Académique Documents

Professionnel Documents

Culture Documents

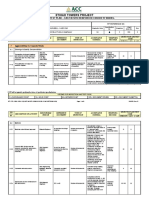

Civil works inspection and test plan for administration building

Transféré par

Lloyd R. PonceDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Civil works inspection and test plan for administration building

Transféré par

Lloyd R. PonceDroits d'auteur :

Formats disponibles

F-04-915-101-R1

NKCI

I.

1 n/a n/a

II.

A. Sec. 02102 02102-1.1 to 2.4 per location As per plan X

B.

Sec. 02221-2.1.2.3 Sec. 02221-2.1.2.3 per location as per recommendation from the

Geotechnical Engineer

X

C.

sec. 02221.2.1 sec. 02232.2.1.1.1 as per required

Dense graded agg. Meeting requirements in

section 02232 Proj. tech'l specs.

X

2232-

2.1.1.1/3.1.1.5.2

ASTM C

136/AASHTO T 27

1,000 tons or each day's run AASHTO M 147 "Grading B" X

2232-2.1.1.1 ASTM C 117 1,000 tons or each day's run 15% max X

2232-2.1.1.1 ASTM D 1883 every 2,500 cu.m 30 min. X

2232-2.1.1.1 ASTM D 4318 1,000 tons or each day's run

LL shall not exceed 25%; PI shall not exceed

5%

X

2232-2.1.1.1 ASTM 1557 every 1,500 cu.m MDD/OMC X

02221-2.1.2.1 ASTM D 2487 every 1,500 cu.m GW,GP,SW,SP X

02221-2.1.2.1 ASTM D 4318 every 1,500 cu.m LL shall not exceed 35%; PI shall not exceed

12%

X

02221-2.1.2.1 ASTM D 1140 every 1,500 cu.m percent passing sieve 200 shall not exceed

35

X

02221-3.7 ASTM 1557 every 1,500 cu.m MDD/OMC X

02221-2.1.2.3 ASTM 2487 every 1,500 cu.m GP,GM,GC,SP,SM,SC X

02221-2.1.2.4 02221-2.1.2.4 as per required Table 2.1.2.4 X

2221-2.1.2.5 2221-2.1.2.5 every 1,500 cu.m Meeting the requirements for

Fill/Backfill/& Granular Fill

X

2221-3.1.1 sec. 2221-3.1.1 Each Preparation As determined by the Engineer X

2232-3.1.1.3 ASTM D 1556 / D

4718

1 set of 3 per 500 sq.m or

fraction thereof

95% minimum

X

D. 2102-2.4 per location Outside from the Project Site/or as per

approved by the Engineer

X

D.TOP SOIL

E.BORROW

Test Results

Test Result

Test Result

Test Result

W

0

Title ITP for ADMINISTRATION BUILDING ITP Rev. Date

Form

AURORA SPECIAL ECONOMIC ZONE AUTHORITY ( PHASE 1 )

INSPECTION AND TEST PLAN-ITP

Contractor New Kanlaon Construction Incorporated Contract No. ASEZA-INFRA-09-01

CIVIL WORKS

Project Name Aseza Project (Phase-1) ITP Rev. No.

EDCOP

PRELIMINARIES

General Requirements

Item No.

Description of the Operation/ Test/ Inspection

2. EXECUTION

H/W

H/W

Backfill

Test Result / Geotechnical Engr. Report

Test Result

Test Result

Test Result

Test Result

Structural Excavation

2.Atterberg Limits

H/W

H/W

H/W

Test Results

C. GENERAL SITE FIILL AND EMBANKMENT MATERIAL

2.1 Field Density Test

Stage/Frequency Acceptance Criteria

Inspection and

Testing

Output/Records

Description / Characterisrics

Site Cleaning Inspectin Report

A. GRANULAR FILL H/W

Test Result

B. BACKFILL

1.Grading/Sieve Analysis

2.Materials Finer than sieve 200

3.California Bearing Ratio

4.Atterberg Limits

5.Laboratory Compaction Test

H/W

H/W

H/W

H/W

1. MATERIALS REQUIREMENT

W

Test Results

Test Results

Test Results

Specification

Reference No.

Procedure

Reference No.

1.Soil Classification

1. Soil Classification H/W

Disposal

H/W

W

W Inspection Report

1.Soil Classification

3.Materials Finer than sieve 200

4.Laboratory Compaction Test

2.0 Placing, Compacting & Finishing

H/W

1.0 Surface Preparation

1.1 Removal of unsatisfactory Materials W Inspection Report

Test Results

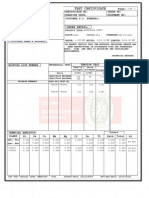

F-04-915-101-R1

NKCI

0

Title ITP for ADMINISTRATION BUILDING ITP Rev. Date

Form

AURORA SPECIAL ECONOMIC ZONE AUTHORITY ( PHASE 1 )

INSPECTION AND TEST PLAN-ITP

Contractor New Kanlaon Construction Incorporated Contract No. ASEZA-INFRA-09-01

Project Name Aseza Project (Phase-1) ITP Rev. No.

EDCOP

Item No.

Description of the Operation/ Test/ Inspection

Stage/Frequency Acceptance Criteria

Inspection and

Testing

Output/Records

Description / Characterisrics

Specification

Reference No.

Procedure

Reference No.

E.

Sec. 02221-2.1.2.3 ASTM D 2487 every 1,500 cu.m GP,GM,GC,SP,SM,SC

X

Similar to the above requirements as mentioned under Item "c. Backfill"

2221-3.1.1 sec. 2221-3.1.1 Each Preparation As determined by the Engineer X

sec. 2221-3.1.1.1 sec. 2221-3.1.1.1 Each Preparation No indications of rutting & pumping after 6

passes of 15 tons pneumatic tire roller

X

2232-3.1.1.3 ASTM D 1556 / D

4718

1 set of 3 per 500 sq.m or

fraction thereof

95%

X

F. per location As determined by the Engineer X

G. 2225-2.1.4 2225-3.3 every 1,500 cu.m GW or GP X

H. per location/application Subject to the Evaluation by the Safety

Engineer

X

I. Each preparation 6 mil minimum thickness X

J.

2232-

2.1.1.1/3.1.1.5.2

ASTM C

136/AASHTO T 27

1,000 tons or each day's run AASHTO M 147 X

2232-2.1.1.1 ASTM C 117 1,000 tons or each day's run 15% max X

2232-2.1.1.1 ASTM D 1883 every 2,500 cu.m 30 min. X

2232-2.1.1.1 ASTM D 4318 1,000 tons or each day's run

LL shall not exceed 25%; PI shall not exceed

5%

X

2232-2.1.1.1 ASTM 1557 every 1,500 cu.m MDD/OMC X

2232-3.1.1.3 ASTM D 1556 / D

4718

1 set of 3 per 500 sq.m or

fraction thereof

100% X

Same as under item Portland Cement Concrete Pavement ( Site Development ) X

Same as under item Portland Cement Concrete Pavement ( Site Development ) X

Test Results

Gravel Bedding

W

Product data and Materials Safety Data

Sheet

Polyethylene Sheet

Parking Area

H/W

Test Results

Test Results

Test Results

Test Results

Test Results

1. MATERIALS REQUIREMENT

3.California Bearing Ratio

H/W Test Results

d. Backfill

H/W

Test Result

H/W Inspection Report

2.1 Field Density Test

Trimming

Soil Poisoning

W

Test Results

Manufacturer's Data/Product Sample

1. Field Density Test

Inspection Report

Test Results

W

1. MATERIALS REQUIREMENT

Earthfill

a. General Site Fill and Embankment Material

a.1 Soil Classification

2.0 Placing, Compacting & Finishing

2. EXECUTION

W

H/W

1.Grading/Sieve Analysis H/W

1. MATERIALS REQUIREMENT

2.Materials Finer than sieve 200

H/W

W

2.0 Concrete Pavement

1.0 Aggregate Base Course

4.Atterberg Limits

5.Laboratory Compaction Test

2. EXECUTION

Placing, Compacting & Finishing

H/W

a. Cement

b. Water

H/W

1.1 Removal of unsatisfactory Materials W Inspection Report

2.0 Subgrade Proof Rolling Inspection Report

H/W

1.0 Surface Preparation

F-04-915-101-R1

NKCI

0

Title ITP for ADMINISTRATION BUILDING ITP Rev. Date

Form

AURORA SPECIAL ECONOMIC ZONE AUTHORITY ( PHASE 1 )

INSPECTION AND TEST PLAN-ITP

Contractor New Kanlaon Construction Incorporated Contract No. ASEZA-INFRA-09-01

Project Name Aseza Project (Phase-1) ITP Rev. No.

EDCOP

Item No.

Description of the Operation/ Test/ Inspection

Stage/Frequency Acceptance Criteria

Inspection and

Testing

Output/Records

Description / Characterisrics

Specification

Reference No.

Procedure

Reference No.

Same as under item Portland Cement Concrete Pavement ( Site Development ) X

Same as under item Portland Cement Concrete Pavement ( Site Development ) X

Same as under item Portland Cement Concrete Pavement ( Site Development ) X

Same as under item Portland Cement Concrete Pavement ( Site Development ) X

2259-1.1.2/1.3.1 ACI 211.1

Before work commence or every

change of matls

source/materials physical

properties

CMD rqmnts: flexural strength @ 28 days=3.8

Mpa,Max agg. Size=25mm, Min Cement

Factor=350 kg/cu.m, W/C ratio=0.50, Slump

25mm-75mm, Air content=6 +/-1.5

X

2259-1.1.2/1.3.1

ASTM C 192/

C 192M

Before work commence or every

change of matls source or

materials physical properties

ACI 318 X

2559-3.7.2.3 ASTM C 143 every 75 cu.m. 25mm-75mm X

2559-3.7.2.3.4 ASTM C 138 Twice each day in every placing

concrete

X

2559-1.3 ASTM C 78 every 75 cu.m. 3.8 Mpa @ 28 days X

2559-3.7.2.3.6 ASTM C 42/C 174 not less than 1,670 sq.m as per Plan X

PNS 49 PNS 49 1 ton 0n each size

PNS 49 / for dia. 12mm fy=Grade 40 and

for dia. 16mm and above fy=Grade 60

X

PNS 49 PNS 49 1 ton 0n each size PNS 49 H

sec. 3100 sec. 3100 each Preparation as per Plan X

III

A.

