Académique Documents

Professionnel Documents

Culture Documents

Internal and External Information

Transféré par

aymen14577155267%(3)67% ont trouvé ce document utile (3 votes)

2K vues2 pagesInternal sources like accident reports, sickness records, maintenance logs, safety tours, and audits help with hazard identification and risk assessment. Accident reports identify direct and underlying causes. Sickness records show frequent injuries and hazards. Maintenance logs ensure safety devices are working. Safety tours find unsafe practices and conditions. Audits identify weaknesses in safety management.

External sources also contribute. HSE guidelines describe hazards and consequences. MSDS provide chemical information and controls. Insurance feedback prevents recurrences. Legislation is regularly updated and provides hazard information like for asbestos. Manufacturers' instructions note inspection frequencies and proper usage to assess risk levels.

Description originale:

Titre original

internal and external information.docx

Copyright

© © All Rights Reserved

Formats disponibles

DOCX, PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentInternal sources like accident reports, sickness records, maintenance logs, safety tours, and audits help with hazard identification and risk assessment. Accident reports identify direct and underlying causes. Sickness records show frequent injuries and hazards. Maintenance logs ensure safety devices are working. Safety tours find unsafe practices and conditions. Audits identify weaknesses in safety management.

External sources also contribute. HSE guidelines describe hazards and consequences. MSDS provide chemical information and controls. Insurance feedback prevents recurrences. Legislation is regularly updated and provides hazard information like for asbestos. Manufacturers' instructions note inspection frequencies and proper usage to assess risk levels.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme DOCX, PDF, TXT ou lisez en ligne sur Scribd

67%(3)67% ont trouvé ce document utile (3 votes)

2K vues2 pagesInternal and External Information

Transféré par

aymen145771552Internal sources like accident reports, sickness records, maintenance logs, safety tours, and audits help with hazard identification and risk assessment. Accident reports identify direct and underlying causes. Sickness records show frequent injuries and hazards. Maintenance logs ensure safety devices are working. Safety tours find unsafe practices and conditions. Audits identify weaknesses in safety management.

External sources also contribute. HSE guidelines describe hazards and consequences. MSDS provide chemical information and controls. Insurance feedback prevents recurrences. Legislation is regularly updated and provides hazard information like for asbestos. Manufacturers' instructions note inspection frequencies and proper usage to assess risk levels.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme DOCX, PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 2

For a range of internal AND external information sources, outline how EACH

source contributes to hazard identification or risk assessment

Internal Sources:-

Accident investigation reports:-

Identifying the immediate, underlying and root causes which will indicate the

weak points whether in safety management system or in unwanted conditions

which will consider then in risk assessment process.

Sickness absence records:-

To check the frequent injuries location and types e.g. most of sickness absence

related to MSDs so control measurements arent suitable in workplace or other

controls which are needed to identify and assess the hazard in risk assessment

process.

Maintenance records:-

To ensure that safety devices are in place, if there is on maintenance records that

mean the probability and severity of the risk increased.

Safety tours results:

Safety tours consider as proactive measurement, to know safe and unsafe

practices of employees, and knowledge of unsafe conditions (poor lighting ...etc.)

which is important for risk assessment.

Audit results:-

To know the weak points of safety management system ( e.g. lack of supervision),

as we know most types of work need to be well monitoring and supervised, so

here the probability of risk increased automatically.

External Sources

HSE guideline:-

Guidelines gives you good information for most hazards and their consequences

of the hazards (electricity hazards lead to secondary effects such as falling from

height) so falling from height considers as one of hazards of electricity which is

should be considered in risk assessment process.

MSDS

Gives you full information of chemicals and control measures for that chemical,

which are useful for identifying hazards and assessing the risk.

Insurance companies:-

Usually gives feedbacks of your assessment that can be useful for assessing the

risk to avoid reoccurrence of adverse events.

Legislation:

Updated regularly, gives you full information about the hazards.

(E.g. asbestos) Control of Asbestos at Work Regulation 2002 has

information about the how to deal with asbestos and then you can

compare the control measures in your place with the legislation, which will

help for assessing the risk.

