Académique Documents

Professionnel Documents

Culture Documents

Enhanced Condensate Recovery Assessment Using Experimental Design Approach

Transféré par

Basil OgbunudeTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Enhanced Condensate Recovery Assessment Using Experimental Design Approach

Transféré par

Basil OgbunudeDroits d'auteur :

Formats disponibles

1

2

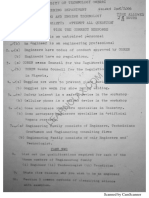

INTER-WORLD JOURNAL OF SCIENCE AND TECHNOLOGY

VOLUME 4 AUGUST 2014 NUMBER 4 ISSN-1597-488X

Blended Learning Versus Conventional Learning Approach in Teaching

Science Schools in Owerri Municipal Council, Imo State, Nigeria

Obasedo Roseline A. Nwaeze U.C.; Mba O. Mba; Ibe

C. O.; and Mbadiugha C.N.

Evaluat ion of the Nutrient Content of Avocado Seed (Persea Americana)

Okere C.S.; Ogwo V.; Okorie A., Osuoha V., Ukpai

Kalu U; and Azoro A.V.

Natural Petroleum: Chemistry and Valuable Products Fractions

Azunna I.B. Ekejiuba

Effects of Aqueous Extracts of Capsicum. Fruitensce, Azadirachta.

Indica, Zingiber Off icinale, Eucalyptus Spp, and Venonia. Amygdalina,

On Some Important Insect Pests of Cowpea Vigna Unguiculata, (L) Walp.

Isika P.I, Azuike P. and Okoro L.

New Model Standoff Casing Pipes and Liner Pipes For High-angle, Hor izontal,

Mult ilateral and Tie-back Wells.

Azunna I.B. Ekejiuba

Study of Water Cement Ratio Influence on Strength Characteristics

of Millet Stem Ash (MSA) Concrete

Oseni Olumide Waheed

Identification of Gifted Children in Basic Sciences for Early Training

and Harnessing of the Potentials in Niger ia.

Ikwuanusi, E.N andOzioko, S.U

Ipomea Batatas (Sweet Potatoes): A Sustainable Source of Food and Ethanol for

the Achievement of Millennium Development Goals.

Ogbuneke R. U., Ngwu S. U., and Okonkwo S. I.

Information Communication Technology (Ict): A Value Added Imperative

For Library Operation And Services In The 21

st

Century Nigerian Library

Oti Ifeanyichukwu

Microbial Evaluation of Frozen Fish Sold in Makurdi Metropolis in Nigeria

Nwachukwu, C.N; Igyor, M, A and Okorie, S.U.

A Review of Demand side Managemtn and Climate Change Mitigation

on Electrical Energy

Lawal Abdur-Raheem Olasupo; and Adeoti, J. Adeshina

Cumulat ive Potential Petroleum Deposit in the Provincial Geology of Nigeria

Azunna I.B. Ekejiuba

Compressive Strength Properties of Millet Stem Ash Concrete in Structures

Oseni, Olumide Waheed

Models Developed For Leak Locating Estimat ion in Oil Pipelines

Obibuike Ubanozie Julian, Anyadiegwu C.I. and Abonyi Chukwunonso

3

Development of Gas Utilisation Model in Nigeria

Obibuike U. J., Anyadiegwu C.I.C, Ogwo, O. J and Ekeh O. Cynthia

Enhanced Recovery Assessment of a Gas Condensate System Using Experimental Design

Approach

Kevin Igwilo, Ogbunude Basil, Ubanatu Samuel,

Comparative Approach to Optimum Selection of Artificial Lift System

Igwilo Kevin Chinwuba, and Ubanatu Samuel,

INTER-WORLD JOURNAL OF SCIENCE AND TECHNOLOGY

VOLUME 4 AUGUST 2014 NUMBER 4 ISSN-1597-488X

Blended Learning Versus Conventional Learning Approach in Teaching

Science Schools in Owerri Municipal Council, Imo State, Nigeria 1-13

Evaluat ion of the Nutrient Content of Avocado Seed (Persea Americana) 14-21

Natural Petroleum: Chemistry and Valuable Products Fractions 22-53

Effects of Aqueous Extracts of Capsicum. Fruitensce, Azadirachta.

Indica, Zingiber Off icinale, Eucalyptus Spp, and Venonia. Amygdalina,

On Some Important Insect Pests of Cowpea Vigna Unguiculata, (L) Walp. 54-66

New Model Standoff Casing Pipes and Liner Pipes For High-angle,

Hor izontal, Mult ilateral and Tie-back Wells. 67-89

Study of Water Cement Ratio Influence on Strength Characteristics

of Millet Stem Ash (MSA) Concrete. 90-106

Identification of Gifted Children in Basic Sciences for Early Training

and Harnessing of the Potentials in Niger ia. 107-

113

Ipomea Batatas (Sweet Potatoes): A Sustainable Source of Food and

Ethanol for the Achievement of Millennium Development Goals. 114-

119

Information Communication Technology (Ict): A Value Added Imperative

For Library Operation And Services In The 21

st

Century Nigerian Library 120-

129

4

Microbial Evaluation of Frozen Fish Sold in Makurdi Metropolis in Nigeria 130-

137

A Review of Demand side Managemtn and Climate Change Mitigation

on Electrical Energy 138-

148

Cumulat ive Potential Petroleum Deposit in the Provincial Geology

of Nigeria 149-

172

Compressive Strength Properties of Millet Stem Ash Concrete in Structures 173-

191

Models Developed For Leak Locating Estimat ion in Oil Pipelines 192-

203

Development of Gas Utilisation Model in Nigeria 204-

226

Enhanced Recovery Assessment of a Gas Condensate System Using Experimental

Design Approach 227

240

Comparative Approach to Optimum Selection of Artificial Lift System 241-

255

INTER-WORLD JOURNAL OF SCIENCE AND TECHNOLOGY

CALL FOR PAPER

Inter-World Journal of Science and Technology.

Inter-World Journal of Medical and Dental Science.

Inter-World Journal of Educational, Social and Economic Studies.

Inter-World Journal of Earth and Environmental Science.

Inter-World Journal of Information and Information Studies.

Inter-World Journal of Law and Jurisprudence.

Inter-World Journal of Management and Development Studies.

5

We present this range of research and professional Journals published by organization

which are of relevance and importance to Governments, International Organizations, Oil

Exploration and Production Companies, Research Institutions, Universities, tertiary

Institutionals, the Professions, the Business World, Individuals and Libraries. These

Journals, bi-annual publications of R.DURSON ASSOCIATES are directed to an

international qualified readership among Scholars, Researchers and Policy makers. Each

journal emphasizes policy relevance and operational aspect of research as well as

theoretical and methodological issues.

R.DURSON ASSOCIATES is a non-governmental organization engaged in high level

consultancy, capacity building and resources processing in science and technology

applications. It is committed to provision of invigorated private sector participation in

development of research results and findings. We invite interested scholar and researchers

to submit manuscripts for publication in the above listed international referred journals.

The opinions and interpretations in these journals are those of authors and do not

necessarily represent views of our anonymous assessors or policies of R.DURSON

ASSOCIATES, its Board or partner institutions.

Material in these journals are copyrighted. Request to reproduce them should be sent to the

Office of the Executive Secretary. Approval for publication of materials in any of the

journals follows successful screening of the materials based on comments by three

anonymous assessors/reviewers and final approval process by the entire Editorial Board.

Materials so accepted cannot be published in another journal without our permission and

may be published I any of the journals in our stable at the discretion of the publisher.

INFORMATION FOR CONTRIBUTORS

Please contributors should comply with the following standard.

4 copies of an abstract not more than 200 word, including authors names, degrees,

status and affiliations.

6

4 copies of full-length paper typewritten, double spaced on A4 paper with margins on

sides.

Full text of the paper should not be more than 15 pages in length including

references.

The writing style should be clear and lucid. A high premium is placed or readability

and high scholarly standards.

Submission are published on the understanding that they have not been published

elsewhere.

Copying on all manuscripts are held by the publisher. The manuscripts cannot be

produced elsewhere without permission.

Single authorship is accepted but premium is placed on co-authored manuscripts

Manuscripts that are interdisciplinary in nature are encouraged.

Letters comments on previous article in the journal are welcome at the discretion of

the Editorial Board and as space permits.

