Académique Documents

Professionnel Documents

Culture Documents

Design of Rope Drum and Chain Hoists

Transféré par

suresh_501Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Design of Rope Drum and Chain Hoists

Transféré par

suresh_501Droits d'auteur :

Formats disponibles

Disclosure to Promote the Right To Information

Whereas the Parliament of India has set out to provide a practical regime of right to

information for citizens to secure access to information under the control of public authorities,

in order to promote transparency and accountability in the working of every public authority,

and whereas the attached publication of the Bureau of Indian Standards is of particular interest

to the public, particularly disadvantaged communities and those engaged in the pursuit of

education and knowledge, the attached public safety standard is made available to promote the

timely dissemination of this information in an accurate manner to the public.

!"#$%&# '(%)

!"# $ %& #' (")* &" +#,-.

Satyanarayan Gangaram Pitroda

Invent a New India Using Knowledge

/0)"1 &2 324 #' 5 *)6

Jawaharlal Nehru

Step Out From the Old to the New

7"#1 &" 8+9&"), 7:1 &" 8+9&")

Mazdoor Kisan Shakti Sangathan

The Right to Information, The Right to Live

!"# %& ;<" =7"#" > 72 &(: ?0)"@" #AB 7" <&*" A*

Bhart+hariN,ti-atakam

Knowledge is such a treasure which cannot be stolen

IS 6938 (2005): Design of rope drum and chain hoists for

hydraulic gates - Code of practice [WRD 12: Hydraulic

Gates and Valves]

IS 6938:2005

~&h-?+Fl-

af aWaT

DESIGN OF ROPE DRUM AND CHAIN HOISTS FOR

HYDRAULIC GATES

CODE OF PRACTICE

(Second Revision )

ICS 93.160

.

Q BIS 2005

BUREAU OF INDIAN STANDARDS

MANAK BHAVAN, 9 BAHADUR SHAH ZAFAR MARG

NEW DELHI 110002

November 2005

Price Group 7

Hydraulic Gates and Valves Sectional Committee, WRD 12

FOREWORD

This Indian Standard ( Second Revision) was adopted by the Bureau of Indian Standards, afier the draft finalized

by the Hydraulic Gates and Valves Sectional Committee had been approved by the Water Resources Division

Council.

Controlled release of water from reservoirs is made by the use of spillway gates provided on crests, control gates

in conduits or in the body of the dam and tunnels. For the operation of these gates, various types of mechanisms

are provided. The rope drum and chain hoists are used for gates which close by their own weight and where no

positive thrust is required to close them.

in the formulation of this standard, due weightage has been given to international co-ordination among the

standards and practices prevailing in different countries in addition to relating it to the practices in the field

in this country.

This standard was first published in 1973 and subsequently revised in 1989. In this revision the requirements

of motors, hoist limit switch, control panel and figures have been modified in the light of experience gained over

the years,

The composition of the Committee responsible for the formulation ofthis standard is given in Annex B.

For the purpose of deciding whether a particular requirement of this standard is complied with, the final

value, observed or calculated expressing the result of a test or analysis, shall be rounded off in accordance with

IS 2:1960 Rules for rounding off numerical values ( revised ). The number of significant places retarned in the

rounded off value should be the same as that of the specified value in this standard.

. .

1S 6938:2005

Indian Standard

DESIGN OF ROPE DRUM AND CHAIN HOISTS FOR

HYDRAULIC GATES CODE OF PRACTICE

(Second Revision )

1 SCOPE

This standard lays down guiding principles for design

of rope drum and chain hoists used for the operation

of hydraulic gates.

2 REFERENCES

The standards listed in Annex.A contain provisions,

which through reference in this text, constitute

provisions of this standard. At the time of publication,

the editions indicated were valid. All standards are

subject -to revision and parties to agreements-based

on this standard are encouraged to in-vestigate

the possibility of applying the most recent editions

of the standards indicated in Annex A.

3 GENERAL

3.1 Hoist Capacity

3.1.1 The hoist capacity shall be determined by taking

into consideration the following forces which might

be required to overcome:

a)

b)

c)

d)

e)

o

Weight of the gate along with all its

components including the weight of wire rope

and its attachments and ballast, if any;

All frictional forces comprising of

1) Wheel friction,

2) Guide friction, and

3) Seal friction including friction due to

initial interference;

Any hydrodynamic load, like downpull/uplift

force, etc;

Silt and ice load wherever encountered;

Weight of lifting beam, if used; and

Any other consideration specific to a

particular site.

3.1.2 The worst combination of the above forces,

during either lowering cycle or raising cycle, shall be

considered.

3.1.3 The hoist capacity thus arrived at shall be

increased by 20 percent to CMWror the reserve

hoist capacity unless otherwise specified by the

purchaser.

3.1.4 The gate shall be designed for closing under

its self weight ( without any positive thrust to the

same ) and the downward forces closing the. gate

while lowering shail be at least 20 percent higher

than the frictional and other forces opposing the

downward motion. The necessary closing/seating

load shall be calculated considering the net cross-

sectional area of the bottom seal and maximum water

pressure acting on it such that the lowering force is

more than the seating load. However, the values of

closingkeating load shall be greater than those given

below:

Type of Gate Minimum Seating Load

Low head gates 2.5 kN/m length of gate

Medium head gates 5.0 kN/m length of gate

High head gates 10.0 kN/m length of gate

3.1.5 The usual operating speed for such hoist shall

be 300 to 700 mm/min. However, higher values may

be adopted depending upon the requirements.

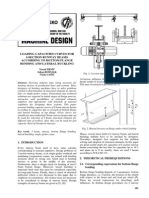

Typical hoisting arrangements for operation of various

gates are shown in Fig. 1 and Fig. 2.

4 DESIGN OF MECHANICAL PARTS

4.1 General Requirements

4.1.1 The various components of hoist mechanism

shall be so proportioned as to take the worst load

coming on individual component.

4.1.2 The stress in various components of hoist

shall be checked for maximum power transmission

in these components, taking into account the

permissible stresses as given in reIevant clauses.

Various structural and mechanical components of

hoist shall also be checked for breakdown torque of

the motor.

4.1.3 All the hoisting machinery parts shall be checked

for static as well as dynamic loads.

4.1.4 The combined stress in each component shall

be found by the following formula:

CTc= J (71~+c+71f32

+3$

where

cc =

Cr,C* =

r

.

combined stress, in N/mm2;

tensile/compressive stresses, in N/mz;

and

torsional shear stress, in N/mmz.

1

IS 6938:2005

2

i?

a

%

o

Ix

I/

II

LEfe=+-------*

L

h----l-i-t

!1

&

I

.,

(

I

I

I

,-

1 11

1,

I

II

I

II

I

t,

I I

I

v

v

h

----- ----

u

5

c!)

?

2

B

+

IS 6938:2005

.