Manufacture instruction:

Manufacture usually gives you a summary how you use the machine or

equipment (e.g. frequent inspection of the machine must be every 3 months), if

the frequent inspection as required from the manufacture was cancelled in the

workplace, so the probability the risk will increase.

Vous aimerez peut-être aussi

- Emc2 Sample v1Document12 pagesEmc2 Sample v1lkjofi100% (2)

- Element 5.1 Criteria IPD IOSHDocument2 pagesElement 5.1 Criteria IPD IOSHSajid ShahPas encore d'évaluation

- NEBOSH Award in Health and Safety at WorkDocument11 pagesNEBOSH Award in Health and Safety at WorkTanzeel Liaqat33% (3)

- 2011 01 IDIP Unit B Past PaperDocument4 pages2011 01 IDIP Unit B Past Paperfh71100% (4)

- IGC 2 Mock Paper and AnswersDocument7 pagesIGC 2 Mock Paper and AnswersMohammad Shahid79% (19)

- Sample DNI 1Document2 pagesSample DNI 1vinu safety0% (1)

- Welding Consumable and Storage ProcedureDocument10 pagesWelding Consumable and Storage Procedurehasan_676489616100% (1)

- Nebosh Idip Unit B: B1 Managing Occupational Health 2017Document44 pagesNebosh Idip Unit B: B1 Managing Occupational Health 2017francis100% (1)

- HSE PlanDocument14 pagesHSE PlankbonairPas encore d'évaluation

- Nebosh ED Miniguide March2008247200854854Document9 pagesNebosh ED Miniguide March2008247200854854sriramPas encore d'évaluation

- Question BDocument23 pagesQuestion BHussien Elhindi Garad100% (5)

- NEBOSH Final ReportDocument19 pagesNEBOSH Final Reportasimnaqvi2008Pas encore d'évaluation

- Nebosh Ndip Examiners Report 2018 & 2019 PDFDocument209 pagesNebosh Ndip Examiners Report 2018 & 2019 PDFKEL I100% (1)

- Iosh Level 3 Course ContentDocument4 pagesIosh Level 3 Course ContentMshoaib AbdullahPas encore d'évaluation

- IOSH Managing Safely Training SyllabusDocument1 pageIOSH Managing Safely Training SyllabusIrfan AhmedPas encore d'évaluation

- Contents of Safety ProgramDocument2 pagesContents of Safety ProgramJohn Francis Sumandal100% (2)

- Foundation Certificate in Environmental Management: OverviewDocument1 pageFoundation Certificate in Environmental Management: OverviewVignesh ShenoyPas encore d'évaluation

- NEBOSH International DiplomaDocument2 pagesNEBOSH International DiplomaBinoy Gopinathan100% (3)

- 2010-06-14 1300 Project Management Broad Spectrum Overview WikibookDocument522 pages2010-06-14 1300 Project Management Broad Spectrum Overview WikibookKits Sri100% (1)

- Franchising Vs LicensingDocument29 pagesFranchising Vs LicensingMarcela Bumbu-Cervinschi100% (1)

- Revision Unit A Sep 2020Document30 pagesRevision Unit A Sep 2020butahra50% (2)

- Nebosh MaterialDocument17 pagesNebosh Materialnaidu9522Pas encore d'évaluation

- Idip Ic Examiners Report Jan20 Final 090420 RewDocument16 pagesIdip Ic Examiners Report Jan20 Final 090420 RewjyothishPas encore d'évaluation

- Appendix 1: GC3 - The Health and Safety Practical ApplicationDocument17 pagesAppendix 1: GC3 - The Health and Safety Practical ApplicationTashrif Yusuf100% (1)

- 2011 01 IDIP Unit A Past PaperDocument3 pages2011 01 IDIP Unit A Past Paperfh71100% (2)

- RRC Sample: Unit IDEM2 Element 1 Enforcement of Environmental LegislationDocument7 pagesRRC Sample: Unit IDEM2 Element 1 Enforcement of Environmental LegislationYU TAO100% (1)

- Diploma Unit A Revision Cards PDFDocument72 pagesDiploma Unit A Revision Cards PDFAli Zafar100% (1)