All citations should be indicated in the body of the text with the name of the author

and the year of publication e.g. (Duru 1980).

References should be listed in alphabetical order using the Harvard System.

S. I. Units should be employed where applicable.

All drawing should be clear and suitable for production without further preparation.

Photographs where applicable should be in the form of large black and white glossy

prints.

As a policy of RDA, the Editorial Board assesses all manuscripts anonymously.

There is no discrimination against any author with reference to age colour, creed,

origin, belief, sex and publications are strictly on first-come, first- served basis etc.

Young scholars with remarkable potentials and women are encouraged.

The Editorial Board reserves right to clarify or condense manuscripts where it is

deemed unavoidable. Such decision is final.

The author(s) of manuscripts published in the journals are entitled to receive only 4

copies of the journal and I clear off-print copies of their articles(s) (if the latter is

requested for).

Manuscripts are accepted through the year but are placed before the Editorial Board

on the basis of first to come first to be served.

Direct all editorial correspondence to:

The Chairman Editorial Board/Editor-In-Chief

R.DURSON ASSOCIATES

NO. 145 Doulgas Road,

Imo State, Nigeria.

Engr. R.U.Duru

(Managing Editor)

7

INTER-WORLD JOURNAL OF SCIENCE AND

TECHNOLOGY

VOLUME 4 AUGUST 2014 NUMBER 4 ISSN-1597-488X

NOTE OF CONTRIBUTORS

OBASEDO, R.A; NWAEZE, U.C.; AND MBA O. MBA are Senior Lectures;

Department of Integrated Science while Ibe C. O; and Mbadiugha, C.N. are Principal

Lectures, Department of Chemistry, Alvan Ikoku Federal College of Education

Owerri Nigeria.

OKERE.; OGWO V. O.; OSUOHA, V; UKPAI KALU AND AZORO, A. V. are

Lecturers, Department of Biology, Alvan Ikoku Federal College of Education while

Okerie, A is Lecturer, Department of Nutrition and Dietetics, Imo State University

Owerri, Nigeria.

AZUNNA I.B. EKEJIUBA a Chartered Engineer is Senior Lecturer, Department of

Petroleum Engineering Federal University of Technology Owerri, Nigeria.

P.I. Isika; P. Azuike and L. Okoro are Lecturers, Imo Polytechnic, Umuagwu,

Owerri Nigeria.

OSENI OLUMIDE WAHEED is Lecturer, Department of Civil Engineering,

University of Abuja, Nigeria.

IKEWUANUSI, E.N. AND OZIOKO, S.U. are Lecturers; Department of Integrated

Science Alvan Ikoku Federal College of Education, Owerri, Nigeria.

R.U. OGBUNEKE is Principal Lecturer and S. U. Ngwu is Lecturer, Department of

Chemistry, Alvan Ikoku Federal College of Education, Owerri while S. I. Okonkwo is

Senior Lecture; Department of Pure and Industrial Chemistry, Anambra State

University, Uli, Anambra State, Nigeria.

OTI IFEANYICHUKWU is a Chief Librarian, Federal Polytechnic Nekede, Owerri,

Nigeria.

C. N NWACHUKWU is Adjunct Assistant Lecturer, S. U OKORIE is Senior

Lecturer, Department of Food Science and Technology, Imo State University while

M. A. IGYOR is Associate Professor, Department of Food Science and Technology,

University of Agriculture, Markurdi, Benue State, Nigeria.

LAWAL ABDUR-RAHEEM OLASUPO and ADEOTI, J. ADESHINA are

Lecturers, Department of Electrical/ Electronic Engineering, Kwara State Polytechnic,

Ilorin, Nigeria.

OSENI OLUMIDE WAHEED is Lecturer, Department of Civil Engineering,

University of Abuja, Nigeria.

OBIBUIKE UBANOZIE JULIAN AND ABONYI CHUKWUNONSO are

Lecturers while ANYADIEGWU is Senior Lecturer and Head, Department

Petroleum Engineering, Federal University of Technology, Owerri, Nigeria.

8

OBIBUIKE UBANOZI E JULIAN is Lecturer and ANYADIEGWU C.I.C is Senior

Lecturer; Department of Petroleum Engineering, Federal University of Technology

Owerri Nigeria while OGWO OBIKE JONES is Staff of Department of Petroleum

Resources Nigeria while EKEH OGOCHUKWU CYNTHIA is Lecturer, Imo State

University Owerri, Nigeria.

KEVIN IGWILO IS LECTURER, Department of Petroleum Engineering, Federal

University of Technology Owerri, Nigeria while OGBUNULE BADIL and

UBANATU SAMUEL are of Society of Petroleum Engineers Nigeria.

9

Blended Learning Versus Conventional Learning Approach

in Teaching Science Schools in Owerri Municipal

Council, Imo State, Nigeria

Obasedo Roseline A. Nwaeze U.C.; Mba O. Mba; Ibe C. O.;

and Mbadiugha C.N.

The study examined effect of blended learning versus convectional learning approach on

secondary school students academic performance in integrated science. The researchers

employed quasi-experimental design. The population consists of ten (10) secondary schools,

in Owerri Zone. Two (2) secondary schools were randomly selected for the study. These

instruments were validated using the blue print & item analysis, also by experts in science

education. A group of 30 students from each school received conventional instruction

(group1), while another group of 30 students for another class were encouraged to learn the

same content from a computer assisted instruction (software) with convectional instruction

(Group2). The pre and post test scores of these two groups of students were compared.

Fifteen (15) students from group 2 were interviewed for their comments on the different

teaching and learning approaches. Findings revealed that; students taught with blended

learning approach performed better than their counterparts exposed to only conventional

classroom instruction (z-cal=- 2.99 < z-crit =+1.96, p =0.05) and they felt the teaching

process was more interesting as they were motivated to study more. Recommendations

include the need for science teachers to encourage blended instruction as these have been

found to encourage more favorable scientific attitudes, improved students achievement than

only conventional instructional approach.

INTRODUCTION

In the past, the most trusted way of learning was by going to school, or

employing a t eacher to teach the student. That is what we call traditional learning.

The main advantages are that; the classes are individualized and built around the

students needs, level, speed of progress and more. However, this requires students

and teachers to be present in the same place at the same time, with the

disadvantage of commuting for both the teacher and student, physical space

management (which is often a very large expense for schools) and location

constraints since a student can only choose what is offered nearby and you can

only study during times close to bus iness hours. Also, students are distanced from

their homes/ workplaces.

Obasedo, R.A; Nwaeze, U.C.; and Mba O. Mba are Senior Lectures; Department of Integrated Science while Ibe C. O; and Mbadiugha,

C.N. are Principal Lectures, Department of Chemistry, Alvan Ikoku Federal College of Education Owerri Nigeria.

2012 R. Durson Associates, @ http://www. rdursonassociates. com

INTER-WORLD JOURNAL OF SCIENCE AND TECHNOLOGY VOL.4. NO.4:1- 13

10

On the other side is the asynchronous learning which could be the book

bought audio lessons, text books, audio or mult imedia and more. This learning can

be done anytime, anywhere, at the students own pace. One of the largest problems

with the asynchronous learning is that, it is not individualized or personalized, as

its built to suit a large mass of students. It lacks the critical interaction between

students and teachers. To solve this trade- off between individualizat ion and

convenience, educators have tried to combine both offering students face to face

lessons and using one of the asynchronous learning resources for self study. We

have all learned this way by going to schools, universit ies and always having at

least one textbook for every class. The new generations now are even lucky to have

e-books and avoid those memories of back pains and hunch back. As Broadband

and Voice Over Internet Protocol (VOIP) penetration keep increasing, the internet

brings new solutions that were previously not possible in the area of education and

e- learning, fully integrat ing the tradit ional and asynchronous learning into a New

Blended Learning. There are many different approaches to blended learning,

depending on the teachers and learners involved. Currently, there is no single

agreed-upon definit ion for blended learning. The terms blended. Hybrid and

mixed-mode are used interchangeably in current research literature. In 2003, the

Amer ican society for training and development ident ified blended learning as one

of the ten trends to emerge in the knowledge deliver ing industry, Rooney (2003) in

Graham, (2004).

What is Blended Learning?

