Académique Documents

Professionnel Documents

Culture Documents

Chain Conveyor Example

Transféré par

deeptidhaCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Chain Conveyor Example

Transféré par

deeptidhaDroits d'auteur :

Formats disponibles

Practical Drive Engineering Project Planning of Drives

103

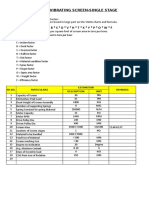

10 Calculation Example: Chain Conveyor with Frequency Inverter

10 Calculation Example: Chain Conveyor with Frequency Inverter

Input data A chain conveyor is to transport wooden boxes up a slope of = 5at a speed of 0.5

m/s. There is a maximum of four boxes each weighing 500 kg on the conveyor. The

chain itself has a weight of 300 kg. The friction factor between chain and base is

specified at = 0.2. A mechanical stop is mounted at the end of the chain conveyor

which aligns the boxes before they are pushed onto a second conveyor belt. During this

process, the box slides on the chain with a friction factor of = 0.7.

The application calls for a helical-worm gear unit that is frequency-controlled up to

approximately 50 Hz.

Velocity v = 0.5 m/s

Incline = 5

Weight of transported material m

L

= 2,000 kg

Weight of chain m

D

= 300 kg

Friction factor between chain and base

1

= 0.2

Friction factor between box and chain

2

= 0.7

Desired acceleration a = 0.25 m/s

2

Sprocket diameter D = 250 mm

Starting frequency 10 cycles/hour and 16

hours/day

00796AXX

Figure 37: Chain conveyor

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

10

104

Practical Drive Engineering Project Planning of Drives

Calculation Example: Chain Conveyor with Frequency Inverter

10.1 Motor calculation

Resistance forces

Description Slope with friction, direction of force upwards! The weight contains the weight of the four

boxes and half of the weight of the chain.

Aligning Sliding friction (box-chain) on the slope, direction of force downwards!

Efficiency of

helical-worm gear

unit

The efficiency of a helical-worm gear unit has a large degree of variation depending on

the reduction gear ratio. For this reason, we recommend calculating with a temporarily

assumed efficiency of 70 %, since the required torque and gear ratio have not been

calculated yet. This situation requires a subsequent check calculation.

The efficiency of the chain is to be calculated with 0.9 according to the table.

As the chain conveyor is operated continuously without a break, we select a motor with

a rated power that is greater than the maximum static power. A smaller motor can often

be used for short-term operation but requires an exact thermal check calculation by

SEW.

Motor selection The following motor was selected based on these conditions:

Static power

DV 132M 4 BM

P

N

= 7.5 kW

n

M

= 1,430 min

-1

J

M

= 0.03237 kgm

2

M

B

= 100 Nm

Practical Drive Engineering Project Planning of Drives

105

10 Calculation Example: Chain Conveyor with Frequency Inverter

The starting time t

A

= 2 s at an assumed acceleration of 0.25 m/s

2

.

The starting torque is based on the "worst case" scenario, i.e. four boxes are on the

chain and one of these is at the stop.

Rated torque We have already mentioned that the starting torque must be less than 130 %of the rated

torque calculated from the rated power provided by the inverter.

Selected frequency inverter, e.g. MOVIDRIVE

MDF 0075.

External moment of

inertia

Load torque

Acceleration torque

M

H

/ M

N

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

10

106

Practical Drive Engineering Project Planning of Drives

Calculation Example: Chain Conveyor with Frequency Inverter

10.2 Gear unit selection

Service factor The following service factor is determined (see the chapter on "Gear Units," required

service factor f

B

) for operation with 16 hours of operation/day and 10 cycles/hour:

Using a mass acceleration factor f

M

= 0.8 results in load classification II and service

factor f

B

1.2.

Gear unit selection You can select an S97 gear unit with n

a

= 39 min

-1

, M

amax

= 3,300 Nm and an f

B

= 2.0.

Checking the

efficiency

An efficiency of 86 % is listed for this gear unit in the geared motors catalog. Since an

efficiency of 70 % was assumed at the beginning, it is now possible to check whether a

smaller drive would be sufficient.

The next smaller motor with a rated power of 5.5 kW is too small.

Selected drive The selected drive system is: S97 DV132M 4 BMG.