- Element 9Document71 pagesElement 9naidu952283% (6)

- ETAC-IDipDL-A-01 ASSIGNMENT-01Document4 pagesETAC-IDipDL-A-01 ASSIGNMENT-01Mohammed ZubairPas encore d'évaluation

- Hazard Identification Reporting and Workplace Inspections - Group Safety Standard 11Document7 pagesHazard Identification Reporting and Workplace Inspections - Group Safety Standard 11reneth davidPas encore d'évaluation

- Nebosh Unit D CoachDocument8 pagesNebosh Unit D CoachNebosh Diploma AssignmentPas encore d'évaluation

- Nebosh H&S Diploma Nebosh H&S Diploma Outline Programme Nebosh H&S DiplomaDocument4 pagesNebosh H&S Diploma Nebosh H&S Diploma Outline Programme Nebosh H&S DiplomaMohamed Adam0% (1)

- IB - 1 Questions & AnswersDocument7 pagesIB - 1 Questions & AnswersAnjana_EdathadanPas encore d'évaluation

- March 2008 IDip Unit IDDocument9 pagesMarch 2008 IDip Unit IDNaeem Iqbal100% (1)

- Nebosh Igc2 QuestionsDocument7 pagesNebosh Igc2 QuestionsMuhammad Younas100% (1)

- NEBOSH Diploma in Environmental Management Unit ED1 (2010 Specification)Document5 pagesNEBOSH Diploma in Environmental Management Unit ED1 (2010 Specification)Raz BiophyPas encore d'évaluation

- IDIP PP Jul 2012 - Unit ICDocument3 pagesIDIP PP Jul 2012 - Unit ICRuppee EdwardPas encore d'évaluation

- NEBOSH Assignment Report Unit D 2017 PDFDocument80 pagesNEBOSH Assignment Report Unit D 2017 PDFSaeed MalikPas encore d'évaluation

- Dip2 - 2019 06 22 03 06 10Document2 pagesDip2 - 2019 06 22 03 06 10Darius DsouzaPas encore d'évaluation

- Nebosh Element - 1 AnswersDocument4 pagesNebosh Element - 1 AnswersSatish KumarPas encore d'évaluation

- Examiner Reports January 2009 Unit IADocument13 pagesExaminer Reports January 2009 Unit IAElavarasan RamalingamPas encore d'évaluation

- July 2017 IDIP Unit A Examiners ReportDocument17 pagesJuly 2017 IDIP Unit A Examiners Reportananthu.u100% (1)

- Nebosh Idip Unit BDocument42 pagesNebosh Idip Unit BAnjana_Edathadan0% (1)

- Health and Safety at The WorkplaceDocument24 pagesHealth and Safety at The Workplacesjarvis5100% (1)

- Unit A Nebosh DIP 2019Document4 pagesUnit A Nebosh DIP 2019francis0% (1)

- DNI - ReportDocument37 pagesDNI - ReportbeddoerocksPas encore d'évaluation

- The Following Questions & Answers (Q&A) Supplement Should Help You With Any Queries You May Have About Our Fees ListDocument8 pagesThe Following Questions & Answers (Q&A) Supplement Should Help You With Any Queries You May Have About Our Fees ListSherinPas encore d'évaluation

- Writing A Health and Safety Policy StatementDocument7 pagesWriting A Health and Safety Policy StatementLove100% (1)

- Critical Success Factors For DWHDocument18 pagesCritical Success Factors For DWHAhmed EsmatPas encore d'évaluation

- Neboshunit Icquestionsmatrix Ans 150920084745 Lva1 App6891Document82 pagesNeboshunit Icquestionsmatrix Ans 150920084745 Lva1 App6891elvis1979Pas encore d'évaluation

- International Diploma in NEBOSH UNIT ONE REVISION Summary of Unit OneDocument43 pagesInternational Diploma in NEBOSH UNIT ONE REVISION Summary of Unit Onefrancis100% (1)

- Nebosh International DiplomaDocument2 pagesNebosh International DiplomaArthurPas encore d'évaluation