2259-2.1

ASTM C 150/ ASTM

C 595

every 2,000 bags

ASTM C 150, Type-1 Cement / ASTM C 595,

Type 1P Cement

X

Same as under item Portland Cement Concrete Pavement ( Site Development ) X

2.3.2 ASTM C 136 1,000 tons ASTM C 33 sec. 6.1 X

2259-2.3.1 ASTM C 227 1,500 cu.m Section 2259-2.3.1 X

2259-2.3.2 ASTM C 128 1,500 cu.m same source from appove Mix des. X

2259-2.3.2 ASTM C 29 1,500 cu.m same source from appove Mix des. X

H/W

H/W

Test Results

1. Grading/Sieve Analysis H/W Test Results

Quality Test for F.A Test Results

2. Alkali Reactivity (Mortar Bar Method) H/W Test Results

H/W

H/W

W Test Results

Test Results

Test Results

H/W Test Results

Test Results

STRUCTURAL WORKS

Concrete

W

H/W

H/W

Inspection Report

Test Results

Test Results

Test Results

Test Results

Test Results

H/W

H/W

W Test Results

W Test Results

H/W

a. Cement

1. Fabrication and Installation

b. Fine aggregate

H/W

3.Reinforcing Bars

2. Chemical Properties

Test Results

3. Specific Gravity

4. Unit weight

c. Fine aggregate

4. Core Test (thickness determination)

4.0 Formworks

1. Slump Test

d. Coarse Aggregate

e. Admixture

f. Curing Agent

g. Concrete

2. Yield Test

2. EXECUTION

1. Mechanical Properties

3. Flexural Stength

1. MATERIALS REQUIREMENT

Quality Test

1. Concrete Mix Design

S

Evaluation of of Concrete Mix Design

2. Trial Mix W Test Results

F-04-915-101-R1

NKCI

0

Title ITP for ADMINISTRATION BUILDING ITP Rev. Date

Form

AURORA SPECIAL ECONOMIC ZONE AUTHORITY ( PHASE 1 )

INSPECTION AND TEST PLAN-ITP

Contractor New Kanlaon Construction Incorporated Contract No. ASEZA-INFRA-09-01

Project Name Aseza Project (Phase-1) ITP Rev. No.

EDCOP

Item No.

Description of the Operation/ Test/ Inspection

Stage/Frequency Acceptance Criteria

Inspection and

Testing

Output/Records

Description / Characterisrics

Specification

Reference No.

Procedure

Reference No.

2259-2.3.2 ASTM C 40 1,500 cu.m not darker than standard color chart X

2259-2.3.2 ASTM C 88 1,500 cu.m 10% max. X

2259-2.3.2 ASTM C 142 1,500 cu.m 3% max. X

2259-2.3.2 ASTM C 136 1,000 tons

will not vary by 0.20 from the value determined

from the mix design

X

X

2259-2.3.3 ASTM C 136 1,000 tons ASTM C 33-Table 3 X

2259-2.3.3 X

2259-2.3.3 ASTM C 227 1,500 cu.m 2259-2.2 X

2259-2.3.3 ASTM C 128 1,500 cu.m same source from appove Mix des. X

2259-2.3.3 ASTM C 29 1,500 cu.m same source from appove Mix des. X

2259-2.3.3 ASTM C 88 1,500 cu.m not to exceed 10% X

2259-2.3.3 ASTM C 142 1,500 cu.m 1 +/- 0.5 X

2259-2.3.3 ASTM C 131/535 1,500 cu.m 40 % X

02259-2.4 ASTM C 494 per shipment Source Approval X

X

2259-2.1 each source Engineer's Certificate for potable water X

2259-2.2 ASTM C 87 1 test each source

90% @ 28 days on specimen made of known

satisfactory quality.

X

02259-2.4

ASTM C 309 /

ASTM C 156

per shipment white-pigmented Type 2, Class B, X

X

2259-1.1.2/1.3.1 ACI 211.1

Before work commence or every

change of matls

source/materials physical

properties

CMD rqmnts: flexural strength @ 28 days=3.8

Mpa,Max agg. Size=25mm, Min Cement

Factor=350 kg/cu.m, W/C ratio=0.50, Slump

25mm-75mm, Air content=6 +/-1.5

X

2259-1.1.2/1.3.1

ASTM C 192/

C 192M

Before work commence or every

change of matls source or

materials physical properties

ACI 318 X

2559-3.7.2.3 ASTM C 143 every 75 cu.m. or each days

pouring

4" maximum X

2559-3.7.2.3.4 ASTM C 138 Twice each day in every placing

of concrete

conformed to concrte mix design X

2559-1.3 ASTM C 78 every 75 cu.m. or each days

pouring

4,000 psi for mat foundation,suspended

slab,colums,beams and girders 3,000psi

for slab on grade 2,500psi for Lean

Concrete.

X

2559-3.7.2.3.6 ASTM C 42/C 174 obtain 3 cores incase of failure

of test cylinder sample

not less than 80% of the specified strength

X

3. Specific Gravity W Test Results

4. Unit weight W Test Results

5. Soundness by Sodium sulfate H/W Test Results

6. Clay lumps & Friable Particles H/W Test Results

7. Abrasion H/W Test Results

e. Water

g. Concrete H/W Test Results

CONCRETE

1. Slump Test

Test Results

H/W

W

Test Results

Test Results

H/W Test Results

H/W Test Results

Test Result

W Test Results

H/W

W

W

W

Test Results

H/W Test Results

H/W

1. Quality Test/Engineer's Certificate

W

Test Results

W Test Results

Test Result

W Inspection Report

3. Compressive Strength

4. Core Test (concrete strength)

1. Concrete Mix Design S

Evaluation of of Concrete Mix Design

2. Trial Mix W Test Results

2. EXECUTION

5. Organic Impurities Test Results

W Test Results

6. Soundness by Sodium sulfate H/W Test Results

7. Clay lumps & Friable Particles H/W Test Results

d. Admixture

2. Yield Test

f. Curing Agent

8. Finess Modulus

1. Grading

Quality Test

2. Alkali Reactivity (Mortar Method)

c. Coarse Aggregate

2. Mortar specimen

F-04-915-101-R1

NKCI

0

Title ITP for ADMINISTRATION BUILDING ITP Rev. Date

Form

AURORA SPECIAL ECONOMIC ZONE AUTHORITY ( PHASE 1 )

INSPECTION AND TEST PLAN-ITP

Contractor New Kanlaon Construction Incorporated Contract No. ASEZA-INFRA-09-01

Project Name Aseza Project (Phase-1) ITP Rev. No.

EDCOP

Item No.

Description of the Operation/ Test/ Inspection

Stage/Frequency Acceptance Criteria

Inspection and

Testing

Output/Records

Description / Characterisrics

Specification

Reference No.

Procedure

Reference No.

B.

sec. 3100 sec. 3100 each Preparation as per Plan X

C.

b. Grade 60

PNS 49 PNS 49 1 ton 0n each size PNS 49 / for dia. 12mm fy=Grade 40 and

for dia. 16mm above fy=Grade 60

X

D.

5120-2.1.2 ASTM A36 or A611 one test each source fy = 248 Mpa min. X

5120-2.1.2 ASTM A36 one test each source fy = 248 Mpa min. X

* 5120-2.1.2 ASTM A36 or A611 one test each source fy = 248 Mpa min.

X

IV

A.

Notes on Plans

sheet#S001

ASTM C 140 3 units Every 10,000 pcs or

Fraction Thereof

not less than 3 Mpa

X

Notes on Plans

sheet#S001

ASTM C 140 3 units Every 10,000 pcs or

Fraction Thereof

not less than 80 PCF

X

4230.2.4 ASTM C 404 1 set per floor level NSCP 703.4.1 f'g 13.8 Mpa tested @ 28

days

X

each Preparation as per Plan X

Notes on Plans

sheet#S001

each lot Mastic Filler 12mm thick X

B

* sec. 06402 sec. 06402

each type As per plan/Materials Approval X

* sec. 06402 sec. 06402

each type As per plan/Materials Approval X

* sec. 06402 sec. 06402

each type As per plan/Materials Approval X

sec. 06402 sec. 06402

each type As per plan/Materials Approval X

C.

1.0 sec. 09255 each type As per plan/Materials Approval X

a. Grade 40

d. Expansion Joint W Product Sample/Inspection Report

Inspection Report W

1. Mechanical and Chemical Properties

H/W

Test Results

Test Results

Product Sample/Inspection Report

W

W

W

W

Test Results

Manufacturer's Data/Product Sample

H/W

W Inspection Report

Product Sample/Inspection Report

Product Sample/Inspection Report

Reinforcing Bars

Flat Ceiling on Gypsum Board & Metal Furring @ Kitchen

Product Sample/Inspection Report

Test Result

Test Results

Test Result

c. Plastering

1. PRODUCTS/MATERIALS REQUIREMENT:

Structural Steel works

1.0 Roof Framings

b. CHB Mortar

H/W

Test Result

Formworks

1. Fabrication and Installation

2. Unit weight

b. Sag Rod

ARCHITECTURAL WORKS

MASONRY WORKS

a. CHB

c. Rafters-Wide Flange

H/W

1. Compressive Strength

H/W

CARPENTRY WORKS

B.1 Stairs

CEILING WORKS

1. Wood Treads

2. Balusters

3. Wood Handrails

4. Base Boards

a. C Purlins H/W

H/W

S

F-04-915-101-R1

NKCI

0

Title ITP for ADMINISTRATION BUILDING ITP Rev. Date

Form

AURORA SPECIAL ECONOMIC ZONE AUTHORITY ( PHASE 1 )

INSPECTION AND TEST PLAN-ITP

Contractor New Kanlaon Construction Incorporated Contract No. ASEZA-INFRA-09-01

Project Name Aseza Project (Phase-1) ITP Rev. No.