(J FLANGE C UPLtNG

W

GEAR BOX BASE

I

FRAME

<f

PROCK FOR

MANNUA DRIVE

1

~ )YJIRM

-~ /REDuCER

I

ti

END REDUCTION UNIT

k

ROPE DRUM

r

z . - .

I

OIST SUPPORT

ELEVATION

MACHINERY ASSEMBLY

Ru~ cOvER~RUM GEAR

\C/L OF ROPE

.

FLOATING

HAND DRIVE

% SPROCKET

SH

SECTION A-A

SECTK)N B-B

IB Machine Asserrtbly

3

SPROCKET FOR

r

MANUAL DRIVE

FLANGE COUPLING r

END REDUCTION UNIT

/41kb----

---- - ----

Ill \\

1

,TOP SHEAVE

R=4Fl

(!llHml-M

\

4 GEAR BOX BASE

FRAME

I

I

1 I . ~l!.J, 11~~

I

,

ii

l!~

!.

1

4 j

i

~HOIST BRIDGE+

HOIST SUhY)RT

I !i:

g

n

STRU(TURE

------ ------ ------ ------ ------ .-.

.

II

. .

I

i

SHEAVE

i~

I

i

~i

I

;;

i

!!

i

!!

a

i f

.

GATE SHEAVE w

i! I

ELEVATION

f i

!!

i

MACHINERY ASSEMBLY i

t.

G

w

.

GATE SHEAVE

1C Gate Attachment with Balancing Sheave Assembly

FI G. 1 TYPI CALHOI STI NGARRANGEMENTS OFGATES

I

S

6

9

3

8

:

2

0

0

5

3 n

m

v

L

5

IS 6938:2005

4.2 Wire Ropes

4.2.1 General

The wire rope shall bemade from improved plough

steel, galvanized ( if required ), Langs lay and fibre

core or normally of 6 x 36 or 6 x 37 construction and

shall conform to 1S2266.

4.2.1.1 For calculating the rope tension pulley

efficiency should be taken into account.

4.2.1.2 In case of multiple falls, the wire rope shall

be provided with a device that takes care of unequal

stretch of rape.

4.2.2 Breaking Strength

The breaking strength of wire rope, if not given by

the manufacturer of rope, shall be calculated on the

basis of IS 2266.

4.2.3 Factor of Safety

The minimum factor of safety based on minimum

breaking strength and safe working load of the wire

rope shall be as given in Table 1..

Table 1 Minimum Factor of Safety for Wire Ropes

4.3.1.3 The drum may be flanged at ends. The flanges

shall project to a height of not less than two rope

diameters above the rope. .4 spur gear secured to

the drum may be regarded as forming one of the

flanges.

4.3.1.4 The lead angle.( fleet angle ) of the rope

shall not exceed 5 or1 in 12 on either side of helix

angle of groove in the drum.

4.3.2 A4aterialfor Drums

The drums shall be made from one of the following

materials:

a) Cast iron conforming to IS21 0,

b) Cast steel conforming to IS 1030, and

c) Mild steel plates conforming to [S 2062.

NOTE Use of cast iron shall be limited to small

capacity hoists only.

4.3.3 Strength of Drum

The drum shall be strong enough to -withstand

the crushing as well as the bending. The crushing

strength of drum shall be calculated by the following

formula:

S1 No. Operating Condition Minimum Fxctor

of Safety

(1) (2) (3)

i) Normal operation condition 6

ii) Breakdown torque condition 3

iii) For counterweight suspension 5

4.2.4 Wire ropes shall be guided over as few pulleys

as possible. Reverse S shaped bends shall be avoided

as far as possible.

4.2.5 The strength of the socket end of wire rope

shall be approximately equal to that of the rope itself.

The ends of wire ropes shall also be secured against

. twisting. The material for wire rope socket shall

conform to 1S2485.

4.3 Drums

4.3.1 General

4.3.1.1 The grooved drum shall.be of such a size that

normally there will not be more than one layer of rope

on the drum when the rope is in its filly wound position

unless specified.

4.3.1.2 The length of the drum shall be such that

each lead off rope has minimum two full turns on the

drum when the gate is at its lowest position, and one

spare groove for each lead off the drum when the gate

is at its highest. position.

f.

Kx T

t

where

c, =

K=

T=

P=

t

.

pxt

.

compressive stress, in N/mm2;

coefficient which depends upon the

number of layers of rope over the drum

and may be taken from Table 2;

tension on one wire rope in N;

pitch of scoring or centre to centre

distan-ce between adjoining grooves,

in mm; and

thickness of drum at the bottom of

groove, in mm.

NOTE The minimum thickness of drum shall not be

less than 16 mm in case of cast steel and 20 mm in case

of cast iron.

Table 2 Value Qf K

S1 No. Number of Layers of Value of K

Rope Over the Drum

(1) (2) (3)

0

I 1

ii) 2 1.75

iii) 3 2.0

iv) 4 2.25

6

4.3.3.1 The permissible compressive stresses for

the various materials from which drum is made shall

be taken as follows:

Material Indian Normal Torque Breakdown

Standard Conditions Conditions

(1) (2) (3) (4)

Cast iron IS 210 0.2 UTS 0.4 UTS

Cast steel IS 1030 0.2 UTS 80 percent of YP

Mild steel 1S 2062 0.17 UTS 80 percentof YP

4.3.4 Grooves on Drum

4.3.4.1 The rope drum shall be machine-grooved and

contour at the bottom of grooves shall be circular over

an angle of at least 120. The radius of groove shall

be 0.53 times the diameter of rope rounded off to next

full millimeter. The depth of groove shall not be less

than 0.35 times the diameter of the rope.

4.3.4.2 The grooves of the drum shall be so pitched

that there is a clearance of not less than the following

values between adjacent turns of rope:

a)

b)

c)

1.5 mm for ropes up to and including 12 mm

diameter,

2.5 mm for ropes over 12 mm and including

30 mm diameter, and

3.0 mm for ropes over 30 mm diameter.

4.3,4.3- Grooving shall be finished smooth and the

edges between the grooves shall be rounded.

4.3.5 Diameter of Drums

The minimum pitch diameter of the drum shall be

20 times the diameter of rope of 6/36 or 6/37

construct ion.

4.3.6 In case of fabricated drums, the number of

segments shall not exceed two.

4.3.7 Fixing of Rope

The ends of the rope shall be fixed at minimum two

points on the drum in such a way that the fixing device

is easily accessible and the rope is not subjected to

undue twists and turns. Each rope shall have not less

than two full turns on the drum before it is fixed.

4.4 Sheaves or Pulleys

4.4.1 Diameter of Pulley.v/Sheaves

The minimum pitch diameter of pulleys/sheaves

shall not be less than that shown in Table 3.

