Académique Documents

Professionnel Documents

Culture Documents

Tlid2004a PDF

Transféré par

satish verma0 évaluation0% ont trouvé ce document utile (0 vote)

49 vues46 pagesThis document provides guidance on loading and unloading goods and cargo. It discusses considerations for loading and unloading such as personal protective equipment, site layout, housekeeping, and communication. It also covers identifying load characteristics and dangerous/hazardous goods, packing/unpacking loads, loading and unloading procedures, lifting aids, special handling goods, and restacking materials. The document is based on competency standards for loading and unloading cargo according to regulations.

Description originale:

Titre original

TLID2004A.pdf

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentThis document provides guidance on loading and unloading goods and cargo. It discusses considerations for loading and unloading such as personal protective equipment, site layout, housekeeping, and communication. It also covers identifying load characteristics and dangerous/hazardous goods, packing/unpacking loads, loading and unloading procedures, lifting aids, special handling goods, and restacking materials. The document is based on competency standards for loading and unloading cargo according to regulations.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

49 vues46 pagesTlid2004a PDF

Transféré par

satish vermaThis document provides guidance on loading and unloading goods and cargo. It discusses considerations for loading and unloading such as personal protective equipment, site layout, housekeeping, and communication. It also covers identifying load characteristics and dangerous/hazardous goods, packing/unpacking loads, loading and unloading procedures, lifting aids, special handling goods, and restacking materials. The document is based on competency standards for loading and unloading cargo according to regulations.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 46

TLID2004A

LOAD AND UNLOAD GOODS/CARGO

LEARNER GUIDE

Module One Load And Unload Goods/Cargo

TLID2004A LOAD AND UNLOAD GOODS/CARGO

Module One Load And Unload Goods/Cargo

Page 2

THE INFORMATION, SOFTWARE, PRODUCTS, AND SERVICES INCLUDED IN OR AVAILABLE THROUGH THE SAFE WORK RESOURCES WEBSITE, CDS,

DOCUMENTS OR ANY OTHER PRODUCTS MAY INCLUDE INACCURACIES OR TYPOGRAPHICAL ERRORS. CHANGES ARE PERIODICALLY ADDED TO THE

INFORMATION HEREIN. SAFE WORK RESOURCES AND/OR ITS ASSOCIATED COMPANIES/BUSINESSES MAY MAKE IMPROVEMENTS AND/OR CHANGES

IN THE SAFE WORK RESOURCES WEBSITE, CDS, DOCUMENTS OR ANY OTHER PRODUCTS AT ANY TIME. ADVICE RECEIVED VIA THE SAFE WORK

RESOURCES WEBSITE, CDS, DOCUMENTS OR ANY OTHER PRODUCTS SHOULD NOT BE RELIED UPON FOR PERSONAL, MEDICAL, LEGAL OR FINANCIAL

DECISIONS AND YOU SHOULD CONSULT AN APPROPRIATE PROFESSIONAL FOR SPECIFIC ADVICE TAILORED TO YOUR SITUATION.

SAFE WORK RESOURCES AND/OR ITS ASSOCIATED COMPANIES/BUSINESSES MAKE NO REPRESENTATIONS ABOUT THE SUITABILITY, RELIABILITY,

AVAILABILITY, TIMELINESS, AND ACCURACY OF THE INFORMATION, SOFTWARE, PRODUCTS, SERVICES AND RELATED GRAPHICS CONTAINED ON THE

SAFE WORK RESOURCES WEBSITE, CDS, DOCUMENTS OR ANY OTHER PRODUCTS FOR ANY PURPOSE. TO THE MAXIMUM EXTENT PERMITTED BY

APPLICABLE LAW, ALL SUCH INFORMATION, SOFTWARE, PRODUCTS, SERVICES AND RELATED GRAPHICS ARE PROVIDED "AS IS" WITHOUT WARRANTY

OR CONDITION OF ANY KIND. SAFE WORK RESOURCES AND/OR ITS ASSOCIATED COMPANIES/BUSINESSES HEREBY DISCLAIM ALL WARRANTIES AND

CONDITIONS WITH REGARD TO THIS INFORMATION, SOFTWARE, PRODUCTS, SERVICES AND RELATED GRAPHICS, INCLUDING ALL IMPLIED

WARRANTIES OR CONDITIONS OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE, TITLE AND NON-INFRINGEMENT.

