Académique Documents

Professionnel Documents

Culture Documents

Oracle EAM Process Flow and Business Cycle

Transféré par

Shailendra Chauhan100%(5)100% ont trouvé ce document utile (5 votes)

1K vues16 pagesOracle EAM Process Flow and Business Cycle

Copyright

© © All Rights Reserved

Formats disponibles

DOCX, PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentOracle EAM Process Flow and Business Cycle

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme DOCX, PDF, TXT ou lisez en ligne sur Scribd

100%(5)100% ont trouvé ce document utile (5 votes)

1K vues16 pagesOracle EAM Process Flow and Business Cycle

Transféré par

Shailendra ChauhanOracle EAM Process Flow and Business Cycle

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme DOCX, PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 16

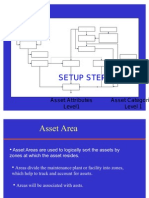

Oracle eAM Process Flow and Business Cycle

Oracle eAM Process Flow and Business Cycle

This document covers the entire business cycle of Enterprise Asset Management with sufficient details to the Business processes

and the Sub processes.

I. General Overview of eAM Business Cycle for any Maintenance Organization

II. Creation Of Work Requests

III. Creation Of Work Orders From Work Requests And Safety Procedures

IV. Process For Releasing Of The Work Orders

V. Material Issue From The Shop Floor Against Work Orders

VI. Work Order Resource Transactions

VII. Completion And Closing of Work Orders

VIII. Failure Analysis Of Assets

IX. Maintenance Cost Analysis

X. Preventive Maintenance Schedule Creation

XI. Preventive Maintenance Work Order Generation

General Overview of eAM Business Cycle For any Maintenance Organization

Description

Whenever equipment breaks down, generally the Equipment operator is the first one to know about it. The Operator will then report

about the breakdown to his supervisor.

The supervisor, upon taking a note of the problem, will raise a Work request. In the Work request, the supervisor will report the asset

number and will also give a brief description of what the problem is. Based on the nature of the problem, he can also assign the work

request to a particular maintenance department (mechanical/electrical/Instrumentation). However if the user is not sure which

department this breakdown is attributed to, the user will keep it blank.

The maintenance user supervisor, upon receiving the Work Request, will designate a person to go to the shop floor and investigate the

problem.

Sometimes the problem could be a minor one (like a loose connection) and could be rectified in minutes. In that case the maintenance

user will rectify the problem and close the work request giving appropriate reasons.

If however, the breakdown takes more time to repair, the maintenance user will use the "Create WO" functionality to directly create a

Work Order (henceforth referred to as WO) from the work request.

Against the work order, the user will add all the sequence of operations and against each operation, the user will need to provide

whatever resources (internal or OSPs) and materials/spares that are required.

In case of OSP items, the user will create a PR and forward it to the purchasing department for raising the PO

The maintenance user will then release the WO. Once the WO is released, transactions against that particular WO will be allowed by

the system.

The maintenance user will now start receiving the PO items (in case of OSPs), charge time (in case of internal resources) and charge

material issued from the stores against the WO number and the operation code.

As and when each operation is finished, the user will complete the particular operation.

Once the equipment is operational, the user will change the status of the WO to complete stage. The equipment is then under the Trial

Run phase.

If the trial run is successfully completed, the user will close the WO order. However, if the trial run fails, then the user will have to un-

complete the WO and again add the necessary operations and repeat the cycle against the same WO.

Creation Of Work Requests

There are 2 sources of information which can lead to a Work request creation:

1- From the Engineer or technician who is on Site

2- Any Operator, or inspector, any user can report or request (by telephone verbally or through a written form) any problem or service

to be done on any asset, this request is to be addressed to the Help Desk

Help Desk (who is receiving the call or the request) after his double check on the problem reported will raise a Work Request on the

same asset, describing the problem in detail. The Help Desk will receive a notification on this Work Request

The Help Desk will also define the Request Type, which can be any of the ones described in the above flowchart

The Requestor will (optionally) classify the Request by their priority with the following LOV: Urgent, Normal and Emergency based on

the business requirements.

