Académique Documents

Professionnel Documents

Culture Documents

A320 Hyd PDF

Transféré par

Stephanie JohnsonTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

A320 Hyd PDF

Transféré par

Stephanie JohnsonDroits d'auteur :

Formats disponibles

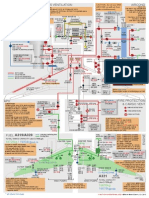

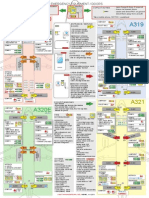

ELAC

1

ELAC

2

ELAC 1

SEC 2 SEC 1

ELAC 2

ELAC 1

SEC 1 SEC 2

ELAC 2 ELAC 2

SEC 2 SEC 1

ELAC 1

S

E

C

2

S

E

C

1

S

E

C

1

S

E

C

3

S

E

C

3

S

E

C

1

S

E

C

1

S

E

C

2

SEC

3

SEC

3

S

P

D

B

R

K

G

N

D

S

P

O

IL

E

R

S

R

O

L

L

ELAC

2

ELAC

1

FAC 2

FAC 1

SFCC 1

[DC ESS]

SFCC 1

[DC ESS]

SFCC 2

[DC2]

SFCC 2

[DC2]

ENG1

PUMP

REV

ENG2

PUMP

ELEC

PUMP

HAND

PUMP

ELEC

PUMP

[AC1]

RAT

AUTO [HOT1]

MAN [HOT2]

REV

RESERVOIR

RESERVOIR

PTU

[DC2]

NORMAL BRK

LDG

GEAR

&

DOORS

NOSE

WHEEL

STEERING

(others)

NOSE

WHEEL

STEERING

(-IJP,Q;R;S)

ALTN & PARK BRK

(others)

ALTN & PARK BRK

(-IOM, -IJP,Q,R;S,W)

WING

TIP BRK

WING

TIP BRK

WING

TIP BRK

WING

TIP BRK

WING

TIP BRK

WING

TIP BRK

WING

TIP BRK

WING

TIP BRK

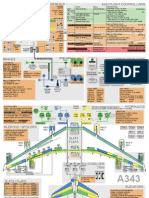

ELEVATOR ACTUATOR MODES

- active, electrically controlled

- damping, follows surface

- centering, hydraulically maintained in neutral

if both jacks not electrically controlled

AILERONS ACTUATOR MODES

- active, electrically controlled

- damping, follows surface

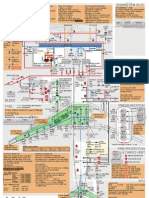

MOT MOT

MOT1

[DC2]

[HOT2]

MOT1

[DC ESS]

MOT2

[DC2]

MOT3

[DC2]

MOT2

[DC ESS]

TRIM WHEEL

ACTU

-ATOR

ACTU

-ATOR

FAC 2

FAC 1

RUDDER TRIM

YAW DAMPER

RUDDER

PEDALS

MOT1

[DC ESS]

MOT2

[DC2]

FAC 2

FAC 1

BSCU

CH1 [AC1/DC1]

CH2 [AC2/DC2]

ABCU

[DC ESS, HOT]

[DC ESS]

BSCU

CH1 [AC1/DC1]

CH2 [AC2/DC2]

LGCIU 1

[DC GND/FLT]

[DC ESS]

LGCIU 2

[DC GND/FLT]

RUDDER LIMITER

NORMAL SERVO

VALVE

SAFETY

VALVE

<260kts

[DC ESS]