TO THE MAXIMUM EXTENT PERMITTED BY APPLICABLE LAW, IN NO EVENT SHALL SAFE WORK RESOURCES AND/OR ITS ASSOCIATED

COMPANIES/BUSINESSES BE LIABLE FOR ANY DIRECT, INDIRECT, PUNITIVE, INCIDENTAL, SPECIAL, CONSEQUENTIAL DAMAGES OR ANY DAMAGES

WHATSOEVER INCLUDING, WITHOUT LIMITATION, DAMAGES FOR LOSS OF USE, DATA OR PROFITS, ARISING OUT OF OR IN ANY WAY CONNECTED

WITH THE USE OR PERFORMANCE OF THE SAFE WORK RESOURCES WEBSITE, CDS, DOCUMENTS OR ANY OTHER PRODUCTS WITH THE DELAY OR

INABILITY TO USE THE SAFE WORK RESOURCES WEBSITE, CDS, DOCUMENTS OR ANY OTHER PRODUCTS OR RELATED SERVICES, THE PROVISION OF

OR FAILURE TO PROVIDE SERVICES, OR FOR ANY INFORMATION, SOFTWARE, PRODUCTS, SERVICES AND RELATED GRAPHICS OBTAINED THROUGH

THE SAFE WORK RESOURCES WEBSITE, CDS, DOCUMENTS OR ANY OTHER PRODUCTS OR OTHERWISE ARISING OUT OF THE USE OF THE SAFE

WORK RESOURCES WEBSITE, CDS, DOCUMENTS OR ANY OTHER PRODUCTS WHETHER BASED ON CONTRACT, TORT, NEGLIGENCE, STRICT LIABILITY

OR OTHERWISE, EVEN IF SAFE WORK RESOURCES OR ANY OF ITS ASSOCIATED COMPANIES/BUSINESSES HAS BEEN ADVISED OF THE POSSIBILITY OF

DAMAGES. BECAUSE SOME STATES/JURISDICTIONS DO NOT ALLOW THE EXCLUSION OR LIMITATION OF LIABILITY FOR CONSEQUENTIAL OR

INCIDENTAL DAMAGES, THE ABOVE LIMITATION MAY NOT APPLY TO YOU. IF YOU ARE DISSATISFIED WITH ANY PORTION OF THE SAFE WORK

RESOURCES WEBSITE, OR WITH ANY OF THESE TERMS OF USE, YOUR SOLE AND EXCLUSIVE REMEDY IS TO DISCONTINUE USING THE SAFE WORK

RESOURCES WEBSITE.

TLID2004A LOAD AND UNLOAD GOODS/CARGO

Module One Load And Unload Goods/Cargo

Page 3

TABLE OF CONTENTS

Review Log ..................................................................................................................................... 4

Module Basis .................................................................................................................................. 4

1.1 Introduction .............................................................................................................................. 5

1.2 Load And Unload Goods/Cargo ............................................................................................. 6

1.2.1 Considerations For Loading And Unloading .......................................................................................... 6

1.2.1.1 Personal Protective Equipment ..................................................................................................... 7

1.2.1.2 Site Layout And Obstacles ............................................................................................................ 8

1.2.1.3 Housekeeping Standards And Procedures ................................................................................... 9

1.2.2 Preparation And Procedures ............................................................................................................... 10

1.2.3 Communication And Working With Others .......................................................................................... 12

1.2.3.1 Collaboration And Adapting To Differences ................................................................................ 13

1.3 Identify Load Characteristics ................................................................................................ 14

1.3.1 Load Characteristics ............................................................................................................................ 15

1.3.2 Interpreting Goods And Cargo Information ......................................................................................... 16

1.4 Identify Dangerous Or Hazardous Goods ........................................................................... 17

1.4.1 Australian Dangerous Goods Code ..................................................................................................... 18

1.4.2 Australian And International Regulations ............................................................................................ 19

1.4.3 Other Coding And Markings ................................................................................................................ 20

1.5 Pack/Unpack The Load .......................................................................................................... 21

1.6 Load The Goods/Cargo ......................................................................................................... 22