Output speed

Gear unit ratio

Static power

Vous aimerez peut-être aussi

- 2kd FTV Workshop Manual PDFDocument3 pages2kd FTV Workshop Manual PDFNoVa RosiTa48% (21)

- Weber ManualDocument28 pagesWeber ManualMedardo SilvaPas encore d'évaluation

- Midterm Examination Transportation LawDocument18 pagesMidterm Examination Transportation LawjearnaezPas encore d'évaluation

- AASHTO Standard Specifications For Highway Bridges (17th Edition) PDFDocument1 029 pagesAASHTO Standard Specifications For Highway Bridges (17th Edition) PDFRelu-Razvan Tibrea83% (30)

- Simplified Steel Stair DesignDocument63 pagesSimplified Steel Stair DesignDarsHan MoHan100% (1)

- Bulk Material Handling Belt-Conveyor-CatalogDocument21 pagesBulk Material Handling Belt-Conveyor-CatalogjayPas encore d'évaluation

- JSW Toranagallu 24m Gallery DesignDocument5 pagesJSW Toranagallu 24m Gallery DesignvivekPas encore d'évaluation

- BELT FEEDER Preliminary Dimension IngDocument29 pagesBELT FEEDER Preliminary Dimension Ingshani5573100% (1)

- KTM 690 Enduro R 2016 ManualDocument220 pagesKTM 690 Enduro R 2016 ManualStefanPas encore d'évaluation

- Conveyor CalculationDocument40 pagesConveyor CalculationAnonymous 5XvUbWynnPas encore d'évaluation

- Bucket ElevatorsDocument16 pagesBucket Elevatorssdmel100% (3)

- Screw Conveyor CalculationDocument1 pageScrew Conveyor CalculationRavindra RautPas encore d'évaluation

- Conveyor design parameters for slag ash materialDocument33 pagesConveyor design parameters for slag ash materialMustafa AkbarPas encore d'évaluation

- Ropeway SystemsDocument16 pagesRopeway SystemsSripuja MishraPas encore d'évaluation

- Beam Deflection CalculationDocument2 pagesBeam Deflection CalculationAriful IslamPas encore d'évaluation

- Hoisting and Rigging Plan ChecklistDocument5 pagesHoisting and Rigging Plan ChecklistRaja GuruPas encore d'évaluation

- M 275 ContentDocument40 pagesM 275 ContentAnonymous DQ4wYUmPas encore d'évaluation

- Chain Conveyors Design Calculation 400 TDocument3 pagesChain Conveyors Design Calculation 400 TAbderrahim AbarayPas encore d'évaluation

- Gearhead and Motor Selection GuidelinesDocument2 pagesGearhead and Motor Selection GuidelinesKarim FawziPas encore d'évaluation

- Apron Weigh FeederDocument4 pagesApron Weigh FeederRaji SuriPas encore d'évaluation

- Chain Breaking Load CalculationDocument1 pageChain Breaking Load CalculationDebkumar958Pas encore d'évaluation

- BELT CONVEYOR DESIGN FORMULASDocument3 pagesBELT CONVEYOR DESIGN FORMULASwidyaditya8Pas encore d'évaluation

- Conveyor Design Summary ReportDocument1 pageConveyor Design Summary ReportAlejandro Castro0% (1)

- Screw ConveyorDocument4 pagesScrew ConveyorRaji SuriPas encore d'évaluation

- Conveying Material Screw Conveyor HP CalculationDocument36 pagesConveying Material Screw Conveyor HP CalculationMugurelVasilescuPas encore d'évaluation

- Underwater Hull Cleaning and Diving Survey in Vietnam AsiaDocument54 pagesUnderwater Hull Cleaning and Diving Survey in Vietnam AsiaInspectionPas encore d'évaluation

- Apron FeederDocument2 pagesApron FeederRaji Suri100% (1)

- Belt Conveyor CalculationDocument8 pagesBelt Conveyor CalculationFarrahxviiiPas encore d'évaluation

- Bulk material chain conveyors design and maintenanceDocument11 pagesBulk material chain conveyors design and maintenancesgupta_61579683% (6)

- 23T Truck Mounted Crane with Maximum Reach of 16.6mDocument2 pages23T Truck Mounted Crane with Maximum Reach of 16.6mAnonymous e3yfLHTBv100% (1)

- Conveyor Screws PDFDocument9 pagesConveyor Screws PDFldavilaluceralPas encore d'évaluation

- RENOLD CHAIN DOUBLE PITCH SPROCKET DESIGN SPECIFICATIONSDocument1 pageRENOLD CHAIN DOUBLE PITCH SPROCKET DESIGN SPECIFICATIONSWaris La Joi Wakatobi0% (1)

