

- Cooling Load EstimationDocument3 pagesCooling Load EstimationDhiraj DhimanPas encore d'évaluation

- Psych Chart TraneDocument1 pagePsych Chart Tranebhargavacharya0% (1)

- Job: Location: Space: Unit in FT.: SizeDocument23 pagesJob: Location: Space: Unit in FT.: SizechepePas encore d'évaluation

- Example Kitchen Ventilation CalculationDocument4 pagesExample Kitchen Ventilation Calculationwillis0000Pas encore d'évaluation

- Cable TakeoffDocument14 pagesCable TakeoffRudivic LumainPas encore d'évaluation

- Liquid Press Drop in PipeDocument4 pagesLiquid Press Drop in PipePanner2009Pas encore d'évaluation

- Ashrae D62Document27 pagesAshrae D62Amro Metwally El HendawyPas encore d'évaluation

- Fan ESP CalculationDocument6 pagesFan ESP CalculationAyesha SiddiquaPas encore d'évaluation

- Motor Engineering FormulasDocument1 pageMotor Engineering FormulasDede SadiPas encore d'évaluation

- Me 162Document48 pagesMe 162Bill Cipher100% (1)

- Dry Type Fire HydrantDocument6 pagesDry Type Fire HydrantAdil MominPas encore d'évaluation

- Ariston Electric Water HeatersDocument2 pagesAriston Electric Water HeatersSuresh SubbarayanPas encore d'évaluation

- Job: Location: Space: Unit in Meter.: SizeDocument24 pagesJob: Location: Space: Unit in Meter.: Sizeamsc bPas encore d'évaluation

- All Cooling Load RulesDocument31 pagesAll Cooling Load RulesEngFaisal AlraiPas encore d'évaluation

- HVAC Cooling Load Estimate SheetDocument1 pageHVAC Cooling Load Estimate SheetCaps LockPas encore d'évaluation

- AC70 - 7460 - 1K - FAA Obstruction Marking and LightingDocument62 pagesAC70 - 7460 - 1K - FAA Obstruction Marking and LightingPramana SidhartaPas encore d'évaluation

- Hydraulic Calculations For Small RoomsDocument4 pagesHydraulic Calculations For Small RoomsAnonymous qrSsYuxyoYPas encore d'évaluation

- Is 13039 External Fire HydrantDocument10 pagesIs 13039 External Fire HydrantNanu PatelPas encore d'évaluation

- Cause&Effect MatrixDocument7 pagesCause&Effect MatrixkotharideepPas encore d'évaluation

- Fire Hydrant CalculatorDocument4 pagesFire Hydrant CalculatorTri SubaktiPas encore d'évaluation

- Smoke Ventilation CalculationDocument4 pagesSmoke Ventilation CalculationJunaid MateenPas encore d'évaluation

- Duct SizerDocument4 pagesDuct Sizeralex yatnoPas encore d'évaluation

- 25hp 4p 284tpa Wpi Bf37 AuDocument15 pages25hp 4p 284tpa Wpi Bf37 Aurhusseinpos4765Pas encore d'évaluation

- Scope of Work For Tn03 ATS Installation - Rev2 - Myrev5 - Power Flower AnalysisDocument5 pagesScope of Work For Tn03 ATS Installation - Rev2 - Myrev5 - Power Flower AnalysisKheldz PicachePas encore d'évaluation

- TIGERFLOW Booster Sizing Worksheet: I. Pressure RequiredDocument3 pagesTIGERFLOW Booster Sizing Worksheet: I. Pressure RequiredAnonymous BJ9omOPas encore d'évaluation

- Dust Collectors MiningDocument5 pagesDust Collectors MiningNicole Schwerter SchillingPas encore d'évaluation

- NFPA 13 Sprinkler System Design Density Curves - Where Did They Come From - Sprinklers Content From Fire Protection Engineering PDFDocument7 pagesNFPA 13 Sprinkler System Design Density Curves - Where Did They Come From - Sprinklers Content From Fire Protection Engineering PDFBùi Trần Trung HậuPas encore d'évaluation

- Ventilation CalculationDocument5 pagesVentilation CalculationHaider Tyebally TyeballyPas encore d'évaluation