1.6.1 Scheduling And Contingency Planning ............................................................................................... 23

1.6.1.1 Contingency Plans And Actions .................................................................................................. 24

1.6.2 Loading Goods And Cargo .................................................................................................................. 25

1.6.2.1 Legislation And OHS/WHS Procedures ...................................................................................... 25

Harmonisation of Work Health & Safety Legislation ........................................................................... 26

Key Elements Of The Work Health & Safety Legislation .................................................................... 27

1.6.2.2 Mass And Loading Regulations ................................................................................................... 28

1.6.2.3 Loading And Centre Of Mass ...................................................................................................... 29

1.6.3 Problems When Loading ..................................................................................................................... 30

1.6.3.1 Resolving Problems ..................................................................................................................... 31

1.6.4 Risk Management In Loading Or Unloading ....................................................................................... 32

1.6.4.1 Load And Supply Chain Security ................................................................................................. 35

1.7 Load With Lifting Aids And Appliances ............................................................................... 37

1.8 Unload Safely And Efficiently ............................................................................................... 39

1.8.1 Places For Unloading .......................................................................................................................... 40

1.8.2 Preparing To Unload ........................................................................................................................... 40

1.8.3 Unloading ............................................................................................................................................ 41

1.9 Identify Goods Requiring Special Handling ........................................................................ 42

1.10 Restack Relocated Material ................................................................................................ 43

Appendix 1A Work Health & Safety Common Terms And Definitions ................................. 45

TLID2004A LOAD AND UNLOAD GOODS/CARGO

Module One Load And Unload Goods/Cargo

Page 4

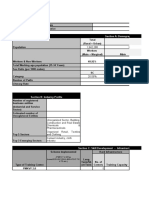

REVIEW LOG

Version Number Date Updated Details of Updates

Version 4H

Released

November, 2012

MODULE BASIS

This module is based on the unit of competency TLID2004A Load And Unload Goods/Cargo:

Element 1 Load and unload

goods/cargo.

1.1 Load characteristics are identified and taken into account when determining

appropriate loading and unloading procedures.

1.2 Dangerous or hazardous goods are identified and handled in accordance with the

Australian Dangerous Goods (ADG) Code and other relevant regulations/permit

requirements.

1.3 Load is packed/unpacked to make safe and effective use of available spaces.

1.4 Goods/cargo are loaded in accordance with relevant mass and loading regulations

and workplace procedures.

1.5 Lifting aids and appliances are selected and used to aid loading procedures in

compliance with workplace procedures and safety legislation.

1.6 Unloading activities are conducted in a safe and efficient manner taking into

account suitable locations, stowage, safe use of equipment and the balance of the

remaining load.

1.7 Goods requiring special handling and/or documentation are identified and

appropriate procedures followed

1.8 Relocated material is restacked appropriate for the transport method, safe height,

weight loading, size and crushability of the goods.

TLID2004A LOAD AND UNLOAD GOODS/CARGO

Module One Load And Unload Goods/Cargo

Page 5

1.1 INTRODUCTION

Welcome to this unit of competency, TLID2004A: Load And Unload Goods/Cargo.

The safe loading and unloading of goods is very important in preventing injury to people and damage to

property. There are economic benefits for everyone if a load arrives at its destination intact and without

damage.

This unit involves the skills and knowledge required to

load and unload goods and cargo, including loading

and unloading goods, securing and protecting a load,

and completing all required documentation.

It includes 2 modules:

Load and unload goods/cargo.

Secure and protect the load and complete

documentation.

Licencing, legislative, regulatory or certification

requirements are applicable to this unit.

TLID2004A LOAD AND UNLOAD GOODS/CARGO

Module One Load And Unload Goods/Cargo

Page 6

1.2 LOAD AND UNLOAD GOODS/CARGO

The principles of loading and unloading goods or cargo apply to loads of all sizes and types. This module

includes procedures and requirements for:

Identifying load characteristics.

Identifying and handling dangerous or

hazardous goods.

Packing and unpacking loads.

Loading goods/cargo.

Selecting lifting aids/appliances.

Unloading goods/cargo.

Identifying goods requiring special handling

and/or documentation.

Restacking relocated material.

