Académique Documents

Professionnel Documents

Culture Documents

Possible Solutions To Clogged Nozzle

Transféré par

AsphystraszaTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Possible Solutions To Clogged Nozzle

Transféré par

AsphystraszaDroits d'auteur :

Formats disponibles

An epoxy dispenser can become clogged if the polymer adhesive is allowed to dry

on the tip. A blockage in the tip of the dispensing unit may cause one or both o

f the epoxy elements to come out unevenly or not at all. Wiping the dispenser ou

tlet clean prior to storage generally prevents the epoxy from forming a seal. Cl

ogged epoxy dispensing equipment is typically unclogged by cutting away the hard

ened plastic polymer with a sharp knife or razor blade. Some epoxy dispensing sy

stems come with a cap or cover for the tip to keep the tubes holding the adhesiv

e sealed when they are not being used.

-----------------------------------------------

In dispensing small volume of material, clogging of the needle can be a signific

ant problem. The microvolume pump uses highly polished stainless steel needles w

ith a chamfered tip, which reduces the surface tension between the needle and th

e material. As a result, the solder paste or adhesive is less likely to stick to

the tip, thus reducing tailing or bridging as the needle lifts up from the disp

ensed dot. The polished interior surface and the fact that the needle is constru

cted of a single piece extrusion ensure the least amount of surface interference

as the material flows through the needle. In contrast, most needles in other di

spensing systems are of two-piece construction using rolled tubing. As a result,

the needle's irregular interior surface can catch the material and lead to buil

d-up over time, thereby degrading the quality and consistency of the dots being

dispensed.

-----------------------------------------------

Dispensing technologies, such as rotating needles, heated outlets and vacuum pul

lback features, help to minimize clogged needles, unwanted drips, viscosity vari

ations and other dispensing irregularities. A simpler method of avoiding these f

rustrations is to seal components with preformed epoxy.

-----------------------------------------------

ASM International. (1989). Electronic Materials Handbook: Packaging (Volume 1).

Ohio: ASM Internationl.

Nozzle clogging:

- Contamination by traces of incompatible adhesives: replace nozzle or clean tho

roughly in solvents such as methyl ethyl ketone, 1-1-1 trichloroethane, of Freon

. Clean after every shift. Severely clogged dispensers or nozzles can be cleaned

with hot N,N-dimethylformamide.

- Nozzle not cleaned properly: see above and clean nozzle after every shift. Tak

e care not to push cured adhesive up into nozzle.

- Anaerobic cure in steel nozzles or use of brass or copper parts: most acrylic

products are somewhat anaerobic in nature. Brass or copper parts should not be u

sed.

Vous aimerez peut-être aussi

- Plasma Etching Processes for Interconnect Realization in VLSID'EverandPlasma Etching Processes for Interconnect Realization in VLSINicolas PossemePas encore d'évaluation

- Ofet Test Chips Low DensityDocument10 pagesOfet Test Chips Low DensityTHULASIRAMAN SUNDARAJOOPas encore d'évaluation

- Section Cutting and Staining: A practical introduction to histological methods for students and practitionersD'EverandSection Cutting and Staining: A practical introduction to histological methods for students and practitionersPas encore d'évaluation

- Query 2Document2 pagesQuery 2ErKRGautamPas encore d'évaluation

- Making ProcessDocument3 pagesMaking ProcessfredyPas encore d'évaluation

- Neurobionics: The Biomedical Engineering of Neural ProsthesesD'EverandNeurobionics: The Biomedical Engineering of Neural ProsthesesRobert K. ShepherdPas encore d'évaluation

- Thread Based Microfluidic Channels: Fabrication and Application in Organic Semiconductor Crystalline NeedlesDocument9 pagesThread Based Microfluidic Channels: Fabrication and Application in Organic Semiconductor Crystalline Needles36Kushal saNdHuPas encore d'évaluation

- Inbound 969313096968477811Document7 pagesInbound 969313096968477811REANNPas encore d'évaluation

- Beyond Basic Stained Glass Making: Techniques and Tools to Expand Your AbilitiesD'EverandBeyond Basic Stained Glass Making: Techniques and Tools to Expand Your AbilitiesÉvaluation : 3 sur 5 étoiles3/5 (1)

- Process Development For Solder Joints On Power ChipsDocument44 pagesProcess Development For Solder Joints On Power ChipsYeong-Tsuen PanPas encore d'évaluation

- Compendium of Atomic Alkali Resistant Optical Thin Films, Diffusion and Electrical Mobility in Diode Pumped Alkali Lasers (DPALs)D'EverandCompendium of Atomic Alkali Resistant Optical Thin Films, Diffusion and Electrical Mobility in Diode Pumped Alkali Lasers (DPALs)Pas encore d'évaluation