7

IS 6938:2005

Table 3 Minimum Value of D/d Ratio for

Pulleys/Sheaves

( Clause 4.4.l )

sl Type of Pulley/ D/d Ratio (Minimum

No. Sheave Value for 6/36 -or

6/37 Ropes)

i) For idler pulleys or balancing 12

pulleys

ii) All pulleyskheaves other than 20

idler or balancing pulleys

NOTE

-D = pitch diameter of pulley, in mm; and

d = diameter of wire rope, in mm.

4.4.2 The diameter at the bottom of the grooves of

the equivalizing sheaves shall be not less than

62 percent of the minimum pulley diameter.

4.4.3 Grooves

Sheaves or pulleys shall be machine-grooved to a

depth of not less than 1.5 times the diameter of the

rope. Grooves shall be finished smooth and shall be

free from surface defects likely to injure rope. The

contour at the bottom of the grooves shall be circuiar

over an angle of approximately 130 * 5. The radius

of the groove shall be 0.53 times the diameter of a

rope. The included angle which is-the angle between

the straight slopes at the sides of the grooves shall

be approximately 52.

.

4.4.4 Sheave Guara%

Sheavelpulley shall be provided with guards to retain

the ropes in the groove, if necessary.

4.4.5 Material for Sheaves/Pulleys

Sheaves/pulieys shall be made from any suitable

material asspecified for drums.

4.5 Gearing

4.5.1 The gear shall be machine-cut with smooth

finish. Following spur gear tooth forms may be used

in the reduction units of these hoists:

a) 20 stub tooth System, and

b) 20 full depth involute system.

Face width of spur gear shall not be less than 8 and

more than 12-modules.

The q value for stub tooth system and full depth

involute system is given in Table 4.

4.5.2 Design

Unless more accurate methods are apptied and

called for the spur gears-shall be designed according

IS 6938:2005

Table 4 q Value for Calculation of Stress in Tooth

at Root ( External Tooth) for 20 Full Depth

-Involute System and 20 Stub Tooth Systems

( Clause 4.5.l )

SI Number of Teeth q -value q Value for

No. on Gear/Pinion for 20 20 Stub Tooth

(1) (2) (3) (4)

i)

12 4.60 3.215

ii) 13 4.35 3.086

iii) 14 4.10 2.941

iv)

v)

vi)

vii)

viii)

ix)

x)

xi)

xii)

15

16

17

18

21

24

28

34

40

3.90

3.75

3.60

3.50

3.30

3.20

3.10

3.00

2.90

2.865

2.770

2.717

2.652

2.506

2.424

2.325

2.242

2.179

xiii) 50 2.80 2.110

xiv) 65 2.70 2.040

xv) 80 2.60 2.008

xvi) I 00 2.50 1.976

xvii) Above 100 2.50 1.976

NOTE Intermediate values may be interpolated.

to the formula given below:

. Pxq

0

root

Fxrn

where

0

root

= stress in N/mm* at root of gear;

P = tooth load, in N;

q

= strength factor indicated in Table 4;

F = face width, in mm; and

m = module in mm.

4.5.3 Allowable Stress

4.5.3.1 The allowable stress shall be taken as 20 percent

of the ultimate tensile strength of material used for

the manufacture of the gear for the normal operating

condition.

4.-5.3.2 For breakdown torque condition, the allowable

stress shall be taken as 80 percent of the yield point

stress of the material.

4.5.4 Material

All spur gear shall be of cast steel, forged steel, carbon

steel surface hardened steel or fabricated mild steel.

The choice of material shall be judicious. The gears

and pinions shall be made from two different grades

of materials, higher strength grade shall be used for

8

pinion and lower strength grade for spur gear.

4.5.5 Keys in gear trains shall be so fitted and secu~ed

that they should not become loose when in service.

4.5.6 Speed Reducem

4.5.6.1 Standard worm or helical reducers, if used,

for the first stage heavy reduction at the central

drive unit, shall be high grade reduction unit suitable

for the service intended. The proportions of all the

parts, therein, shall be in accordance with the best

engineering practices.

4.5.6.2 Rating and efficiency of the reducers used in

calculations shall be according to the manufacturer

recommendation.

4.5.6.3 Speed reducers shall be filled with lubricants

as per recommendations of the manufacturer.

4.6 Chain

The roller chain is usually made from straps and

pins. All straps should bear evenly. Subject to this

condition, the safe bearing pressure between the

straps and the pins shall be as folIows:

a) Chain for crest gates : 90 N/mm*, and

b) Chain for sluice gates : 70 Nhnrn2.

4.6.1 The minimum breaking strength shall amount

to:

. .

a) 500 N/mm* in case of straps, and

b) 600 N/mm* in case of pins.

4.6.2 Maintenance shall also be given due

consideration in arriving at the selection of the size

of the chains. Materials for various~arts of the chain

shall be as follows:

a) Straps :

b) Bushings :

c) Rollers

d) Pins

High carbon steel ( Temper

1/4 HofIS 5L3 ),

Steel ( Grade 280-520 W for

weldingandGrade280-520 N for

without welding of.IS 1030),

Steel ( with hardened tread and

tough centres ) ( Grade 55 C8

of 1S3445), and

High carbon heat treated steel

or chromium plated alloy steel

(Class 4 of IS 2004 ).

4.7 Shafts

4.7.1 General

The shafts shall be designed for appropriate load/

torque, that is, being transmitted. Shafis shall have

ample strength and rigidity and adequate bearing

surfaces. They shall be finished smoothly and, if

shouldered, shall be provided with fillets of large

radius.

4.7.2 Dimensioning of Shafts

In dimensioning the shaft with ratio ( length/

diameter ) 2 50, the angle of twist and the

revolutions/minute shall be taken into account, in

addition to simple bending, pure torsion, or the

combined effect of bending and torsion. The twist

that shall be permitted is 1/4 to 1/3 per m. Linear

deflection in the shaft shall not exceed 1 mm/m

of length.

4.7.3 Material

All shafts shall be of forged/rolled steel.

4.7.4 Allowable Stress

The allowable stress for solid shaft shall be as follows:

a)

b)

c)

Maximum allowable bending stress, ( -Ub)

either in tension or compression only

b

= 0.5 yield point or 20 percent of ultimate

strength whichever is less.

Maximum allowable torsional shear stress

(r)

T = 30 percent of the yield point stress.

Combined stress shall be calculated with the

following formula and shall not be greater

than that at (a) above

where

c 4

crb*+ 31J

combined stress, in N/mm* and shall

not exceed 0.24 UTS or 0.60 YP,

whichever is less;

tensile/compressive stress, in N/mm*;

and

shear stress, in N/mm*.

The allowable stress for shafts with keys shall be

75 percent of the above value.

The shatl shall also be designed for combined bending

and twisting by making use of the following formulae

and shall be checked for breakdown torque condition.