1.2.1 CONSIDERATIONS FOR LOADING AND UNLOADING

Loading and unloading goods/cargo and the work activities

associated with it are carried out under certain conditions.

Based on these conditions, it is important that you are aware

of and can apply the following considerations to the work:

Use of personal protective equipment (PPE).

Site layout and obstacles.

Housekeeping standards.

TLID2004A LOAD AND UNLOAD GOODS/CARGO

Module One Load And Unload Goods/Cargo

Page 7

1.2.1.1 PERSONAL PROTECTIVE EQUIPMENT

You need to identify and use the required personal protective

equipment (PPE) in accordance with industry and Occupational

Health & Safety/Work Health & Safety (OHS/WHS) standards.

This PPE may include:

Gloves.

Safety headwear and footwear.

Safety glasses.

Two-way radios.

High-visibility clothing.

It is important to check that the PPE you are using fits

you correctly and conforms to OHS/WHS and industry

requirements.

Always wear the available PPE that is going to protect

you from the hazards and risks posed on the site and

in your role.

TLID2004A LOAD AND UNLOAD GOODS/CARGO

Module One Load And Unload Goods/Cargo

Page 8

1.2.1.2 SITE LAYOUT AND OBSTACLES

Loading and unloading may be conducted in:

Various locations.

Controlled or open environments.

Restricted spaces.

Exposed conditions.

For this reason, you need to be aware of the layout of

the site and obstacles, for example:

When a vehicle is being loaded or unloaded

by forklift, make sure the site area is clear of

obstructions and that you are always in full

view of the forklift driver. Forklift operations

are a major cause of injury to drivers and

loaders. Do not approach a forklift whilst it is

moving.

Check there is adequate ventilation for

vehicle fumes, toxic goods, etc.

When throwing lashings over the vehicle, be

careful that no one is standing on the other

side, i.e. be aware of the location of

colleagues.

Before throwing the lashings, check there are

no electric cables or obstructions/obstacles

above the vehicle that could come into

contact with the lashings.

TLID2004A LOAD AND UNLOAD GOODS/CARGO

Module One Load And Unload Goods/Cargo

Page 9

1.2.1.3 HOUSEKEEPING STANDARDS AND PROCEDURES

You need to be mindful of housekeeping standards and

procedures required in the workplace. This includes:

General tidiness and cleanliness of the site area,

vehicle, load and restraints, e.g. removal and

storage of unwanted packaging or dunnage away

from the site.

Administration and presentation of paperwork,

e.g. items relating to a load are kept together and

in order.

The whereabouts and location of

personnel/workers on the job, e.g. do not stand

or work on one side of a vehicle if the other side

is being loaded or unloaded. Part of the load may

be pushed onto you during the loading or

unloading operations.

TLID2004A LOAD AND UNLOAD GOODS/CARGO

Module One Load And Unload Goods/Cargo

Page 10

1.2.2 PREPARATION AND PROCEDURES

Loading and unloading cargo requires a methodical and systematic approach. You need to work with

required attention to detail, without injury to yourself or others, or damage to goods or equipment.

In general, a systematic approach to loading and

unloading means you should:

Choose a suitable vehicle.

Position the load and dunnage correctly.

Use suitable restraint equipment.

Provide adequate load restraint as outlined in

the National Load Restraint Guide.

Use appropriate driving methods.

TLID2004A LOAD AND UNLOAD GOODS/CARGO

Module One Load And Unload Goods/Cargo

Page 11

You need to be aware of workplace procedures and policies for the loading and unloading of goods/cargo,

including:

Emergency procedures, e.g. accidents during

loading and unloading.

Company policies and procedures, e.g. safe lifting,

hours of operation, trained staff.

Client/supplier policies and procedures, e.g. delivery

times for loading and unloading, breakages caused

during loading and unloading.

Quality assurance procedures, e.g. errors when

handling dangerous goods, incomplete paperwork.

When loading and unloading cargo you will be required to

interpret and follow operational instructions and prioritise

your work. This may involve:

Understanding and clarifying instructions from the

supplier and/or client.

Giving precedence to loading and unloading

activities over other tasks.

Gaining commitment from individuals and

supervisors.

Setting aside the time and place for the loading and

unloading to occur.