EDCOP

Item No.

Description of the Operation/ Test/ Inspection

Stage/Frequency Acceptance Criteria

Inspection and

Testing

Output/Records

Description / Characterisrics

Specification

Reference No.

Procedure

Reference No.

2.0

sec. 09255 each type As per plan/Materials Approval X

3.0 each type As per plan/Materials Approval X

4.0 each type As per plan/Materials Approval X

5.0 sec. 9512 sec. 9512 each type As per plan/Jardine Building System X

D.

1.0 each type As per plan/Materials Approval X

2.0 each type As per plan/Materials Approval X

3.0 sec. 9300 sec. 9300 1 sample each type Mariwasa Product or approved equal X

E.

each type As per plan/Materials Approval X

sec.09900 sec.09900 each type Davies/Colortex-Stucco; or approved equal X

sec.09900 sec.09900 each type Davies/Colortex-Stucco; or approved equal X

F.

sec.08111/08211 sec.08111/08211 each type As per plan/Materials Approval X

sec.08111/08211 sec.08111/08211 each type As per plan/Materials Approval X

sec.08111/08211 sec.08111/08211 each type As per plan/Materials Approval X

sec.08111/08211 sec.08111/08211 each type As per plan/Materials Approval X

sec.08111/08211 sec.08111/08211 each type As per plan/Materials Approval X

Manufacturer's Data/Product Sample

Manufacturer's Data/Product Sample

Manufacturer's Data/Product Sample

Manufacturer's Data/Product Sample

Manufacturer's Data/Product Sample

S

Cove Lighting on Gypsum Board & Metal Furring @ Main

Lobby

Manufacturer's Data/Product Sample

Manufacturer's Data/Product Sample

S

Acoustical Panel Board @ Adminstrator's Office, Admin Staff

Room, Conferrence Room, Cafeteria, Offices & Audio Visual

Rooms

FLOOR FINISHES

C.3 Drop Ceiling @ Audio Visual Room

Moisture Resistant Gypsum Board @ Administrator's Toilet,

Cafeteria Toilet, Common Toilet & Main Lobby Area

S

S

1. Interior - Semi-gloss Latex

E.2 Painting Works

2. Interior- T & B-Semi-gloss Latex

DOORS

F.1 Doors

WALL FINISHES

E.1 Ceramic Wall Tiles @ T&B

S

S

S

S Product Sample/Inspection Report

S Product Sample/Inspection Report

S Product Sample/Inspection Report

S Product Sample/Inspection Report

S Product Sample/Inspection Report

Homogeneous Floor Tiles - 600mmx1400mm @Main Lobby

Armstrong High Traffic Vinyl Floor Tiles

(@Administrator's Office & Admin Staff Room)

Ceramic Floor Tiles - (@ Administrator's Toilet, Conference

Room, Cafeteria, Kitchen, Cafeteria Toilet, Common Toilet &

Main Lobby Area, Offices, Common Toilet, Audio Visual

Rooms)

S Manufacturer's Data/Product Sample

S Manufacturer's Data/inspection report

S Manufacturer's Data/inspection report

D-1 Aluminum Frame, Double Panel,Double Swing Type

Door, Powder Coated Matte Finish w/ 6mm thk clear

tempered glass (2.1m x 2.1m)

D-2 Wooden Frame Swing Type Door, w/ 6mm thk clear

tempred glass (.9m X 2.1m)

D-3 Swing Type Hollow Core Flush Door in Wood Stain

Finish (.7m x 2.1m)

D-4 Swing Type Hollow Core Flush Door in Wood Stain

Finish (.8m x 2.4m)

D-5 Swing Type Hollow Core Flush Door in Wood Stain

Finish (.9m x 2.4m)

F-04-915-101-R1

NKCI

0

Title ITP for ADMINISTRATION BUILDING ITP Rev. Date

Form

AURORA SPECIAL ECONOMIC ZONE AUTHORITY ( PHASE 1 )

INSPECTION AND TEST PLAN-ITP

Contractor New Kanlaon Construction Incorporated Contract No. ASEZA-INFRA-09-01

Project Name Aseza Project (Phase-1) ITP Rev. No.

EDCOP

Item No.

Description of the Operation/ Test/ Inspection

Stage/Frequency Acceptance Criteria

Inspection and

Testing

Output/Records

Description / Characterisrics

Specification

Reference No.

Procedure

Reference No.

sec.08111/08211 sec.08111/08211 each type As per plan/Materials Approval X

sec.08111/08211 sec.08111/08211 each type As per plan/Materials Approval X

G.

sec. 0820 sec. 08920-2.3 each type As per Plan sheet#A010/Materials Approval X

sec. 0820 sec. 08920-2.3 each type As per Plan sheet#A010/Materials Approval X

sec. 0820 sec. 08920-2.3 each type As per Plan sheet#A010/Materials Approval X

sec. 0820 sec. 08920-2.3 each type As per Plan sheet#A010/Materials Approval X

H.

sec.7110-2.1 sec.7110-3.1 each type Nito proof 600, Brush Bond, Fosroc 3M or

approved equal

X

I.

sec.09900 sec.09900-3.0 each type and color Davies Liquid Tile X

sec.09900 sec.09900-3.0 each type and color Plastron Type R X

sec.09900 sec.09900-3.0 each type and color Plastron Type R X

J.

each type as per plan / Materials Approval x

K.

per lot as per plan / Materials Approval X

V

B.

each type as per plan / Materials Approval X

Product Sample/Inspection Report

Manufacturer's Data/Product Sample

Manufacturer's Data/Product Sample

Product Sample/Inspection Report

Manufacturer's Data/Product Sample

S

Manufacturer's Data/Product Sample

Manufacturer's Data/Product Sample

Specialty Items

K.1 Lattice Wood Works

Waterproofing and Thermal Protection

H.1 Waterproofing toilets

Exterior Finishing

I.1 Painting (Plain Cement Paint Finish)-

I.2 Painting(Plain Cement Paint Finish) @ Beam Soffit

I.3 Painting(Plain Cement Paint Finish) @ Exterior (12"

thk )

Roofing

ARCHITECTURAL WORKS (SUNDRIES)

Carpentry Works

B.1 Roof Eaves

1. 25mm thk solid wood fascia in sadolin finish; 0.12m

w

WINDOWS

J.1 Concrete Roof Tiles w

S

S

S

S

S

D-6 Swing Type Double Panel Hollow Core door in wood

stain finish (1.8m x 2.1m)

D-7 Wooden Frame Double Panel Swing Type Door, w/

6mm thk clear tempered glass (1.8m x 2.1m)

S Product Sample/Inspection Report

S Product Sample/Inspection Report

W-1 Aluminum Frame 4-Panels Awning Type Window in

Powder Coated Matte Finish, with 6mm thk. Clear Glass

with Sliding Type Windows at lower Panels (Ventanillas)

4800 x 4000mm

W-2 Aluminum Frame 3-Panel Awning Type Window in

Powder Coated Matte Finish, with 6mm thk. Clear Glass

with Sliding Type Windows at lower Panels

(Ventanillas)3625 x 3200mm

W-3 Aluminum Frame Single-Panels Awning Type

Window in Powder Coated Matte Finish, with 6mm thk.

Clear Glass with Sliding Type Windows at lower Panels

(Ventanillas)1276 x 3200mm

W-2 Aluminum Frame Single-Panel Open Type Window

in Powder Coated Matte Finish, with 6mm thk. Clear Glass

with Sliding Type Windows at lower Panels

(Ventanillas)3200 x 3200mm

W Manufacturer's Data/Product

Sample/Inspection Report

W Manufacturer's Data/Product

Sample/Inspection Report

W Manufacturer's Data/Product

Sample/Inspection Report

W Manufacturer's Data/Product

Sample/Inspection Report

F-04-915-101-R1

NKCI

0

Title ITP for ADMINISTRATION BUILDING ITP Rev. Date

Form

AURORA SPECIAL ECONOMIC ZONE AUTHORITY ( PHASE 1 )

INSPECTION AND TEST PLAN-ITP

Contractor New Kanlaon Construction Incorporated Contract No. ASEZA-INFRA-09-01

Project Name Aseza Project (Phase-1) ITP Rev. No.

EDCOP

Item No.

Description of the Operation/ Test/ Inspection

Stage/Frequency Acceptance Criteria

Inspection and

Testing

Output/Records

Description / Characterisrics

Specification

Reference No.

Procedure

Reference No.

each type as per plan / Materials Approval X

each type as per plan / Materials Approval X

C.

each type as per plan / Materials Approval X

each type as per plan / Materials Approval X

each type as per plan / Materials Approval X

each type as per plan / Materials Approval X

D.

sec.9300 each type mariwasa product or approved equal X

E.

sec.9900 each type Davies Megacryl Latex Paint X

F.

sec. 08111/08211 each type as per plan / Materials Approval X

G.

each type as per plan (window schedule) X

H.

1.0

sec. 7110 sec. 7110-3.0

each type Fosroc 3M or approved equal X

2.0 sec. 7110 sec. 7110-3.0 each type Sec. 7110-2.1 (B) X

3.0 each type as per plan X

4.0 each type as per plan X

I.

1.0 each type as per plan / Materials Approval X

2.0 each type as per plan / Materials Approval X

L.

