Académique Documents

Professionnel Documents

Culture Documents

Training at Khan Electrical Aniruddha

Transféré par

Aritra Ravenor Jana0 évaluation0% ont trouvé ce document utile (0 vote)

23 vues21 pagesaaa

Copyright

© © All Rights Reserved

Formats disponibles

DOCX, PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentaaa

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme DOCX, PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

23 vues21 pagesTraining at Khan Electrical Aniruddha

Transféré par

Aritra Ravenor Janaaaa

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme DOCX, PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 21

Report on Vocational Training(Summer)2011

KHAN ELECTRICAL ENGINEERING CENTRE

(PALAN INDUSTRIAL ESTATE,BANERJEEPARA,MAHESTALA.KOL-141)

Under : KHAN ELECTRICAL ENGINEERING CENTRE

Reference-Prof. Subhasis Bandopadhyay

Submitted By: Aniruddha Koley

Roll no. :08156028025

Stream: Electrical & Electronics Engineering

College: Pailan College of Management & Technology

Submitted on: ___________________________

1

st

August 2011 (ANIRUDDHA KOLEY)

CONTENTS

1. Introduction to Electrical Engg. Centre

2. Operations at Khan Electrical Engg. Centre

3. Manufacture of Electrical Panel

4.Assembling of various parts

5.Fuses description

6.Various types of Breaker

7. Current Transformer

8. Various types of feeder

9.Busbars

10.Voltmeter & Ammeter

11.Digital Panel Meter

12.Insulation testing

13.Load testing

14.VVVF Operation

15.Safety Measurement

16.Conclusion

Introduction to Electrical Engg. Centre

An Electrical Engg. Centre is a hub where graduates from Electrical Engg. Departments are

familiarized with various electrical components such as :

Electrical Panels

Electrical drives

Transformers

Relays

Protection of various components

Safety measures to be taken

Operations at Khan Electrical Engineering Centre:-

The various operations at Khan Electrical Engg. Center are :-

Machine Design

Assembling of various modules

Manufacture of Design components & Electrical Panels

Testing & final delivery of the manufactured products

Manufacture of Electrical Panel:

The basic operation for manufacturing panels is Lathe Operation.

Lathe Operation:

Metals are brought in and various operations are done like:

Cutting

Drilling

Bending

Welding

Painting/Galvanizing

Insulation

Lathe Lathe Machining Lathe Bore

Lathe trial Lathe Painting-using-the-lathe

Assembling of Panel Components:

The basic components used for panel assembling are :-

1>FUSES:- In electrical and electronics engineering, a fuse is a type of low

resistance resistor that acts as a sacrificial device to provide over current protection, of either

the load or source circuit. Its essential component is a metal wire or strip that melts when too

much current flows, which interrupts the circuit in which it is connected. Short circuit,

overloading, mismatched loads or device failure are the prime reasons for excessive current.

A fuse interrupts excessive current (blows) so that further damage by overheating or fire is

prevented. Wiring regulations often define a maximum fuse current rating for particular

circuits. Over current protection devices are essential in electrical systems to limit threats to

human life and property damage. Fuses are selected to allow passage of normal current plus a

marginal percentage and to allow excessive current only for short periods. Slow blow fuses are

designed to allow higher currents for a modest amount of time longer, and such considerations

are and were commonly necessary when electronics devices or systems had electronic

tube tech or a large number of incandescent lights were being powered such as in a large hall,

theater or stadium. Tubes and incandescent lights each have reduced current needs as they

heat up to operating temperatures for their internal resistance grows as they are heated the

same physics principle causes the fuse material to melt, disconnecting the circuit from power.

A fuse consists of a metal strip or wire fuse element, of small cross-section compared to the

circuit conductors, mounted between a pair of electrical terminals, and (usually) enclosed by a

non-conducting and non-combustible housing. The fuse is arranged in series to carry all the

current passing through the protected circuit. The resistance of the element generates heat due

to the current flow. The size and construction of the element is (empirically) determined so that

the heat produced for a normal current does not cause the element to attain a high

temperature. If too high a current flows, the element rises to a higher temperature and either

directly melts, or else melts a soldered joint within the fuse, opening the circuit

The fuse element is made of zinc, copper, silver, aluminum, or alloys to provide stable and

predictable characteristics. The fuse ideally would carry its rated current indefinitely, and melt

quickly on a small excess. The element must not be damaged by minor harmless surges of

current, and must not oxidize or change its behavior after possibly years of service.