The Maintenance Planner will do an investigation, enabling him to approve or to reject the work request.

If approved The Maintenance Planner will place the work request on a work order.

Creation Of Work Orders From Work Requests And Safety Procedures

Description

WO Number will be a running serial number for each Inventory Organization. That is every project will have a different WO sequence.

Similarly each unit of KDB will have a different WO sequence

WO could be of any user defined types Three most commonly used are Breakdown/Corrective Maintenance, Preventive

Maintenance, and Major Overhaul. A new WO type called Major Overhauling will be defined. The WO costs for these overhauling

maintenance types will be allocated to the capitalization account by passing a manual journal.

If Work Orders are created from Work requests using the Auto create mode, WOs will keep a reference of the Work request number

which will again be a running serial number

A Particular WO will have one and only one Activity code against the asset number

Accounting classes will be attached to the assets in the Asset master screen. At the time of WO creation, the Accounting class field will

not be updatable at the time of the WO creation

Each Work order will contain a set of predefined operations. It will be defaulted if operations are defined against the Activity in the

Routing. Optionally the user can add and remove operations

Each operation will contain at least one resource and optionally materials/spares that needs to be issued from the stores

The Work Order will go through the following stages during its entire life cycle:

At the time of creation the WO will be at the Draft stage. Work orders are checked and reviewed by the safety Engineer /Supervisor

Safety Engineer might add a safety operation to the Work order by entering

o in which area the risk is

o what are the precaution to be taken (for instance putting mask)

o Safety instruction list might be attached and printed with the work order

Safety Engineer / Supervisor will change the Work order status into Safe, then only the work can be conducted

Process For Releasing Of The Work Orders

To perform Resource and material transactions against the WO, the Supervisor will have to change the WO status to Released.

Transactions will be allowed only when the WO is in Released state.

In order to Release the Work Order, the WO needs to be necessarily in the "Safe" status (please refer to the previous process on

safety).

If maintenance routing exists for the particular asset Activity, then the operations and its corresponding material/resources are defaulted

from the routing details only and get imported into the WO upon saving. User can however change/delete and add new operations

based on his requirements.

If routing does not exist, the Planner will have to himself add the operations.

Against each operation, the planner will need to specify the materials required and the resource required for the successful completion

of the particular operation. These will be estimated values based on the Planners experience and operation requirements. These

materials/resources will be added in the structure shown in the above flowchart.

Upon releasing the WO, for OSP resources, a purchase requisition will be created which will contain reference to the WO number and

the resource will be charged directly against the WO upon receipt of the PO. For internal resources, time will be charged manually.

Material will have to be issued from warehouse by the stores owner (discussed later)

Material Issue From The Shop Floor Against Work Orders

Description

The maintenance supervisor will first check the available on-hand quantity for the requested material. If the requisite quantity doesnt

exist, the supervisor will change the WO type to "Material Shortage" and will raise purchase requisitions for the procurement of that item.

Approach 1: If Maintenance and Stores are defined as separate Inventory Orgs

The Supervisor/planner will run two processes in succession:

o Shop Floor Replenishment Process

o Shop Floor Replenishment Import

These two processes will create Internal Requisitions for the required items and the convert these internal requisitions into Internal

Orders

The Stores in charge will Pick-Release these material and ship them to the Maintenance Inventory Organizations

Approach 2: If Maintenance and Stores are defined as the same Inventory Org

A separate Sub-inventory called Maintenance will be created for stocking the materials required for maintenance

The Maintenance supervisor will create a Move Order for bulk issue of the material from the stores and thereafter get it approved by the

department head.

Stores will receive the Move Order and will Transact the move order so that the material will be shifted to the maintenance sub-

inventory.

Thereafter the maintenance supervisor will issue those materials as and when required against the WO operations using the One-Step

Material Issue feature of eAM.