1.0 sec. 5500-2.5.1 sec. 5500-2.5.1 each type ASTM A53 / Schedule 40 X

M.

2 sec.10800-2.1 sec. 5500-2.5.1 each type as per plan / Materials Approval X

VI MECHANICAL WORKS

I. Air-conditioning System

A. Equipment

1.0 Sec. 1(Mech'l) each type with same capacity as per plan / Materials Approval X

Product Sample/Inspection Report

ACCU-G-1 (24HP) - Outdoor Unit - Serves 8 FCUs

S

S

Manufacturer's Cert. of Compliance

Product Sample/Inspection Report

S Product Sample/Inspection Report

Product Sample/Inspection Report

Product Sample/Inspection Report

S

Manufacturer's Data/Product Sample

Product Sample/Inspection Report

Product Sample/Inspection Report

Product Sample/Inspection Report

Waterproofing for kitchen

S

S

PRODUCTS/MATERIALS REQUIREMENTS:

Waterproofing for underground tank

Tools and Equipment

Wall Accent 200mm w x 2730mm h

C.2 Cornice for kitchen

C.3 Cornice for T&B

C.4 Rubbed Concrete Ceiling

3. Continuous Vent (200mm)

E.2 Painting Works

E.1 Random Cut for Ramp at Drop off

S

S

S

Floor Finishes

PRODUCTS/MATERIALS REQUIREMENTS:

S

S

Ceiling Works

C.1 12mm thk plain ficem board ceiling for roof eaves

PRODUCTS/MATERIALS REQUIREMENTS:

Doors

Accessories

Exterior Finishing

Manufacturer's Data/Product Sample

Manufacturer's Data/Product Sample

Product Sample/Inspection Report

Inspection Report

Column Cladding (Ledgestones Cladding)

Metal Works

1000mm high steel railing with 50x75 rectangular steel

handrail steel baluster at 150mm o.c.

Toilet Accessories

PRODUCTS/MATERIALS REQUIREMENTS:

Waterproofing and Thermal Protection

S

Wall Finishes

Windows

S

S

S

2. 25mm thk solid wood fascia in sadolin finish; 0.314m

w

S Manufacturer's Cert. of Compliance/ Product

Sample/Inspection Report/

S Product Sample/Inspection Report

S Product Sample/Inspection Report

Manufacturer's Data/Product Sample

S Product Sample/Inspection Report

F-04-915-101-R1

NKCI

0

Title ITP for ADMINISTRATION BUILDING ITP Rev. Date

Form

AURORA SPECIAL ECONOMIC ZONE AUTHORITY ( PHASE 1 )

INSPECTION AND TEST PLAN-ITP

Contractor New Kanlaon Construction Incorporated Contract No. ASEZA-INFRA-09-01

Project Name Aseza Project (Phase-1) ITP Rev. No.

EDCOP

Item No.

Description of the Operation/ Test/ Inspection

Stage/Frequency Acceptance Criteria

Inspection and

Testing

Output/Records

Description / Characterisrics

Specification

Reference No.

Procedure

Reference No.

2.0 Sec. 1(Mech'l) each type with same capacity as per plan / Materials Approval X

3.0 Sec. 1(Mech'l) each type with same capacity as per plan / Materials Approval X

4.0 Sec. 1(Mech'l) each type with same capacity as per plan / Materials Approval X

5.0 Sec. 1(Mech'l) each type with same capacity as per plan / Materials Approval X

6.0 Sec. 1(Mech'l) each type with same capacity as per plan / Materials Approval X

7.0 Sec. 1(Mech'l) each type with same capacity as per plan / Materials Approval X

8.0 Sec. 1(Mech'l) each type with same capacity as per plan / Materials Approval X

9.0 Sec. 1(Mech'l) each type with same capacity as per plan / Materials Approval X

10.0 Sec. 1(Mech'l) each type with same capacity as per plan / Materials Approval X

11.0 Sec. 1(Mech'l) each type with same capacity as per plan / Materials Approval X

Note: ACCU- Air Cooled Condensing Unit VRF - Variable Refrigerant Flow FCU-Fan Coil Unit

B. Refrigerant Piping & Accessories

1.0 Sec. 3-1.0(Mech'l) Each type with same diameter not less than 2413 kPa. X

2.0 Sec. 3-1.0(Mech'l) Each type with same diameter as per plan / Materials Approval X

3.0 Sec. 3-1.0(Mech'l) Each type with same diameter as per plan / Materials Approval X

4.0 Sec. 3-5.a(Mech'l) Each type with same diameter shall be laminated integral aluminum foil

vapor barrier

X

5.0 Sec. 3-1.0(Mech'l) Each type with same diameter as per plan / Materials Approval X

6.0 Sec. 3-1.0(Mech'l) Each type as per plan / Materials Approval X

Pressure Test and Dehydration Sec.3-1.0(g)Mech'l Entire System High side shall be subjected to 350 psig and

a low side to a pressure of 150 psig

maintained for a period of 24 hrs.

X

II. Ventilation System

A.

1.0 Sec. 2-5.0(Mech'l) each type with same capacity as per plan / Materials Approval X

2.0 each type with same capacity as per plan / Materials Approval X

3.0 02750-11.1.1.6(a) each type with same capacity as per plan / Materials Approval X

4.0 02750-11.1.1.6(a)

each type with same capacity as per plan / Materials Approval X

B.

1.0 BI Sheet Gage #18 each type as per plan / Materials Approval X

2.0 Duct Insulation, 12mm thk. X 80kg/m

3

Polyester Sec. 3-5.a(Mech'l) each type as per plan / Materials Approval X

3.0 GI Sheet Gage #24 each type as per plan / Materials Approval X

4.0 Duct Hangers and Supports Sec. 3-

3.g.1(Mech'l)

each type as per plan / Materials Approval X

Manufacturer's Cert. of Compliance

Manufacturer's Cert. of Compliance

CEF G-1 to CEF G-13 ( Ceiling Exhaust Fan)

EAC-1 to EAC-2 (Electronic Air Cleaner)

KEB-1 (Kitchen Exhaust Blower)

FAB-1 (Fressh Air Blower)

Manufacturer's Cert. of Compliance

Manufacturer's Cert. of Compliance

Manufacturer's Cert. of Compliance

Product Sample/Inspection Report

Manufacturer's Cert. of Compliance

H/W Test Result

Equipment

S

Product Sample/Inspection Report

Product Sample/Inspection Report

Product Sample/Inspection Report

ACCU-G-4 (24HP) - Outdoor Unit - Serves 3 FCUs

FCU-G- ( 11,12,23 )

Wired Remote Controller

Branch Joint

Centralized Remote Controller for VRF System

Refrigerant Pipe Insulation, Dual Layer; Inner Layer-

Polypropylene/Outer Layer of Polyolefin

6.35,6.35,6.35,6.35, 6.35, 6.35,6.35 mm

Refrigerant Pipe Hangers & Supports

Copper Pipe Fittings

Copper Pipe, Type "L" Hard Drawn 6.35,9.52,12.7, 15.88,

19.05,22.2,28.58 - mm

Electrical Wiring

Miscallaneous

S

S

S

Manufacturer's Cert. of Compliance

S

S

S

S

Manufacturer's Cert. of Compliance

Manufacturer's Cert. of Compliance

Manufacturer's Cert. of Compliance

Manufacturer's Cert. of Compliance

FCU-G-( 1 up to 8 )

ACCU-G-2 (24HP) - Outdoor Unit - Serves 6 FCUs

S

Manufacturer's Cert. of Compliance

Manufacturer's Cert. of Compliance

Manufacturer's Cert. of Compliance

S

S

Product Sample/Inspection Report

Product Sample/Inspection Report

S

S

S

S

FCU-G-( 9,10,13,14,15,16 )

ACCU-G-3 (24HP) - Outdoor Unit - Serves 6 FCUs

FCU-G- ( 17 up to 22 )

S

S

S

S

S

S

S

Product Sample/Inspection Report

S

S

Product Sample/Inspection Report

Inspection Report

Product Sample/Inspection Report

Ventilation System Ductworks & Accessories

F-04-915-101-R1

NKCI

0

Title ITP for ADMINISTRATION BUILDING ITP Rev. Date

Form

AURORA SPECIAL ECONOMIC ZONE AUTHORITY ( PHASE 1 )

INSPECTION AND TEST PLAN-ITP

Contractor New Kanlaon Construction Incorporated Contract No. ASEZA-INFRA-09-01

Project Name Aseza Project (Phase-1) ITP Rev. No.

EDCOP

Item No.

Description of the Operation/ Test/ Inspection

Stage/Frequency Acceptance Criteria

Inspection and

Testing

Output/Records

Description / Characterisrics

Specification

Reference No.

Procedure

Reference No.

5.0 700 x 300 FAG (Fresh Air Grille) each type as per plan / Materials Approval X

6.0 PVC Pipe (150, 100) each type as per plan / Materials Approval X

7.0 Vent Cap (100, 150 ) each type as per plan / Materials Approval X

8.0 Electrical Wiring for Ventilation Fans each type as per plan / Materials Approval X

9.0 Motor Controller & Wiring for KEB-1 & FAB-1 each type as per plan / Materials Approval X

10.0 Spring Vibrator Isolator for KEB-1 & FAB-1 each type as per plan / Materials Approval X

11.0 Miscellaneous each type as per plan / Materials Approval X

VII

A.