For breakdown torque condition, the allowable stress

shall be taken as 80 percent of the yield point stress

of the.material except for shear for which value sha[l

be limited inthe ratio of permissible stress under normal

conditions. The equivalent bending and twisting

stress shall not exceed 1.2 times the maximum

allowable stress as at 4.7.4 (a) and 4.7.4(b) separately.

1) Bending

Me = 0.5( Iu+Jm

IS 6938:2005

2) Twisting:

where

Me =

M=

T=

< .=

equiva-lent bending moment, in

Nm;

bending moment, in Nm;

twisting moment, in Nm; and

equivalent twisting moment, in Nm.

4.8 Bearings

4.8.1 Types of Bearing

All the running shatls shall be provided with ball,

roller or bush bearings. Selection of bearings shall

be done on consideration of duty, load and-speed of

the shaft.

4.8.1.1 Life of ball and roller bearings shall be

calculated in accordance with the maufacturers

recommendations.

4.8.1.2 Bearings shall be easily accessible for

lubrication and/or replacement. If there is more than

one bearing on one shaft, every bearing shall be

provided with individual lubrication arrangement.

4.8.-1.3 The minimum thickness of bronze bush shall

be calculated by the following formula:

t=O:08 d+3 mm

.,

where

d = diameter of the shafl, in mm; and

t = thickness of bush, in mm.

NOTE Allowable bearing streaa in case of bronze

bush shall be as per Annex B of IS 4622. However,

in case of breakdown torque condition it may be

increased by 33 I/3 percent.

4.9 Couplings

4.9.1 Material

All couplings shall be of forged steel or cast steel

and shall be designed to transmit the maximum torque

that may be developed.

4.9.2 Solid couplings shall be aligned in such away

that they meet accurately. Flexible couplings shall

be initially aligned with-the same accuracy as solid

couplings.

4.9.3 Flexible couplings shall be fitted between motor

shafts and extension shafts.

4.10 Gear Boxes

4.10.1 Gear boxes shall be of rigid construction fitted

with inspection covers and Iifling handles where

necessary. The gear boxes shall be so designed that

9

IS 6938:2005

the gears can be easily removed or replaced and shall

be such that the gears are suitably lubricated. Facilities

for oil tilling and draining, connection for oil level

indication and adequate breathing shall be provided

where necessary. The boxes shall be mounted on a

level surface.

4.10.2 Material for the gear box shalI be cast iron,

cast steel or fabricated from mild steel conforming to

relevant Indian Standards.

4.11 Hoist Supporting Structure

Allowable stresses for hoist supporting structure

shall be in accordance with 1S800 and an impact factor

of 1.1 shall be considered. For breakdown torque

condition, the allowable stress shall be taken as

80 percent of the yield point stress of the material.

4.11.1 The deflection of hoist bridge shall be limited

to 1/800 for spans up to 12 m and 1/1 000 for spans

above 12 m.

NOTE Impact factor shouldnot be taken for breakdown

torque condition.

5 ELECTRICAL EQUIPMENT

5.1 Efficiency of System

5.1.1 The usual values of efficiencies adopted

for the various elements of hoisting mechanism

shal I be taken from Table 5. The overall etliciency of

the system which is the product of -individual

efficiency of eiements, shall then be worked out. This

overall efficiency of the system shall be used in

calculating the capacity of the electric motor.

5.1.2 The ratio of overall running efficiency to the

overall-starting efficiency shall be less than the ratio

of starting torque to running torque of the motor.

5.2 Motors

5.2.1 The motor shall be totally enclosed fancooled,

high starting torque, squirrel cage, three phase

induction motor of rated capacity conforming to

IS 325. Unless otherwise specified the motor rating

shall be 40 percent cyclic duration factor, rated S 3

duty ( with six starts per hour).

5.2.2 The motor shall be suitable for outdoor type

duty. The motor shall be suitable for reversing

frequent acceleration and mechanical braking.

5.2.3 The breakdown torque of the motor at rated

voltage shall be not less than 2 times ( that is,

200 percent ) of the rated torque. During-this

condition, for checking the -hoist components and

hoist supporting structure, the starting efficiency

of the system shall be considered.

5.2.4 Motors shaIl be so located that the bush

gear and terminals are readily accessible for inspection

and maintenance and normal ventilation is not

-restricted.

5.2.5 Motor shall be provided with strip type anti

condensation heater.

5.3 Etectro-magnetic Brake

5.3.1 The electro-magnetic brake shall be of spring

set, shoe type. It shall be solenoid operated and

continuously rated. The brake shall be effective in

both directions of travel and shall be capable of over-

coming at least 150 percent of the full load torque

exerted by the motor.

5.3.2 The brake shall set automatically when the

current is cut off from the motor and it shall be

electrically released when the current is applied to

the motor. The brake shall be equipped with a hand-

operated release lever, A weather-prtif cover complete

with.heaters, if required, shall be provided to prevent

condensation on moving parts.

5.3.3 In addition to electro-magnetic brake, additional

brakes shall also be provided, in such case where

urtdesirable gravity fall of gate is to be arrested or

where frequent intermediate stopping of gate is

required during lowering cycle or where the selected

Table 5 Efficiencies of Various Components of Hoisting Mechanism

( Clause 5.1.1)

S1 No. Particular of Elements

(1) (2)

i)

Drum/sheave/pulley:

a) Bronze bushing

b) Anti-friction bearing

ii) Each set of spur gears

iii) Each set of helical gears

iv) Standarddrives, such as, worm reducer,

helical gear reducer. etc

v)

Electrical motor

Starting Efficiency

Percent

(3)

93

95

93

95

As per manufacturers

recommendations

do

Rwnning Efficiency

Percent

(4)

95

98

95

98

As per manufacturers

recommendations

do

10

gear box is not of self locking type.

5.4 Limit Switches

5.4.1 General

The limit switches, after being tripped, shall

automatically reset themselves within a reasonable

distance travelled in opposite direction, This does

not prevent the use of changeover type limit switches

where resetting is achieved by striker when moving

inopposite direction. They maybe mechanically driven

from the shaft.

5.4.2 Hoist Limit Switch

5.4.2.1 It is a device provided to.cut off the current,

stop the motion of hoist mechanism and to apply

the brake when the gate has reached a predetermined

level. Rotary type double acting limit switch shall

be provided.

5.4.2.2 Limit switches for intermediate positions of

travel, if required, shall also be provided.

5.4.3 Limit switches shall be weather-proof type.

Adequate adjustment shall also be provided to

compensate for rope elongation.

6 GATE POSITION INDICATOR

6.1 The gate position indicators shall invariably

be provided with each hoist unless otherwise

specified by the purchaser.

6.2 The indicator dial shall be made from non-

rustingmetal or~namelled plate or thick plastic sheet.

It shall generally-be of circular shape. If agreed to,

other shapes may also be adopted.