- Ans: (A) Occupational Health Should Aim at The Promotion and Maintenance of The Highest Degree ofDocument4 pagesAns: (A) Occupational Health Should Aim at The Promotion and Maintenance of The Highest Degree ofAnjana_EdathadanPas encore d'évaluation

- Unit DNI Candidate Guidance v4 Feb17 FINAL (150217 Rew) 1522017261047 PDFDocument13 pagesUnit DNI Candidate Guidance v4 Feb17 FINAL (150217 Rew) 1522017261047 PDFJamshar KtPas encore d'évaluation

- Nebosh ReviewDocument95 pagesNebosh Reviewjaved100% (1)

- IGC-1 NotesDocument39 pagesIGC-1 Noteskhurram60% (5)

- NEBOSH International Technical Certificate in Oil & Gas Operational SafetyDocument26 pagesNEBOSH International Technical Certificate in Oil & Gas Operational SafetyRanish P. Kurian100% (2)

- Core Elements For Health and Safety ManagementDocument5 pagesCore Elements For Health and Safety ManagementVernie Soriano100% (2)

- InstallationDocument1 pageInstallationaymen145771552Pas encore d'évaluation

- Fire Triangle Consists of Oxygen, Heat and Fuel Remove Oxygen Fire Will Be Extinguished Remove Fuel The Fire Will Be ExtinguishedDocument1 pageFire Triangle Consists of Oxygen, Heat and Fuel Remove Oxygen Fire Will Be Extinguished Remove Fuel The Fire Will Be Extinguishedaymen145771552Pas encore d'évaluation

- InstallationDocument1 pageInstallationaymen145771552Pas encore d'évaluation

- Confined SpaceDocument2 pagesConfined Spaceaymen145771552Pas encore d'évaluation

- By The Name of Ullah The Words of Ullah The Merciful The Peaceful Ulmad Eullah Rabi AlaalameenDocument1 pageBy The Name of Ullah The Words of Ullah The Merciful The Peaceful Ulmad Eullah Rabi Alaalameenaymen145771552Pas encore d'évaluation

- Thermal Comfort in The Workplace HSG 194 PDFDocument21 pagesThermal Comfort in The Workplace HSG 194 PDFaymen145771552Pas encore d'évaluation

- Purpose:-: Guidelines On Occupational Safety and Health Management SystemsDocument4 pagesPurpose:-: Guidelines On Occupational Safety and Health Management Systemsaymen145771552Pas encore d'évaluation

- Fire 1Document1 pageFire 1aymen145771552Pas encore d'évaluation

- Safety Is A State of Being Safe Freedom From Danger or HazardDocument1 pageSafety Is A State of Being Safe Freedom From Danger or Hazardaymen145771552Pas encore d'évaluation

- Ladder and StepladderDocument4 pagesLadder and Stepladderaymen145771552Pas encore d'évaluation

- A Review of The Occupational Diseases Reporting System in The Republic of Ireland PDFDocument113 pagesA Review of The Occupational Diseases Reporting System in The Republic of Ireland PDFaymen145771552Pas encore d'évaluation

- I Had Never Felt So Nervous Before in My Life... !Document1 pageI Had Never Felt So Nervous Before in My Life... !aymen145771552Pas encore d'évaluation

- Hazards and Control Measures of DSEDocument3 pagesHazards and Control Measures of DSEaymen145771552Pas encore d'évaluation

- Printed Circuit Board Manufacturing ProcessDocument2 pagesPrinted Circuit Board Manufacturing ProcessDipesh AggarwalPas encore d'évaluation

- Dresser Blackhawk Hot Tap-Line Stop ProductsDocument20 pagesDresser Blackhawk Hot Tap-Line Stop Productskjpatel2Pas encore d'évaluation

- 7 4 Options Gauge Plates Sizing RingsDocument1 page7 4 Options Gauge Plates Sizing RingsGauravPas encore d'évaluation

- Unit I Management Information Systems (MIS) : Other NamesDocument6 pagesUnit I Management Information Systems (MIS) : Other Namesfelix777sPas encore d'évaluation