- CHAPTER 11: Testing, Assembly, and Packaging: Individual ChipsDocument13 pagesCHAPTER 11: Testing, Assembly, and Packaging: Individual ChipsMohamad JamalPas encore d'évaluation

- Seminar On Flip ChipDocument10 pagesSeminar On Flip ChipDebashis DasPas encore d'évaluation

- How to Make Electrical Machines: Containing Full Directions for Making Electrical Machines, Induction Coils, Dynamos, and Many Novel Toys to Be Worked by ElectricityD'EverandHow to Make Electrical Machines: Containing Full Directions for Making Electrical Machines, Induction Coils, Dynamos, and Many Novel Toys to Be Worked by ElectricityPas encore d'évaluation

- A Cheap Sensitive Hydrophone For Monitoring CetaceanDocument4 pagesA Cheap Sensitive Hydrophone For Monitoring CetaceanAmador Garcia IIIPas encore d'évaluation

- HydrophoneDocument4 pagesHydrophoneJordan DaltonPas encore d'évaluation

- Ic Packaging PDFDocument11 pagesIc Packaging PDFRIANSYAHPas encore d'évaluation

- Ceramic (Porcelain and Glass) Insulators: More Information High Voltage ProtectionDocument7 pagesCeramic (Porcelain and Glass) Insulators: More Information High Voltage ProtectionLaox TzuPas encore d'évaluation

- Lab ManualDocument80 pagesLab ManualSrini VasuluPas encore d'évaluation

- Polishing of Fibre Optic ConnectorsDocument8 pagesPolishing of Fibre Optic ConnectorsfitomenaPas encore d'évaluation

- Chapter 9Document6 pagesChapter 9Nandhini PPas encore d'évaluation

- Printed Circuit BoardDocument25 pagesPrinted Circuit Boardchristineparpan100% (7)

- General Process Flow For Chip AssemblyDocument6 pagesGeneral Process Flow For Chip AssemblyKuhan StylomilloboyPas encore d'évaluation

- Instructions For The Use of WirelockDocument6 pagesInstructions For The Use of WirelockLeo MottaPas encore d'évaluation

- POF Tool Kit: - Kit Components - Operating Instructions - Warranty InformationDocument8 pagesPOF Tool Kit: - Kit Components - Operating Instructions - Warranty Informationershivkumar2002Pas encore d'évaluation

- Lab Manual Fiber OpticDocument80 pagesLab Manual Fiber Optic_john_123Pas encore d'évaluation

- File 1696992905 GUSBAS202131582 L1 SemiconductorWafersDocument5 pagesFile 1696992905 GUSBAS202131582 L1 SemiconductorWafersÃMĪT KUMAR SINGHPas encore d'évaluation

- Craig Vaughan CHPTR 02 PDFDocument22 pagesCraig Vaughan CHPTR 02 PDFPetrology GSITIPas encore d'évaluation

- The Products We Rely OnDocument14 pagesThe Products We Rely Onjaslinda_jamalPas encore d'évaluation

- Lab ManualDocument80 pagesLab ManualRavindra KumarPas encore d'évaluation

- PCB JarDocument16 pagesPCB JarNoddy 0pPas encore d'évaluation

- 1 of 2 M501 - Ch. 4.0 - Subtopic - 4.2Document2 pages1 of 2 M501 - Ch. 4.0 - Subtopic - 4.2rameshdendgePas encore d'évaluation

- SpliceDocument2 pagesSplicesudheeshmanjuPas encore d'évaluation

- Single Fiber Fusion Splicing: Application NoteDocument8 pagesSingle Fiber Fusion Splicing: Application NoteShaik EsubPas encore d'évaluation

- Schlegel Conductive Elastomers r1Document31 pagesSchlegel Conductive Elastomers r1yobet_navaPas encore d'évaluation

- Handbook On Opitical Fiber CableDocument38 pagesHandbook On Opitical Fiber CableSatya PrakashPas encore d'évaluation

- Metal Spray Moulds in The Shoe IndustryDocument3 pagesMetal Spray Moulds in The Shoe IndustrySiméon ANDRIAMANDROSOPas encore d'évaluation

- IC AssemblyDocument18 pagesIC AssemblyRio PerezPas encore d'évaluation

- Electrolytic Etching by Dauvit AlexanderDocument15 pagesElectrolytic Etching by Dauvit AlexanderDexter HullezaPas encore d'évaluation

- Contact With Your TubesDocument5 pagesContact With Your TubesyogimgurtPas encore d'évaluation