6.3 The markings on dial in the operating range

may preferably be kept at reading of 1/20th of metre.

The metre markings shall be very bold. The words

closed, open or fully raised.shall also be engraved

or permanently marked.

-6.4 The dial shall be located at a convenient place

from where it maybe easily seen by the gate operator.

6.5 The indicator point shall be made of non-rusting

metal. Electroplated indicator pointer can also b-e

provided, if mutually agreed to. Digital type indicator

may also be used.

6.6 Control Equipment

6.6.1 The hoist mechanism shall be complete with

one local control panel with push buttons, The control

panel shall be totally enclosed with 1P54 protection.

The.push buttons shall be suitably labelled as Raise,

Stop and Lower.

6.6.2 Lamps to indicate the condition of the control

IS 6938:2005

circuits and direction of motion maybe provided.

6.6.3 For emergency gate hoist requiring crack opening,

one additional push button of momentary contact

type, labelled Crack shall be provided along with

the indicating lamp showing Gate cracked open.

6.6.3.1 Crack operation push button shall have

suitable limit switch/timer control to limit the initial

operation time of motor crack opening as per

recommendations of the manufacturer of the motor

for utilizing torque higher than that referred for

normal operation.

6.6.4 The hoist shall be-provided with all the necessary

relays, starter, heaters, if required, fises, limit switches

and indicating lights complete with suitable wiring

so that all the functions are carried out smoothly.

6.6.5 Remote control equipment, ifrequirecf, shall be

provided to enable the operation of gates from

regulation roam. Gate position indicator, alarms,

suitable interlocks with local control panel, shall be

provided in regulation room, if required. Fibre optical/

conventional cables may be used for communication

link.

6.6.6 All the controls shall be so interlocked that the

proper functioning of individual parts for the purpose

is ensured.

6.6.7 Alternative source of electrical supply+nay be

provided by the purchaser for important projects, if

considered necessary.

6.6.8 Protection for rope overload and slack rope may

be provided at the discretion of the designer.

6.7 Manual Operation for EleetricallyOperated Hoists

6.7.1 The manual operation shall be provided, if

required for emergency operation in.theevent of electric

supply failure.

6.7.2 Electrical interlocks shall be provided to prevent

operation by electrical power when the manual drive

is engaged.

6.7.3 The manual operation should be designed

in such a manner that the continuous effort per

man does not exceed a crank force of 100 N with

400 mm of crank radius at a continuous rating of

24 rev/rein. The maximum number of persons may

be restricted to 4.

6.7.4 Manual operation shall be provided with

ratchet and pawl arrangement so that the gates do

not fall of their own weight during manual operation.

6.8 If desired by the purchaser, only manual operation

may be provided for small capacity hoists.

11

IS 6938:2005

IS No.

210:1993

325:1996

513:1994

800:1984

1030:1998

2004:1991

ANNEX A

(Clause 2)

LIST OF REFERRED INDIAN STANDARDS

Title

Grey iron casting Specification

(fourth revision )

Three-phase induction motors

Specification (flJth revision)

Cold rolled low carbon steel sheets

and strips (fourth revision )

Code of practice for general

construction in steel ( second

revision _)

Carbon steel castings for general

engineering purposes ( fifth

revision )

Carbon steel forgings for general

engineering purposes ( third

revision ) .

IS No.

2062:1999

2266:2002

2485:1979

3445:1992

4622:2003

Stee! for

purposes

revision )

Steel wire

Title

general structural

Specification ( fifth

ropes for general

engineering purposes

Specification (fourth revision )

Specification for drop forged

sockets for wire ropes for general

engineering purposes ( first

revision )

Forged steel rolls (first revision )

Recommendations for structural

design of fixed Wheel gates

( third revision)

12

IS 6938:2005

ANNEX B

( Foreword)

COMMITTEE COMPOSITION

Hydraulic Gates and Valves Sectional Committee, WRD 12

Organization

In Personal Capacity ( 2047, Pocket 2, Sector D, Vasant

Kunj, New Delhi 110 070)

Bhakra Beas Management Board, Punjab

Bharat Heavy Electrical Ltd, Bhopal

Central Electricity Authority, New Delhi

Central Water and Power Research Station, Pune

Central Water Commission, New Delhi

Himachal Pradesh State Electricity Board, Sunder Nagar,

Himachal Pradesh

Irrigation Department, Government of Maharashtra, Nasik

Irrigation Research Institute, Roorkee

National Hydroelectric Power Corporation Ltd, Faridabad

Orissa Construction Corporation Ltd, Bhubaneshwar

Texmaco Ltd, Kolkatta

Triveni Structural Ltd, Allahabad

Tungabhadra Steel Products Ltd, -Karnataka

Water Resources Development Training Centre, Roorkee

BIS Directorate General

Representative(s)

SHRI N. VISHWANATHAN( Chairman )

DEPUTY CHIEFE ENGINEER

EXECUTIVEENGINEER( Alternate )

DGM ( HTE )

SHIUR. K. RUSTACiI

SHRI R. M. SINNARKAR

SHRI S, L. PATIL( Alternate )

DIRECTORGATES( E &NE)

DIRECTOR( GATES-NW& S ) ( Alternate)

CHIEF ENGINEER( DESIGN)

SHRI K. D. SHARMA( Alternate )

SUPERINTENDINGENGINEER( GATES)

EXECUTIVEENGINEER( Alternate )

CHIEF ENGINEER( DESIGN)

SUPERINTENDINGENGINEER( Alternate )

SHRIG. S. SHAFtMA

SHRI A. K. Rov ( Alternate )

DIRECTOR( MECHANICAL) .

SENIORMANAGER( DESIGN) ( Alternate )

SHRI S. R. SINHA

SHRI UDAYANBANEREJEE( Alternate )

SHRI J. P. MISHRA

SHRI B. P. SINGH( Alternate )

SHRI HUSSAINBIN ALI

SHRI Y. S. CHANDRASHEKARAIAH ( Alternate )

PROFGOPALCHAU~AN

DIKECTORANDHEAO( WRD )

[ Representing Director General ( Ex-of&cio Member ) ]

Member Secretary

SHRIMATIROSY DHAWAN

Joint Director ( WRD ), BIS

13

Bureau of Indian Standards

131S is a statutory institution established under the Bureau of Indian ,Vlandards a et, 1986 to promote

harmonious development of the activities of standardization, marking and quality certification of goods and

attending to connected matters in the country.

Copyright

BI-Shas the.copyright of all its publications. NO part of these publications may be reproduced in any form

without the prior permission inwriting of BIS. This does not preclude the free use, in the course of implementing

the standard, of necessary details, such as symbols and sizes, type or grade designations. Enquiries relating

to copyright be addressed to the Director (Publications), BIS.