Completing associated paperwork and

documentation.

Communicating deadlines for the goods/cargo to be

loaded and unloaded.

TLID2004A LOAD AND UNLOAD GOODS/CARGO

Module One Load And Unload Goods/Cargo

Page 12

1.2.3 COMMUNICATION AND WORKING WITH OTHERS

You need to communicate effectively with others when

loading and unloading goods and cargo. This may involve:

Oral communication.

Written communication.

Non-verbal communication such as body language

and signals.

Some examples of communication when loading and unloading goods and cargo include:

Explaining your preference for a vehicle

location or loading techniques to be used.

Asking questions of work colleagues and

clarifying instructions.

Submitting documentation related to loading

and unloading procedures to relevant

personnel/workers.

Directing lifting aids with signals when loading

or unloading.

You will generally be required to operate electronic

communication equipment in line with organisational and site

protocols. Communication in the work area may be via:

Phone.

Electronic data interchange.

Fax.

Email.

Internet.

Radio.

TLID2004A LOAD AND UNLOAD GOODS/CARGO

Module One Load And Unload Goods/Cargo

Page 13

1.2.3.1 COLLABORATION AND ADAPTING TO DIFFERENCES

You need to work collaboratively with others when

loading and unloading goods and cargo. This could

involve:

Identifying and agreeing on roles and

responsibilities, e.g. who will operate the

vehicle jib crane whilst the other person is

checking the load.

Liaising with the driver of the vehicle to clarify

details of the load, damage, etc.

When collaborating with other people, you may also

need to adapt appropriately to cultural differences in

the workplace, including modes of behaviour and

interactions with others. This may include:

Use of greetings, salutations, seniority.

Recognising colleagues from non-English

speaking backgrounds and how they may

interpret loading/unloading procedures and

details.

Recognising cultural differences in giving

instructions, e.g. using hand gestures or

expressions that could have different

meanings or may be considered vulgar.

TLID2004A LOAD AND UNLOAD GOODS/CARGO

Module One Load And Unload Goods/Cargo

Page 14

1.3 IDENTIFY LOAD CHARACTERISTICS

General freight can be comprised of a large number of small items, e.g. boxes, cartons, crates, bags,

drums and plastic containers. It can also often include large items such as pallets, steel coils and

machinery.

A load is a number of separate items bound together to form a single item of load, also known as unitised

load. The benefit of a load is that it is easier to handle and restrain.

TLID2004A LOAD AND UNLOAD GOODS/CARGO

Module One Load And Unload Goods/Cargo

Page 15

1.3.1 LOAD CHARACTERISTICS

When working with different types of loads you will be required to determine the appropriate loading and

unloading procedures. To do this you will need to identify and take into account the load characteristics.

The characteristics and considerations of a load can vary considerably and include:

Characteristic Consideration

Size Length, width, height.

Shape Square, round, irregular.

Special Requirements Dangerous goods, fragile items.

Packaged or Unpackaged Multiple layers or stacks of material, or bundles of individual lengths.

Labelled or Unlabelled Identification, ownership, warnings.

Palleted or Unpalleted On a portable platform, or loose.

Dunnage may also be associated with the load. Dunnage is packing used to separate loads, typically a

length of square-shaped or rectangular-shaped timber.

You need to estimate the size, shape and special

requirements of loads and decide how to deal with them.

This involves:

Getting an approximate idea or making rough

calculations on the size of a load.

Ascertaining the number of loads.

Assessing any special requirements based on

visual checks and load characteristics.

Taking appropriate action, e.g. working out

where loads go, how loads might be lifted, what

loads need to be tied.

TLID2004A LOAD AND UNLOAD GOODS/CARGO

Module One Load And Unload Goods/Cargo

Page 16

1.3.2 INTERPRETING GOODS AND CARGO INFORMATION

Each load may have several different types of information associated with it. It is important to read and

interpret instructions, procedures, information, signs and labels relevant to the loading and unloading of

goods and cargo.

Types of information include:

When identifying load characteristics, special consideration needs to be given to dangerous or hazardous

goods.

TLID2004A LOAD AND UNLOAD GOODS/CARGO

Module One Load And Unload Goods/Cargo

Page 17

1.4 IDENTIFY DANGEROUS OR HAZARDOUS

GOODS

Dangerous or hazardous goods can be presented for loading or unloading as packages, unit loads or bulk

loads.