1.0 Electl 2.5 UL 83 each size Phelps Dodge/Philtex X

2.0 Electl 2.2.1 NEMA TC/UL 651 each size PVC type EPC-40(NELTEX,EMERALD,

ATLANTA)

X

3.0 Electl 2.1 NEMA TC3 per location sec. electl 2.15 X

4.0 per location as per plan / Materials Approval X

5.0

similar requirements to the Civil Work Specification (Administration Building) X

B

1.0 Electl 2.5

UL 83 per location Phelps Dodge/Philtex X

2.0 Electl 2.2.1 NEMA TC/UL 651 per location PVC type EPC-40(NELTEX,EMERALD,

ATLANTA)

X

3.0 electl 3.1.3.1 electl 3.1.3.1 each type MC GILL/MATSUSHITA/SUMITOMO X

4.0 electl 2.4 UL 50 each type STEEL CITY/APPLETON X

5.0 electl 1.1.4 UL 360 each type MC GILL/MATSUSHITA/SUMITOMO X

6.0 electl 2.6 UL 48SA/UL 486C each type MC GILL/MATSUSHITA/SUMITOMO X

7.0 Sec. 3.1.2.6 NFPA/PEC each type 3M/CAMSCO X

8.0 electl 2.2 electl 2.2 each type MC GILL/MATSUSHITA/SUMITOMO X

9.0 each type as per plan / Materials Approval X

C

1.0 Sec. 08625 each type as per plan / Materials Approval X

2.0 Sec. 08625 each type as per plan / Materials Approval X

3.0 Sec. 08625 each type as per plan / Materials Approval X

4.0 Sec. 08625 each type as per plan / Materials Approval X

5.0 Sec. 08625 each type as per plan / Materials Approval X

6.0 Sec. 08625 each type as per plan / Materials Approval X

7.0 Sec. 08625 each type as per plan / Materials Approval X

8.0 Sec. 08625 each type as per plan / Materials Approval X

9.0 Sec. 08625 each type as per plan / Materials Approval X

10.0 Sec. 08625 each type as per plan / Materials Approval X

S/W Product Sample/Inspection Report

S/W

Product Sample/Inspection Report

S/W

Product Sample/Inspection Report

200W Metal Halide

120W Par 38 Ground Spotlight

Product Sample/Inspection Report

Product Sample/Inspection Report

Product Sample/Inspection Report

S

S

Product Sample/Inspection Report

S/W Product Sample/Inspection Report

Product Sample/Inspection Report

S/W Product Sample/Inspection Report

S/W Product Sample/Inspection Report

S/W

THHN Wire

100W lamp post

100W Bollard Light

Flexible Conduit

Straight Connector

Locknut & Bushing

Fitting & Accessories

Miscellaneous

20mm PVC pipe

S/W

S/W

Lighting Fixtures

S/W

S

S

S

S

S Product Sample/Inspection Report

Product Sample/Inspection Report

Utility box

Junction box with cover

THHN Wire

Fittings and Accessories

Miscellaneous

Lighting & Power Layout

Product Sample/Inspection Report

Product Sample/Inspection Report

Product Sample/Inspection Report

Product Sample/Inspection Report

S/W Product Sample/Inspection Report

Product Sample/Inspection Report

S/W Product Sample/Inspection Report

Civil Works

S/W

S/W

Parabolic Rectangular Troffer with 2x40W

40W Linear Fluorescent Light

40W Linear Fluorescent Light (cove lighting)

40W Warm white Fluorescent fixture

60W Ceiling Pinlight

50W Recessed Wall Light Flush Mounted

PVC pipe

ELECTRICAL WORKS

Main Feeder Line

S/W

Product Sample/Inspection Report

S/W

S/W

S/W

S/W

w/S Product Sample/Inspection Report

Product Sample/Inspection Report

Product Sample/Inspection Report

S/W

Product Sample/Inspection Report

Product Sample/Inspection Report

Product Sample/Inspection Report

S/W Product Sample/Inspection Report

Test Results/Inspection Report

Product Sample/Inspection Report

S/W Product Sample/Inspection Report

S/W

1. PRODUCTS/MATERIALS REQUIREMENT:

F-04-915-101-R1

NKCI

0

Title ITP for ADMINISTRATION BUILDING ITP Rev. Date

Form

AURORA SPECIAL ECONOMIC ZONE AUTHORITY ( PHASE 1 )

INSPECTION AND TEST PLAN-ITP

Contractor New Kanlaon Construction Incorporated Contract No. ASEZA-INFRA-09-01

Project Name Aseza Project (Phase-1) ITP Rev. No.

EDCOP

Item No.

Description of the Operation/ Test/ Inspection

Stage/Frequency Acceptance Criteria

Inspection and

Testing

Output/Records

Description / Characterisrics

Specification

Reference No.

Procedure

Reference No.

11.0 Sec. 08625 each type as per plan / Materials Approval X

12.0 Sec. 08625 each type as per plan / Materials Approval X

13.0 Sec. 08625 each type as per plan / Materials Approval X

14.0 Sec. 08625 each type as per plan / Materials Approval X

15.0 Sec. 08625 each type as per plan / Materials Approval X

16.0 Sec. 08625 each type as per plan / Materials Approval X

17.0 Sec. 08625 each type as per plan / Materials Approval X

D

1.0 electl 2.10 UL67/UL50/UL 489 each type L.J Industriaand FUJI HAYA/SQUARE-D/E.G X

2.0 electl 2.10 UL67/UL50/UL 489 each type L.J Industriaand FUJI HAYA/SQUARE-D/E.G X

3.0 electl 2.10 UL67/UL50/UL 489 each type L.J Industriaand FUJI HAYA/SQUARE-D/E.G X

4.0 electl 2.10 UL67/UL50/UL 489 each type L.J Industriaand FUJI HAYA/SQUARE-D/E.G X

5.0 electl 2.10 UL67/UL50/UL 489 each type L.J Industriaand FUJI HAYA/SQUARE-D/E.G X

6.0 electl 2.10 UL67/UL50/UL 489 each type L.J Industriaand FUJI HAYA/SQUARE-D/E.G X

7.0 electl 2.10 UL67/UL50/UL 489 each type L.J Industriaand FUJI HAYA/SQUARE-D/E.G X

8.0 electl 2.10 UL67/UL50/UL 489 each type L.J Industriaand FUJI HAYA/SQUARE-D/E.G X

9.0 electl 2.10 UL67/UL50/UL 489 each type as per plan / Materials Approval X

10.0 electl 2.10 UL67/UL50/UL 489 each type as per plan / Materials Approval X

11.0 electl 2.10 UL67/UL50/UL 489 each type as per plan / Materials Approval X

12.0 electl 2.10 UL67/UL50/UL 489 each type as per plan / Materials Approval X

E

1.0 electl 2.9 NEMA WD 1

/UL50/UL514A

each type as per plan / Materials Approval X

2.0 electl 2.9 NEMA WD 1

/UL50/UL514A

each type as per plan / Materials Approval X

3.0 electl 2.9 NEMA WD 1

/UL50/UL514A

each type as per plan / Materials Approval X

4.0 electl 2.9 NEMA WD 1

/UL50/UL514A

each type as per plan / Materials Approval X

5.0 electl 2.8 NEMA WD 1

/UL50/UL514A

each type NATIONAL WIDE SERIES X

6.0 electl 2.8 NEMA WD 1

/UL50/UL514A

each type NATIONAL WIDE SERIES X

7.0 electl 2.8 NEMA WD 1

/UL50/UL514A

each type NATIONAL WIDE SERIES X

8.0 electl 2.8 NEMA WD 1

/UL50/UL514A

each type NATIONAL WIDE SERIES X

9.0 electl 2.8 NEMA WD 1

/UL50/UL514A

each type NATIONAL WIDE SERIES X

10.0 each type as per plan / Materials Approval X

F

Product Sample/Inspection Report

S/W

S/W Product Sample/Inspection Report

LP (Lighting Panel)

S/W Product Sample/Inspection Report

S/W

MEP/MTS (Main Electl Panel/Manual Transfer Switch)

LP 2 (Lightning Panel 2)

PPM (Power Panel Main)

PP2 (Power Panel 2)

EP/FCU (Elect'l Panel/Fan Coil Unit)

Switch 1 gang

Consumables

Switch 2 gang

Switch 3 gang

3Way Switch 3 gang

3Way Switch 2 gang

Telephone System

MDP (Main Distribution Panel)

S/W Product Sample/Inspection Report

S/W Product Sample/Inspection Report

S/W

PP (Power Panel 1)

800AT, 3P, 230V, NEMA 3R

50AT, 3P, 230V, NEMA 3R

125AT, 3P, 230V, NEMA 3R

20AT, 3P, 230V, NEMA 3R

Wiring Devices

Duplex Convenience outlet

Duplex Convenience outlet WP

Duplex Convenience outlet Floor Mounted

Range Outlet

21" x 21" Solatube 300DS square

21" Solatube 330DS with dimmer

21" Solatube 330DS Round

21" Solatube 290DS

Panel Board & Enclosed Circuit Breaker

Exit Light

Battery Operated Emergency Light

Exhaust Fan

Others Please Specify

S/W

S/W

Product Sample/Inspection Report

Product Sample/Inspection Report

Product Sample/Inspection Report

Product Sample/Inspection Report

Product Sample/Inspection Report

Product Sample/Inspection Report

S/W

S/W

S/W

S/W

Product Sample/Inspection Report

S/W

S/W

S/W

S/W

S/W

Product Sample/Inspection Report

Product Sample/Inspection Report

Product Sample/Inspection Report

Product Sample/Inspection Report

Product Sample/Inspection Report

S/W Product Sample/Inspection Report

S/W Product Sample/Inspection Report

S/W Product Sample/Inspection Report

S/W Product Sample/Inspection Report

Product Sample/Inspection Report

S/W

S/W Product Sample/Inspection Report

S/W Product Sample/Inspection Report

S/W Product Sample/Inspection Report

S/W Product Sample/Inspection Report

Product Sample/Inspection Report

S/W

Product Sample/Inspection Report

S/W Product Sample/Inspection Report

F-04-915-101-R1

NKCI

0

Title ITP for ADMINISTRATION BUILDING ITP Rev. Date

Form

AURORA SPECIAL ECONOMIC ZONE AUTHORITY ( PHASE 1 )

INSPECTION AND TEST PLAN-ITP

Contractor New Kanlaon Construction Incorporated Contract No. ASEZA-INFRA-09-01

Project Name Aseza Project (Phase-1) ITP Rev. No.