Review of Indian Standards

Amendments are iss-ued to standar-ds as the need ariseson the basis of comments. Standards are also reviewed

periodically; a standard along with amendments is reaffirmed when such review indicates that no changes are

needed; if the review indicates that changes are needed, it is taken, up for revision. Users of Indian Standards

should ascertain that they are in possession of the latest amendments or edition by referring to the latest issue

of BIS Catalogue and Standards : Monthly Additions.

This Indian Standard has been developed from Doc : No WRD 12( 339).

Amendments Issued Since Publication

Amend No. Date of Issue Text Affected

BUREAU OF INDIAN STANDARDS

Headquarters:

Manak Bhavan, 9 Bahadur Shah Zafar Marg, New Delhi 110002

Telephones: 23230131,23233375,2323 9402 Website: www.bis.org.in

Regional Offices: Telephones

Central : Manak Bhavan, 9 Bahadur Shah Zafar Marg

{

23237617

NEW DELHI 110002 2323384 I

Eastern : 1/14 C. 1. T. Scheme VII M, V. 1. P..Road, Kankurgachi

{

23378499,23378561

KOLKATA 700054 23378626,23379120

Northern: SCO 335-336, Sector 34-A, CHANDIGARH 167)022

{

2603843

260.9285

Southern: C. 1.T. Campus, IV CrossRoad, CHENNAI 600113

{

22541216,22541442

22542519,22542315

Western : Manakalaya, E9 MlDC, Marol, Andheri (East)

{

28329295,28327858

MUMBAI 400093 28327891,28327892

-Branches: AHMEDABAD. BANGALORE. BHOPAL. BHUBANESH WAR. COIMBATORE.

FARIDABAD. GHAZIABAD. GUWAHATI. HYDERABAD. JAIPUR. KANPUR.

LUCKNOW. NAGPUR. NALAGARH. PATNA. PUNE. RAJKOr. THIRUVANANTHAPURAM.

VI SAKHAPATNAM .

7

Printedat New India PrintingPress, Khurja, India

Vous aimerez peut-être aussi

- IS 6938 (2005) - Design of Rope Drum and Chain Hoists For Hydraulic Gates - Code of PracticeDocument16 pagesIS 6938 (2005) - Design of Rope Drum and Chain Hoists For Hydraulic Gates - Code of PracticeSuleman KhanPas encore d'évaluation

- Is 4622 2003Document27 pagesIs 4622 2003Apurba Haldar100% (1)

- Design of Rope Drum HoistDocument5 pagesDesign of Rope Drum HoistDheeraj Verma100% (5)

- Design Concepts For Jib Cranes PDFDocument12 pagesDesign Concepts For Jib Cranes PDFanthony cordovaPas encore d'évaluation

- Wall Mounted Jib Crane (H-Type) : Mechanical System DesignDocument65 pagesWall Mounted Jib Crane (H-Type) : Mechanical System DesignFitra VertikalPas encore d'évaluation

- 40t Rope Drum Hoist220512Document37 pages40t Rope Drum Hoist220512Anonymous sfkedkymPas encore d'évaluation

- Wheel Load Design Calculation of Eot CraneDocument12 pagesWheel Load Design Calculation of Eot Craneram_babu_59100% (3)

- 181-186 For Web PDFDocument6 pages181-186 For Web PDFdiego.peinado8856100% (1)

- Crane Rail Selection: Calculation of Required Rail Head WidthDocument1 pageCrane Rail Selection: Calculation of Required Rail Head WidthMAHMOUD YOUNISPas encore d'évaluation

- Lecture 14.4: Crane Runway Girders: Objective/ScopeDocument22 pagesLecture 14.4: Crane Runway Girders: Objective/ScopeScooby DooPas encore d'évaluation

- Design of Crane Runway Beam With ChannelDocument9 pagesDesign of Crane Runway Beam With Channellatyrniang100% (3)

- DesignDocument4 pagesDesignJigneshkumar PatelPas encore d'évaluation

- Crane Buffer ForcesDocument243 pagesCrane Buffer ForcesFourHorsemenPas encore d'évaluation

- FEA and Optimization of Telescopic Boom of Mobiles Hydraulic CraneDocument6 pagesFEA and Optimization of Telescopic Boom of Mobiles Hydraulic Cranenpd1986100% (2)

- ISO.4302 - Is.14467.1997Document12 pagesISO.4302 - Is.14467.1997tiele_barcelosPas encore d'évaluation

- GantryDocument7 pagesGantrysatydevsinghnegiPas encore d'évaluation

- Discussion - Design Concepts For Jib CranesDocument2 pagesDiscussion - Design Concepts For Jib Cranesheitor29Pas encore d'évaluation

- Cranes-Design Principles For Loads and Load CombinationsDocument10 pagesCranes-Design Principles For Loads and Load CombinationsEnrique Santiago BenavidesPas encore d'évaluation

- Design of Rope DrumsDocument8 pagesDesign of Rope DrumsBhaskar AnupamPas encore d'évaluation

- Wire Ropes Data Book PgsDocument6 pagesWire Ropes Data Book Pgssiddharth Gautam100% (1)

- Jib CraneDocument16 pagesJib Cranesuperman3k100% (2)

- Eot Crane During SeismicDocument12 pagesEot Crane During SeismicboyzesPas encore d'évaluation

- Designing of Cranes With StandardsDocument95 pagesDesigning of Cranes With Standardsank_mehraPas encore d'évaluation

- Calculation DesignDocument25 pagesCalculation DesignMuhammad Fadzil100% (1)

- ASME BTH-1-2011 Design of Below The Hook Lifting Devices ReducedDocument68 pagesASME BTH-1-2011 Design of Below The Hook Lifting Devices ReducedAnthony Gravagne100% (5)

- 1 - Overview of Gate Operating SystemsDocument6 pages1 - Overview of Gate Operating SystemsPradeep VM100% (1)

- Jib Crane HandbookDocument10 pagesJib Crane Handbookprp_a100% (3)

- Hoisting DesignDocument25 pagesHoisting DesignIshaan00748850% (2)

- Axle HoldersDocument1 pageAxle HoldersjoseocsilvaPas encore d'évaluation

- Crane Girder DesignDocument6 pagesCrane Girder Designarzu50% (2)

- Overhead Crane Governing Bodies and Specs PDFDocument1 pageOverhead Crane Governing Bodies and Specs PDFscofiel1Pas encore d'évaluation

- Design Concept For Jib CraneDocument12 pagesDesign Concept For Jib Cranevish5610100% (3)

- DWP Calculation 1601139173Document18 pagesDWP Calculation 1601139173Ashutosh KumarPas encore d'évaluation

- Jib CraneDocument42 pagesJib Cranethiru_jsr67% (6)

- Crane Wheel Heat Treating MethodsDocument20 pagesCrane Wheel Heat Treating Methodsgmurdzhev67% (3)