- Masdar City: The World'S Greenest City?: InshareDocument7 pagesMasdar City: The World'S Greenest City?: InshareMohd HazaziPas encore d'évaluation

- CA Business Intelligence For CAServDeskMgr PDFDocument395 pagesCA Business Intelligence For CAServDeskMgr PDFOctavio DiazPas encore d'évaluation

- Catawissa BrochureDocument12 pagesCatawissa Brochurepacho916Pas encore d'évaluation

- Strategic Mine Planning Integrating Computer Software, Simulation, and Social ResponsibilityDocument66 pagesStrategic Mine Planning Integrating Computer Software, Simulation, and Social ResponsibilityLuis BPas encore d'évaluation

- Handbook Oxford OM PDFDocument27 pagesHandbook Oxford OM PDFSantiago RobledoPas encore d'évaluation

- FAPPPDocument422 pagesFAPPPMarcos David Revoredo MezaPas encore d'évaluation

- Kiruna Iron Drilling SuccessDocument12 pagesKiruna Iron Drilling SuccessHannans Reward LtdPas encore d'évaluation

- Clearwater TribuneDocument6 pagesClearwater TribunewestribPas encore d'évaluation

- NASA-CR-1457 Manual For Structural Stability Analysis of Sandwich PanelsDocument385 pagesNASA-CR-1457 Manual For Structural Stability Analysis of Sandwich Panelsmuhanned100% (1)

- Shaper Slotter PlannerDocument21 pagesShaper Slotter PlannerPraveen Mathi100% (1)

- WPS 6.1.WPS 6.1.2 Business Process Choreographer2 Business Process Choreographer PDFDocument732 pagesWPS 6.1.WPS 6.1.2 Business Process Choreographer2 Business Process Choreographer PDFmaldoreurPas encore d'évaluation

- Voltech IT Infrastructure IT StructureDocument3 pagesVoltech IT Infrastructure IT StructurePratik ChourasiaPas encore d'évaluation

- NIKKI Precision Locknut Catalog 2019Document32 pagesNIKKI Precision Locknut Catalog 2019George babuPas encore d'évaluation

- Eureka Forbes CRMDocument65 pagesEureka Forbes CRMMonalisha DasPas encore d'évaluation

- Digital Transformation: Online Guide To Digital Business TransformationDocument19 pagesDigital Transformation: Online Guide To Digital Business TransformationraminahPas encore d'évaluation

- Tableau Neil Raden Guided Open Ended AnalyticsDocument15 pagesTableau Neil Raden Guided Open Ended AnalyticsPrakarn KorkiatcharoonPas encore d'évaluation

- Deloitte - 2022 Global Automotive Consumer StudyDocument34 pagesDeloitte - 2022 Global Automotive Consumer StudyAakash MalhotraPas encore d'évaluation

- 100044-02 Document, NPSi-1 Quick Setup Guide, Warnings and WarrantyDocument2 pages100044-02 Document, NPSi-1 Quick Setup Guide, Warnings and WarrantyNurevaPas encore d'évaluation

- CSD April 2019 List Download HP CurrentPriceListZero - NormalDocument48 pagesCSD April 2019 List Download HP CurrentPriceListZero - NormalWajeeha NaseerPas encore d'évaluation

- BSC Project Proposal DefenceDocument24 pagesBSC Project Proposal DefenceAbdul Wahab KhanPas encore d'évaluation

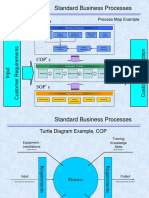

- Process Maps and Turtle Diagrams ExampleDocument2 pagesProcess Maps and Turtle Diagrams ExampleJohn Oo100% (1)

- A Project Report On Financial Performance Evaluation With Key Ratios at Vasavadatta Cement Kesoram Industries LTD Sedam GulbargaDocument82 pagesA Project Report On Financial Performance Evaluation With Key Ratios at Vasavadatta Cement Kesoram Industries LTD Sedam GulbargaK Sagar KondollaPas encore d'évaluation

- Tender For Cable Car FeasibilityDocument26 pagesTender For Cable Car FeasibilityaqhammamPas encore d'évaluation