Académique Documents

Professionnel Documents

Culture Documents

Pages From WSM - 0000592 - 01 PDF

Transféré par

yliu070 évaluation0% ont trouvé ce document utile (0 vote)

11 vues3 pagesNew valve block, V97, is introduced in production from 9908 on trucks and from 9910 on buses. There are two annular chambers 12 between the rotor 2 and the stators 1. The oil flows extremely quickly and in a curved spiral path. Higher pressure gives more oil in the chambers and higher brake torque.

Description originale:

Titre original

Pages from WSM_0000592_01.pdf

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentNew valve block, V97, is introduced in production from 9908 on trucks and from 9910 on buses. There are two annular chambers 12 between the rotor 2 and the stators 1. The oil flows extremely quickly and in a curved spiral path. Higher pressure gives more oil in the chambers and higher brake torque.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

11 vues3 pagesPages From WSM - 0000592 - 01 PDF

Transféré par

yliu07New valve block, V97, is introduced in production from 9908 on trucks and from 9910 on buses. There are two annular chambers 12 between the rotor 2 and the stators 1. The oil flows extremely quickly and in a curved spiral path. Higher pressure gives more oil in the chambers and higher brake torque.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 3

16

Scania CV AB 1999, Sweden 1050f16b.mkr

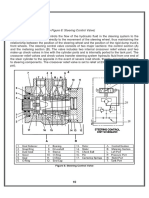

Hydraulic system, overview of later

design

Components in the hydraulic system

1 Stators

2 Rotor

3 Shaft

7 Oil pump

8 Sump

9 Filter

10 Control valve

11 Oil cooler

12 Chamber

13 Air ducts

14 Coolant oilway

15 Radial seals

16 Accumulator

17 Solenoid valve

18 Non-return restriction valve

19 Proportional valve

20 Solenoid valve

21 Bypass valve

22 Safety valve

23 Channel

24 Spring

20

19

18 16

17

11

12

2 7

13

24

8

23

22

21

9

14 1

3 15

10

25

1

1

5

4

2

5

3

2

7

6 5

4 1

25 Cone

Hydraulic system

1050f16b.mkr

Scania CV AB 1999, Sweden 17

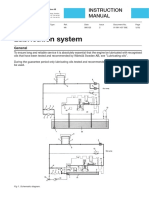

New design of the proportional valve

A new valve block, V97, is introduced in

production from 9908 on trucks and from 9910

on buses. The functions for the following are

incorporated into the valve block:

Proportional valve 19

Air supply for solenoid valve (ON/OFF) 20

Solenoid valve for oil accumulator 17

Note: The new valve block V97 requires a

higher control frequency, 360 Hz. This

frequency is available from control units

manufactured from 9902. Otherwise, the

system is not modified but works in the same

way irrespective of valve design.

Retarder

There is an oil pump 7 on shaft 3 which

receives oil from the sump 8, via the filter 9.

From there, the oil is directed via the control

valve 10, either to the rotor 2 for braking or to

the oil cooler 11 for cooling in disengaged

mode.

There are two annular chambers 12 between

the rotor 2 and the stators 1. When these are

filled with oil, the rotor and the stators force the

oil to change direction repeatedly. The flow of

oil thus provides resistance to the rotor and

counteracts its rotation.

The oil flows extremely quickly and in a

curved spiral path. Centrifugal force causes the

oil in the chambers to accumulat on the

periphery and attempt to escape. The oil is

therefore retained in the chambers by back

pressure from the outside. Higher pressure

gives more oil in the chambers and higher

brake torque.

The chambers are connected to the sump via air

ducts 13. These are necessary to enable the

quantity of oil to be adjusted quickly when the

driver wants to adjust the brake torque.

The oil pump 7 rotates as soon as the vehicle is

in motion. When braking, the oil is directed via

the control valve to the rotor and the oil cooler.

When the retarder is disengaged, most of the

oil is directed via the control valve to the oil

cooler and the sump. A small proportion is

directed via the coolant oilway 14 for

lubrication and cooling.

Safety valve 22 is fitted with an additional

sealing ring from chassis number SS1251239,

SN4414949, SA9043610, SBK1835768.

The retarder and gearbox oil systems are

separated by two radial seals 15.