ALTERNATE

SERVO

VALVE

DUAL

VALVE

PARKING BRAKE VALVE

PARKING BRAKE VALVE

DUAL

SHUTTLE

VALVE

ALTN BRK

SEL VALVE

LP DISTRIBUTION

LINE

NORMAL

SELECTOR VLV

AUTOMATIC

SELECTOR

STEERING

SERVO

VALVE

G HYD

FROM

DOOR

SYS

Y HYD

GRAVITY

EXTENSION

CUT OFF

VALVE

EMER

GEN

ACCU

All reservoirs pressurized

with ENG 1 HP BLEED or

X-BLEED duct

ACCU

ACCU

Normal PRESS 3000+/-200psi

purpose of Y ELEC PUMP is not to power the whole

yellow hydraulic system but only the cargo door operation

RAT comes out automatically in

case of loss of AC1 & AC2 &

speed > 100kts

RAT pressure 2500psi

GRAVITY

EXTENSION

HANDLE

ELEVATORS

AILERONS

SPOILERS

SLATS

FLAPS

LANDING GEAR & NWS BRAKES

CARGO

DOORS

HYDRAULICS

RUDDER

STABILIZER

TRIM

ELECTRICAL SUPPLY

FLIGHT CONTROL COMPUTERS

MAIN STBY

ELAC 1 DC ESS HOT1

ELAC 2 DC2 HOT2

SEC 1 DC ESS HOT1

SEC 2 DC2

SEC 3 DC2

FAC 1 AC ESS DC SHED

FAC 2 AC2 DC2

FCDC 1 DC SHED

FCDC 2 DC2

BUS in red are available in ELEC EMER config

1 1

2

2

3

4

5

3

4

5

FIRE SHUT OFF VLV

[DC ESS]

FIRE SHUT

OFF VLV

[DC ESS]

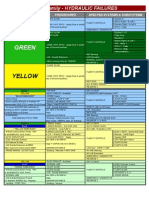

NWS LIMITS

- steering hanwheels (max 75 at

20kts, zero at 70kts)

(at 80kts for -IOM, -IJP,Q,R;S,W)

- rudder pedals (max 6 at 40kts,

zero at 130kts)

- towing max 95

GEAR LIMITS

- retraction 220kts

- extension 250kts

- gravity ext 200kts

- max alt ext 25'000ft

- extended 280/M.67

- gear down flight

235/M.60

- tyre speed 195kts

TAXI SPEED

max 20kts in turn

if GW>76t

(A320/A321)

BRAKE TEMPERATURE

- T/O MAX 300C

maintenance action if

- (TEMP diff on same gear >

150C) and

(1 BRK >600C or <60C)

- diff avg TEMP L-R 200C

- TEMP > 900C(A319/A320)

- TEMP > 800C(A321)

TIRE DEFLATED

1 tire -> 7kts in turn

2 on same -> 3kts & NWS 30

!!! NOT FOR OPERATIONAL USE !!! Pierre-Michel Gasser , 15.1.2013

RUDER TRIM LIMITS

- 25 for A319

- 20 for A320/A321

RUDER LIMITS

- 30 for A319

- 25 for A320/A321

ELEVATOR DEFLECTION LIMITS

- 30 nose up

- 15 nose down

ROLL DEFLECTION LIMITS

- 25 for ailerons

- 35 for spoilers

(A321, 7 for spoiler 3)

Ground spoilers limits: 50 for all spoilers

STABILIZER LIMITS

- 13.5 nose up

- 4 nose down

RESERVOIR

FLAPS extension / max speed

[slats] A319 A320 A321

1 [18] 0/ 230

1+F [18] 10/215

2 [22] 15/200 15/200 14/215

3 [22] 20/185 20/185 21/195

Full [27] 40/177 35/177 25/190

No Flaps/Slats above 20'000ft

Flaps of A321 are double-slotted

Operation via Y ELEC PUMP or via HANP PUMP,

without other YELLOW consumer

NORMAL

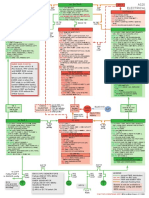

FLT CONTROL LAWS

PITCH

GND

FLT

FLARE

ROLL PROTECTIONS

Direct deflection Direct deflection

Roll rate

Load factor +2.5g / -1g (clean)

+2.0g / 0g (not clean)

=

Pitch FLAPS 0-3: 30, FULL: 25 ANU, any: 15 AND

=

Bank 67/33(stick 0), 45 if AOA or 40 if hi spd PROT

Side slip blue if eng failure

High , V prot, V floor, V max

=

High speed bank 45/0 (stick 0)

Low energy warning Flaps 2,3 or FULL 100ft - 2000ft

Pitch attitude demand

50ft pitch to 2AND in 8s

Load factor demand

Auto pitch Trim

Same as Normal except:

If reduced protections available:

X

no Pitch attitude

High : LOST if VS1g computation failure

Low speed, nose down demand 5-10kts, Stall warning

High speed, light nose up demand

Roll direct

Yaw alternate

only damping +-5

No turn coord.

same as Normal

MECHANICAL BACK-UP

Roll direct

Yaw mechanical

No protection

Overspeed & Stall warning

Direct control

USE MAN PITCH TRIM

RUDDER ONLY

Mechanical

MAN PITCH TRIM ONLY

RA<50ft

GEAR DN

RA>50ft

[AC2]

CARGO

DOOR

BRAKE ACCU

7 full brakes application or at

least 12 hrs prk brk

[DC ESS,

AC ESS SHED]

A32X

F/CTL ALTN LAW

F/CTL DIRECT LAW

140

160

180

200

220

F

1

S

=

=

Green Dot speed, (FAC)

1.35Vs g-load NOT considered.