2>CIRCUIT BREAKER:- Mainly four types of circuit breaker are used in panel, i.e.

i)ACB(Air-blast Circuit Breaker)

ii)VCB(Vacuum Circuit Breaker)

iii)MCB(Miniature Circuit Breaker)

iv)MCCB(Molded Case Circuit Breaker)

v)RCCB

i)ACB:- Air circuit breakers can be used both as circuit-breakers for general protection (of

plants, of user complexes, of electric lines) and as protection circuit breakers of electrical

machines (generators, motors, transformers, capacitors).

These can be used both as circuit-breakers for general protection (of plants, of user complexes,

of electric lines) and as protection circuit-breakers of electrical machines (generators, motors,

transformers, capacitors). They are used in all types of plants (civil, industrial, and in the service

sector) as well as in the equipment on-board ships, in mines, in prefabricated substations, and

for primary and secondary distribution in general.

ii)VCB:- Vacuum interrupters mounted vertically within the circuit breaker frame, perform

the circuit breaker interruption.

Consisting of a pair of butt contacts, one movable and one fixed, interrupters require only a

short contact gap for circuit interruption. The resulting high-speed operation allows the entire

operating sequence, from fault to clear, to be consistently performed in three cycles or less.

Never use the primary disconnects as handles when maneuvering the

breaker.

iii)MCB:- Our miniature circuit breakers provide efficient and trustworthy protection for cables

and systems in severe industrial environments and in service installations in buildings.

It possesses three different tripping characteristics to provide the perfect solution for all kinds

of application from cable production up to the protection & control. Our manufacturers have

manufactured these with facilities for quick, easy and safe field application of supporting

contacts and shunt trip release mechanisms. We also offer facilities such as mechanism locking

and sealing wire are provided wherever needed.

iv)MCCB:-Our MCCB conforms to the standards of GB14048.2 and IEC947-2. Molded case

circuit breaker (MCCB) is mainly used in electric power system with rated frequency of AC50Hz,

rated voltage up to 690V and rated current up to 800A to distribute electric power.

Moreover, these are also used to protect the line and equipment from being damaged due to

overload, short circuit and under voltage.

v)RCCB:- These are in compliance with the standards of IEC1008-1 and GB16916.1-1997.

Applied to the circuit of AC 50/60Hz, 1P 240V, 3P4 15V, these are mainly used for preventing

electric fire and personal casual accidents caused by personal electric shock or leakage. They

act as current-operated and fast leakage protectors.

3>CURRENT TRANSFORMER: - In electrical engineering, a Current Transformer (CT) is used

for measurement of electric currents. Current transformers, together with Voltage

Transformers (VT) (potential transformers (PT)), are known as Instrument Transformers. When

current in a circuit is too high to directly apply to measuring instruments, a current transformer

produces a reduced current accurately proportional to the current in the circuit, which can be

conveniently connected to measuring and recording instruments. A current transformer also

isolates the measuring instruments from what may be very high voltage in the monitored

circuit. Current transformers are commonly used in metering and protective relays in the

electrical power industry.

Like any other transformer, a current transformer has a primary winding, a magnetic

core, and a secondary winding. The alternating current flowing in the primary produces a

magnetic field in the core, which then induces a current in the secondary winding circuit. A

primary objective of current transformer design is to ensure that the primary and secondary

circuits are efficiently coupled, so that the secondary current bears an accurate relationship to

the primary current.

The most common design of CT consists of a length of wire wrapped many times around

a silicon steel ring passed over the circuit being measured. The primary winding may be a

permanent part of the current transformer, with a heavy copper bar to carry current through

the magnetic core. Window-type current transformers are also common, which can have circuit

cables run through the middle of an opening in the core to provide a single-turn primary

winding. When conductors passing through a CT are not centered in the circular (or oval)

opening, slight inaccuracies may occur.

The rated secondary current in CT is commonly standardized at 1 or 5 amperes. For

example, a 4000:5 CT would provide an output current of 5 amperes when the primary was

passing 4000 amperes. The secondary winding can be single ratio or multi ratio, with five taps

being common for multi ratio CTs. The load, or burden, of the CT should be of low resistance. If

the voltage time integral area is higher than the core's design rating, the core goes into

saturation towards the end of each cycle, distorting the waveform and affecting accuracy.