Hydraulic system

18

Scania CV AB 1999, Sweden 1050f16b.mkr

Oil accumulator

The accumulator 16 is emptied and quickly fills

the retarder when braking begins. This is

activated with compressed air from a solenoid

valve 17. There is a non-return restriction valve

18 in the accumulator outlet.

The left-hand position is the non-return valve

position. The oil then passes both through the

restriction and on the outside of the bushing.

The non-return valve position is used both

when emptying and refilling when the driver

ceases braking.

The right-hand position is the restriction valve

position. The oil then passes only through the

restriction. The restriction valve position is

used when refilling the accumulator during

braking.

Oil cooler

The oil cooler 11 transmits the heat from the

retarder oil to the engine cooling system where

the heat is finally dissipated by the vehicle's

ordinary radiator.

Proportional valve

The supply air solenoid valve 20 and the

proportional valve 19 are both actuated by the

control unit. Unreduced air pressure is fed from

solenoid valve 20 to the proportional valve 19.

The control unit supplies a current, whose

strength corresponds to the required brake

torque, to the proportional valve. This then

delivers air pressure to control valve 10 which

creates the oil pressure necessary to achieve the

required brake torque.

Safety system

See When the retarder is to stop braking, under

Safety system

Hydraulic system

Vous aimerez peut-être aussi

- Marvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SD'EverandMarvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SPas encore d'évaluation

- Zenith CD Carburetters GuideDocument5 pagesZenith CD Carburetters GuideKalrobPas encore d'évaluation

- 980c Especificaciones InglesDocument19 pages980c Especificaciones InglesEdgar TorresPas encore d'évaluation

- CAT 3412 Lubrication SystemDocument5 pagesCAT 3412 Lubrication SystemCEVegaO100% (1)

- ασκήσεις υδραυλικων λαδιουDocument160 pagesασκήσεις υδραυλικων λαδιουchristodoulos charalambousPas encore d'évaluation

- 2 DescriptionDocument24 pages2 Descriptionvanapeer100% (3)

- 182 - Audi A3Document57 pages182 - Audi A3Kaloyan Marinov100% (4)

- Sistema Control Trans 140hDocument7 pagesSistema Control Trans 140hFernando Ortiz86% (7)

- Sistema de Operacion 14G HidraulicaDocument25 pagesSistema de Operacion 14G Hidraulicayeison100% (3)

- 2ZZGE Engine - Part of ManualDocument46 pages2ZZGE Engine - Part of ManualDavide Faelli100% (2)

- Techdoc Print PageDocument47 pagesTechdoc Print PageBuku DigitalPas encore d'évaluation

- EH750-3 Hitachi Euclid Rigid Hauler Hydraulic Training 2nd PartDocument15 pagesEH750-3 Hitachi Euclid Rigid Hauler Hydraulic Training 2nd Partthan zaw win100% (1)

- EH750-3 Rigid Hauler Hydraulic Training 3 RD PartDocument15 pagesEH750-3 Rigid Hauler Hydraulic Training 3 RD Partthan zaw win100% (1)

- CSHA KatalogDocument40 pagesCSHA Kataloglist16947100% (5)

- Presented By:: Sachin Shirke Sarvesh Yadav Hemant SharmaDocument17 pagesPresented By:: Sachin Shirke Sarvesh Yadav Hemant SharmaSarvesh YadavPas encore d'évaluation

- Dismantling Hermetically Sealed CompressorDocument6 pagesDismantling Hermetically Sealed Compressorparchure123100% (2)

- WRV-WRVi Service Manual - September 2012Document64 pagesWRV-WRVi Service Manual - September 2012frigoremont79% (24)

- 9 - Purejet EngineDocument44 pages9 - Purejet EngineРуслан МужиковPas encore d'évaluation

- 930T Wheel Loader Specs and OperationDocument35 pages930T Wheel Loader Specs and OperationBrunoPas encore d'évaluation

- Operacion Impeller ClutchDocument6 pagesOperacion Impeller ClutchticoplazaPas encore d'évaluation

- Lubrication System: Shutdown SIS Previous ScreenDocument7 pagesLubrication System: Shutdown SIS Previous ScreenHector VallesPas encore d'évaluation

- Cummins L10 Engine FamiliarisationDocument16 pagesCummins L10 Engine FamiliarisationTariqMaqsood100% (2)

- Steering System: Systems OperationDocument12 pagesSteering System: Systems Operationhidekel crafort vinicioPas encore d'évaluation