Every time material is issued against the WO, the Inventory evaluation account will get credited and the WIP material account will get

debited.

Note: To track Repairable Spares which have been repaired and miscellaneous receipt of the item is done in the stores at 0 cost, a new

item code could be generated using this logic: -1. This -1 will indicate that this item has been repaired. Also it will not affect the cost of

the same item in Inventory. This is however just a suggestion

Work Order Resource Transactions

Outside Processing (OSP) Resources

o The user will receive the OSP item against the WO and the respective operation using the Receipts functionality in Oracle Inventory

against the OSP Purchase order

o If the OSP item is a direct delivery item, no inspection will be required and the resource will be charged directly against the operation.

o However, if inspection is required for the OSP item, the user will have to go to the "Receiving Transactions" screen in Oracle Inventory

inspect the item. If the service is not acceptable, a Return to vendor transaction is done.

o Once the service is accepted, it is delivered and the item gets charged against the Work Order.

Internal Resource Transactions

o The planner will be opening the WO from the Self service page and will "Charge Time" against each of the resource units. These

resources could be labor or even equipments.

o If the Resource is defined as "Costed" (and is associated to a fixed rate) the system will charge the equivalent amount of the resource

cost against the Work Order. Else the system will only charge the time for with the resource had spent on the particular WO operation.

Resource Transaction through Oracle Time and Labor

o This is done for internal resources of the type Labor. Herein the employees fill up the Time card from Oracle Time and Labor model.

While filling the time card, the employee mentions the total time spent with reference to the WO and the operation.

o Once the time card is approved, the maintenance supervisor runs the concurrent process "Import Time Card from OTL" which charges

the resource cost against the WO operation as a proportion to the employee's salary.

Whenever resource is charged against a Work Order, the resource absorption account gets credited and the WIP resource cost gets

debited.

Completion And Closing of Work Orders

As and when each operation is completed, the maintenance supervisor will open the WO and complete the operations

Once equipment is operational, the WO status will be changed to Completed. After this, the equipment will be in what is commonly

referred to as "Trial-Run" phase. In case a problem in the equipment is reported during the trial run, the supervisor will have to go back to

the WO and un-complete the same in order to resume work.

After the trial run is completed successfully, or during the Inventory closing, the WO will have to be Closed.

Failure Analysis Of Assets

Whenever a breakdown/corrective maintenance WO is created, the Planner should associate an applicable failure set to the same. This is

required to analyze the failure breakdown history of the asset and helps in planning/budgeting of the preventive maintenance schedules.

If an appropriate Failure set does not exist, the planner should go to the Failure Analysis and define the appropriate failure codes. A failure

set should comprise of the following codes:

o Failure Code -> What kind of failure has occurred in the asset

o Cause Code -> What is/are the possible reason/s for such a failure

o Resolution Code -> What could be the possible method/s to rectify the current failure

Once the failure set is defined, it should be associated with the WO. Failure sets need not be associated at the time of WO creation. Ideally

they should be associated to the WO at just before completing the same so that the exact causes and resolutions are known and accurate

data is fed into the system.

From time to time the following analysis could be done on the system for the failure of a particular asset:

o Number of failures in a given period

o Mean time between failures

o Distribution of failures over Failure Codes

Maintenance Cost Analysis

Every WO needs to be associated with a set of accounts called the Accounting Class. The accounting class generally defaults from the

Asset (as defined in the asset master) and the same will be available for maintenance.

Accounting class contains different cost elements under the heads: Material, Resource, Equipment and each of their overheads.

Generally, only the cost elements Material and Resource are be tracked by organizations

Material and spares will be issued at the inventory cost from the inventory against the WO

OSP Purchase Requisition creation will be manual. OSP resources (outside labor, etc) are charged directly to the WO based on their PO

price upon receipt.

AMC (Annual Maintenance Contracts) are generally treated as OSP items

At any point of time, the total cost (and also the cost break-up) for any particular WO will be available

Also the total maintenance cost of any particular asset throughout its maintainable existence will be available.