4>FEEDER: Feeders are conductors which carry electric power from the service equipment (or

generator switchboard) to the over current devices for groups of branch circuits or load centers

supplying various loads.

Feeder Rating:- 200A 800A

Feeder Description:- 100comu Machine Repair Shop FDR1

Cable:- Bus Truncking 5*(3*185+1*95)AYFY

Sub feeders originate at a distribution center other than the service equipment or generator

switchboard and supply one or more other distribution panel boards, branch circuit panel

boards, or branch circuits. Code rules on feeders also apply to sub feeders.

5>BUS BARS(Aluminum & Coppers):- In electrical power distribution, a bus bar is a strip

of copper or aluminum that conducts electricity within a switchboard, distribution

board, substation or other electrical apparatus.

Bus bars are typically either flat strips or hollow tubes as these shapes allow heat to dissipate

more efficiently due to their high surface area to cross-sectional area ratio. The skin

effect makes 5060 Hz AC bus bars more than about 8 mm (1/3 in) thick inefficient, so hollow

or flat shapes are prevalent in higher current applications. A hollow section has higher stiffness

than a solid rod of equivalent current-carrying capacity, which allows a greater span between

busbar supports in outdoor switchyards.

A bus bar may either be supported on insulators, or else insulation may completely surround it.

Bus bars are protected from accidental contact either by a metal earthed enclosure or by

elevation out of normal reach. Neutral bus bars may also be insulated. Earth bus bars are

typically bolted directly onto any metal chassis of their enclosure. Busbars may be enclosed in a

metal housing, in the form of bus duct or busway, segregated-phase bus, or isolated-phase bus.

Bus bars may be connected to each other and to electrical apparatus by bolted, clamp, or

welded connections.

6>VOLTMETER/AMMETER(Moving coil galvanometer):- AC electromechanical meter

movements come in two basic arrangements: those based on DC movement designs, those

engineered specifically for AC use. Permanent-magnet moving coil (PMMC) meter movements

will not work correctly if directly connected to alternating current, because the direction of

needle movement will change with each half-cycle of the AC.

In order to use a DC-style meter movement such as the D'Arsonval design, the alternating

current must be rectified into DC. This is most easily accomplished through the use of devices

called diodes.

here is a voltage current meter panel from a three-phase AC system. The three donut current

transformers can be seen in the rear of the panel. Three AC ammeters on the front of the panel

indicate current through each conductor going through a CT. As this panel has been removed

from service, there are no current-carrying conductors threaded through the center of the CT

donuts anymore.

Because of the expense of instrument transformers, they are not used to scale AC meters for

any applications other than high voltage and high current. For scaling a milliamp or micro amp

movement to a range of 120 volts or 5 amps, normal precision resistors are used, just as with

DC.

7>DIGITAL PANEL METER:- Based on the feedback received from its valued customer base,

MECO has now launched Digital Panel Meters (DPMs) in DIN72, DIN96 and DIN144 sizes in

compact reinforced molded plastic cases. With these additions, MECO offers DPMs in all

popular sizes suitable for every application. This helps the user to select the correct instrument

and add value to their equipment or the panel.

The DPMs in 3, 3.5, 4.5 and 5 digit, with LED and LCD display are suitable to measure all

electrical parameters like V,A,W,VAR, PF and Hz in electrical networks of 1Phase, 3Phase 3Wire

and 3Phase 4Wire for balanced as well as unbalanced loads. These meters can also be scaled

for displaying process parameters like kmph, RPM, %, CPS, Ft/s, psi etc against an input of 4-

20mA or 1-5V. A choice of AC and DC auxiliary power supply is also available. A range of over

100 models of DPMs is available in sizes of 144x144mm, 96x96mm, 72x72mm, 48x96mm,

50x85mm and 71x46mm. The DPMs are available with a choice of built-in as well as external

transducers.

Insulation Testing/meggaring:-

A regular program of testing insulation resistance is strongly recommended to prevent

electrical shocks, assure safety of personal & to reduce or eliminate down time.

It helps to detect deterioration of insulation in order to schedule repair work such as :

vacuum cleaning, steam cleaning, drying & rewinding. It also helpful when evaluating the

quality of the repairs before the equipment is put back into operation.

Necessary equipments for insulation test:-

Megohommeter with a timed test function

Temperature indicator

Humidity meter

Total current in the body of insulation is the sum of three components:-

Capacitance charging currents

Absorption current

Leakage or conductance current

Testing of Load(HV,LV):-

Full HV system consists of:-

10 SY1527 main power supply units

64 A876 boards

250 A877 boards

Most of the boards are at ISR waiting to be tested.3 SY1527 and some A876 and A877

are in use since more than 1 year to power several DTs.