VFE NEXT next flap, only < FL200

VMAX lowest of VMO, MMO, VLE, VFE

High speed protection (AP OFF,

Pitch Trim freezes, nose-up order,

bank 0 with stick neutral)

Slats retraction & manoeuvring F1

(1.43Vs F1 or 1.22-1.25 Vs clean)

g-load NOT considered, (FAC)

Flaps retraction & manoeuvring F2

(1.29Vs F2 or 1.18-1.26Vs F1+F)

g-load NOT considered, (FAC)

V2 (V2>1.13Vs and V2>1.1Vmca)

V1 = decision speed

Alpha max, max AOA

g-load considered. (FAC)

Alpha floor, A/THR gives TOGA.

g-load considered. (FAC)

Alpha prot, g-load considered.

Max AOA with stick neutral, (FAC)

VLS 1.13Vs at T/O, 1.23Vs with flap

1.28Vs clean,g-load not con.,(FAC)

Vmcg = (109 / 111 / 107.5)

Vmu = V minimum unstick

Vmca = (111 / 110 / 109 )

Vr (Vr >= V1 and Vr > 1.05Vmca)

AUTOBRAKE

LO : 4s delay, 1.7m/s2

MED: 2s delay, 3m/s2

MAX: max pressure

DECEL light if 80% of rate

PTU activates if press diff. >500psi

PTU inhibited 6 sec after

HYD G or Y RSVR LO LVL

Vous aimerez peut-être aussi

- Al-Qadim - Golden VoyagesDocument139 pagesAl-Qadim - Golden VoyagesMichael Aung100% (11)

- A330 Normal Law: Putting Fly-by-Wire Into PerspectiveD'EverandA330 Normal Law: Putting Fly-by-Wire Into PerspectiveÉvaluation : 5 sur 5 étoiles5/5 (2)

- HydraulicDocument44 pagesHydraulicEnrique Barberan67% (3)

- A320 Air PDFDocument1 pageA320 Air PDFStephanie Johnson100% (1)

- PFD & ND A320 A330Document8 pagesPFD & ND A320 A330Amit Saha90% (21)

- Flight Mode Annuciator EFIS PFD NDDocument51 pagesFlight Mode Annuciator EFIS PFD NDdarkdatkomPas encore d'évaluation

- Aircraft Flight Control SystemDocument165 pagesAircraft Flight Control SystemDamon Leong100% (5)

- UNIVAIR CessnaDocument13 pagesUNIVAIR CessnaJessie Bechayda100% (1)

- B767 Flightdeck and AvionicsDocument142 pagesB767 Flightdeck and Avionicsoscar89% (19)

- Prestige Telephone Company (Solutions)Document4 pagesPrestige Telephone Company (Solutions)Joseph Loyola71% (7)

- A320 Debrief SchematicsDocument26 pagesA320 Debrief Schematicsflyjeetu100% (8)

- ShipbuildingDocument32 pagesShipbuildingyapalexrey100% (2)

- A320 Walk AroundDocument105 pagesA320 Walk AroundJaroslav Navrkal100% (1)

- A320 PowerplantDocument4 pagesA320 PowerplantJoao Melo100% (1)

- A320 Hydraulic FailuresDocument2 pagesA320 Hydraulic FailuresMarcos Braga90% (42)

- A330 28 L3Document186 pagesA330 28 L3Thanh Vinh Nguyen80% (5)

- A320 Fault Reset PDFDocument156 pagesA320 Fault Reset PDFariefPas encore d'évaluation

- 3406C Eng SchematicDocument4 pages3406C Eng Schematicmurugu197983% (12)

- North Star 2 Listening and Speaking 2 PDFDocument49 pagesNorth Star 2 Listening and Speaking 2 PDFStephanie Johnson56% (9)

- A320-Slats or Flaps JammedDocument19 pagesA320-Slats or Flaps Jammedswathikanagarajan75% (4)

- A330 Flight ControlsDocument56 pagesA330 Flight ControlsMUSSA100% (3)

- Airbus A320 Technical QuestionsDocument360 pagesAirbus A320 Technical QuestionsGurpal Singh Chahal91% (43)