- Design and Analysis of Screw Conveyor at Inlet of Ash/Dust ConditionerDocument6 pagesDesign and Analysis of Screw Conveyor at Inlet of Ash/Dust ConditionerMohd HafizzPas encore d'évaluation

- Bucket Elevator Design StudyDocument24 pagesBucket Elevator Design StudyIrfan AhmedPas encore d'évaluation

- CHAIN PULL AND POWER CALCULATION FOR HORIZONTAL AND INCLINED CONVEYORDocument2 pagesCHAIN PULL AND POWER CALCULATION FOR HORIZONTAL AND INCLINED CONVEYORdeddy ariyanto100% (1)

- Hoist DesignDocument16 pagesHoist DesignluisparedesPas encore d'évaluation

- Belt Tension CalculationDocument5 pagesBelt Tension Calculationmanoj983@gmail.comPas encore d'évaluation

- Boru Bant Versiyon 3Document38 pagesBoru Bant Versiyon 3Hasan arif KısaalioğluPas encore d'évaluation

- Calculate Bucket Elevator CapacityDocument2 pagesCalculate Bucket Elevator CapacityBùi Hắc HảiPas encore d'évaluation

- Conveyor Chains TsubakiDocument184 pagesConveyor Chains Tsubakitepu msosaPas encore d'évaluation

- Screw Conveyor Excel CalculationDocument8 pagesScrew Conveyor Excel Calculationhardik033Pas encore d'évaluation

- BELT CONVEYOR - Discharge TrajectoryDocument1 pageBELT CONVEYOR - Discharge TrajectoryEslam FaroukPas encore d'évaluation

- Vibrating ScreensDocument3 pagesVibrating ScreensvinodsnPas encore d'évaluation

- Screw Conveyor CalculationDocument1 pageScrew Conveyor Calculation113314Pas encore d'évaluation

- Bucket Elevator Calculation for Quang Trach 1 Thermal Power PlantDocument8 pagesBucket Elevator Calculation for Quang Trach 1 Thermal Power PlanthbookPas encore d'évaluation

- CCE-TMS-300 Track Construction Requirements and TolerancesDocument58 pagesCCE-TMS-300 Track Construction Requirements and TolerancesSamuel Carlos Sanjuán TorresPas encore d'évaluation

- Belt Conveyor Drive Sizing CalculationsDocument3 pagesBelt Conveyor Drive Sizing Calculationsmishra_1982Pas encore d'évaluation

- The Design of Conveyor PulleysDocument10 pagesThe Design of Conveyor PulleysJam BabPas encore d'évaluation

- Article PT3 ESSAY - Form 2 - Exam 2b (KELVIN)Document2 pagesArticle PT3 ESSAY - Form 2 - Exam 2b (KELVIN)Kelvin83% (6)

- Belt Bucket Elevator DesignDocument14 pagesBelt Bucket Elevator Designking100% (1)

- Line-by-line conveyor code for material handling parameters and calculationsDocument4 pagesLine-by-line conveyor code for material handling parameters and calculationskmats2Pas encore d'évaluation

- TS of Travelling TripperDocument10 pagesTS of Travelling TripperShashank HegdePas encore d'évaluation

- 45 TPH DRAG CHAIN CONVEYOR DESIGNDocument7 pages45 TPH DRAG CHAIN CONVEYOR DESIGNImam SampoernoPas encore d'évaluation

- Design of ConveyorsDocument15 pagesDesign of ConveyorsRamachandran VenkateshPas encore d'évaluation

- Conveyor Tension and Trajectory CalculationDocument8 pagesConveyor Tension and Trajectory CalculationGregory Nick Toledo Veliz50% (2)

- Belt Conveyor Take Up DesignDocument4 pagesBelt Conveyor Take Up DesignKroya HunPas encore d'évaluation

- Careem PakistanDocument20 pagesCareem PakistanSana Ambreen50% (2)

- 5566 Drag ConveyorsDocument8 pages5566 Drag ConveyorsEduardo SaucedoPas encore d'évaluation

- Rotary Airlock FeedersDocument28 pagesRotary Airlock Feederslhphong021191Pas encore d'évaluation

- Bucket Elevator Capacity Formulas REVISEDDocument1 pageBucket Elevator Capacity Formulas REVISEDbrpnaidu2157Pas encore d'évaluation

- Belt Conveyor PowerDocument10 pagesBelt Conveyor PowerRyukiPas encore d'évaluation