Since asset hierarchies will be correctly defined, the total maintenance cost roll up of a particular parent asset (including the child assets

will also be available)

For major overhaul type of breakdown, the maintenance cost will be capitalized against the asset.

Preventive Maintenance Schedule Creation

To create the PM schedule, the planner might need to refer to the failure analysis of the asset over a period of time to determine the

frequency of PM and quantify the PM scheduling rules.

Once that is done, the PM planner will check whether a suitable PM schedule Set is available for the Asset or not. If it is not available, the

planner will have to go to the "PM Set name" form and define an appropriate schedule set name to associate the PM schedule of the

equipment with.

Thereafter the PM planner will have to define a particular schedule for the Asset's PM. While doing that the planner will have to specify

the following attributes:

a. The Equipment name and the associated PM activity.

b. Check the Default flag. This option has to be selected if PM WOs are to be generated for this equipment. There could be only one

active schedule for a particular set of Asset Number and Activity

c. Scheduling Rules. Usually the rules should be scheduled in a manner that the Last Scheduled start date would be used to Predict

the next scheduled start date of the PM Work Order.

d. If it is a Rule based PM schedule, then the Days interval needs to be given.

e. If it is a meterized PM schedule, then meter information also needs to be furnished with the PM schedule.

Finally the Planner will enter the Last Service Information of the Asset Activity and save all the changes. The PM schedule definition is

now complete and it could be used for PM scheduling.

Preventive Maintenance Work Order Generation

There are two ways of generating PM Work orders.

Method 1: The planner runs the concurrent process "Generate Work Orders". The system will ask for a few parameters out of which the

End date is mandatory. This end date will be the final date till which the system will generate the PM Work orders. The user can also

streamline his choices by generating PM WOs only for a few assets or for a department or even for a particular Asset area (as explained in

the flow diagram).

Method2: This is a method by which the Planner gets to pick and choose which PM Work orders will be implemented.

o The planner first goes to the Maintenance Workbench. Using a few filter conditions, the planner will choose a few assets for which he

wants to forecast the Work Orders

o The planner will then go to the "Forecast" and Run a simulation till a selected cut off date. The system fill forecast all the PM WOs that

should be generated for a particular asset over the time period using the rules defined in the schedules.

o The Planner will use these suggestions to either Implement those Work Orders or manually reschedule them. Thus the PM Work orders

will be generated.

Vous aimerez peut-être aussi

- EAM - Oracle Enterprise Asset Management Training ManualDocument27 pagesEAM - Oracle Enterprise Asset Management Training Manualsrinivas100% (3)

- EAM StepsDocument9 pagesEAM Stepsvamc232855Pas encore d'évaluation

- General eAM SetupDocument8 pagesGeneral eAM SetupAbu SiddiquePas encore d'évaluation

- Oracle EAM R12 - Overview of Asset Acquisition and Maintenance ProcessDocument38 pagesOracle EAM R12 - Overview of Asset Acquisition and Maintenance ProcessGuillermo Todd100% (4)

- EAM Work Orders Stuck In Release-Pending After Approval (Data FixDocument2 pagesEAM Work Orders Stuck In Release-Pending After Approval (Data FixAhmed ForsanPas encore d'évaluation

- Oracle Apps EAM FunctionalDocument842 pagesOracle Apps EAM Functionalrajus241Pas encore d'évaluation

- EAM TablesDocument3 pagesEAM TablesGaurav Sharma100% (2)

- Oracle Manufacturing Modules GuideDocument11 pagesOracle Manufacturing Modules GuideDebasish Mohapatra100% (1)

- Oracle Apps EAM TechnicalDocument440 pagesOracle Apps EAM Technicalrajus241100% (1)

- Oracle Order Management Interview QuestionsDocument6 pagesOracle Order Management Interview QuestionsKatie Ruiz100% (2)

- Oracle eAM Student Guide VOL1Document498 pagesOracle eAM Student Guide VOL1nabilparkar100% (1)