- A320 EcamDocument41 pagesA320 EcamMaitreya Shah71% (7)

- Airbus Flight Control Laws: The Reconfiguration LawsD'EverandAirbus Flight Control Laws: The Reconfiguration LawsÉvaluation : 4.5 sur 5 étoiles4.5/5 (16)

- A320 CB PanelsDocument67 pagesA320 CB PanelsMiklós Meixner100% (4)

- Landing Gear / Nws Brakes: X F/CTL Altn Law (Prot Lost)Document1 pageLanding Gear / Nws Brakes: X F/CTL Altn Law (Prot Lost)Elias IruelaPas encore d'évaluation

- Wet With Sand or Dust: LPC Calculation Take-Off Is Not Authorised (Om A 8.3 8.3.3)Document7 pagesWet With Sand or Dust: LPC Calculation Take-Off Is Not Authorised (Om A 8.3 8.3.3)solnegro7100% (1)

- A320 - Ecam - Pages PDFDocument1 pageA320 - Ecam - Pages PDFRaja17450% (2)

- g550 Notes Feb16Document18 pagesg550 Notes Feb16christosPas encore d'évaluation

- C550 PTM V2 PDFDocument271 pagesC550 PTM V2 PDFJoey Marks92% (12)

- A320 TakeOffDocument1 pageA320 TakeOffEnrique Barberan100% (4)

- Elac Sec Efcs Trouble Shooting Tips Booklet PDFDocument57 pagesElac Sec Efcs Trouble Shooting Tips Booklet PDFGenaro Rodriguez100% (1)

- A330 HydDocument1 pageA330 HydElias Iruela100% (7)

- A340 A330 ElectricalDocument2 pagesA340 A330 Electricalpontoo75% (4)

- All Atas A320 Ecam Warnings ResetsDocument243 pagesAll Atas A320 Ecam Warnings ResetsLuis Gallegos100% (4)

- HP GND Air With APU Bleed: CAUTION, Do Not UseDocument1 pageHP GND Air With APU Bleed: CAUTION, Do Not UseElias Iruela100% (1)

- A320 ElecDocument1 pageA320 ElecEnrique Barberan100% (1)

- A320 - A330 QRH Abnormal and Emergency Procedures SummaryDocument8 pagesA320 - A330 QRH Abnormal and Emergency Procedures SummaryAlexander Sturm50% (2)

- Gardner W. Yacht Designs, 1977Document225 pagesGardner W. Yacht Designs, 1977VitBar100% (10)

- Adl Ap4g3Document100 pagesAdl Ap4g3Catia Santoro100% (1)

- A320 Schematics PDFDocument4 pagesA320 Schematics PDFAlina Costica100% (2)

- Airbus A320 Fault Verification GuideDocument76 pagesAirbus A320 Fault Verification Guideprsnjt11100% (1)

- A320 NotesDocument112 pagesA320 Notesapi-3753120100% (4)

- VFD DocumentsDocument592 pagesVFD DocumentsLe Anh Dang50% (2)

- A320 EmerDocument1 pageA320 EmerEnrique BarberanPas encore d'évaluation

- Communication A320 PDFDocument41 pagesCommunication A320 PDFAsraf100% (1)

- Konstantin Stanislavski For IGCSE DRAMADocument7 pagesKonstantin Stanislavski For IGCSE DRAMAStephanie Johnson100% (1)

- A320 Abnormal NotesDocument12 pagesA320 Abnormal NotesCheck Singh100% (1)

- A320 Hyd PDFDocument1 pageA320 Hyd PDFStephanie Johnson100% (1)

- Aircraft General: Menu MenuDocument27 pagesAircraft General: Menu MenuHarold DongoPas encore d'évaluation

- Hindustan Shipyard Limited (Project)Document67 pagesHindustan Shipyard Limited (Project)Arish Adduri67% (6)

- A320 Eletrical SystemDocument1 pageA320 Eletrical SystemEduardo Almeida SilvaPas encore d'évaluation

- Pivot PointDocument22 pagesPivot Pointjanderclanderpeich100% (1)

- Tips A320 ResetDocument82 pagesTips A320 Resetgarry pangkey100% (1)

- A320 Overhead PanelDocument1 pageA320 Overhead PanelMartha B. de Lima100% (4)

- A333 Elec PDFDocument1 pageA333 Elec PDFStephanie JohnsonPas encore d'évaluation