- Crane Girder DesignDocument1 pageCrane Girder Designmonther_alsalkhadiPas encore d'évaluation

- Idea - Wheel CalculationDocument35 pagesIdea - Wheel Calculationbambang satryojatiPas encore d'évaluation

- JDN Monocrane - Manufacturers of Overhead Lifting EquipmentDocument19 pagesJDN Monocrane - Manufacturers of Overhead Lifting EquipmentJDN MonocranePas encore d'évaluation

- Crane HookDocument55 pagesCrane HookEr Prabhakar100% (3)

- Tong HookDocument8 pagesTong HookEricPas encore d'évaluation

- KBK Brochure PDFDocument12 pagesKBK Brochure PDFMahendran KuppusamyPas encore d'évaluation

- 50t Rope Drum HoistDocument30 pages50t Rope Drum HoistAnonymous sfkedkym100% (2)

- Standard CraneDocument20 pagesStandard CranecehaiguPas encore d'évaluation

- Design of Hoisting Mechanism For Crane R1Document45 pagesDesign of Hoisting Mechanism For Crane R1Bhalchandra Desai100% (2)

- ARRIUM - Standards For Crane Anti-Derailment Final R4Document18 pagesARRIUM - Standards For Crane Anti-Derailment Final R4YOO SHIN0% (1)

- 13.15 B - Presentation - Forces Experienced by Winch Drums and Reels Systems PDFDocument26 pages13.15 B - Presentation - Forces Experienced by Winch Drums and Reels Systems PDFarturomPas encore d'évaluation

- Crane Transportation DesignDocument65 pagesCrane Transportation Designdawit100% (1)

- Is 6938Document13 pagesIs 6938Dhanashri Patil100% (1)

- Disclosure To Promote The Right To InformationDocument26 pagesDisclosure To Promote The Right To InformationArvindPas encore d'évaluation

- 3938Document23 pages3938Ritu Saroa0% (1)

- Section 8 Windlasses, Winches and Hydraulic Systems: Chapter 2, Section 8, B Chapter 2, Sec-Tion 8, B.3 B.4Document12 pagesSection 8 Windlasses, Winches and Hydraulic Systems: Chapter 2, Section 8, B Chapter 2, Sec-Tion 8, B.3 B.4Suresh KumarPas encore d'évaluation

- Specification For Electric Chain Hoists (First Revision of IS 6547)Document24 pagesSpecification For Electric Chain Hoists (First Revision of IS 6547)Dheeraj ThakurPas encore d'évaluation

- IS:11592Document64 pagesIS:11592Santanu KararPas encore d'évaluation

- Iso4310 1981Document6 pagesIso4310 1981somsak9100% (2)

- Is 12466 2012 PDFDocument11 pagesIs 12466 2012 PDFlokeshras12Pas encore d'évaluation

- Shell Lifting AttachmentsDocument12 pagesShell Lifting AttachmentsjesusgameboyPas encore d'évaluation

- IS.11639.Part 2.1995Document13 pagesIS.11639.Part 2.1995imadhuryya5023Pas encore d'évaluation

- D03MOORINGWINCHES CleanDocument9 pagesD03MOORINGWINCHES CleanRao SgPas encore d'évaluation

- OSHA Technical ManualDocument102 pagesOSHA Technical ManualthugpanditPas encore d'évaluation

- Disclosure To Promote The Right To InformationDocument12 pagesDisclosure To Promote The Right To InformationyesvvnPas encore d'évaluation

- Sensitivity Analysis and Optimisation of HVOF Process Inputs To Reduce Porosity and Maximise Hardness of WC-10Co-4Cr CoatingsDocument23 pagesSensitivity Analysis and Optimisation of HVOF Process Inputs To Reduce Porosity and Maximise Hardness of WC-10Co-4Cr Coatingssuresh_501Pas encore d'évaluation

- Research Article: Porosity Analysis of Plasma Sprayed Coating by Application of Soft ComputingDocument7 pagesResearch Article: Porosity Analysis of Plasma Sprayed Coating by Application of Soft Computingsuresh_501Pas encore d'évaluation

- Sensors: Evaluation of The Uniformity of Protective Coatings On Concrete Structure Surfaces Based On Cluster AnalysisDocument19 pagesSensors: Evaluation of The Uniformity of Protective Coatings On Concrete Structure Surfaces Based On Cluster Analysissuresh_501Pas encore d'évaluation

- Plasma Spray Process Operating Parameters Optimization Basedon Artificial IntelligenceDocument18 pagesPlasma Spray Process Operating Parameters Optimization Basedon Artificial Intelligencesuresh_501Pas encore d'évaluation

- Metals: High Velocity Oxygen Liquid-Fuel (HVOLF) Spraying of WC-Based Coatings For Transport Industrial ApplicationsDocument21 pagesMetals: High Velocity Oxygen Liquid-Fuel (HVOLF) Spraying of WC-Based Coatings For Transport Industrial Applicationssuresh_501Pas encore d'évaluation

- Macroparticle Detection in Surface Coating Using Image ProcessingDocument6 pagesMacroparticle Detection in Surface Coating Using Image Processingsuresh_501Pas encore d'évaluation

- Research ArticleDocument20 pagesResearch Articlesuresh_501Pas encore d'évaluation

- Sándor Hajdu : Multi-Body Modelling of Single-Mast Stacker CranesDocument9 pagesSándor Hajdu : Multi-Body Modelling of Single-Mast Stacker Cranessuresh_501Pas encore d'évaluation

- Structural Engineering: Indian Society OF Structural EngineersDocument24 pagesStructural Engineering: Indian Society OF Structural Engineerssuresh_501Pas encore d'évaluation

- Research ArticleDocument12 pagesResearch Articlesuresh_501Pas encore d'évaluation

- Advanced Simulation of Tower Crane Operation Utilizing System Dynamics Modeling and Lean PrinciplesDocument10 pagesAdvanced Simulation of Tower Crane Operation Utilizing System Dynamics Modeling and Lean Principlessuresh_501Pas encore d'évaluation

- Proiect Masa Ridicare PDFDocument41 pagesProiect Masa Ridicare PDFEpure GabrielPas encore d'évaluation

- Prediction and Analysis of High Velocity Oxy Fuel (HVOF) Sprayed Coating Using Artificial Neural NetworkDocument31 pagesPrediction and Analysis of High Velocity Oxy Fuel (HVOF) Sprayed Coating Using Artificial Neural Networksuresh_501Pas encore d'évaluation

- Beam With Joint and Offset LoadDocument9 pagesBeam With Joint and Offset Loadsuresh_501Pas encore d'évaluation

- CPA CHIG1901 GPG Tying Hoists To Supporting Structures Rev 1 191201Document84 pagesCPA CHIG1901 GPG Tying Hoists To Supporting Structures Rev 1 191201suresh_501Pas encore d'évaluation