The term Blended Learning ( BL) refers to a mixing of different learning

environments. It combines traditional face to face classroom methods with more

modern computer-mediated activities. For instance, consider a traditional class

meeting schedule course from 1pm-3pm. If the institution were to apply a blended

approach, the course may change, so that it meets once per week instead of the

usual three session format. Learning activit ies that otherwise would have taken

place during classroom time can be moved online. In other circumstance, a greater

reliance on technology within the classroom may occur. Activit ies may be

INTER-WORLD JOURNAL OF SCIENCE AND TECHNOLOGY VOL.4. NO.4

11

structured around access to online resources, communication via social media or

interaction with distance learners in other classroom or other learning environment.

Singh (2003) described blended learning as a much richer set of learning strategies

or dimensions that can be blended in ways such as: offline with online, self-paled

with live, collaborative structured with instructed custom content with off- the

shelf and so on. Thus, Blended Learning ( BL) combines Information

Communication Technology (ICT) instructional packages with one or more

instructional approaches to promote the achievement of setting aims, goals, and

objectives in teaching/learning a part icular course/discipline. To an individual or

group of students. Blended learning emphasizes the need to assist learners to

maximally benefit from the resources of teaching. The goal is to ensure that a

student acquires sufficient knowledge, skills and attitudes that he subsequently

uses for his benefit and that of the society. To achieve this objective the content to

learn, resource use and learning environment is important to assist the teacher and

students.

Importance of Blended Learning

Good mix of technologies and interactions-Blended learning provides a good

mix of technologies and interactions, resulting in a socially supported

constructive learning experience.

Pacing and attendance- In most blended learning classrooms, there is the ability

to study whenever the student chooses to do so. If a student is absent, he/she

may view some of the missed materials at the same time that the rest of the

class does, even though the student cannot be physically in the classroom. This

helps students stay on track and not fall behind, which is especially helpful for

students with prolonged sicknesses or injuries that prevent them from attending

school. These self-study modules also allow learners to view certain content

at any time for help in understanding a concept or to work ahead for those

students who learn at a faster pace.

Obasedo, Nwaeze, Mba, Ibe and Mbadiugha

12

Blended learning helps to harmonize ideas

Cost effectiveness for both the accrediting learning institut ion and the learner,

accessibility to a post-secondary education and flexibility in scheduling and

time tabling of course work.

It is connected with different instruction custom-designing instruction based

on student need.

Blended learning can fit into a number of areas.

A study was carried out in Turkish educational system in 2009, to find out the

effect of blended learning on developing administrator leadership skills.

Questionnaires were applied to 72 school administrators who were selected from

33 primary schools in 11 regions of Ankara, capital city. The school administrators

were separated into 3 groups as Computer Based Learning (CBL), Blended

Learning (BL) and Traditional Learning (TL). These groups were observed

separately within the three different environments, the results of pretest, posttest

achievement scores means were observed, and BL groups score was the highest

when compared to TL and CBL groups. Also in terms of achievements and

effectiveness, BL was found to be the most effective learning environment when

compared to the others.

Another study in New Zealand schools by Sue, Pinelopi and Niki (2011)

examined online Learning Management System (LMS) as part of home economics

course in a New Zealand high school. Data collected include the observations of

online and face to face learning environments plus interviews with the teacher and

selected students. The positive outcomes of the blended course implementat ion in

this case study included opportunit ies for extended and flexible learning,

development of ICT confidence and skills, enhanced interactions, independent

learning with increased self- management and higher order thinking skills, a

variety of authentic resource and the teachers professional growth. Challenges

included students limited access to ICT. Confidence, ability to self-direct their

INTER-WORLD JOURNAL OF SCIENCE AND TECHNOLOGY VOL.4. NO.4

13

learning and interacting online, the teachers lack blended teaching experience and

limited school support and infrastructure.

Supporting others views, Chan Meiwai and Sue (2011), investigated the

effect of computer-assisted teaching and learning in the religious education of

secondary students in Hong Kong. In the study, a group of 20 students from a class

received the traditional teaching method while another group of 20 students from

another class was encouraged to learn the same content from a computer-based

simulat ion game (my young Bible Stories). The pre and posttest scores of these

two groups of students were compared. Three students from each group were also

interviewed for their comments on the different teaching and learning methods.

The results showed that students who learnt from the software obtained

signif icantly the better scores in the test and felt the learning process was more

interesting and they were motivated to student more.

According to Davis (2008); Wright (2010); Davis and Fletcher (2010)

preparing students for learning in the 21

st

century should enable them to become

autonomous lifelong learners and being proficient e-learners, as many information

sources will be accessed digitally.

Educational providers globally are adopting online education, either with

fully online taught courses that replace face to face instruction or blended courses,

where traditional instruction is enhanced with online content.

To Cavanaugh et al, (2009), enhancing student motivation, expending

educational access, providing high quality learning opportunit ies and improving

student outcomes and skill are among the benefits of online education. Some

scholars argue that blended approaches, are more suitable for school students

compared to fully online taught courses, due to the enhanced onsite support and

face to face interaction opportunities within the classroom that facilitate students to

engage more easily in self-directed learning.

Survey made by Kynog and Curtis, (2006) on the future of online teaching

and learning in higher education concluded that more emphas is expected on

blended learning instruction that combines face to face with online offerings than

on fully online courses. In addition the institut ions of higher education need to

Obasedo, Nwaeze, Mba, Ibe and Mbadiugha

14

consider whether they are ready to meet growing learner demands in the coming

years. Respondents agreed that blended learning would have greater signif icances

in higher education in the future. Although some institut ions have already

embraced blended learning, many others are slower at adopting it for various

reasons. Blended learning increases the options for greater quality and quant ity of

human interaction in learning environment Blended learning offers learners the

opportunity to be both together and apart.

Several online opt ions, in addition to tradit ional classroom training actually

increased what students learned. Also, studies showed that students interaction

and satisfaction improved with students learning more in courses that incorporated

blended learning. Currently in most Nigerian classrooms, whether primary,

secondary and tertiary institutions, learning tends to resemble a one- person show

with a captive but often comatose audience. Classes are usually driven by teacher-

talk and depend heavily on textbooks for the structure of the course. There is the

idea, that there is a fixed world of knowledge which is divided into parts and builds

into a whole concept. Teachers serve as pipelines and seek to transfer their

thoughts and meaning to the passive students. There is litt le room for student

init iated questions, independent thought or interaction between students. Research

reports revealed that negat ive att itude towards integrated science is caused majorly

by teachers conventional method of teaching int egrated science, Oludipe and

Oludipe, (2010). Teachers as sole information givers to passive students appears

outdated.

The research questions are:

Will there be difference in pretest and post test scores performance of students

taught with blended and conventional learning approach?

Will there be difference in the post test scores performance of students taught

with blended and conventional learning approach?

Do students enjoy blended learning lessons more than conventional learning

approach?

INTER-WORLD JOURNAL OF SCIENCE AND TECHNOLOGY VOL.4. NO.4

15

Does blended learning help to understand course content better than

conventional learning?

Are students more motivat ed during blended learning than during conventional

learning

The research Hypotheses are:

Ho

1

: There is no signif icant difference in the pretest and post test scores

performance of students taught with blended and conventional approach.

Ho

2

:

There is no signif icant difference in the pretest and post test scores

performance of students taught with blended approach.

Ho

3

: There is no significant difference in the post test scores performance of

students taught with blended and conventional learning approach?

Ho

4

: Students have negative attitude towards blended learning approach with

respect to, learning experience, understanding course content, and

motivat ion.

This study was carried out to determine the comparative effect of the use of

blended learning approach and conventional learning approach on the academic

performance of Integrated Science students of secondary schools in Owerri

Municipal zone, Imo State, Nigeria during their third term 2010/2011 academic

session.

This research design was a quasi- experimental design, the pretest posttest

non- randomized control group designs carried out in some randomly selected

secondary schools in Owerri Municipal Imo State Nigeria.

The population comprised 10 secondary schools in Owerri zone. Two (2)

schools were randomly sampled from 10 secondary schools in Owerri zone, Imo

State. Intact classes of Junior Secondary School (JSSII) from the sampled school

were assigned to 2 groups (blended and conventional). The JSSII students in each

sampled schools were 90 (arm A, B and C) of which 30 students from each school

Obasedo, Nwaeze, Mba, Ibe and Mbadiugha

16

were randomly selected for the study by assigning Nos 1, 2, and 3. All students

with No 3 made up group1, taught without computer software (conventional

learning approach). While all students with no 1 in the other school made up group

2, taught with conventional and computer software packages (blended learning

approach).