EDCOP

Item No.

Description of the Operation/ Test/ Inspection

Stage/Frequency Acceptance Criteria

Inspection and

Testing

Output/Records

Description / Characterisrics

Specification

Reference No.

Procedure

Reference No.

1.0 each type as per plan / Materials Approval X

2.0 each type as per plan / Materials Approval X

3.0 each type as per plan / Materials Approval X

4.0 electl 3.1.3.2 NFPA

70/PEC3.14.2.14

each type as per plan / Materials Approval X

5.0 electl 2.12 electl 2.4 each type Volume greater than 1640 mL, UL 50,hot-dip,

zinc-coated, if sheet steel.

X

6.0 each type as per plan / Materials Approval X

7.0 each type as per plan / Materials Approval X

8.0 electl 2.12 NEMA TC 3 each type as per plan / Materials Approval X

9.0 each type as per plan / Materials Approval X

VIII

A

1.0 15400 part3-3.2(J) each type as per plan / Materials Approval X

2.0 15400 part3-3.2(J) each type as per plan / Materials Approval X

3.0 15400 part3-3.2(J) each type as per plan / Materials Approval X

4.0 15400 part3-3.2(J) each type as per plan / Materials Approval X

5.0 15400 part3-3.2(J) each type as per plan / Materials Approval X

B

B.1

1.0 15400 Part2-2.3 ASTM 2729 each size Neltex PVC Pipe or approved equivalent,

Series 1000 High Impact

X

B.2

1.0 15400 Part2-2.3 AWWA C 900 each size Neltex PVC Pipe Pressure Class 150 or

approved equal

X

2.0 15400 Part2-2.4(E) AWWA C 900 each size Cast Iron Body by ANILEX / METMA 2 X

3.0 15400 Part2-2.4(C) AWWA C 900 each size Cast Iron X

15400 part3-

3.11(b)

entire water system cold water piping system shall be tested at

200 psi for period of 2 Hrs

X

15400 part3-

3.14(A)

entire water system not less than 120 psi for a period of 24 hrs. X

Junction box

MTTC w/ Backboard

1.0 MATERIALS REQUIREMENT

2. EXECUTION

1.0 Hydrostatic Test

TTC w/ Backboard 24"x18"x8"

Telephone Outlet

PLUMBING (Administration Bldg.)

Floor Clean out ( 150mm ,100mm )

Lavatory w/ faucet

Urinal w/ faucet

Kitchen Sink with Faucet

Grease Trap

Sewer Lines

PVC Pipes including fittings (150mm,100mm,75mm)

PVC Pipes including fittings

(150mm,100mm,75mm,50mm)

Above Ground

Under Ground

Floor Drain 50mm

Consumables

Fixtures

Water Closest w/ fittings

UTP Cat 5e Cable

PVC pipe (32mm,20mm)

Utility Box

Alphet Cable 12pairs

S/W

S/W Product Sample/Inspection Report

S/W Product Sample/Inspection Report

S/W Product Sample/Inspection Report

S/W Product Sample/Inspection Report

S/W Product Sample/Inspection Report

S/W Manufacturer's Data/Inspection Report

S/W Manufacturer's Data/Inspection Report

S/W

S/W Product Sample/Inspection Report

S/W Product Sample/Inspection Report

S/W Manufacturer's Data/Inspection Report

S/W Manufacturer's Data/Inspection Report

S/W Manufacturer's Data/Inspection Report

S/W Product Sample/Inspection Report

S/W Product Sample/Inspection Report

S/W

S/W Product Sample/Inspection Report

Product Sample/Inspection Report

Product Sample/Inspection Report

Product Sample/Inspection Report

1.0 MATERIALS REQUIREMENT

1.1 Cold Water Piping System

1.2 Newly laid Pipe or Valved Section of piping

H/W Test Result / Inspection Report

H/W Test Result / Inspection Report

F-04-915-101-R1

NKCI

0

Title ITP for ADMINISTRATION BUILDING ITP Rev. Date

Form

AURORA SPECIAL ECONOMIC ZONE AUTHORITY ( PHASE 1 )

INSPECTION AND TEST PLAN-ITP

Contractor New Kanlaon Construction Incorporated Contract No. ASEZA-INFRA-09-01

Project Name Aseza Project (Phase-1) ITP Rev. No.

EDCOP

Item No.

Description of the Operation/ Test/ Inspection

Stage/Frequency Acceptance Criteria

Inspection and

Testing

Output/Records

Description / Characterisrics

Specification

Reference No.

Procedure

Reference No.

15140 part3-

3.15(b)

entire water system liquid chlorine or hypochloride; minimum

dosage=50 parts per million

X

Similar Requirements to Civil Works

C

1.0 15400 Part2-

2.1(A.1)

DIN16892 each type Vesbo Pipes or/ multi layered High Density

Polyetelyne Pipes (Philsatherm, Unitec Pipes

or Equivlent)

X

2.0 15400 Part2-2.2(D) each type Brass or Bronze (Honeywell, Tozen or

Approved Equivalent)

X

3.0 15400 Part2-2.8(C) each type Lockable type, suitable for water pressure up

to 100 psi

X

4.0 15400 Part2-2.2(F) AWWA C 500 each size Class 150/Bermad or Claval or approved

equal

X

5.0 15400 Part2-2.2(E) AWWA C 500 each size as per plan / Materials Approval X

6.0 15400 Part2-2.2(E) AWWA C 500 each size shall be all bronze construction with the disc

swiveling on the hinge and with a disc stop.

X

7.0 15400 part1-1.2

(A)10

each type as per plan / Materials Approval X

8.0 15400 Part2-2.9(A) each type Black Iron Pipe Schedule 40 X

D

1.0 15140 Part2-2.1

each type TDH=140 FT / RPM=3,500 X

2.0 15140 Part2-2.1

each type as per plan / Materials Approval X

3.0 15140 Part2-2.1

each type Well-X-Trol WX-572 or approved equal X

E

1.0 15400 2.3(A) ASTM D 2729 each type NEL TEX Polyvinyl Chloride (PVC) Pipe SDR

34 or approved equal.

X

2.0 2722.2.1.1.1 ASTM D 3034 each type NEL TEX Polyvinyl Chloride (PVC) Pipe SDR

34/Series 1000 or approved equal.

X

3.0 7600.3.1(A) 7600.3.1(A) each type as per plan / Materials Approval X

4.0 Similar Requirements to Civil Works

5.0 15400 Part2-

2.1(A)4

each type Metma, Unilex or approved equivalent. X

IX

I

2.0 Disinfection H/W Inspection Report

Hydropneumatic Tank (528 gals)

Hose Bibb 1/2"

Float Valve (63mm)

Gate Valves

Water Lines: (Vesvo)

PPR pipe including fittings

Foot Valve (63mm)

Check Valve (63mm)

Water Meter 50mm

Septic Tank

Equipment

FIRE PROTECTION SYSTEM

PVC fittings

Roof Strainer 75mm

Catch Basin

Parking Drain 100mm

Storm Drainage System

PVC Pipes

Equipment

Pump 60gpm, 5Hp, 3 phase

Pump 80gpm, 5Hp, 3 phase

S/W Product Sample/Inspection Report

Manufacturer's Cert. of Compliance

Manufacturer's Cert. of Compliance

Manufacturer's Cert. of Compliance

S/W Manufacturer's Cert. of Compliance

S/W

Manufacturer's Data/ Product

Sample/Inspection Report

S/W Manufacturer's Data/ Product

Sample/Inspection Report

S/W Manufacturer's Data/ Product

Sample/Inspection Report

S/W Manufacturer's Data/ Product

Sample/Inspection Report

S/W Manufacturer's Data/ Product Sample/

Result of Calibration

S/W

S/W

S/W

S/W

S/W

Product Sample/Inspection Report

Product Sample/Inspection Report

S/W

S/W

Manufacturer's Cert. of Compliance

S/W Product Sample/Inspection Report

Manufacturer's Data/ Product Sample/

Result of Calibration

Pipe Sleeves

F-04-915-101-R1

NKCI

0

Title ITP for ADMINISTRATION BUILDING ITP Rev. Date

Form

AURORA SPECIAL ECONOMIC ZONE AUTHORITY ( PHASE 1 )

INSPECTION AND TEST PLAN-ITP

Contractor New Kanlaon Construction Incorporated Contract No. ASEZA-INFRA-09-01

Project Name Aseza Project (Phase-1) ITP Rev. No.

EDCOP

Item No.

Description of the Operation/ Test/ Inspection

Stage/Frequency Acceptance Criteria

Inspection and

Testing

Output/Records

Description / Characterisrics

Specification

Reference No.

Procedure

Reference No.

1 15500 part II /

02713-2.2.2

UL / FM each type / assembly 1.0-Vertical Turbine Type-250 GPM;

TDH=184 ft/Electric Motor Driven 1800 RPM

(20Hp/ 230V/ 3phase/ 60Hz) with Motor

Contoller & Other Standard Accessories

2.0- Peerless horizontal single stage

electric motor driven Fire Pump Model 5 AF10

with Firetrol controller or

approved equal/

X

2.0 02713-2.2.3 each type / assembly Grundfos Series Multi-Stage Centrifugal Pump

Series C Model CR4-80U or approved equal

X

3.0 each type / assembly as per plan X

II

1.0 15500 part 9-9.02 ASTM A 120/ A 53 each size Schedule 40 X

15500 Part12-12.04 each type Galvanized steel Pipe-Sched. 40;provision of

insulated packed tight fire resistive materials

between annular spaces of pipes.