- Stretchable Silicon EssayDocument8 pagesStretchable Silicon Essayrachit1986Pas encore d'évaluation

- Kit Empalme 3M Resina Mineria 8096-2Document8 pagesKit Empalme 3M Resina Mineria 8096-2Claudio Joaquin PérezPas encore d'évaluation

- ObjectDocument77 pagesObjectامير بشير جوادPas encore d'évaluation

- Ofclii 3Document6 pagesOfclii 3محمد الساعديPas encore d'évaluation

- FILMTEC Membranes Interconnector Technology For 8-Inch Diameter FILMTEC ElementsDocument4 pagesFILMTEC Membranes Interconnector Technology For 8-Inch Diameter FILMTEC ElementsGonzalo MijaresPas encore d'évaluation

- Corona Protection in Rotating High Voltage MachinesDocument6 pagesCorona Protection in Rotating High Voltage MachinesLaplaceFourier100% (1)

- Transformer Bushing Damage Accident AnalysisDocument8 pagesTransformer Bushing Damage Accident AnalysisFirda FitriaPas encore d'évaluation

- OC PultrusionDocument29 pagesOC PultrusionalmakmenPas encore d'évaluation

- Causes of Cable FailuresDocument14 pagesCauses of Cable FailuresDenzil D'SouzaPas encore d'évaluation

- 443Document2 pages443nile_asterPas encore d'évaluation

- Wirelock ManualDocument27 pagesWirelock Manualmujeebtalib100% (1)

- Considerations On The Design of Composite Suspension InsulatorsDocument6 pagesConsiderations On The Design of Composite Suspension Insulatorsرائد الدوغجيPas encore d'évaluation

- ProjectDocument34 pagesProjectmansukhPas encore d'évaluation

- Brosur LS-VINA HV - CatalogueDocument36 pagesBrosur LS-VINA HV - CatalogueDian EkaPas encore d'évaluation

- Segmental Bridges: Epoxy Jointing and Prepackaged GroutDocument10 pagesSegmental Bridges: Epoxy Jointing and Prepackaged GroutSantosoPas encore d'évaluation

- Splicing in Optical Fibre CommunicationDocument9 pagesSplicing in Optical Fibre CommunicationchocolatePas encore d'évaluation

- Final em Material ManualDocument43 pagesFinal em Material Manualprashant patilPas encore d'évaluation

- Form 4 Estate Agency Agreement For The Lease of Residential Property by A Tenant PDFDocument7 pagesForm 4 Estate Agency Agreement For The Lease of Residential Property by A Tenant PDFAsphystraszaPas encore d'évaluation

- Form 5 Exclusive Estate Agency Agreement For The Sale of Residential Property PDFDocument7 pagesForm 5 Exclusive Estate Agency Agreement For The Sale of Residential Property PDFAsphystraszaPas encore d'évaluation

- Form 3 Estate Agency Agreement For The Lease of Residential Property by A Landlord PDFDocument7 pagesForm 3 Estate Agency Agreement For The Lease of Residential Property by A Landlord PDFAsphystraszaPas encore d'évaluation

- Form 1 Estate Agency Agreement For The Sale of Residential Property PDFDocument7 pagesForm 1 Estate Agency Agreement For The Sale of Residential Property PDFAsphystraszaPas encore d'évaluation

- Overview Polymer ProcessingDocument9 pagesOverview Polymer ProcessingTrevor J. HutleyPas encore d'évaluation

- Hunter L-A-BDocument4 pagesHunter L-A-BAsphystraszaPas encore d'évaluation

- Comparison of Properties of Ionic and Covalent CompoundsDocument1 pageComparison of Properties of Ionic and Covalent CompoundsAsphystraszaPas encore d'évaluation

- SS316 Corrosion RateDocument13 pagesSS316 Corrosion Ratenarayana reddy100% (1)

- Progress Report (Week 1) Work Done Previously: Toh Beng Leong (KEK110060) Group 5Document1 pageProgress Report (Week 1) Work Done Previously: Toh Beng Leong (KEK110060) Group 5AsphystraszaPas encore d'évaluation

- List of Unit OperationDocument1 pageList of Unit OperationAsphystraszaPas encore d'évaluation

- Enzyme CompilationDocument1 pageEnzyme CompilationAsphystraszaPas encore d'évaluation

- ASME B36.19M Stainless Steel PipesDocument14 pagesASME B36.19M Stainless Steel Pipesdssscarface50% (2)

- Product AnalysisDocument1 pageProduct AnalysisAsphystraszaPas encore d'évaluation