The independent var iables in the study are the use of blended and

conventional methods of teaching. The dependent variable in the students scores

was obtained from a research designed performance test.

Instruments used were the interview and researcher designed Performance

Test in Integrated Science (PTISC). The PTISC contained 40 items, 4 option

mult iple choice objective test developed in the units used in the study. The students

were made to select the correct answer from four options. The PTISC was used to

measure the performance of students in both pre-test and post- test. Some

intervening variables extraneous to the study such as teacher effect were controlled

by the presence of the researcher and the subject teacher in the schools.

The instrument was subjected to face and content validation using test blue

print and item analysis. The test items were carefully drawn to ensure that the

items fell within the scope of the JSSII syllabus and the specific area that was

selected for the purpose of the study. The items were referred to experts in science

education for criticisms and their observation influenced some modifications on

the instrument.

The mean, standard deviation, percentage, chi-square and the Z-test

statistical analyses were used. Scores of the different groups were computed and

used in test ing the hypotheses. The level of the significance adopted for the

analys is was p = 0.05. This level of signif icance formed the basis for

rejecting/accepting each of the hypotheses.

FINDI NGS

Five research questions were raised in this study and three null hypotheses

were formulated and tested to provide answers to the research questions. Analys is

of the pretest and post test data collected by means of students taught with blended

INTER-WORLD JOURNAL OF SCIENCE AND TECHNOLOGY VOL.4. NO.4

17

and conventional learning approach was used to answer the questions using the

three null hypotheses as guide. Mean, Standard deviat ions and the Z test were

employed in analyzing the pretest and post test data while chi-square (X

2

) and

percentage (%) were employed in Ho

3.

Summary of the data analyses and results are presented below:

Table 1: There is no Significant Difference in the Pretest and Post Test

Scores Performance of Students Taught with Conventional Approach.

Variable N X S.D Std. Error *Z cal **Zcrit Remark

Pre-test 30 4.60 1.50 0.89 4.64 +1.96

Post-test 30 8.73 4.61 Reject

Significant at 0.05

The result in Table 1 indicates that there is significant difference at 0.05 level of

signif icance between the pre and posttest mean scores of students taught with

conventional method.

Table 2: There is no Significant Difference in the Pretest and Post Test Scores

Performance of Students Taught with Blended Approach

Variable N X S.D Std. Error *Z cal **Zcrit Remark

Pre-test 30 6.20 1.42 0.89 0.84 +1.96

Post-test 30 12.2 4.37

Significant at 0.05

In table 2, result revealed that Z cal = 7. 14 is greater than Z crit +1.96 so, we reject

the null hypothesis and conclude that the pre-test mean score was signif icantly

different from the posttest mean score with regards to blended learning.

Obasedo, Nwaeze, Mba, Ibe and Mbadiugha

18

Table 3: There is no Significant Difference in the Post Scores Performance of

Students Taught with Conventional and Blended Learning Approach

Variable N X S.D Std. Error *Z cal **Zcrit Remark

Post GP1 30 8.73 1.35 1.35 -2.99 +1.96 Reject

Post Gp2 30 12.20

The result of Z-test analysis in table 3 shows that there was significant difference,

since Z Cal = -2.99 > +1.96. This implies that the there is significant difference

between GP1 and GP2.

Table 4: Students Attitude towards Blended Learning Approach With

Respect to Learning Experience, Understanding Course Contests and

Motivation.

Enjoy Blended Leaning Lessons

Not at all A Little A lot X

2

Cal

Observed 0.00 2.00 13.00

Expected 5.00 5.00 5.00

% 0.00 13.30 86.67

Understanding Content More Than Taught Conventionally

Not at all A Little A lot X

2

Cal

Observed 0.00 2.00 13.00

Expected 5.00 5.00 5.00

% 0.00 13.3 86.67

INTER-WORLD JOURNAL OF SCIENCE AND TECHNOLOGY VOL.4. NO.4

19

Motivation

Understanding Content More Than Taught Conventionally

Not at all A Little A lot X

2

Cal

Observed 0.00 1.00 14.00

Expected 5.00 5.00 5.00

% 0.00 6.67 93.33 63.60

Significant at 0.05

Table 4 shows that students have positive attitude toward blended learning

approach with respect to learning exper ience, understanding course contents and

motivat ion. The percentages of students who enjoy blended learning lesson is

86.67% while the percentage of students who enjoy it a litt le is 13.30%, similar ly

86.67% of students understand Blended Learning content more than taught

conventionally while 13.300% understands a litt le of the content, also 93.33% of

students were motivated using blended approach and 6.67% were motivated a

little. Therefore, we can conclude that students have pos itive att itude to blended

learning.

Supporting this notion, Cavanaugh e t al (2009), said some scholars argue

that blended approaches, are more suitable for the school students compared to

fully online tough courses, due to the enhanced onsite and face to face interactions

opportunities within the classroom that facilitate students to engage more easily in

self-directed learning. Moreso, study by Sue, Prinelopi and Niki in Newzeland

Schools (2011) revealed that the posit ive outcome of blended learning exist as;

opportunities for extended and flexible learning, development of ICT confidence

and skills, enhanced int eractions, independent learning with increased self-

management, higher order thinking skills, a variety of authent ic resource and the

teachers professional growth.

Obasedo, Nwaeze, Mba, Ibe and Mbadiugha

20

Again, students preferred the blended learning to conventional learning

approach. To Cavanaugh (2009), online education enhances student motivat ion,

expending educat ional access, providing high quality learning opportunit ies and

improving students outcomes and skills.

CONCLUSION

The study investigated whether blended learning/teaching could be a better

pedagogy to conventional learning/reaching that is currently the norm in teaching

Integrated Science in Nigerian schools. Literature on this study revealed that

blended learning mot ivates students to learn more. The pretest and post test scores

of students taught with blended and conventional learning approach where

compared statistically. The result revealed that students taught with blended

approach (conventional method and computer software packages) performed better

then their counterparts taught with only conventional method. The implication of

using blended learning/ teaching approach is shift in paradigms in the roles of

teachers and students. For example, the teacher is seen as a facilitator not an

instructor while the learner is interactive not passive.

RECOMMENDATION

In consideration of the findings and implicat ions, the researchers made the

following recommendations:

* Specialist subject teachers should venture into electronic publishing.

* Parents and guardians of school children should be encouraged to finance

the purchase of ICT materials.

* There should be provision for electricity in schools. The government should

make effort to supply schools with low capacity generating sets.

* Finally, it is very necessary that Educational Resource Centers be

established in every secondary school to house facilit ies such as Computers,

Television Monitors; packs of Video Compact Disc (VCD), videotaped, as

well as the electric generating sets.

INTER-WORLD JOURNAL OF SCIENCE AND TECHNOLOGY VOL.4. NO.4

21

REFERENCES

Cavanaugh C.S., Barbour M.K. and Clark T. (2009) Research and Practice in

K-12 Online Learning. A Review of Open Access Literature, International

Review of Research in Open and Distance Learning, 10 (1), 1-22.

Davis, N.E. (2008). How May Teachers Learning Be Promoted for Educational

Renewal with Its Models and Theories of it Diffusion. In J. Voogt and G. J

Knezek (Eds.), International Handbook of Information Technology in

Primary and Secondary Education (PP.507-519). New York: Springer.

Davis N.E. and Fletcher, J. (2010),E-learning for Adult Literacy, Language and

Numeracy: Summary Report Wellington: Ministry of Education. Retr ieved

February 10, 2011 from htt/www.education/7697.

Kynog and Cufrtis (2006), The Future of Online Teaching and Learning in

Higher Education: A Survey Substant iates Some Ideas About Online

Learning and Refutes Others.

Oludipe and Oludipe (2010) Effect of Constructivist Based Teaching Strategy

on Academic Performance of Students in Integrated Science at the Junior

Secondary Level.

Singh H. (2003). Building Effective Blended Learning Programs, Educational

Technology 2003:44 (1); 5-27.

Sue.P. Pineio Z., Niki D. (2011), The First Blended or Hybrid Online Course in

New Zealand Secondary School, Computer in New Zealand Schools Vol.23

N0 1 (2011).