Test setup consists of :-

1 SY1527 mainframe

8 A876 modules

32 A877 modules Location: end of

ISR test area.

Two racks with 1 SY1527 and crates for the A877 already in place. All HV and communication

cables needed for this setup are ready. 5 tests envisaged:

Min voltage and max current with resistive load

Max voltage and max current with resistive load

Transient test. Ramp-up/ramp-down tests with

RC load

Min voltage and min current

Measurement of output voltages before and

Resistive and RC loads with Radial connectors

Software. It will be adapted from the existing

PVSS project used at the ISR..Time required of the order of 6-8 months We should start as soon

as possible as some boards are going out of warranty.

LV system for magnet test is a great unknown! We should decide NOW what to do. So

far, at labs or at test beams, we have powered with LV at most 2 DTs at the time.

We need to go one order of magnitude

beyond. We will not be able to do this with

home made supplies.

We should decide now whether we want to

order some LV equipment for the magnet

test or whether we should abandon the idea

of reading out 12 chambers.

VVVF Operation:-

FEATURES

State of the art Micro Processor based design

Integrated User Interface for adjusting controller parameters, viewing status and

accessing Event and Statistical Information

Optically Isolated Inputs with Red Status LEDs Dry Contact Outputs with Green Status

LEDs

All Inputs & Outputs clearly labeled

Factory Wired Terminal Strip for ease of installation and maintenance Event Log with

Date/Time Stamp

Free Tech Support

Remote Monitoring

Factory Programmed Frequency Drive Unit

Simplex, Duplex or Triplex Selective Collective Operation

Top of Car TS-89 Tape Unit

The VVVF advantage:- Quickly installed, easily maintained and 100% factory tested

Suited for use with single or two speed, three phase, AC induction motors

Delivers level floor stops bringing your AC elevator up to accepted leveling standards

Provides zero-speed brake stops, which will reduce wear on the elevator machine and brake

Existing motor may be reused in modernizations

Excellent ride quality and dependable operations

Safety Measurement, Grounding, Earthing, Protection

of Transformer:-

TESTING OF TRANSFORMER:-

TESTING IS CARRIED OUT AS PER IS-2026.

ROUTINE , TYPE TESTS & SPECIAL TESTS

ROUTINE TESTS ( TO BE CARRIED OUT ON EACH JOB)

1.Measurement of winding resistance

2.Measurement of insulation resistance

3.Seperate source voltage withstand test (High Voltage tests on HV & LV)

4.Induced Over voltage Withstand test (DVDF test)

5.Measurement of voltage ratio

6.Measurement of NO LOAD LOSS & current.

7.Measurement of LOAD LOSS & IMPEDENCE.(EFFICIENCY &

REGULATION)

8.Vector Group Verification

9.Oil BDV test.

10.Tests on OLTC (if Attached)

Conclusion:-

Though being from Electrical & Electronics Engineering discipline, during the vocational training

period at KHAN ELECTRICAL ENGINEERING CENTRE, I have come to know about other details in

the process of running of a electrical engineering centre like lathe machine, transformer,

meggar, etc. which undoubtedly has been a very helpful & fruitful knowledge from this training.

I would like to be grateful to everyone of the KHAN ELECTRICAL ENGINEERING

CENTRE Family without whose valuable support this training would not have been a success. I

would specially like to thanks, Sr.Manager & Manager & the stuffs without whose valuable help

and guidance this training would have been impossible.

________________________

========

Vous aimerez peut-être aussi

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- BY-Vijaya Lakshmi KambhampatiDocument35 pagesBY-Vijaya Lakshmi KambhampatiAritra Ravenor JanaPas encore d'évaluation

- Customer Buying Behaviour in Bikes ReportDocument78 pagesCustomer Buying Behaviour in Bikes ReportSahil Arora75% (16)

- Mayank Mohan (10BM60048) Prashant Saurabh (10BM60062) Sudeep Yadav (10BM60089)Document14 pagesMayank Mohan (10BM60048) Prashant Saurabh (10BM60062) Sudeep Yadav (10BM60089)Aritra Ravenor JanaPas encore d'évaluation