- Paracetamol Market SurveyDocument1 pageParacetamol Market SurveyAsphystrasza0% (1)

- EssayDocument1 pageEssayAsphystraszaPas encore d'évaluation

- Memoirs of JMCDocument1 pageMemoirs of JMCAsphystraszaPas encore d'évaluation

- Production of InsulinDocument5 pagesProduction of InsulinAsphystrasza50% (2)

- PG Metric Threaded CABLE GLANDDocument1 pagePG Metric Threaded CABLE GLANDjigneshPas encore d'évaluation

- Worksheet#9.2 - Ampere's Law Solutions - 2Document5 pagesWorksheet#9.2 - Ampere's Law Solutions - 2Joseph SadderntillionsenPas encore d'évaluation

- Estabilidad de Emulsiones PDFDocument94 pagesEstabilidad de Emulsiones PDFfraniq2007Pas encore d'évaluation

- Ormus and BiocharDocument15 pagesOrmus and Biocharfafsdfdf12Pas encore d'évaluation

- Episode 607: Specific Heat Capacity: Changes Phase From A Solid To A Liquid or Liquid To A GasDocument19 pagesEpisode 607: Specific Heat Capacity: Changes Phase From A Solid To A Liquid or Liquid To A GasMuhamadMarufPas encore d'évaluation

- Brosure Gridswitch MK 1.1Document1 pageBrosure Gridswitch MK 1.1Anwar regarPas encore d'évaluation

- Vol 31 PhotochemistryDocument69 pagesVol 31 PhotochemistryRicardo Gamboa CastellanosPas encore d'évaluation

- Module 3 Chm02L Physical and Chemical Changes - RevisedDocument9 pagesModule 3 Chm02L Physical and Chemical Changes - RevisedemmanPas encore d'évaluation

- Alkanes and HalogenoalkanesDocument67 pagesAlkanes and HalogenoalkanesRAFIDPas encore d'évaluation

- Pub 83 Al Bronze Alloys For Industry PDFDocument24 pagesPub 83 Al Bronze Alloys For Industry PDFpbanerjeePas encore d'évaluation

- Science Lab Report Reactivity of Metalsthis One2Document6 pagesScience Lab Report Reactivity of Metalsthis One2api-237517118100% (2)

- ElectrochemistryDocument15 pagesElectrochemistryÅmìßhã PŕãťãpPas encore d'évaluation

- Mme405 PDFDocument129 pagesMme405 PDFkanakatharavijayanPas encore d'évaluation

- Project Sherazi 12april2010Document159 pagesProject Sherazi 12april2010Carlos MarquezPas encore d'évaluation

- 568 RR Thulasi - CMS Agro Madurai BOQDocument30 pages568 RR Thulasi - CMS Agro Madurai BOQEr S Thirumarai NathanPas encore d'évaluation

- Aquifers of Dera Ghazi KhanDocument12 pagesAquifers of Dera Ghazi KhanArslan geoscientistPas encore d'évaluation

- Class 12th Chemistry Chapter 9 (Coordination Compounds) Important Unsolved QuestionsDocument6 pagesClass 12th Chemistry Chapter 9 (Coordination Compounds) Important Unsolved Questionsanuragk.kumar2006Pas encore d'évaluation

- Trusses and Complex Problems Related To It.Document3 pagesTrusses and Complex Problems Related To It.sukka100% (1)

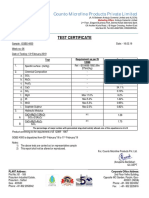

- Test Certificate: Counto Microfine Products Private LimitedDocument1 pageTest Certificate: Counto Microfine Products Private LimitedSiddhesh Kamat MhamaiPas encore d'évaluation

- Heat and Mass Transfer of Single Droplet Particle DryingDocument9 pagesHeat and Mass Transfer of Single Droplet Particle DryingLiliam Teresita Manrique DelgadoPas encore d'évaluation

- CBSE Worksheets For Class 12 PhysicsDocument2 pagesCBSE Worksheets For Class 12 Physicsshanugamer0042Pas encore d'évaluation

- FLC2000 and Wellbore StrengtheningDocument10 pagesFLC2000 and Wellbore StrengtheningKinni ShenoldPas encore d'évaluation

- Crystallographic Imperfections PDFDocument17 pagesCrystallographic Imperfections PDFAmitPas encore d'évaluation

- 7m.span SlabDocument15 pages7m.span SlabEngineeri TadiyosPas encore d'évaluation

- Stainless Steel Tube Stock DataDocument18 pagesStainless Steel Tube Stock DataFU SHING STAINLESS STEEL CO.Pas encore d'évaluation