Sue, T. and Chan Mei Wai B. (2011) Using A Computer Base Simulat ion

Game to Enhance Secondary Students Learning of Christian Education.

Wright, N. (2010). E- Learning and Implications for NewZealand Schools; A

Lit erature Review, Wllington, New Zealand: Ministry of Education.

Retrieved August 6, August 6, 2010, from http://www. education counts

go.nz/publicat ions/ict/77614 Vol. 23, (2011).

Obasedo, Nwaeze, Mba, Ibe and Mbadiugha

22

Evaluation of the Nutrient Content of Avocado

Seed (Persea Americana)

Okere C.S.; Ogwo V.; Okorie A., Osuoha V., Ukpai

Kalu U; and Azoro A. V.

The evaluation of the nutrient content of avocado seed was studied The

purpose was to evaluate the nutrients, acceptability of the products and

using different processing methods to know the significant difference

between the processed avocado seeds. The seeds were boiled, fermented,

roasted and sundried. There was a significant difference (P 0.05) in the

energy content of the processed avocado seeds but non in the other

nutrients.The energy content was highest (333.94 314.45 kcal) followed

by the carbohydrate (8062-75.59%), moisture (11.60 -9.90%) crude fibre

(6.16-3.86%), ash (6.15-2.30%), Fat (1.24 0.58%) and protein (1.23-

0.35%). The boiling and fermentation process had the highest effect on

the avocado seed composition followed by roasting and sun drying which

was seen in the result. The boiled (6 hrs) + fermented avocado seed was

the most accepted

INTRODUCTION

The avacado (Persea Americana) is a tree nat ive to central mexico,

classified in the f lowering plant family as Laurancea. They are commercially

valuable and are cult ivated in tropical and Mediterranean climat es throughout the

world.

It is estimated that Mexico is the largest producer (1,040.3901 metric tones)

with Ethiopia having the smallest quantity (81, 50610 metric tones), and Niger ias

quantity is (170,100 metric tones) as one of the producers of avocado seed in

Africa World Bank, (2009).

Cultivars of avocado include Hass, Gwen, Lula, pinkerton, Reed, Fuerts,

Sharwil, etc with the Hass cultivar as the most common in Nigeria and worldwide

Lu et al, (2005). It produces fruit year round and accounts for 80% of cultivated

avocados in the world. Hass trees have medium sized (150 250g) ovate fruits

with black, pebbled skin. The flesh has a nutt ing, rich flavour with 19% oil while

the seed has a crude fat of 18.63%, Lu et al (2005).

Okere. ; Ogwo V. O. ; Osuoha, V; Ukpai Kaluand Azoro, A. V. areLecturers, Department of Biology, Alvan Ikoku Federal College of Education while Okerie, A

is Lecturer, Department of Nutrition and Dietetics , Imo State University Owerri, Nigeria.

2014 R. Durson Associates @http://www. rdurson associates. com.

n Associates, @ http://www. rdursonassociates. com

INTER-WORLD JOURNAL OF SCIENCE AND TECHNOLOGY VOL.4. NO.4:14-21

23

INTER-WORLD JOURNAL OF SCIENCE AND TECHNOLOGY VOL.4. NO.4

Once the edible pulp is separated, the skin and seed are left as residues. The seed

has lower lipid content than pulp, therefore, lipids are not considered important in

processes such as the obtaining of oil, Lee (1981).

In addition, enzymes and substances with antibiotic and antimicrobial

characteristics maybe found in the stone. The seeds maybe used to extract tannins

and pigments. Furthermost avocado stones may have some compounds that avoid

the browning of the Fruit Canto (1980).

In the present study, the Nutrient proximate composition of processed

avocado seeds. From Hass cultivar were evaluated

MATERIALS AND METHODS

The experiment was carried out at the research centre Michael Okpara

University of Agriculture Umudike. The avocado seed variety used in this study

were bought form Owerri main market Imo State. Proximate analys is was carried

out as indicated below.

Proximate Composition

Determinat ion of Moisture content

This was done by the gravimetric method AOAC (2005). A measured weight of

sample 2.0g was weighted into a previously weighed moisture can. The sample in

the can was dried in the oven at 105

o

C for 3hrs. It was cooled in a desicator and

weighed. It was then returned to the oven for further drying.

Drying, cooling and weighing were done repeatedly at hour ly (one hour)

internal until there was no further demination in weight (ie content weight was

obtained).

The weight of moisture loss was calculated and expressed as a percentage of

the weight of sample analyzed. It was given by the expression below

% Moisture = 100 x w2 w

3

1 w

2

w

1

24

Okere, Ogwo, Okorie, Osuoha, Ukpai and Azoro

where w

1

= weight of empty can

W

2

= weight of empty can + sample before drying

W

3

= weight of can + sample dried to constant weight

Determination of Protein.

This was done by Kjeldahi method described by Change, (2003). The total

Nitrogen (N

2

) was determined and mult iplied with factor 6.25 to obtain the protein

content. One gram of the sample was mixed with 10mls of conc H

2

SO

4

in a

digestion flask.

A tablet of Selenium catalyst was added to it before it was heated under

fumed cupboard until a clear solut ion was obtained ( ie the digest). The digest was

distilled to 100mls in a volumetric flask and used for the analysis 100mls of the

digest was with mixed equal volume of 45% NAOH solut ion in a kjeldahi

distillat ion apparatus. The mixture was distilled into 10mls of 4% buric acid

containing 3 drops of mixed indicator (methyl red). A total of 50mls of distillate

was collected and titrated against 0.2 EDTA from green to deep red and end point.

A blank reagent was digested & titrated. The nitrogen content and hence the

protein content was calculated using the formular below.

1ml of IN H

2

SO

4

= 14mg N

2

% protein = % N

2

x 6.25

% N

2

= (100 x Nx1.4 x vt) T xB

w 1000 va

where

w = Weight of Sample (1g)

N = Normality of titrent (0.02 N, H

2

SO

4

)

vt = Total digest volume (100mls)

T = Sample titre value

B = Blank t itre value

Va = Volume of digest analyzed (10mls)

25

Determination of Fat

This was determined by the continuous solvent extraction in a soxhlet

apparatus. 2g of the sample was wrapped in a weighed absorbent paper (whatman

No 1. filt er). The wrapped sample was put in a soxhlet ref lux flask. The flask was

mounted unto an oil extraction flask containing 30mls petroleum ether. The upper

of the reflux flask was connected to a condenser. The ether in the flask was heated

by means of hot plate and boiling ether vapour condenses with the reflux flask

thereby vapour condenses with the reflux flask thereby covering wrapped sample

completely the sample was thus immersed in the ether unt il the f lask filled up and

siphoned over hereby carrying the extracted oil (fat) down to the boiling flask. The

process was allowed to continue for up to 4 hrs. The defatted wrapped sample was

carefully removed, dr ied in the oven at 105

o

C for an hour and weighted after

cooling in a desicator. The fat content was calculated as shown below.

% flat = w

2

w

3

x 100

w

2

w

1

1

where w

1

= weight of empty filter paper

W

2

= weight of filter paper + sample before defatting

W

3

= weight of filter paper + sample after defatting.

The defatted sample was reserved for crude fibre analysis.

Determination of Ash

This was done by the furnaces inceneration gravimetric method James,

(1995). Two grams (2g) of the processed sample was measured into a previously

weighed porcelain crucible. The sample was burnt to ashes in a muffle furnace at

550

o

C. When it has become completely ashed, it was cooled in a dissector and

weighed. The weight of ash obtained was calculated by difference and expressed as

a percentage of the weight of sample analyszed as shown below.

% ash = 100 x w

2

w

1

1 wt of sample

where

W

1

= weight of empty crucible

W

2

= weight of crucible + ash

INTER-WORLD JOURNAL OF SCIENCE AND TECHNOLOGY VOL.4. NO.4

26

Okere, Ogwo, Okorie, Osuoha, Ukpai and Azoro

Determination of Crude Fibre

The wend method (James 1995) was employed 2.0g of the processed sample

was boiled in 150mls of 1.25% H

2

SO

4

solution for 30 minutes under reflux. The

boiled sample was washed in several portions of hot water using a two fold

muslim cloth to wrap the partic les. It was returned to the flask and boiled again in

150mls of 1.25% NAOH for another 30 minutes under same condition. After

washing, the several portion of hot water, the sample was allowed to drain dry

before being transferred quantitatively to a weighted crucible where it was dried in

the oven at 105

o

C to a constant weight. It was therefore taken to a muffle furnace

in which it was burnt until only ash was left in it.