- Quality Integration SetupDocument12 pagesQuality Integration SetupAbu SiddiquePas encore d'évaluation

- Oracle EAM - Implementation Steps For Oracle eAM ModuleDocument2 pagesOracle EAM - Implementation Steps For Oracle eAM Moduleoraclefever100% (4)

- Defining Maintenance Routes - Oracle Enterprise Asset ManagementDocument4 pagesDefining Maintenance Routes - Oracle Enterprise Asset ManagementPedro ViegasPas encore d'évaluation

- Different Oracle EAM Process Flows and Implementation StepsDocument5 pagesDifferent Oracle EAM Process Flows and Implementation Stepsh_sleemPas encore d'évaluation

- Setup Oracle AMEDocument51 pagesSetup Oracle AMEhmza_6Pas encore d'évaluation

- eAM With Linear Asset PDFDocument64 pageseAM With Linear Asset PDFAl Busaidi100% (1)

- Oracle eAMDocument92 pagesOracle eAMsri0403809235100% (2)

- EAM - Oracle Enterprise Asset Management Training ManualDocument72 pagesEAM - Oracle Enterprise Asset Management Training Manualprabhu181Pas encore d'évaluation

- Oracle EAM Setup StepsDocument3 pagesOracle EAM Setup Stepsmurad0% (1)

- OPM WorkflowsDocument48 pagesOPM Workflowsata_rehman70Pas encore d'évaluation

- Service Contract - Install BaseDocument10 pagesService Contract - Install Baseshivamba_chinnu_3332100% (1)

- Oracle EAM 1Document61 pagesOracle EAM 1MohammedMustafaPas encore d'évaluation

- Short Notes On Oracle WIP User GuideDocument22 pagesShort Notes On Oracle WIP User Guidetsurendar0% (1)

- EAM Process FlowDocument3 pagesEAM Process Flowwasif_ahmed_4Pas encore d'évaluation

- EAM Asset MoveDocument16 pagesEAM Asset MoveVictor MillanPas encore d'évaluation

- R12: Introduction To Asset TrackingDocument9 pagesR12: Introduction To Asset TrackingAymen HamdounPas encore d'évaluation

- CRM - Oracle Deport Repair Setups and ProcessDocument11 pagesCRM - Oracle Deport Repair Setups and ProcessPreethi Kishore100% (1)

- Oracle EAM Understanding Process FlowsDocument7 pagesOracle EAM Understanding Process FlowsRamesh GarikapatiPas encore d'évaluation

- Fundamentals of Preventive Maintenance Schedule Definition With Oracle eAMDocument42 pagesFundamentals of Preventive Maintenance Schedule Definition With Oracle eAMBennie MareePas encore d'évaluation

- Mechanical Testing of MaterialsDocument38 pagesMechanical Testing of MaterialsAanand Rishabh DagaPas encore d'évaluation

- The r12 Enterprise Asset Management An OverviewDocument64 pagesThe r12 Enterprise Asset Management An OverviewabiyePas encore d'évaluation

- Oracle Applications Inventory Training ManualDocument171 pagesOracle Applications Inventory Training ManualLaxminarayanaPas encore d'évaluation

- Oracle Enterprise Asset ManagementDocument68 pagesOracle Enterprise Asset ManagementMohmed Badawy100% (1)

- Purchasing Presentation OADocument39 pagesPurchasing Presentation OASanthosh Kumar PathaPas encore d'évaluation

- eAM PresentationDocument42 pageseAM PresentationKherfan100% (5)

- Trade Skills Assessment GuideDocument25 pagesTrade Skills Assessment GuideRandz Lampa0% (1)

- eAM Data Model 012808Document19 pageseAM Data Model 012808Shanish Poovathodiyil100% (1)

- What Is Oracle Shopfloor ManagementDocument7 pagesWhat Is Oracle Shopfloor ManagementRamesh GarikapatiPas encore d'évaluation