X

2.0 15500 part 13 NFPA 14 each type Honeywel,Tozen, or approved equal X

3.0 15500 part 9-9.09 UL/FM each type Iron body; Bronze seat ring; Disc Ring; 175

psi (12 Bars) Working Pressure; Approved

Manufacturer=Central

X

4.0 15500 part 9-9.09 UL/FM each type Honeywel,Tozen, or approved equal X

5.0 02750-6.4.11 each type as per plan

6.0 15500 part 9-9.11 each type Gauge 16 Steel Body; Allumunum Door Trim;

30 mt Hose pin rack; Full Glass Panel

X

7.0 15500 part 9-9.16 UL/FM each type UL Listed & FM (Factory Mutual) Approved

Manufacturer = Kiddie

X

8.0 as per required Owners Instruction / per BOQ X

15500 part14-14.03

whole system not less than 200 PSIG for a period of 2

Hours

X

Pipe Hangers & Supports

Check Valve

Submersible pump

Piping and Other Accessories

BI Pipe Sched. 40, ERW

Jockey Pump

Fire Extinguisher, 10lbs, ABC

Gate Valve

Flexible Connector

Fire Horse Cabinet S/W

Fire Pump and Accessories

S/W Manufacturer's Certificate of Compliance

S/W Manufacturer's Certificate of Compliance

S/W Manufacturer's Certificate of Compliance

S/W Product Sample/Inspection Report

S/W

Manufacturer's Data/ Product

Sample/Inspection Report

Pipe Sleeves

Product Sample/Inspection Report

S/W Manufacturer's Certificate of Compliance

Manufacturer's Data / Manfacturer's

Certificate of Compliance / Inspection

Report

S/W Manufacturer's Certificate of Compliance

H/W Test Results

Consumables S/W Inspection Report

Test and Inspection

S/W

a. Hydrostatic Pressure Test H/W Test Result / Inspection Report

Vous aimerez peut-être aussi

- Wyckoff e BookDocument43 pagesWyckoff e BookIan Moncrieffe95% (22)

- Inspection Test PlanDocument7 pagesInspection Test PlanWalha Wassim100% (1)

- Inspection & Test Plan for Masonry WorksDocument3 pagesInspection & Test Plan for Masonry Worksiman arief100% (4)

- Inspection and Test Plan For Steel StrucDocument6 pagesInspection and Test Plan For Steel Strucwawan gunawan100% (1)

- Curtain Wall ItpDocument5 pagesCurtain Wall ItpYassin DerbeliPas encore d'évaluation

- Engineering Development/Quality Inspection Test Plan (ITPDocument13 pagesEngineering Development/Quality Inspection Test Plan (ITPPageduesca RouelPas encore d'évaluation

- Inspection and Testing PlanDocument7 pagesInspection and Testing PlanStephen David Gozun50% (2)

- 043-ITP FOR Water Proofing (Buildings) PDFDocument13 pages043-ITP FOR Water Proofing (Buildings) PDFKöksal Patan100% (3)

- CHECKLIST Light Fixture Material InspectionDocument3 pagesCHECKLIST Light Fixture Material Inspectionalisha karimPas encore d'évaluation

- JMC Office Building Construction Inspection and Testing PlanDocument41 pagesJMC Office Building Construction Inspection and Testing Planmurtada kamilPas encore d'évaluation

- Saudi Oger Ltd. (Project Name) : PlasteringDocument1 pageSaudi Oger Ltd. (Project Name) : PlasteringAnthony AngelesPas encore d'évaluation

- Inspection and Test Plan - Plumbing Works (Qcitp) : Material InspectionsDocument28 pagesInspection and Test Plan - Plumbing Works (Qcitp) : Material InspectionsJay Chris L. BeronPas encore d'évaluation

- TN 76Document6 pagesTN 76Lloyd R. Ponce100% (3)

- TN 76Document6 pagesTN 76Lloyd R. Ponce100% (3)

- 045-ITP For MASONRY & PLASTERING WORKS (Buildings) PDFDocument10 pages045-ITP For MASONRY & PLASTERING WORKS (Buildings) PDFKöksal Patan83% (12)

- Inspection & Test Plan for SEPCOIII Electric Power Construction CorporationDocument3 pagesInspection & Test Plan for SEPCOIII Electric Power Construction Corporationtrey100% (4)

- GPU Programming in MATLABDocument6 pagesGPU Programming in MATLABkhaardPas encore d'évaluation

- ITP-01 - BackfillingDocument1 pageITP-01 - BackfillingMaddala Srinivasa Rao50% (2)

- Checklist-Masonry - Brickwork and BlockworkDocument6 pagesChecklist-Masonry - Brickwork and Blockworkapi-372251810Pas encore d'évaluation

- Inspection Test PlanDocument3 pagesInspection Test Planfabin100% (3)

- ITP-FW For Civil & Building WorksDocument17 pagesITP-FW For Civil & Building WorksRajnath Rajbhar Pancham86% (7)

- ITP For Plumbing & Drainage SystemDocument97 pagesITP For Plumbing & Drainage Systemmagdi badran100% (7)

- Concrete Expansion JointsDocument80 pagesConcrete Expansion JointsDiana Sekar Sari100% (1)

- Itp For Steel Structure Erection (Content) Rev.1Document3 pagesItp For Steel Structure Erection (Content) Rev.1Anonymous nLMJGu100% (5)

- Construction of Dormitory & Housing compounds in NorochcholaiDocument33 pagesConstruction of Dormitory & Housing compounds in Norochcholaisaranga100% (1)

- Lab Soil Testing StandardsDocument5 pagesLab Soil Testing Standardssamoonibrahim100% (1)

- ITP For Painting WorksDocument27 pagesITP For Painting Workssree50% (2)

- Planning Process 12 Step CLUPDocument10 pagesPlanning Process 12 Step CLUPLloyd R. Ponce100% (1)

- Inspection and Test Plan For Structure Steel Erection WorksDocument11 pagesInspection and Test Plan For Structure Steel Erection WorksVijaya BaraniPas encore d'évaluation

- 041 - ITP For Painting (Building) PDFDocument12 pages041 - ITP For Painting (Building) PDFKöksal Patan78% (9)

- 023-Itp Concrete Works PDFDocument32 pages023-Itp Concrete Works PDFKöksal Patan100% (5)

- Field ITP Civil Rev-8after Lump-Sump.Document17 pagesField ITP Civil Rev-8after Lump-Sump.Echik Kici100% (3)

- Civil ItpDocument60 pagesCivil ItpBiswas100% (1)

- 18.9 ITP SUB BASE Rev01Document2 pages18.9 ITP SUB BASE Rev01YEHIA100% (1)

- Check List For Inspection of Road WorksDocument6 pagesCheck List For Inspection of Road WorksPranjeet ChakravartyPas encore d'évaluation

- Cb2 Q Zen 05 60211 Itp For Earth Work - Rev.bDocument6 pagesCb2 Q Zen 05 60211 Itp For Earth Work - Rev.bAnonymous wIPMQ5rhPas encore d'évaluation

- Itp - EarthworkDocument16 pagesItp - Earthworksaharui50% (2)

- Contract of Lease-Water Refilling StationDocument4 pagesContract of Lease-Water Refilling StationEkeena Lim100% (1)

- Rapp-7&8 Construction of Main Plant Civil Work-Package-I: List of Approved Qaps/ ItpsDocument2 pagesRapp-7&8 Construction of Main Plant Civil Work-Package-I: List of Approved Qaps/ ItpsAkansh JainPas encore d'évaluation

- Filled Composite ColumnDocument1 pageFilled Composite ColumnLloyd R. PoncePas encore d'évaluation

- ITP For CivilDocument85 pagesITP For CivilBilibili weekly TOP 10 videos100% (6)

- Etihad Towers Project: Inspection & Test Plan - Cast in Situ Reinforced Concrete WorksDocument8 pagesEtihad Towers Project: Inspection & Test Plan - Cast in Situ Reinforced Concrete WorksjiniPas encore d'évaluation

- Plumbing Works (Plumbing & Sanitary Works) : Inspection and Test PlanDocument3 pagesPlumbing Works (Plumbing & Sanitary Works) : Inspection and Test PlanAyi67% (3)

- Approvals Management Responsibilities and Setups in AME.BDocument20 pagesApprovals Management Responsibilities and Setups in AME.BAli LoganPas encore d'évaluation

- 027 ITP For Pre Cast Concrete PDFDocument27 pages027 ITP For Pre Cast Concrete PDFlinga2014Pas encore d'évaluation

- 03 Rebar InspectionDocument1 page03 Rebar InspectionDawit SolomonPas encore d'évaluation

- ITP CIVIL WORK-Rev-1Document6 pagesITP CIVIL WORK-Rev-1Ateeq Rahman100% (1)

- Construction of Metro Train Depot Brick Masonry Work Inspection PlanDocument8 pagesConstruction of Metro Train Depot Brick Masonry Work Inspection PlanVipin Kumar ParasharPas encore d'évaluation

- 3.ITP For Erection of Precast - Rev-01Document3 pages3.ITP For Erection of Precast - Rev-01Suju Rajan100% (1)

- NAV-TP-0283 Scaffold ChecklistDocument2 pagesNAV-TP-0283 Scaffold ChecklistRicky Hawk100% (1)

- ITP of Admin Building NEW AutosavedDocument14 pagesITP of Admin Building NEW Autosavedomda4wady0% (1)

- 8 Field Quality PlanDocument18 pages8 Field Quality Plangeorge_hem100% (1)

- MS For Hot Weather ConcretingDocument8 pagesMS For Hot Weather ConcretingYuvaraj Ponraj100% (2)

- 5.itp For Construction MaterialsDocument8 pages5.itp For Construction Materialsbinunalukandam100% (1)