By difference, the weight of fibre was obtained and expressed a percentages

of the weight of sample analyzed as shown below

Where

% crude fibre = 100(w

2

-w

3

)

Wt of Sample

W

2

= weight of crucible + sample after boiling, washing and drying

W

3

= Weight of crucible + samples ash

Determination of Carbohydrate and Energy.

Total carbohydrate was determined by difference (total carbohydrate = 100 -

(protein + % ash + % moisture + % fat)

Energy = % crude protein x 4 + % fat x 9 + % carbohydrate x 4.

RESULT AND DISCUSSION

From the table below there was no significant difference at ( 0.05) in the

samples, in terms of their moisture, ash, protein, fat, carbohydrate, energy and

crude fibre but a significant difference exists between some of the samples in terms

of their energy value. The moisture content of the various samples ranged from

9.0% - 11.60%. The moisture content of the boiled (6hrs) + fermented (9.90%) was

27

INTER-WORLD JOURNAL OF SCIENCE AND TECHNOLOGY VOL.4. NO.4

the least with that of boiled only (11.16%) as the highest, followed by that of the

sundried (11.20%), boiled (3 hrs) + fermented (10.80%) and roasted (10.75%). the

ash content of the sundried avocado seed (6.15%) is the highest and the boiled

(3hrs) + fermented avocado seed (2.3%) as the least. The roasted avocado seed

(0.58%) had the least fat content with that of the boiled (6hrs) + fermented (1.24%)

as the highest. The protein content of the boiled avocado seed (1.23%) was highest

with that of the boiled (6hrs) + fermented avocado seed (0.35%) as the least. The

carbohydrate content of the boiled (3hrs) + fermented (80.62%) was the highest

with that of the sundried avocado seed (75.59%) as the least. The energy (kcal)

content is highest in the boiled 3hrs fermented avocado seed (333.94kcal) with the

sundreid avocado seed (314.45 kcal) as the least. Then the crude fibre content was

highest in the roasted avocado seed with that of the boiled (6hrs) + fermented

avocado seed (3.86%) as the least. The energy (kcal) content is very high in all the

processed avocado seeds (333.94 314.45kcal). Processed avocado seeds had a

very how protein content.

28

Okere, Ogwo , Okorie, Osuoha, Ukpai and Azoro

PROXIMATE COMPOSITION OF PROCESSED AVOCADO SEED

Sample Moisture Ash Protein Fat Carbohydrate Energy

(Kcal)

Crude Fibre

Boiled (6hrs) fermented

Avocado Seed

9.900.1

4

a

4.450.

20

a

0.350.

00

a

1.240.

01

a

80.210.36

a

333.241.50

a

3.860.

01

a

Boiled (3hrs) fermented

Avocado Seed

10.800.

28

a

2.300.

14

a

0.530.

53

a

1.040.

01

a

80.210.13

a

333.940.60

a

4.720.

01

a

Sundried Avocado Seed 11.201.

39

a

6.150.

08

a

0.000.

24

a

1.030.

12

a

75.590.92

a

314.454.87

a

z

5.230.

01

a

Roasted Avocado Seed 10.750.

20

a

3.600.

00

a

0.700.

00

a

0.580.

01

a

78.220.23

a

320.840.87

a

6.160.

01

a

Boiled Avocado Seed 11.600.

24

a

3.750.

07

a

0.232.

24

a

1.100.

14

77.720.87

a

325.681.24

a

b

4.610.

01

a

Note: Samples with different superscripts indicate signif icant difference at 0.05 confidence level from each other

21

INTER-WORLD JOURNAL OF SCIENCE AND TECHNOLOGY VOL.4. NO.4

REFERENCE

AOAC (2005): Official Methods of Analysis Association of Official analytical

Chemists, Washington DC Hornworts wand Latin G.W. 18

th

Edition. PP. 14.

Change, S.M.K (2003): Protein Analysis in Food Analysis. 3

rd

Edition Kluwet

Academic/Plenum Publishers, New York.

James C.S. (1995): The Analytical Chemistry of Foods. Chapman and Hale, New

York.

Lee S (1981) Methods for Percent Oil Analysis of Avocado fruit. Calif. Avoc. Soc.

Yearb. 65:133-141

LU Q.Y Arteage J.R, Zhang Q, Huertas, GO V.L and Herber D (2005). Inhibition of

Prostrate Cancer Cell Growth by an Avocado Seed Extract. Role of lipid

Soluble Bioactive Substances. Journal of Nutrition and Biochemistry 166: 23-

30.

World Bank (2009): World Development Indicators (Database).

22

Natural Petroleum: Chemistry and Valuable

Products Fractions

Azunna I.B. Ekejiuba

Petroleum exist in all three physical states of nature; gas, liquid, semisolid or solid.

Thus, we distinguish between gaseous petroleum Natural gas, liquid petroleum: Crude

Oil, semisolid and solid petroleum Coal tar, Bitumen, Asphalt etc. Therefore, no two

petroleum occurring in different reservoirs are exactly alike, for each consists of mixtures

of countries different hydrocarbons, each has different characters and qualities in the basic

elements. Subsequently, the chemistry of petroleums a part of organic chemistry (generally

divided into two class: aromatic and aliphatic), since the bulk of the compounds found in

most petroleum are hydrocarbons; which are grouped in families known as homologous

series, such that if the behavior of one member of the series is known in detail, it is possible

to predict with remarkable accuracy the probable behavior of any other member. Liquid

petroleum is called crude oil to distinguish it from refined oil. Although it is hardly ever

possible to use petroleum (crude oil or nature gas) as such, the liquids and gases of which

they are composed are very useful indeed, for they are the products we use and depend

upon. The various liquids that together make up crude oil are known as fractions, and the

process of distillation results in various fractions which boil at different temperatures.

Since the composition of the various crude oil from different parts of the world and

different reservoirs various, the compositions of the fractions thus collected also vary

according to the source, but usually it follows the broad pattern illustrated on figure 5 and

tables 7 & 8. Similarly, due to the variety of natural gas constituents, it finds wide

application as wither an energy source or as feed stock to the chemical / petrochemical

industries. Generally, this process of linking together many similar simple units (or bricks)

to form larger more complex molecules is known as Polymerization, the product being

known as a polymer and the simple units as monomers; table 9. Thus petroleum, apart

from serving the traditional purposes, is now the chief source of raw materials of the

manufacture of chemicals especially organic chemicals, such as textiles, artificial fibres,

plastics of all descriptions, rubber, nitrogen fertilizers, dyestuffs, detergents and

pharmaceuticals.

INTRODUCTION

Collectively, petroleum (natural gas or crude oil) is a mixture of naturally

occurring hydrocarbons which may exist in the solid, liquid, or gaseous states,

based on pressure and temperature it is subjected to, on the earth.

INTER-WORLD JOURNAL OF SCIENCE AND TECHNOLOGY VOL.4. NO.4:22-53

Azunna I.B. Ekejiuba a Chartered Engineer is SeniorLecturer, Department of Petroleum Engineering Federal University of Technology

Owerri, Nigeria

2011 R. Durson Associates, @http://www. rdursonassociates. com

23

Virtually all petroleum is produced from the earth in either gaseous or liquid form,

although it could exits also in the semisolid or solid such as hydrates, bitumen and

asphalt. Thus petroleum generally refers to crude oil and natural gas;

In the early days, around 1859, when Colonel Edwin Drake drilled the first

well, crude oil was the material most sought after of these naturally occurring

hydrocarbons, while natural gas was considered to be a nuisance and was burned at the

well site. Then also, the main aim of refining the crude oil was to produce lubricants

and illuminating fuel (kerosene for lamp oil), while gasoline was flared off.

Precisely, beginning with the Industrial Revolution of the early nineteenth

century, due to the development of internal-combustion engines and other devices, the

use of petroleum for fuel (gasoline) became increasingly important. Gasoline later

became the essential ingredient of twentieth century life. Subsequently, with the

advent of transcontinental transmission lines and petrochemical industries, during the

late twentieth and the early twenty-first (21st) century the demand for natural gas as a

fuel and a raw material for many modern industries such as paints, plastics, rubber

etc., increased the value of natural gas; to the point where it is now regarded as the

fastest growing primary energy source and the fuel of the twenty-first (21

st

) century.