- Doha ASHRAE 2017 FundamentalsDocument2 pagesDoha ASHRAE 2017 FundamentalsAhmed LabibPas encore d'évaluation

- Elite SoftwareDocument22 pagesElite SoftwareERIC SALGADOPas encore d'évaluation

- How To Design Kitchen HoodDocument2 pagesHow To Design Kitchen HoodSandeep KumawatPas encore d'évaluation

- Manual HC For in Rack Sprinklers Reference NFPA 13 - 2013, Chapter 23 (PLANS AND CALCULATIONS) (Mehboob Shaikh)Document16 pagesManual HC For in Rack Sprinklers Reference NFPA 13 - 2013, Chapter 23 (PLANS AND CALCULATIONS) (Mehboob Shaikh)Jerry TomPas encore d'évaluation

- E20 SheetDocument12 pagesE20 SheetTaha AmjadPas encore d'évaluation

- Paint Booth Design Review Checklist: Means of EgressDocument6 pagesPaint Booth Design Review Checklist: Means of EgressFranciscoVicentePas encore d'évaluation

- ACGIH - Abrasive Blasting Operations Design Review Checklist Feb 2012Document3 pagesACGIH - Abrasive Blasting Operations Design Review Checklist Feb 2012newnse2008Pas encore d'évaluation

- Bukel Fire Aircraft - HangarsDocument7 pagesBukel Fire Aircraft - HangarsmukeshsinghtomarPas encore d'évaluation

- MBBLDocument4 pagesMBBLSubadharshiniPas encore d'évaluation

- Chemguard Aircraft HangarsDocument7 pagesChemguard Aircraft HangarsRaymond ZuYang HngPas encore d'évaluation

- Assembly OccupanciesDocument4 pagesAssembly OccupanciesdgvvfxcxwpPas encore d'évaluation

- HepvO PIC Aug2003Condensate DrainDocument2 pagesHepvO PIC Aug2003Condensate DrainAhmed TahaPas encore d'évaluation

- CFD - ACUD CodeDocument6 pagesCFD - ACUD CodeDharmeswar SahPas encore d'évaluation

- RA 6541 National Building Code of The PH StandPipeDocument5 pagesRA 6541 National Building Code of The PH StandPipejungzki jungzkiPas encore d'évaluation

- Devara Pathigam 2Document86 pagesDevara Pathigam 2comdcePas encore d'évaluation

- Guide To The Installation of PV Systems - 2nd EditionDocument32 pagesGuide To The Installation of PV Systems - 2nd Editionnikanako100% (5)

- Devara Pathigam 2Document86 pagesDevara Pathigam 2comdcePas encore d'évaluation

- Hac PresentationDocument14 pagesHac PresentationARC Electrical Safety ConsultingPas encore d'évaluation

- HAC GuideDocument16 pagesHAC GuideARC Electrical Safety ConsultingPas encore d'évaluation

- Cellphones Hazardous LocationsDocument13 pagesCellphones Hazardous LocationssandystaysPas encore d'évaluation

- Designs of Earthing and Short-Circuiting DevicesDocument4 pagesDesigns of Earthing and Short-Circuiting DevicesARC Electrical Safety ConsultingPas encore d'évaluation

- Practical Solution Guide To Arc Flash HazardsDocument146 pagesPractical Solution Guide To Arc Flash Hazardsom987Pas encore d'évaluation

- Advanced Electrical Safety Audit Synopsis PDFDocument2 pagesAdvanced Electrical Safety Audit Synopsis PDFARC Electrical Safety Consulting100% (3)

- ESA Arc Flash FAQ PDFDocument0 pageESA Arc Flash FAQ PDFjopaypagasPas encore d'évaluation

- Arc Flash Clothing in Indian ScenarioDocument2 pagesArc Flash Clothing in Indian ScenarioARC Electrical Safety ConsultingPas encore d'évaluation

- Understanding Earth Leakage RelayDocument3 pagesUnderstanding Earth Leakage RelayARC Electrical Safety ConsultingPas encore d'évaluation

- Down To EarthDocument41 pagesDown To EarthARC Electrical Safety ConsultingPas encore d'évaluation

- Electrical Safety AuditDocument4 pagesElectrical Safety AuditE.ANANDANPas encore d'évaluation