- Oracle Install Base OverviewDocument18 pagesOracle Install Base OverviewmallikarjunPas encore d'évaluation

- Enterprise Asset Management Overview and Walkthrough Deloitte Designer Tech Forum PresentationDocument50 pagesEnterprise Asset Management Overview and Walkthrough Deloitte Designer Tech Forum PresentationRamya BalachandarPas encore d'évaluation

- Short Notes On Oracle WIP Userguide IVDocument31 pagesShort Notes On Oracle WIP Userguide IVtsurendarPas encore d'évaluation

- Oracle Supply Change and Warehouse Management.Document46 pagesOracle Supply Change and Warehouse Management.madhugover123Pas encore d'évaluation

- Solve Process Problems Quickly with Simulation TrainingDocument6 pagesSolve Process Problems Quickly with Simulation TrainingAnonymous qPt2MHzXTPas encore d'évaluation

- Uploading Catalogs For Iproc SetupDocument7 pagesUploading Catalogs For Iproc Setuphuda_10Pas encore d'évaluation

- Oracle EAM Product RoadmapDocument38 pagesOracle EAM Product RoadmapUmerPas encore d'évaluation

- Introduction To Oracle Enterprise Asset ManagementDocument59 pagesIntroduction To Oracle Enterprise Asset ManagementFarooq MohammedPas encore d'évaluation

- EAM Implementation QuestionnaireDocument2 pagesEAM Implementation QuestionnaireShyam Ganugapati80% (5)

- Understanding of Various EAM Work Order TypesDocument14 pagesUnderstanding of Various EAM Work Order TypesUmer100% (1)

- Quick Tour of Oracle Enterprise Asset Management for BeginnersDocument33 pagesQuick Tour of Oracle Enterprise Asset Management for BeginnersBalasubramanya ChowdaryPas encore d'évaluation

- Properties of LPGDocument33 pagesProperties of LPGmukund madhav100% (2)

- Oracle EamDocument14 pagesOracle Eamblshinde88Pas encore d'évaluation

- A380-LEVEL III - ATA 42 Integrated Modular Avionics - Avionics DaDocument66 pagesA380-LEVEL III - ATA 42 Integrated Modular Avionics - Avionics DaAbolfazl Mazloomi100% (11)

- Hot Bolting FPSO BrazilDocument1 pageHot Bolting FPSO BrazilKhan Arshi100% (1)

- Consign Inventory Process FlowDocument1 pageConsign Inventory Process FlowNaveed MohammadPas encore d'évaluation

- Oracle EAM Training ContentsDocument4 pagesOracle EAM Training ContentsAnonymous oSTh85100% (1)

- Distributed Oracle EAM - A White PaperDocument38 pagesDistributed Oracle EAM - A White PaperrpgudlaPas encore d'évaluation

- Oracle EAM Failure AnalysisDocument4 pagesOracle EAM Failure AnalysisDock N DenPas encore d'évaluation

- Accounting Entires For Oracle Apps R12Document27 pagesAccounting Entires For Oracle Apps R12Vimalakkannan GopalPas encore d'évaluation

- Oracle E-Business Suite The Ultimate Step-By-Step GuideD'EverandOracle E-Business Suite The Ultimate Step-By-Step GuidePas encore d'évaluation

- EAM Process FlowchartDocument2 pagesEAM Process Flowchartwasif_ahmed_4Pas encore d'évaluation

- Returns and Repairs ProcessingDocument3 pagesReturns and Repairs ProcessingFabrizio CiavolaPas encore d'évaluation

- Setting Up Oracle Depot RepairDocument5 pagesSetting Up Oracle Depot RepairShahjahan MohammedPas encore d'évaluation

- Move Order Approval Workflow - NotesDocument8 pagesMove Order Approval Workflow - Notestahirghafoor50% (2)

- Part-Mr-Heng ImsDocument23 pagesPart-Mr-Heng ImsMR MARWANE OFFICIELPas encore d'évaluation