No two petroleum (natural gas or crude oil) occurring in different reservoirs are

exactly alike, for each consists of mixtures of countless different hydrocarbons, each

has different characters and qualities in the basic elements.

The typical chemical analysis, however, of crude oil, Natural gas and natural

asphalt are rather uniform and fall within a general pattern.

Table 1: Typical Chemical Analysis of Crude Oil, Natural Gas and

Asphalt

Element Crude of %

wt.

Asphalt %

wt.

Natural gas %

wt.

Carbon 82.2-87.1 80-85 65-80

Hydrogen 11.7-14.7 8.5 -11 1-25

Sulfur 0.1-5.5 2-8 Trace-0.2

Nitrogen 0.1-1.5 0-2 1-15

Oxygen 0.1-4.5 - -

Therefore, crude petroleum is an extremely complex mixture of Hydrogen and Carbon, with

minor amounts of nitrogen, oxygen, and sulfur etc as impurities. Thus, the molecular constitution of

crude oils differs widely (about 18 series of hydrocarbons have been recognized in crude petroleum).

For example, natural gas is composed largely of the lower-molecular weight hydrocarbons of the

paraffin series. Methane and ethane frequently comprise 80 to 90 per cent by volume of a natural gas

while other hydrocarbons (propane to decane), together with impurities such as carbon dioxide,

nitrogen and hydrogen sulfide, helium, other inert rare gases compose the remaining percentage.

INTER-WORLD JOURNAL OF SCIENCE AND TECHNOLOGY VOL.4. NO. 4

24

RAW PETROLEUM CHEMISTRY

The chemistry of petroleum is a part of organic chemistry, since the bulk of the compounds found

in most petroleum are hydrocarbons. Hydrocarbons can be classified into essentially four categories

depending on the structural formula. Two of the categories refer to the structural arrangement of the

carbon atoms in the molecule. These are:

Open chain and

Ring or cyclic compounds.

The remaining two categories refer to the bonds between the carbon atoms. These are;

* Saturated or single bond and

* Unsaturated or multiple-bond compounds.

(a) The saturated hydrocarbons, that is, those that have all the carbon atoms linked to each other

by single electron-pair bonds.

(b) The unsaturated hydrocarbons, that is, those that contain one or more carbon carbon

multiple bonds.

Furthermore, hydrocarbons are grouped in families known as Homologous series, such that all the

members have formulae which fit the general formula of the series, thus they have very similar

general physical and chemical properties which vary more or less regularly from member to member.

For instance, the boiling and melting points increase as we go up the series, while solubility in a

particular solvent may either increase or decrease progressively depending on the nature of the

solvent, and the same type of gradation is noted in their reaction towards reagents etc.

Usually, if the behaviour of one member of the series is known in detail, it is possible to

predict with remarkable accuracy the probable behaviour of any other member.

Table 2:Boiling and Melting Points of Hydrocarbon

o

C

Compound Molecular Boiling Melting

Weight Point Point

Methane 16 -161.5 -184

Ethane 30 -88.3 -172

Propane 44 -42.7 -189

Benzene 78 80 5

Cyclohexane 84 81.4 6.5

Naphthalene (C

10

H

8

) 128 217.9 80.2

The Principal homologous series of hydrocarbons are shown in the table belo

Ekejiuba

25

Table 3: Homologous Series

Name Formula Familiar Member

Alkane or Paraffin C

n

H

2n+2

Methane CH

4

(predominant)

Ethane C

2

H

6

Propane C

3

H

8

Butane C

4

H

10

Octane C

8

H

18

C

5

H

12

Pentane

C

6

H

14

Hexane

C

7

H

16

Heptane

Olefine or Alkene C

n

H

2n

Ethylene C

2

H

4

C

3

H

6

Propene

C

4

H

8

Butene

Acetylene or Alkyne C

n

H

2n-2

Acetylene C

2

H

2

Cycloparaffin or naphthenes CnH

2

n Cyclopentane C

5

H

10

Benzene C

n

H

2n-6

Benzene C

6

H

6

Toluene - C

6

H

5

CH

3

Generally, Cycli c or Ri ng Hydrocarbons are of three kinds: naphtheni c, aromatic, and xylene

hydrocarbons.

Naphthenic hydrocarbons are saturated cyclic hydrocarbons with formula C

2

H

2n

C

3

H

6

Cyclopropane

C

4

H

8

Cyclobutane

C

5

H

10

Cyclopentane

C

6

H

12

Cyclohexane

Aromatic hydrocarbons are unsaturated cyclic hydrocarbons

- Benzene

- Toluene (Methyl benzene)

- Ethyl benzene

Xylenes are hydrocarbons in which two or more methyl groups or side chains are

attached to the benzene ring. There are three isomers:

- Orthoxylene

- Metaxylene

- Paraxylene

INTER-WORLD JOURNAL OF SCIENCE AND TECHNOLOGY VOL.4. NO4.

26

Single Double Triple

H H

| |

H H H C = C

| \ / / \

H C H C C H C C H

| / \ \\ //

H H H C C

| |

H H

Methane Ethylene Acetylene Benzene

CH

4

C

2

H

4

C

2

H

2

C

6

H

6

Cycloalkanes are alkanes that have rings e. g.

Cyclopentane Cyclohexane Cyclopropane

C

5

H

10

C

6

H

12

C

3

H

6

The International Union of Chemistry established names of individual hydrocarbons of

the paraffin series with word endings and prefixes designating the group to which the

compound belongs. The word ending ane designates saturated hydrocarbons while

ene designates unsaturated hydrocarbons that have double bonds between carbon

atoms.

If more than one double bond exists in unsaturated hydrocarbons, the ending is

modified to indicate the number of double bonds; thus, two double bonds are

designated by diene, three double bonds by triene, etc.

Ring or cyclic compounds are designated by adding the prefix cyclo to the

name of the compound as derived from the above rules. However, the cyclic aromatic

hydrocarbons, benzenes, retain the customary names except that the ending ene is

used rather than the older forms, benzol, etc.

Although the alkene and cycloparaffin series have the same formula, they

behave chemically quite differently. In the alkene series there is a double bond double

bond present between two carbon atoms which greatly increases the chemical

reactivity of these hydrocarbons. In the cycloparaffin series the carbon atoms are

joined to each other forming a ring (such a structure is relatively inert).

Both the paraffin and the cycloparaffin series are said to be saturated because they

contain only single bonds. The other series are unsaturated because they contain either

double or triple bonds.

H C C H

Ekejiuba

27

Because alkanes (saturated hydrocarbons) contain no polar gps, they are generally

unreactive towards common reagents under normal conditions. They are called

paraffines (from latin Parvum = little and affins = affinity or attraction).

Alkenes, alternatively known as Olefins, are series of compounds of carbon and

hydrogen only having one unsaturated carbon to carbon double bond.

Alkyne is the systematic name for unsaturated hydrocarbons which contain one

carbon-to-carbon triple bond. This homologous series is usually named after the first

member of the series acetylene. Thus they are usually called acetylenes.

Generally, the compounds of organic chemistry may be divided into two

classes; aromatic and aliphatic:

Aromatic Compounds: all contain a molecular structure consisting of one or more

benzene rings, that is, its six carbon atoms are arranged in a hexagon with alternate

single and double bonds between them. One hydrogen atom is bonded to each carbon

atom.

Aliphatic compounds: include all organic compounds which do not posses a benzene

ring. Their basic structure involves chains of carbon atoms which are likely to be

straight, puckered or coiled, or branched.

The carbon atoms may also be arranged in rings which are different from the

benzene rings. Such compounds are called alicyclic compounds.

Note

In both, other functional groups such as (alcohol OH, ether O, Chloro CL,

methyl CH

3

etc) may replace the hydrogen atoms to form an almost endless variety

of either aromatic or aliphatic compounds.

From the point of view of composition, the most common organic compounds

fall into the following classes:

Hydrocarbons

Ethers

Carbohydrates

Esters

Oxidation products of hydrocarbons, including alcohols, aldehydes,

ketones, and acids

Derivatives, which are basically hydrocarbons which have one or more

hydrogen atoms replaced by functional groups.