- 7.4 Tower Design: Bracing SystemsDocument49 pages7.4 Tower Design: Bracing SystemsBoisterous_Girl100% (1)

- University of Mumbai: "Installation of Safety Brakes in Eot Cranes"Document56 pagesUniversity of Mumbai: "Installation of Safety Brakes in Eot Cranes"suresh_501Pas encore d'évaluation

- EOT CraneDocument84 pagesEOT CraneSambhav Poddar80% (5)

- Beam Design Formulas With Shear and MomentDocument20 pagesBeam Design Formulas With Shear and MomentMuhammad Saqib Abrar100% (8)

- Production DrawingDocument98 pagesProduction DrawingThangadurai Senthil Ram PrabhuPas encore d'évaluation

- Mohd Fauzi Muhammad (CD 4928)Document24 pagesMohd Fauzi Muhammad (CD 4928)selvakumarPas encore d'évaluation

- Hernandez Eileen C 201212 MastDocument99 pagesHernandez Eileen C 201212 Mastsuresh_501Pas encore d'évaluation

- DSIR Guidlines 2015Document4 pagesDSIR Guidlines 2015suresh_501Pas encore d'évaluation

- Design and Analysis of Bucket Elevator: I. Ii. Literature ReviewDocument6 pagesDesign and Analysis of Bucket Elevator: I. Ii. Literature ReviewRescuemanPas encore d'évaluation

- Main CraneDocument8 pagesMain CraneMateri BelajarPas encore d'évaluation

- Finite Element Analysis of Rack-Pinion System of A Jack-Up RigDocument6 pagesFinite Element Analysis of Rack-Pinion System of A Jack-Up Rigsuresh_501Pas encore d'évaluation

- Failure Analysis of A Pinion of The Jacking System of A Jack-Up PlatformDocument12 pagesFailure Analysis of A Pinion of The Jacking System of A Jack-Up Platformfle92Pas encore d'évaluation

- A Model To Optimize Single Tower Crane Location Within A Construction Site (PDFDrive)Document468 pagesA Model To Optimize Single Tower Crane Location Within A Construction Site (PDFDrive)suresh_501Pas encore d'évaluation

- Beam Design Formulas With Shear and MomentDocument20 pagesBeam Design Formulas With Shear and MomentMuhammad Saqib Abrar100% (8)

- Crane Foundation DesignDocument14 pagesCrane Foundation Designway2saleem100% (2)

- ISO-14236-2000 Traducido EspañolDocument11 pagesISO-14236-2000 Traducido EspañolPablo A.100% (1)

- Chapter 4-The Simple Interest 2Document121 pagesChapter 4-The Simple Interest 2course heroPas encore d'évaluation

- I Twin Technology: Submitted in Partial Fulfillment of The Requirements For The Award of The Degree ofDocument30 pagesI Twin Technology: Submitted in Partial Fulfillment of The Requirements For The Award of The Degree ofBarma RajkumarPas encore d'évaluation

- GCT 2015-16 - Final Exam - 2015-12-18 - SolutionDocument9 pagesGCT 2015-16 - Final Exam - 2015-12-18 - SolutionpadrefloPas encore d'évaluation

- PlaxisDocument6 pagesPlaxisRehan HakroPas encore d'évaluation

- Foundation Design RequirementsDocument18 pagesFoundation Design RequirementsDanyal AhmedPas encore d'évaluation

- D82167GC10-Practices For Lesson 8Document36 pagesD82167GC10-Practices For Lesson 8ChristianQuirozPlefkePas encore d'évaluation

- Cuda GDBDocument64 pagesCuda GDBVinícius LisboaPas encore d'évaluation

- RBK-PROC-MK3 Raychem MK3Document83 pagesRBK-PROC-MK3 Raychem MK3VictorPas encore d'évaluation

- Ama WB NX PDFDocument36 pagesAma WB NX PDFirinaPas encore d'évaluation

- Coca Cola Potentiometric TitrationDocument5 pagesCoca Cola Potentiometric TitrationDaniela Delgadillo RestrepoPas encore d'évaluation

- Skewed Bridges: Effect of SkewDocument2 pagesSkewed Bridges: Effect of SkewArun K RajPas encore d'évaluation

- Exam Syllabus For Genius20Document2 pagesExam Syllabus For Genius20Vaishali PandeyPas encore d'évaluation

- IptablesDocument3 pagesIptablessoomalikPas encore d'évaluation

- Parametric Modeling A Simple ToolDocument6 pagesParametric Modeling A Simple ToolFatimeh ShahinPas encore d'évaluation

- 2014oct FE PM QuestionDocument34 pages2014oct FE PM QuestionShwe Yee Win ThantPas encore d'évaluation

- Condenser & Heater PerformanceDocument116 pagesCondenser & Heater PerformanceGaurav Singh100% (2)

- Sainsbury 2010 PDFDocument13 pagesSainsbury 2010 PDFronaldPas encore d'évaluation

- ACC20 Engine Safety UnitDocument2 pagesACC20 Engine Safety UnitVictor EugenPas encore d'évaluation

- Motion 2000 Hydraulic v8 42-02-1P20 B7Document248 pagesMotion 2000 Hydraulic v8 42-02-1P20 B7ElputoAmo XD100% (1)

- Astm c1060Document6 pagesAstm c1060jorgePas encore d'évaluation

- What Is Generator Efficiency Calculation Formula GuideDocument6 pagesWhat Is Generator Efficiency Calculation Formula Guidejitender.singh29Pas encore d'évaluation

- A30050-X6026-X-4-7618-rectifier GR60Document17 pagesA30050-X6026-X-4-7618-rectifier GR60baothienbinhPas encore d'évaluation

- 6.report Face RecognitionDocument45 pages6.report Face RecognitionSuresh MgPas encore d'évaluation

- Alkali MetalsDocument12 pagesAlkali MetalsSaki Sultana LizaPas encore d'évaluation

- Mid-Semester Paper 09Document2 pagesMid-Semester Paper 09Harsh ThakurPas encore d'évaluation

- E 1354 - 02 - Rtezntqtmdm - PDFDocument18 pagesE 1354 - 02 - Rtezntqtmdm - PDFdelta lab sangliPas encore d'évaluation

- A1 - Full Papers PS1 10834 2022Document18 pagesA1 - Full Papers PS1 10834 2022DmitryPas encore d'évaluation

- Mill Test Certificate: 唐山中厚板材有限公司 Tangshan Heavy Plate Co.,Document1 pageMill Test Certificate: 唐山中厚板材有限公司 Tangshan Heavy Plate Co.,engbilal.qaqc786Pas encore d'évaluation

- SAP Batch Determination - SAPs'WORD - We SAP For Your CauseDocument15 pagesSAP Batch Determination - SAPs'WORD - We SAP For Your CauseNikhil RaviPas encore d'évaluation