- Ref FQP ErectionDocument12 pagesRef FQP ErectionSaurabh HimkarPas encore d'évaluation

- British Standard document reviewDocument23 pagesBritish Standard document reviewLloyd R. PoncePas encore d'évaluation

- EnP Ultimate Reviewer No. 2ADocument22 pagesEnP Ultimate Reviewer No. 2ALloyd R. Ponce0% (1)

- QA-000-AA-5013 ITP For Structure Steel Erection Works Rev1 (APPROVED)Document10 pagesQA-000-AA-5013 ITP For Structure Steel Erection Works Rev1 (APPROVED)miaicarba100% (2)

- Itp PlasteringDocument7 pagesItp PlasteringJervino RuahPas encore d'évaluation

- 044 ITP For Installation of Gypsum Board Buildings PDFDocument10 pages044 ITP For Installation of Gypsum Board Buildings PDFHarshvardhan PathakPas encore d'évaluation

- 5.ITP For Excavation and Back FillingDocument19 pages5.ITP For Excavation and Back FillingDaniel Sinaga100% (5)

- Itp For InsulationDocument14 pagesItp For InsulationHytham El-NoubyPas encore d'évaluation

- DIN 17007-4-1963, Material Type NumberDocument9 pagesDIN 17007-4-1963, Material Type NumberLloyd R. PoncePas encore d'évaluation

- FM-16 Material Verification RecordDocument1 pageFM-16 Material Verification RecordBleep NewsPas encore d'évaluation

- 026-Itp For Structural Steel PDFDocument18 pages026-Itp For Structural Steel PDFKöksal Patan100% (11)

- ITP AllDocument1 pageITP AllMuhammadIqbalMughalPas encore d'évaluation

- A2U8A2 - KBR Quality Plan For Phase Two Mechanical and Electrical Work PDFDocument53 pagesA2U8A2 - KBR Quality Plan For Phase Two Mechanical and Electrical Work PDFMOST PASONPas encore d'évaluation

- PSC Single SpanDocument99 pagesPSC Single SpanRaden Budi HermawanPas encore d'évaluation

- Repair Grouting ChecklistDocument1 pageRepair Grouting ChecklistSushil GuptaPas encore d'évaluation

- Request For Inspection Civil Concrete Pre-PouringDocument2 pagesRequest For Inspection Civil Concrete Pre-PouringProject m707Pas encore d'évaluation

- Dow Corning 993 Product InfoDocument4 pagesDow Corning 993 Product InfoLloyd R. PoncePas encore d'évaluation

- ITP-CONCRETE Blinding WorkDocument2 pagesITP-CONCRETE Blinding WorkYash Sharma100% (1)

- SECTION 02200 EarthworksDocument8 pagesSECTION 02200 EarthworksStraus WaseemPas encore d'évaluation

- Lime Soil Stabilization Master SpecificationDocument5 pagesLime Soil Stabilization Master SpecificationdadarwinpopogiPas encore d'évaluation

- Asphalt Concrete PavingDocument10 pagesAsphalt Concrete Pavingsethu1091Pas encore d'évaluation

- Winds Peed To Pressure ConversionDocument1 pageWinds Peed To Pressure ConversionLloyd R. PoncePas encore d'évaluation

- Braided Hose Expansion JointDocument1 pageBraided Hose Expansion JointLloyd R. PoncePas encore d'évaluation

- BS 957-1-1941, Specification For Feeler Gauges PDFDocument14 pagesBS 957-1-1941, Specification For Feeler Gauges PDFLloyd R. PoncePas encore d'évaluation

- FanEffectPPT2 PDFDocument41 pagesFanEffectPPT2 PDFJoel AlcantaraPas encore d'évaluation

- What plumbing designers need to know about valve materials and ratingsDocument4 pagesWhat plumbing designers need to know about valve materials and ratingsLloyd R. PoncePas encore d'évaluation

- Calculating Fiber Loss and DistanceDocument4 pagesCalculating Fiber Loss and DistanceroomforsquaresPas encore d'évaluation

- DIN 17155-1983, Creep Resistant Steel Plate and StripDocument16 pagesDIN 17155-1983, Creep Resistant Steel Plate and StripLloyd R. Ponce100% (1)

- CLASS NOTES Chap 10 1 Bond & AnchorageDocument13 pagesCLASS NOTES Chap 10 1 Bond & Anchoragekohatian27796105Pas encore d'évaluation

- Galvalume Rolling ShuttersDocument40 pagesGalvalume Rolling ShuttersLloyd R. PoncePas encore d'évaluation

- TSSC 65 - 410Document1 pageTSSC 65 - 410Lloyd R. PoncePas encore d'évaluation

- Directive 2006-42-CE - Machinery PDFDocument63 pagesDirective 2006-42-CE - Machinery PDFeng13Pas encore d'évaluation

- Planning Mandates of Local GovernmentsDocument20 pagesPlanning Mandates of Local GovernmentsLloyd R. PoncePas encore d'évaluation

- CrackDocument83 pagesCrackSeba Roskopf100% (1)

- Fulltext01 Early Age ConcreteDocument18 pagesFulltext01 Early Age ConcreteLloyd R. PoncePas encore d'évaluation

- Jet FansDocument15 pagesJet FansLloyd R. PoncePas encore d'évaluation

- FanEffectPPT2 PDFDocument41 pagesFanEffectPPT2 PDFJoel AlcantaraPas encore d'évaluation

- CrackDocument83 pagesCrackSeba Roskopf100% (1)

- A R A T I o N A L I Z e D L o C A L P L A N N I N G S y S T e M I N T H e P H I L I P P I N e SDocument25 pagesA R A T I o N A L I Z e D L o C A L P L A N N I N G S y S T e M I N T H e P H I L I P P I N e SLloyd R. PoncePas encore d'évaluation

- M-Bloc Type C SubmittalDocument2 pagesM-Bloc Type C SubmittalLloyd R. PoncePas encore d'évaluation

- MTC AluminumDocument1 pageMTC AluminumLloyd R. PoncePas encore d'évaluation

- Finishing MaterialsDocument13 pagesFinishing MaterialsLloyd R. PoncePas encore d'évaluation

- Chap1 7Document292 pagesChap1 7Zorez ShabkhezPas encore d'évaluation

- 028 Ptrs Modul Matematik t4 Sel-96-99Document4 pages028 Ptrs Modul Matematik t4 Sel-96-99mardhiah88Pas encore d'évaluation

- Recent Advances in Mobile Robotics - TopalovDocument464 pagesRecent Advances in Mobile Robotics - TopalovBruno MacedoPas encore d'évaluation

- Readiness of Barangay Masalukot During TyphoonsDocument34 pagesReadiness of Barangay Masalukot During TyphoonsJerome AbrigoPas encore d'évaluation

- Design of A Double Corbel Using CAST Per ACI 318-02 Appendix A, SI UnitDocument41 pagesDesign of A Double Corbel Using CAST Per ACI 318-02 Appendix A, SI Unityoga arkanPas encore d'évaluation

- Private Car Package Policy - Zone B Motor Insurance Certificate Cum Policy ScheduleDocument3 pagesPrivate Car Package Policy - Zone B Motor Insurance Certificate Cum Policy ScheduleijustyadavPas encore d'évaluation

- $$TR Sas 114 AllDocument384 pages$$TR Sas 114 Allctudose4282Pas encore d'évaluation

- Lunakleen: Standard Type Hepa FilterDocument1 pageLunakleen: Standard Type Hepa FilterRyan Au YongPas encore d'évaluation

- ENY1-03-0203-M UserDocument101 pagesENY1-03-0203-M UserAnil KumarPas encore d'évaluation

- Maximum Yield USA 2013 December PDFDocument190 pagesMaximum Yield USA 2013 December PDFmushroomman88Pas encore d'évaluation

- NSTP 1: Pre-AssessmentDocument3 pagesNSTP 1: Pre-AssessmentMaureen FloresPas encore d'évaluation

- SSPC Paint 25 BCSDocument6 pagesSSPC Paint 25 BCSanoopkumarPas encore d'évaluation

- My Con Pds Sikafloor 161 HCDocument5 pagesMy Con Pds Sikafloor 161 HClaurenjiaPas encore d'évaluation

- The Ball Is Now in Their Hands': Lumumba Responds After City Council Rescinds Emergency DeclarationDocument2 pagesThe Ball Is Now in Their Hands': Lumumba Responds After City Council Rescinds Emergency DeclarationWLBT NewsPas encore d'évaluation

- Panda CheatsheetDocument17 pagesPanda CheatsheetAdevair JuniorPas encore d'évaluation

- Black Box Components and FunctionsDocument9 pagesBlack Box Components and FunctionsSaifPas encore d'évaluation

- Critical Aspects in Simulating Cold Working Processes For Screws and BoltsDocument4 pagesCritical Aspects in Simulating Cold Working Processes For Screws and BoltsstefanomazzalaiPas encore d'évaluation

- Feedback Mechanism InstrumentDocument2 pagesFeedback Mechanism InstrumentKing RickPas encore d'évaluation

- Mom Luby and The Social WorkerDocument1 pageMom Luby and The Social WorkerqtissskrazyPas encore d'évaluation

- Midterm Exam SolutionsDocument11 pagesMidterm Exam SolutionsPatrick Browne100% (1)

- Chilled Beam SystemsDocument3 pagesChilled Beam SystemsIppiPas encore d'évaluation

- HOS Dials in The Driver App - Samsara SupportDocument3 pagesHOS Dials in The Driver App - Samsara SupportMaryPas encore d'évaluation

- (DO-CYT-T1-16) - KASSAHUN ComparisionDocument126 pages(DO-CYT-T1-16) - KASSAHUN ComparisionMohammed AdanePas encore d'évaluation

- Personal Selling ProcessDocument21 pagesPersonal Selling ProcessRuchika Singh MalyanPas encore d'évaluation