- 930R e 930T Power TrainDocument34 pages930R e 930T Power TrainGilson RodriguesPas encore d'évaluation

- Instruction and Maintenance Manual For Alfa Romeo 2000 Fuel Injection Models U.S.A. VersionDocument42 pagesInstruction and Maintenance Manual For Alfa Romeo 2000 Fuel Injection Models U.S.A. VersionVladimirPas encore d'évaluation

- Construction of Gas TurbineDocument88 pagesConstruction of Gas Turbinesanjeev kushwaha100% (2)

- 980b Wheel Loader HydraDocument13 pages980b Wheel Loader HydraChrissz Noxd0% (1)

- SOP - TG - Seal Oil System Charging1Document6 pagesSOP - TG - Seal Oil System Charging1Rupesh Sinha100% (1)

- Brake SystemDocument6 pagesBrake SystemSumit KatwalPas encore d'évaluation

- Transmission 2Document23 pagesTransmission 2ait mimounePas encore d'évaluation

- Lubrication System C27Document4 pagesLubrication System C27insano008Pas encore d'évaluation

- Valvula Selectora Trans.Document4 pagesValvula Selectora Trans.enriquePas encore d'évaluation

- Refrigeration Compressor Capacity ControlDocument6 pagesRefrigeration Compressor Capacity ControlRachit SharmaPas encore d'évaluation

- SSP - 296 - d1 VW 1.4 FSI EngineDocument40 pagesSSP - 296 - d1 VW 1.4 FSI EngineGavriloae Ion75% (4)

- Lub Sys qsx15Document10 pagesLub Sys qsx15ibrahim salemPas encore d'évaluation

- 1 Edf 005 FB 3Document8 pages1 Edf 005 FB 3George GavriliuPas encore d'évaluation

- ML e C1Document38 pagesML e C1helmi_69Pas encore d'évaluation

- Boiler Feed PumpDocument11 pagesBoiler Feed PumpSolai100% (2)

- Self-Study Programme 246 - Variable Valve TimingDocument30 pagesSelf-Study Programme 246 - Variable Valve TimingTombalicious100% (1)

- Four Cylinder Four Stroke Petrol Engine Test RigDocument8 pagesFour Cylinder Four Stroke Petrol Engine Test RigJaishree ChauhanPas encore d'évaluation

- Convert Id orDocument6 pagesConvert Id orPablo GutierrezPas encore d'évaluation

- D6C Power Shift OperationDocument40 pagesD6C Power Shift OperationJhon AschPas encore d'évaluation

- Low-pressure side refrigeration cycleDocument5 pagesLow-pressure side refrigeration cycleGoriong Butete100% (1)

- Miscellaneous Information On AutomotiveDocument6 pagesMiscellaneous Information On AutomotiveShashank ChheniyaPas encore d'évaluation

- Hydraulic System Operation for D11N Track-Type TractorDocument43 pagesHydraulic System Operation for D11N Track-Type Tractormiguel_catPas encore d'évaluation

- SSP 327 - Audi Engines - Chain Drives - Part 2Document47 pagesSSP 327 - Audi Engines - Chain Drives - Part 2McGiver990100% (2)

- Torque Converter With The Impeller Clutch and The Lockup ClutchDocument10 pagesTorque Converter With The Impeller Clutch and The Lockup ClutchrickcyPas encore d'évaluation

- Hydrogen Cooling and Seal Oil System for Stage II TurbineDocument13 pagesHydrogen Cooling and Seal Oil System for Stage II Turbineraghavendran raghu100% (1)

- Solex Carburettor SchematicDocument3 pagesSolex Carburettor SchematicAnish Sukumar100% (1)

- Wärtsilä lubrication system manualDocument10 pagesWärtsilä lubrication system manualLIVIAPas encore d'évaluation

- INTERNAL COMBUSTION ENGINES & TURBINESDocument24 pagesINTERNAL COMBUSTION ENGINES & TURBINESBanwari Lal Prajapat100% (1)

- Essex Terraplane Six 1933 Owner's Manual of InformationD'EverandEssex Terraplane Six 1933 Owner's Manual of InformationPas encore d'évaluation

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementD'EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementPas encore d'évaluation

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitD'EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitPas encore d'évaluation

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceD'EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenancePas encore d'évaluation