- COLREGDocument41 pagesCOLREGselozok1Pas encore d'évaluation

- A320 Circuit BreakersDocument12 pagesA320 Circuit BreakersMuhammad IchsanPas encore d'évaluation

- Airbus A320 Performance TestDocument100 pagesAirbus A320 Performance TestHarjeevChawla87% (15)

- A320 TestDocument1 pageA320 Testcaptmon351100% (2)

- Daewoo Manuals 1021Document39 pagesDaewoo Manuals 1021Erkan özdenPas encore d'évaluation

- A320 AirDocument1 pageA320 AirEnrique Barberan100% (1)

- A330 Emer PDFDocument1 pageA330 Emer PDFStephanie Johnson67% (3)

- A330Document6 pagesA330Jay France50% (2)

- Nav 08 - Arrival ChecklistDocument3 pagesNav 08 - Arrival ChecklistCORIN EDWARD100% (1)

- Case Study in Improving Tug Escort ProceduresDocument7 pagesCase Study in Improving Tug Escort ProceduresAleksey ChetvertakovPas encore d'évaluation

- AFM Embraer 170 Emergency and Abnormal Procedures 1385 003 FAA SECTION04Document140 pagesAFM Embraer 170 Emergency and Abnormal Procedures 1385 003 FAA SECTION04Vitor Palomanes100% (1)

- Laboratory ApparatusDocument35 pagesLaboratory ApparatusDëv Pacificar100% (2)

- Laboratory ApparatusDocument35 pagesLaboratory ApparatusDëv Pacificar100% (2)

- Laboratory ApparatusDocument35 pagesLaboratory ApparatusDëv Pacificar100% (2)

- Laboratory ApparatusDocument35 pagesLaboratory ApparatusDëv Pacificar100% (2)

- A319 & 320 Fault Verification GuideDocument62 pagesA319 & 320 Fault Verification GuideMarcos Braga93% (14)

- Kfc-Fayol's PrinciplesDocument12 pagesKfc-Fayol's PrinciplesStephanie Johnson68% (44)

- A320 Faults PDFDocument130 pagesA320 Faults PDFRC AgulayPas encore d'évaluation

- Manual Vavitron Systems NT990ASIDocument47 pagesManual Vavitron Systems NT990ASIpevalpeval100% (3)

- PA28-200 Arrow PerformanceDocument4 pagesPA28-200 Arrow PerformanceMichael LinnPas encore d'évaluation

- SD 5 eDocument12 pagesSD 5 eseaqu3stPas encore d'évaluation

- Valve Hyd Cetop 3 Crossover - GuideDocument8 pagesValve Hyd Cetop 3 Crossover - GuideZMCONTROLPas encore d'évaluation

- IPS-EnERGY Available Relay Models - April 2010Document18 pagesIPS-EnERGY Available Relay Models - April 2010Kaveh JbPas encore d'évaluation

- 11kV Colony Switchgear Panel Spares ListDocument21 pages11kV Colony Switchgear Panel Spares ListRaihanKhanPas encore d'évaluation

- Airbus A320 No-Go Items AtaDocument1 pageAirbus A320 No-Go Items Ata57tnd7czznPas encore d'évaluation

- Power Products Ls Industrial SystemsDocument11 pagesPower Products Ls Industrial SystemsHeinekentigerlaruewhite Saigonbluefestivallaruegold Huda-hahaPas encore d'évaluation

- Note FormulaeDocument4 pagesNote FormulaeKaran N ShahPas encore d'évaluation

- Partnership Detailed ProcessesDocument16 pagesPartnership Detailed ProcessesStephanie Johnson100% (2)

- Marking Scheme: Strictly Confidential: (For Internal and Restricted Use Only)Document5 pagesMarking Scheme: Strictly Confidential: (For Internal and Restricted Use Only)Gajender Singh RauthanPas encore d'évaluation

- Science Question Paper Cbse XTH PDFDocument5 pagesScience Question Paper Cbse XTH PDFStephanie JohnsonPas encore d'évaluation

- 9 Future Architecture Developments - PpsDocument19 pages9 Future Architecture Developments - PpsStephanie JohnsonPas encore d'évaluation

- Anza M3akom Twad3o M3anaDocument1 pageAnza M3akom Twad3o M3anaStephanie JohnsonPas encore d'évaluation