- CMMI Maturity Profile 30 June 2018Document25 pagesCMMI Maturity Profile 30 June 2018TomTomPas encore d'évaluation

- Ekahau Wireless Site Survey ToolDocument2 pagesEkahau Wireless Site Survey ToolHugh Haskell-ThomasPas encore d'évaluation

- Tny 264Document20 pagesTny 264Juri BehariPas encore d'évaluation

- DL205 User Manual Vol1 PDFDocument415 pagesDL205 User Manual Vol1 PDFLoloy NorybPas encore d'évaluation

- Encoder Conversor Pu210 eDocument9 pagesEncoder Conversor Pu210 eChristian JuniorPas encore d'évaluation

- Denon PMA 500AE Owners ManualDocument12 pagesDenon PMA 500AE Owners ManualJora MormontPas encore d'évaluation

- Personnel Administration PPT Chap 1Document16 pagesPersonnel Administration PPT Chap 1Zanz Lee Greywolf100% (2)

- Jeep Chrysler Corporation Marketing PlanDocument5 pagesJeep Chrysler Corporation Marketing PlanJaswani R.L Rana100% (1)

- Kick StartDocument38 pagesKick StartUday ChoudharyPas encore d'évaluation

- Field Work No 8 SurveyingDocument18 pagesField Work No 8 SurveyingRalph GalvezPas encore d'évaluation

- AIRTEC-Katalog ProizvodaDocument27 pagesAIRTEC-Katalog ProizvodaIvana DincicPas encore d'évaluation

- Telecom Service Capability MethodologyDocument27 pagesTelecom Service Capability MethodologyLuis OlavarrietaPas encore d'évaluation

- Cadilac Gage V-300Document11 pagesCadilac Gage V-300Bill SmithPas encore d'évaluation

- En 10253-3 2008 PDFDocument50 pagesEn 10253-3 2008 PDFAlexandru AsmarandeiPas encore d'évaluation

- Data BMT332Document25 pagesData BMT332mauricio_138Pas encore d'évaluation

- Mtag Howto Singlesignonforapexapplicationsusingkerberos 150330020541 Conversion Gate01Document29 pagesMtag Howto Singlesignonforapexapplicationsusingkerberos 150330020541 Conversion Gate01Quique FLow-ersPas encore d'évaluation

- v0650028000 Full Accessories Catalogue 2017 2018 PDFDocument84 pagesv0650028000 Full Accessories Catalogue 2017 2018 PDFDragos BmrPas encore d'évaluation

- Rope TensionerDocument4 pagesRope TensionerblizanacPas encore d'évaluation

- Basf Bed Bug GuideDocument8 pagesBasf Bed Bug Guideapi-214441294Pas encore d'évaluation

- Nemo File Format 2 03Document373 pagesNemo File Format 2 03Umar PervaizPas encore d'évaluation

- GET6600G Section 10 Guide Form Spec Rev 2Document14 pagesGET6600G Section 10 Guide Form Spec Rev 2NestorNateraPas encore d'évaluation

- VNX 5100 - Initialize An Array With No Network AccessDocument6 pagesVNX 5100 - Initialize An Array With No Network AccessRaghunandan BhogaiahPas encore d'évaluation

- Bim by R.WDocument23 pagesBim by R.WRobel WendwesenPas encore d'évaluation

- Adeniran Obafemi O. Department of Electrical/ Electronics Engineering University of IbadanDocument39 pagesAdeniran Obafemi O. Department of Electrical/ Electronics Engineering University of IbadanmartinsPas encore d'évaluation

- Functional Safety Assessment of Valve Assemblies Part 1Document6 pagesFunctional Safety Assessment of Valve Assemblies Part 1Serge RINAUDOPas encore d'évaluation

- An Express Guide SNMP For Secure Rremote Resource MonitoringDocument5 pagesAn Express Guide SNMP For Secure Rremote Resource MonitoringAbhishekKrPas encore d'évaluation

- Photo Signature GuidelinesDocument2 pagesPhoto Signature GuidelinesNadeemPas encore d'évaluation

- w00067 20141226042219 268Document28 pagesw00067 20141226042219 268Beer TalesPas encore d'évaluation