- Evaluate Financial Health, Customer Strength, and Efficiency of Tide Water Oil Co. (India) LtdDocument15 pagesEvaluate Financial Health, Customer Strength, and Efficiency of Tide Water Oil Co. (India) LtdAritra Ravenor JanaPas encore d'évaluation

- Pailan CollegeDocument4 pagesPailan CollegeAritra Ravenor JanaPas encore d'évaluation

- MAT Aptitude Test Detailed Analysis Provides Insights Into 2005 ExamDocument10 pagesMAT Aptitude Test Detailed Analysis Provides Insights Into 2005 ExamAritra Ravenor JanaPas encore d'évaluation

- Screen ShotsaaaDocument5 pagesScreen ShotsaaaAritra Ravenor JanaPas encore d'évaluation

- Stufdy of Perception in Scooter in Rural Marketing Perception of Tvs Scooter in Rural MarketingDocument53 pagesStufdy of Perception in Scooter in Rural Marketing Perception of Tvs Scooter in Rural MarketingAritra Ravenor JanaPas encore d'évaluation

- Executive Summary: Our TeamDocument49 pagesExecutive Summary: Our TeamAritra Ravenor JanaPas encore d'évaluation

- CAT 2006 Section I Answer Questions 1 To 5 On The Basis of The Information Given BelowDocument19 pagesCAT 2006 Section I Answer Questions 1 To 5 On The Basis of The Information Given BelowAritra Ravenor JanaPas encore d'évaluation

- A Project By: Inscribe: Pailan College of Management and TechnologyDocument1 pageA Project By: Inscribe: Pailan College of Management and TechnologyAritra Ravenor JanaPas encore d'évaluation

- Financial Management: Sources of Funds: Topic 13Document23 pagesFinancial Management: Sources of Funds: Topic 13Aritra Ravenor JanaPas encore d'évaluation

- OneStopMBA CAT 2007 Question PaperDocument60 pagesOneStopMBA CAT 2007 Question PaperShyam GodbolePas encore d'évaluation

- SECTION I Sub-Section I-A: Number of Questions 10 Directions For Questions 1 To 5: Answer The Questions Independently of Each OtherDocument31 pagesSECTION I Sub-Section I-A: Number of Questions 10 Directions For Questions 1 To 5: Answer The Questions Independently of Each OtherRahul KamblePas encore d'évaluation

- 5412aa5917 Tvs Motors ProjectDocument77 pages5412aa5917 Tvs Motors ProjectAritra Ravenor JanaPas encore d'évaluation

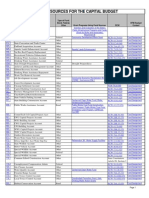

- Funding Sources for Capital Budget ProjectsDocument2 pagesFunding Sources for Capital Budget ProjectsAritra Ravenor JanaPas encore d'évaluation

- Brand Equity - Economic Times Discusses Purpose-Driven Growth at P&GDocument1 pageBrand Equity - Economic Times Discusses Purpose-Driven Growth at P&GAritra Ravenor JanaPas encore d'évaluation

- Cost of Capital: Liuren WuDocument42 pagesCost of Capital: Liuren WuAritra Ravenor JanaPas encore d'évaluation

- Fifa 13 Tips and TricksDocument16 pagesFifa 13 Tips and Tricksemilio1198Pas encore d'évaluation

- ArcDocument4 pagesArcAritra Ravenor JanaPas encore d'évaluation

- Funding Sources for Capital Budget ProjectsDocument2 pagesFunding Sources for Capital Budget ProjectsAritra Ravenor JanaPas encore d'évaluation

- DesalinationFNU41 RevisedDocument16 pagesDesalinationFNU41 RevisedAritra Ravenor JanaPas encore d'évaluation

- Admission Aanotice For MbaDocument2 pagesAdmission Aanotice For MbaAritra Ravenor JanaPas encore d'évaluation

- Genpact FactsheetDocument2 pagesGenpact FactsheetRaja NarenPas encore d'évaluation

- CV SoumyajeetDocument2 pagesCV SoumyajeetAritra Ravenor JanaPas encore d'évaluation

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Transformers: Physics Project WorkDocument26 pagesTransformers: Physics Project WorkAkshay NachappaPas encore d'évaluation

- Amphenol - 05022017 - TP 101 CP 1156596Document2 pagesAmphenol - 05022017 - TP 101 CP 1156596Fredson SidilenePas encore d'évaluation