- Anza M3akomDocument1 pageAnza M3akomStephanie JohnsonPas encore d'évaluation

- Anza M3akomDocument1 pageAnza M3akomStephanie JohnsonPas encore d'évaluation

- Assignment 1 of BBA Students SdnsakdakdakndnasdasdajbdjasbdasbdbasjbdsbDocument9 pagesAssignment 1 of BBA Students SdnsakdakdakndnasdasdajbdjasbdasbdbasjbdsbStephanie JohnsonPas encore d'évaluation

- Anza M3akomDocument1 pageAnza M3akomStephanie JohnsonPas encore d'évaluation

- Yellow-Black Rent A CarDocument6 pagesYellow-Black Rent A CarStephanie JohnsonPas encore d'évaluation

- Aggregation CompostionDocument6 pagesAggregation CompostionStephanie JohnsonPas encore d'évaluation

- Immanuel Velikovsky - When Was The Lunar Surface Last Molten (1972) PDFDocument4 pagesImmanuel Velikovsky - When Was The Lunar Surface Last Molten (1972) PDFStephanie JohnsonPas encore d'évaluation

- Hello WorldDocument1 pageHello WorldStephanie JohnsonPas encore d'évaluation

- Ahmad Et - Customer Retention - Potent StrategyDocument17 pagesAhmad Et - Customer Retention - Potent StrategyrajnimahajanPas encore d'évaluation

- Business Mathematics HODocument171 pagesBusiness Mathematics HOStephanie JohnsonPas encore d'évaluation

- Adv QFTDocument1 pageAdv QFTStephanie JohnsonPas encore d'évaluation

- Hire Systems Company Income Statement For The Six Months Ended December 31, 2009Document2 pagesHire Systems Company Income Statement For The Six Months Ended December 31, 2009Stephanie JohnsonPas encore d'évaluation

- Iron Kingdoms Character Sheet (B&W) PDFDocument2 pagesIron Kingdoms Character Sheet (B&W) PDFStephanie JohnsonPas encore d'évaluation

- Mhfu WDocument416 pagesMhfu WStephanie JohnsonPas encore d'évaluation

- Nitroen Fertilizers PDFDocument13 pagesNitroen Fertilizers PDFStephanie JohnsonPas encore d'évaluation

- TradeDocument13 pagesTradeStephanie JohnsonPas encore d'évaluation

- Uscg - General MCQ 3Document6 pagesUscg - General MCQ 3Anshu BhushanPas encore d'évaluation

- Bakersfield Fairwind For RacingDocument14 pagesBakersfield Fairwind For Racingsuite123Pas encore d'évaluation

- CBLM SampleDocument48 pagesCBLM SampleMieflor PatilanoPas encore d'évaluation

- Me 262 PDFDocument40 pagesMe 262 PDFCICCIO FASCIOPas encore d'évaluation

- Parts Locator: Vanguard Club 420Document5 pagesParts Locator: Vanguard Club 420Cesar Arango GomezPas encore d'évaluation

- Constant Running Hydraulic Pump (E12171, E12172) Installation Instructions 87039-3-ENDocument28 pagesConstant Running Hydraulic Pump (E12171, E12172) Installation Instructions 87039-3-ENPanificados MarielaPas encore d'évaluation

- Troubleshooting Airframe Vibrations: OperationsDocument8 pagesTroubleshooting Airframe Vibrations: OperationsMaher Abu-ElolaPas encore d'évaluation

- Lifeboat StanderedsDocument62 pagesLifeboat StanderedsBhupender SinghPas encore d'évaluation

- User Manual RV Mech SystemDocument61 pagesUser Manual RV Mech SystemSilviu Tichieru100% (1)

- TH e Mechanical Problems in The Corpus of Aristotle: TH Omas N. WinterDocument24 pagesTH e Mechanical Problems in The Corpus of Aristotle: TH Omas N. Winterdavid.contatos4308Pas encore d'évaluation

- Units in ROMDocument10 pagesUnits in ROMMehmetcan TutarPas encore d'évaluation

- Module Propulsion and SteeringDocument55 pagesModule Propulsion and SteeringSasha KaraPas encore d'évaluation

- Wave ManualDocument20 pagesWave ManualAnastácio Paggi MatosPas encore d'évaluation

- Reglas Alternativas Pirates of Spanish MainDocument26 pagesReglas Alternativas Pirates of Spanish MainjvilladomiPas encore d'évaluation

- Lubrication Requirements Item Lubricant: MonthlyDocument2 pagesLubrication Requirements Item Lubricant: Monthlyreyna.hernandezPas encore d'évaluation

- Ship WheelDocument18 pagesShip Wheelkevineli100% (1)