- Isolation of Caffeine from TeaDocument6 pagesIsolation of Caffeine from TeaDaisy Joyce Seroje BuslonPas encore d'évaluation

- c600 17lookinsideDocument6 pagesc600 17lookinsideИван МинчевPas encore d'évaluation

- Sennheiser MD 441Document2 pagesSennheiser MD 441ndujaPas encore d'évaluation

- Cisco SD-WAN Policy Architecture - Dana Yanch PDFDocument1 pageCisco SD-WAN Policy Architecture - Dana Yanch PDFEmilio PazPas encore d'évaluation

- GRAS 46BE 1/4Document9 pagesGRAS 46BE 1/4nino16041973Pas encore d'évaluation

- Appendix B - Design Examples: B.1 Multi-Span Precast Concrete Girder Made Continuous With Composite DeckDocument35 pagesAppendix B - Design Examples: B.1 Multi-Span Precast Concrete Girder Made Continuous With Composite DeckMICHAEL TADESSEPas encore d'évaluation

- Air Conditioning Fact SheetDocument6 pagesAir Conditioning Fact SheetrjchpPas encore d'évaluation

- Pairwise testing: A powerful technique for reducing test casesDocument26 pagesPairwise testing: A powerful technique for reducing test casesvineeta1234Pas encore d'évaluation

- Emp2 Box Pressure TransmitterDocument8 pagesEmp2 Box Pressure TransmitterAsif HameedPas encore d'évaluation

- Ansul Wheeled RedLine 150lb F-2002046Document4 pagesAnsul Wheeled RedLine 150lb F-2002046German Duvan HernandezPas encore d'évaluation

- Mechanical Power Transmission ReviewDocument17 pagesMechanical Power Transmission ReviewRoshan TiwariPas encore d'évaluation

- Messerschmitt Me 262 - Wikipedia, The Free Encyclopedia3Document5 pagesMesserschmitt Me 262 - Wikipedia, The Free Encyclopedia3beta2009Pas encore d'évaluation

- What Is AmplifierDocument18 pagesWhat Is AmplifierEbayLunaPas encore d'évaluation

- Abbreviations Plumbing Symbols: Fort Worth DistrictDocument21 pagesAbbreviations Plumbing Symbols: Fort Worth DistrictDenzel NgPas encore d'évaluation

- Bots and Automation Over Twitter During The U.S. Election: CompropDocument5 pagesBots and Automation Over Twitter During The U.S. Election: CompropRaninha MoraisPas encore d'évaluation

- Petri Net Modeling and ApplicationsDocument13 pagesPetri Net Modeling and ApplicationsRishiraj SenguptaPas encore d'évaluation

- Appendix 400.4 - Traffic Count TemplateDocument7 pagesAppendix 400.4 - Traffic Count TemplateOgunranti RasaqPas encore d'évaluation

- Sheds Direct Ireland's Wooden BrochureDocument12 pagesSheds Direct Ireland's Wooden BrochureVictor Celestino Montañez CarranzaPas encore d'évaluation

- Iso Dis 20283-4 2011Document27 pagesIso Dis 20283-4 2011Ricardo RamirezPas encore d'évaluation

- Peanut Brittle LabDocument2 pagesPeanut Brittle LabMary Bacon HillebrandPas encore d'évaluation

- Contactor Cap Lc1dDocument4 pagesContactor Cap Lc1dAlfiansyah Dharma Setia DjaketraPas encore d'évaluation

- Aerial Robotics Lecture 1B - 5 Agility and ManoeuvrabilityDocument4 pagesAerial Robotics Lecture 1B - 5 Agility and ManoeuvrabilityIain McCulloch100% (1)

- d-Copia3500MF 4500MF 5500MFsmY113351-4Document1 051 pagesd-Copia3500MF 4500MF 5500MFsmY113351-4ctecisbPas encore d'évaluation

- Control Valve and Steam Line PDFDocument19 pagesControl Valve and Steam Line PDFRofi MuhammadPas encore d'évaluation