- Slat ConveyorDocument8 pagesSlat ConveyorpkjddjsydPas encore d'évaluation

- Chain Conveyor Design Calculation for 400 TPH Drag ConveyorDocument3 pagesChain Conveyor Design Calculation for 400 TPH Drag Conveyorsudip giriPas encore d'évaluation

- Screw ConveyorsDocument4 pagesScrew ConveyorsAshish SharmaPas encore d'évaluation

- Chain Conveyor CapacityDocument1 pageChain Conveyor Capacitysubathramesh100% (1)

- Screw Conveyor RatingDocument6 pagesScrew Conveyor RatingPereiraePas encore d'évaluation

- DTS - Belt Bucket Elevator - DatasheetDocument3 pagesDTS - Belt Bucket Elevator - DatasheetBRUNA NASCIMENTOPas encore d'évaluation

- 3.3.1 Motor Sizing and Selection 1. Measuring Chamber Sliding Valve Drive Mechanism (A) Determination of The Drive MechanismDocument6 pages3.3.1 Motor Sizing and Selection 1. Measuring Chamber Sliding Valve Drive Mechanism (A) Determination of The Drive MechanismproteuscarrillusPas encore d'évaluation

- Designing of Chain Drive Mechanism 1: Selection of Power Transmission EfficiencyDocument1 pageDesigning of Chain Drive Mechanism 1: Selection of Power Transmission EfficiencyBenny Agung PrasetyoPas encore d'évaluation

- SAAd CepDocument6 pagesSAAd Cepgillanis multimediaPas encore d'évaluation

- Useful EquationsDocument3 pagesUseful EquationsAal KhalidPas encore d'évaluation

- Designing of Chain Drive MechanismDocument1 pageDesigning of Chain Drive MechanismrasgeetsinghPas encore d'évaluation

- An Serv 002 PDFDocument20 pagesAn Serv 002 PDFMario TapiaPas encore d'évaluation

- Booksand PeriodicalsDocument188 pagesBooksand PeriodicalsNUTHI SIVA SANTHANPas encore d'évaluation

- IATA - IATA Forecast Predicts 8.2 Billion Air Travelers in 2037Document8 pagesIATA - IATA Forecast Predicts 8.2 Billion Air Travelers in 2037Santosh ShivharePas encore d'évaluation

- Airport Runway DesignDocument3 pagesAirport Runway DesignAnem PoojaPas encore d'évaluation

- Reporter: Group of BRAZIL: MemberDocument23 pagesReporter: Group of BRAZIL: MemberRayza MaglaquePas encore d'évaluation

- Pemilihan Pipa Dan Pompa Ballast Pada Pembuatan Kapal Perang Jenis Angkut Tank Baja 4 Di PT Daya Radar Utama Unit 3 LampungDocument6 pagesPemilihan Pipa Dan Pompa Ballast Pada Pembuatan Kapal Perang Jenis Angkut Tank Baja 4 Di PT Daya Radar Utama Unit 3 Lampungugik arfiandiPas encore d'évaluation

- Invoice Polytech IQBALDocument1 pageInvoice Polytech IQBALmuhammad iqbalPas encore d'évaluation

- Brake SystemDocument19 pagesBrake SystemToua YajPas encore d'évaluation

- Mechanical Department in Indian RailwayDocument5 pagesMechanical Department in Indian RailwaySoumen BhattaPas encore d'évaluation

- Balanced Cantilever Method of Bridge ConstructionDocument7 pagesBalanced Cantilever Method of Bridge ConstructionyyingmunPas encore d'évaluation

- Invoice Parts ReportDocument308 pagesInvoice Parts Reportrahul siddharth100% (1)

- Mercedes 190D Wiring Diagrams CollectionDocument17 pagesMercedes 190D Wiring Diagrams CollectionJorge GómezPas encore d'évaluation

- Unit 5. Transmission SystemDocument5 pagesUnit 5. Transmission SystemDipak ZopePas encore d'évaluation

- Security and Privacy Reference ArchitectureDocument137 pagesSecurity and Privacy Reference ArchitectureAditya MehtaPas encore d'évaluation

- Women On WheelsDocument3 pagesWomen On WheelsShiv KumarPas encore d'évaluation

- Parking Brake - TestDocument2 pagesParking Brake - Testyan100% (2)

- Love - in - La - Text 1Document4 pagesLove - in - La - Text 1sweetnsourwrPas encore d'évaluation

- Multiple and Intensive Land Use: Case Studies in Hong KongDocument20 pagesMultiple and Intensive Land Use: Case Studies in Hong KongAbel Huancahuire SanchesPas encore d'évaluation