- Isolated IGBT Gate-Drive Push-Pull Power Supply With 4 OutputsDocument43 pagesIsolated IGBT Gate-Drive Push-Pull Power Supply With 4 OutputsRenePas encore d'évaluation

- NPO X5R X7R Y5V: Ceramic Chip CapacitorsDocument6 pagesNPO X5R X7R Y5V: Ceramic Chip CapacitorsmateusT850Pas encore d'évaluation

- SN09031510A HV Termination Plug For No Load KV TroubleshootingDocument19 pagesSN09031510A HV Termination Plug For No Load KV TroubleshootingJavier PayáPas encore d'évaluation

- ECE 551 Assignment 2: Ajit R Kanale, 200132821 January 25, 2017Document5 pagesECE 551 Assignment 2: Ajit R Kanale, 200132821 January 25, 2017Ajit KanalePas encore d'évaluation

- M202-50A Miniature Circuit Breaker Technical DetailsDocument3 pagesM202-50A Miniature Circuit Breaker Technical DetailsCARLOS EDUARDO SALAZAR VANEGASPas encore d'évaluation

- 30 V Power Supplies for ASi NetworksDocument4 pages30 V Power Supplies for ASi NetworksBogdan VasilePas encore d'évaluation

- G900 Portable Generator InstructionsDocument0 pageG900 Portable Generator InstructionsLEDOMPas encore d'évaluation

- Catalog - Wastewater DuplexDocument2 pagesCatalog - Wastewater DuplexYohemir MarinPas encore d'évaluation

- SPWM V/HZ InverterDocument51 pagesSPWM V/HZ InverterLabi BajracharyaPas encore d'évaluation

- Manual: XieliDocument2 pagesManual: Xielinurhadi kusumaPas encore d'évaluation

- Color Codes and Irregular Marking-SampleDocument23 pagesColor Codes and Irregular Marking-Samplemahrez laabidiPas encore d'évaluation

- Cascade17-0231y1 - Data - Sheet 1Document5 pagesCascade17-0231y1 - Data - Sheet 1heliosmariano8350Pas encore d'évaluation

- Arduino Powered HomeDocument23 pagesArduino Powered HomeMarius DanilaPas encore d'évaluation

- Color Stabilization of RGB LEDsDocument8 pagesColor Stabilization of RGB LEDsMartinPas encore d'évaluation

- Nexans XT Medium Voltage Single Core...Document15 pagesNexans XT Medium Voltage Single Core...Mathias CanalesPas encore d'évaluation

- Sylvania Fluorescent Lighting Guide Book 1962Document20 pagesSylvania Fluorescent Lighting Guide Book 1962Alan MastersPas encore d'évaluation

- FB 17000Document2 pagesFB 17000Ren MatPas encore d'évaluation

- 211 Single Ended Schematic PDFDocument45 pages211 Single Ended Schematic PDFLuisAlejandroPardoPas encore d'évaluation

- Hysteresis Motors 1Document10 pagesHysteresis Motors 1Nelis OosthuizenPas encore d'évaluation

- Teori MSTEPDocument144 pagesTeori MSTEPDaniel Sopian FernandesPas encore d'évaluation

- Tsp23708-Wiring Diagram Fh12, Fh16 LHDDocument134 pagesTsp23708-Wiring Diagram Fh12, Fh16 LHDJose Alejandro Burgos Miranda80% (5)

- Lab ManualDocument17 pagesLab ManualSatyam Govila100% (1)

- Assessment 1 - Questioning - Written Assessment - AURETR129Document22 pagesAssessment 1 - Questioning - Written Assessment - AURETR129Sana SiddiquePas encore d'évaluation

- Three-Phase Voltage and Phase-Sequence Phase-Loss Relay: K8Ak-PmDocument16 pagesThree-Phase Voltage and Phase-Sequence Phase-Loss Relay: K8Ak-PmsajujohnyPas encore d'évaluation

- Relay Panel 9Document1 pageRelay Panel 9Santosh InchalPas encore d'évaluation

- E Series M12Document6 pagesE Series M12Anonymous lQyR2IWPas encore d'évaluation

- Arc Flash Hazard Safety Program: 10 Steps of An EffectiveDocument4 pagesArc Flash Hazard Safety Program: 10 Steps of An Effectivejdcpe17Pas encore d'évaluation

- Minarc Evo 180 technical specs summaryDocument2 pagesMinarc Evo 180 technical specs summaryIonel ȘearpePas encore d'évaluation