- Heat Transfer Fluid MechanicsDocument12 pagesHeat Transfer Fluid MechanicsKieran YeowPas encore d'évaluation

- Acid Rain Explanation TextDocument2 pagesAcid Rain Explanation TextIndah Dwi Cahayany100% (2)

- VMS WetarDocument24 pagesVMS WetarErwin AnshariPas encore d'évaluation

- Ytong Product Brochure CXDocument8 pagesYtong Product Brochure CXtrickyggPas encore d'évaluation

- Ball Clay Is A Highly Plastic Variety of Clay of Kaolinite Group Like China Clay and Fire ClayDocument2 pagesBall Clay Is A Highly Plastic Variety of Clay of Kaolinite Group Like China Clay and Fire Clayashleyyy5Pas encore d'évaluation

- Pocket Guide to Flanges, Fittings, and Piping DataD'EverandPocket Guide to Flanges, Fittings, and Piping DataÉvaluation : 3.5 sur 5 étoiles3.5/5 (22)

- Practical Reservoir Engineering and CharacterizationD'EverandPractical Reservoir Engineering and CharacterizationÉvaluation : 4.5 sur 5 étoiles4.5/5 (3)

- The Long Hangover: Putin's New Russia and the Ghosts of the PastD'EverandThe Long Hangover: Putin's New Russia and the Ghosts of the PastÉvaluation : 4.5 sur 5 étoiles4.5/5 (76)

- Gas-Liquid And Liquid-Liquid SeparatorsD'EverandGas-Liquid And Liquid-Liquid SeparatorsÉvaluation : 3.5 sur 5 étoiles3.5/5 (3)

- Well Control for Completions and InterventionsD'EverandWell Control for Completions and InterventionsÉvaluation : 4 sur 5 étoiles4/5 (10)

- Well Testing Project Management: Onshore and Offshore OperationsD'EverandWell Testing Project Management: Onshore and Offshore OperationsPas encore d'évaluation

- Machine Learning Guide for Oil and Gas Using Python: A Step-by-Step Breakdown with Data, Algorithms, Codes, and ApplicationsD'EverandMachine Learning Guide for Oil and Gas Using Python: A Step-by-Step Breakdown with Data, Algorithms, Codes, and ApplicationsÉvaluation : 4 sur 5 étoiles4/5 (4)

- Fundamentals and Applications of Bionic Drilling FluidsD'EverandFundamentals and Applications of Bionic Drilling FluidsPas encore d'évaluation

- Ukraine: What Everyone Needs to KnowD'EverandUkraine: What Everyone Needs to KnowÉvaluation : 4.5 sur 5 étoiles4.5/5 (117)

- Gas and Oil Reliability Engineering: Modeling and AnalysisD'EverandGas and Oil Reliability Engineering: Modeling and AnalysisÉvaluation : 4.5 sur 5 étoiles4.5/5 (6)

- Advanced Production Decline Analysis and ApplicationD'EverandAdvanced Production Decline Analysis and ApplicationÉvaluation : 3.5 sur 5 étoiles3.5/5 (4)

- Essentials of Coating, Painting, and Lining for the Oil, Gas and Petrochemical IndustriesD'EverandEssentials of Coating, Painting, and Lining for the Oil, Gas and Petrochemical IndustriesÉvaluation : 5 sur 5 étoiles5/5 (5)

- Case Studies of Material Corrosion Prevention for Oil and Gas ValvesD'EverandCase Studies of Material Corrosion Prevention for Oil and Gas ValvesPas encore d'évaluation

- Advanced Biomass Gasification: New Concepts for Efficiency Increase and Product FlexibilityD'EverandAdvanced Biomass Gasification: New Concepts for Efficiency Increase and Product FlexibilityÉvaluation : 3 sur 5 étoiles3/5 (2)

- Heavy and Extra-heavy Oil Upgrading TechnologiesD'EverandHeavy and Extra-heavy Oil Upgrading TechnologiesÉvaluation : 4 sur 5 étoiles4/5 (2)

- Heat Exchanger Equipment Field Manual: Common Operating Problems and Practical SolutionsD'EverandHeat Exchanger Equipment Field Manual: Common Operating Problems and Practical SolutionsÉvaluation : 4 sur 5 étoiles4/5 (6)

- Petroleum Production Engineering, A Computer-Assisted ApproachD'EverandPetroleum Production Engineering, A Computer-Assisted ApproachÉvaluation : 4.5 sur 5 étoiles4.5/5 (11)

- Asset Integrity Management for Offshore and Onshore StructuresD'EverandAsset Integrity Management for Offshore and Onshore StructuresPas encore d'évaluation