- Construction and Manufacture of AutomobilesD'EverandConstruction and Manufacture of AutomobilesÉvaluation : 5 sur 5 étoiles5/5 (1)

- Types of SewerDocument14 pagesTypes of SewerAmbalal DhongadiPas encore d'évaluation

- Zak SystemDocument10 pagesZak SystemSlavisa BjelicPas encore d'évaluation

- All about the Properties and Uses of Common StonesDocument41 pagesAll about the Properties and Uses of Common StonesBhavya MewadaPas encore d'évaluation

- Fisa Tehnica ROBODURDocument1 pageFisa Tehnica ROBODURdneprmt1Pas encore d'évaluation

- Tài liệu ôn tập tiếng anh 4Document7 pagesTài liệu ôn tập tiếng anh 4Ngọc AmiiPas encore d'évaluation

- X-ray Absorption Spectroscopy TechniqueDocument74 pagesX-ray Absorption Spectroscopy TechniqueAnonymous hz3n3HK1RNPas encore d'évaluation

- API Standard 614 - Lubrication, Shaft-Sealing, and Control-Oil Systems For Special-Purpose ApplicationDocument4 pagesAPI Standard 614 - Lubrication, Shaft-Sealing, and Control-Oil Systems For Special-Purpose ApplicationFabioSalaPas encore d'évaluation

- Turbine Desk OperatorDocument3 pagesTurbine Desk Operatortajshah283Pas encore d'évaluation

- BiochemistryDocument410 pagesBiochemistryCaptainReeham79% (14)

- Japanning 103, Traditional Japanning, The BlacDocument8 pagesJapanning 103, Traditional Japanning, The BlacFredy Alvarez LucasPas encore d'évaluation

- Journal 9 PDFDocument45 pagesJournal 9 PDFRuzengulalebih ZEta's-ListikPas encore d'évaluation

- Ammonium 2520sulphate Material 2520balance.Document9 pagesAmmonium 2520sulphate Material 2520balance.AgadmatorPas encore d'évaluation

- CamberDocument33 pagesCamberIES-GATEWizPas encore d'évaluation

- 01 Well Cementing - Day 1 PDFDocument131 pages01 Well Cementing - Day 1 PDFام فاطمة البطاط100% (1)

- SafetyDataSheet (SDS) 31 Liquid en 03122020Document14 pagesSafetyDataSheet (SDS) 31 Liquid en 03122020Harry VandermeerPas encore d'évaluation

- Improvements of Foundation RocksDocument2 pagesImprovements of Foundation RocksSteven Joseph Incio100% (1)

- METALS PresentationDocument28 pagesMETALS PresentationTheresa TuliaoPas encore d'évaluation

- Brochure Coating ConstructionDocument16 pagesBrochure Coating ConstructionALİ ÖRSPas encore d'évaluation

- Lab Technician Interview QuestionsDocument3 pagesLab Technician Interview QuestionsCandra AprizalPas encore d'évaluation

- SRS 400 A 475 GPMDocument12 pagesSRS 400 A 475 GPMrhusseinpos4765Pas encore d'évaluation

- Solid, Liquid, Gas Explanation TextDocument2 pagesSolid, Liquid, Gas Explanation Textnettexts100% (1)

- Toxicology: Metal Chosen: MERCURYDocument13 pagesToxicology: Metal Chosen: MERCURYsamarpita senguptaPas encore d'évaluation

- 1995Document283 pages1995Robert BataraPas encore d'évaluation

- Structure of The EarthDocument21 pagesStructure of The EarthKaren DarilaPas encore d'évaluation

- APL - Emulsifiers Products ListDocument2 pagesAPL - Emulsifiers Products Listshreeket3953Pas encore d'évaluation

- Primus Operation FS6 To FS23Document50 pagesPrimus Operation FS6 To FS23Arun George50% (2)

- BoilerDocument48 pagesBoilerAbdallah Mansour100% (2)

- Composite Fish Culture PDFDocument2 pagesComposite Fish Culture PDFHanumant JagtapPas encore d'évaluation

- Noble Gases 20 Aug 2022Document2 pagesNoble Gases 20 Aug 2022PLABAN DASPas encore d'évaluation

- Sudharshan Seneviratne 1995Document41 pagesSudharshan Seneviratne 1995darshanieratnawalliPas encore d'évaluation