Sources of Petroleum Organic Compounds

The basic organic compounds which serve as raw materials for the preparation

of the many specific synthetic compounds are obtained from three sources:

INTER-WORLD JOURNAL OF SCIENCE AND TECHNOLOGY VOL.4. NO. 4

28

Plant Life: Plants form the principal source of carbohydrates: sugar, starch, and

cellulose, as well as some special hydrocarbons, such as turpentine and natural rubber.

Coal Tar: When coal tar is heated in the absence of air (destructive distillation) in

huge ovens to form coke, all of the volatile matter escapes from the coal. It is collected

and condensed to a black tarry liquid called coal tar. This is the chief source of

aromatic hydrocarbons.

Petroleum (Crude Oil and Natural Gas): Crude oil is a mixture of principally

aliphatic hydrocarbons. Many of these are liquid at ordinary temperatures, and these in

turn serve as solvents for low-molecular-weight compounds which would otherwise be

gases, and high-molecular-weight compounds which would otherwise be solids.

Natural gas consists of the very light hydrocarbons which have escaped from the crude

oil solution. Petroleum is thus the chief source of aliphatic hydrocarbons.

The four hydrocarbon series that comprise most of the naturally occurring petroleum

are the:-

- normal paraffin (or alkane) series

- the isoparaffin series (or branched chain paraffins)

- the naphthene (cycloparaffin) series, and

- the aromatic (or benzene) series

In addition, we also have the asphalt type.

Asphalts are solid to semisolids with high boiling point and high molecular

weight. They are made up of cyclic hydrocarbons with substantial amount of sulfur,

nitrogen and oxygen contents.

Petroleum in its natural state is generally a brownish-green to black liquid

consisted principally of a mixture of thousands of hydrocarbons of differing molecular

weight and structure which can be divided into four groups according to their

percentage of hydrocarbons of the three series (paraffinic, naphthenic and aromatic).

The paraffin base crude usually possesses low percentage of sulphur

Naphthenic base crudes (Nigerian, Venezuela, etc) are often rich in sulphur

Aromatic base crude are quite scarce with respect to the other types, but are

produced in certain areas of Iran, Russia and Mexico

Mixed base crude represent about 75% of the total production in the world;

among them are the majority of the middle East crudes.

Ekejiuba

29

The molecular weight or number of carbon atoms present, determines the phase of the

petroleum.

C

1

- C

4

: gaseous phase

C

5

- C

40

: liquid phase

Above C

40

: solid / semisolid phase

Gaseous and solid hydrocarbons are paraffinic, while the liquid form is complex and

belong to paraffins, naphthenes and aromatics. Liquid petroleum is called crude oil to

distinguish it from refined oil. Usually, hydrocarbon is a term often used

interchangeably with Petroleum for any of its forms. Thus it stands for the generic

name for hydrocarbon. This is not strictly correct, since hydrocarbon consist only

Hydrogen and carbons, whereas petroleum contains many impurities as defined

earlier.

Hydrocarbons of the paraffin series are the most common constituents of

petroleum (e.g. crudes from Nigeria and Pennsylvania) Naphthenes are similar to the

paraffins in their chemical characteristics and they are second in importance as

constituents of petroleum.

PARAFFINIC

NAPHTHENIC

ARPMATIC ASPHALTIC

Grozny

(USSR)

Pennsylvania

Rumania

(Meot ic)

Poland

(Boryslaw)

Borneo

(Koet oi)

Rumania

(Dacic)

Japan

No. Calif.

Barneo (USSR)

Mid-Continent

Borneo (Miri)

Mexico

Gulf

Coast

Figure 1: The Relations of Constituents of Various Crude Oils.

INTER-WORLD JOURNAL OF SCIENCE AND TECHNOLOGY VOL.4. NO. 4

30

Olefins are present in only small quantities in crude oil. Aromatics comprise a

large percentage of some crudes from California and Indonesia. Aromatic oils are

more easily oxidized than paraffinic or naphthenic oils.

Natural gas is composed predominantly

the lower-molecular weight hydrocarbons of the paraffin series. Compositional

analyses of natural gases are readily obtained by low-temperature distillation,

chromatography, or mass spectrometry. Volume or mole percentages of the individual

components present are ordinarily reported through heptanes plus. The heptanes-plus

fraction includes heptane and all heavier hydrocarbons.

On the other hand, crude oil are commonly analyzed, on refining by distillation,

which separates it into many useful fractions, differing in boiling points.

Table4: Composition (In Mole Percent) of Typical Reservoir Hydrocarbons

Reservoir type Dry

gas

High-

Pressure gas

High- Pressure

Oil

Low-Pressure

Oil

Methane 91.00 72.00 56.00 14.00

Ethane 5.00 8.00 6.00 8.00

Propane 3.00 5.00 6.00 8.00

Butanes 1.00 4.00 5.00 8.00

Pentanes Trace 2.00 4.00 5.00

Hexanes Trace 2.00 3.00 5.00

Heptanes plus

(heptanes and

heavier)

- 7.00 2.00 53.00

Figure 2: An overview of Petroleum Processing from Nature to Products

OR

Exploration team

Petroleum

Productio

n

Engineer

Petroleum

Process

Engineer

Petroleum

Reservoir

Engineer

Petroleum

Drilling

Engineer

Flowstation

wellhead

Refinery

Reservoir

Ekejiuba

31

Field Processing of Petroleum (Natural Gas or Crude Oil)

Oil and gas having been produced through the well head pass into the flowline

which carry them to the flow-stations where they are separated into different

components from undesirable elements.

They are then passed on to the terminals where they are loaded for sale or for

further refining processes.

Fig. 3: Schematic Flow Diagram Illustrating Process Route and Ultimate Products of

Produced Oil and Gas (Courtesy Carl Gatlin)

CRUDE OIL REFINING

The Refining of Oil

Crude oil (petroleum) is not a simple substance but a mixture of many different

kinds of liquid (complex hydrocarbons). Although it is hardly ever possible to use

crude oil as such, the liquids of which it is composed are very useful indeed, for they

are the products we all use and depend upon.

These useful liquids must be separated, and the separation process known as

distillation is the first job of the oil refinery. Distillation is what happens when a

Plus many

other

products

derived

from

petroleum

Methane

Natural gasoline

LPG (Butane and propane)

Gasoline

P

L

A

N

T

R

E

F

I

N

E

R

Y

Gas to gasoline

Oil to

refinery

WELL

Plant

oil + gas

kerozen

Diesel fuels

Lube oils

Wax

Fuel oils

Well

Head

Separator

Gas Injection, flaring, generators, LNG

Oil Meter [tank farms or storage tank] Tankers $

Water treat dispose

INTER-WORLD JOURNAL OF SCIENCE AND TECHNOLOGY VOL.4. NO. 4

32

liquid is boiled, becomes a vapour, and is then condensed (or turned back into a

liquid) by cooling it. The various liquids that together make up crude oil are known

as fractions, and the process of distillation takes place in a tall steel tower called a

fractionating column or tower. In this process, crude oil can be separated into

fractions or groups of similar compounds that fall within a certain range of boiling

points. These fractions can be differentiated from one another by their different

volatility, odour, texture and their relative ease to ignition and burning. The

fractions are collected in horizontal trays at different heights on the column,

redistilled to improve purity and then further treated to obtain different liquid fuels

and petrochemicals.

Process Description

The fractionating column is divided into several compartments by perforated

plates called trays, each of which is maintained within a specified range of

temperature. Its temperature ranges from 400

o

C at the bottom and 40

o

C at the top.

The crude oil is first heated to about 400

o

C so that all the components are vapourised.

The vapour is then passed into the tower at the bottom, and it cools as it rises up the

column. The fractions condense to liquids at their various boiling points. Thus those

with high boiling points will not move far up the column, whereas those with low

boiling points will move towards the top, before cooling considerably for

condensation.

Figure 4: Schematic Showing Fractionating Column or Tower

The hot crude is sent into the fractionators. It enters the fractionating column at

the flash zone very close to the bottom of the column. Low pressure

steam is passed into the main column at a point below the flash zone, to strip the

hydrocarbon products as the vapour passes through the trays of the column.

Crude oil

Light lubricating oil (fuel oil)

Diesel oil

Petrol (gasoline)

Kerosene