There can be extra risks for safety and the environment during the transport of such goods.

You need to identify and handle dangerous or hazardous goods in accordance with the Australian

Dangerous Goods (ADG) code and other relevant regulations or permit requirements.

Labels, symbols, associated paperwork, permits, use of specialised vehicles, bar codes, and other goods

and container identifiers can identify dangerous or hazardous goods.

TLID2004A LOAD AND UNLOAD GOODS/CARGO

Module One Load And Unload Goods/Cargo

Page 18

1.4.1 AUSTRALIAN DANGEROUS GOODS CODE

The Australian Dangerous Goods (ADG) code sets out the requirements for transporting dangerous good

by road or rail. These and other regulations/permit requirements aim to reduce the risk of personal injury,

property damage and environmental harm.

The provisions for handling dangerous goods

include:

Protection of goods and staff during loading

and unloading.

Stowage, e.g. for moving the goods on the

vehicle or within a container.

Packing/stacking, e.g. stable, without empty

spaces between items.

TLID2004A LOAD AND UNLOAD GOODS/CARGO

Module One Load And Unload Goods/Cargo

Page 19

1.4.2 AUSTRALIAN AND INTERNATIONAL REGULATIONS

You need to work within Australian and international regulations and codes of practice for the handling and

transport of dangerous goods and hazardous substances. These codes and regulations include:

Australian and International Dangerous Goods

codes.

Australian Marine Orders and the International

Maritime Dangerous Goods (IMDG) code.

International Air Transport Association (IATA)

regulations for the carriage of dangerous goods

by air.

Australian and International Explosives codes.

The provisions for handling and transport of these goods

include:

Use of dunnage or restraints in conjunction with

dangerous goods.

Mandatory securing, e.g. to prevent goods from

being displaced during transit.

Use of labels on goods, e.g. class labels for toxic

and corrosive substances, legibility of labels,

removal or masking of irrelevant dangerous

goods labels and instructions on a load unit.

Use of signage on vehicles, e.g. dangerous

goods placards.

TLID2004A LOAD AND UNLOAD GOODS/CARGO

Module One Load And Unload Goods/Cargo

Page 20

1.4.3 OTHER CODING AND MARKINGS

Other information displayed on containers and goods may include:

Coding, e.g. to prove that the item has been

codified according to safety rules, Emergency

Action code for action to take as a first

responder should goods become involved in

an accident.

ADG and IMDG markings, e.g. for advice on

attachment points, container capacity.

Emergency information, e.g. emergency

responses, warnings, what to do in the event

of fire.

Upon identification of any containers and goods coding, ADG

and IMDG markings and, where applicable, emergency

information panels, you need to take the appropriate action.

This may include:

Conducting safety awareness programs.

Communicating information to drivers, clients,

suppliers.

Training staff in the handling of containers.

Wearing additional PPE, e.g. goggles.

Having identified your dangerous and hazardous goods, you

are ready to work with the load, utilising all possible space.

TLID2004A LOAD AND UNLOAD GOODS/CARGO

Module One Load And Unload Goods/Cargo

Page 21

1.5 PACK/UNPACK THE LOAD

A vehicle must have adequate load-carrying capacity and sufficient space for a load. A tightly packed load

is less likely to move than one with spaces between parts of the load. You need to pack/unpack the load to

make safe and effective use of available spaces.

You can organise different goods for the best fit from a manifest/list of goods, as applicable.

Empty spaces resulting from the load units being of

different shapes and sizes must generally be filled to

provide sufficient support and stability for the load.

This can mean:

Using webbing nets as barriers to divide

the load space into compartments.

Using spacer boards between cargo layers.

Using support materials, e.g. foam, bubble

wrap, padding, cardboard.

Once the goods/cargo are packed and ready, you can proceed to load them.

TLID2004A LOAD AND UNLOAD GOODS/CARGO

Module One Load And Unload Goods/Cargo

Page 22

1.6 LOAD THE GOODS/CARGO

Your loading and unloading procedures must be conducted according to a planned schedule.

TLID2004A LOAD AND UNLOAD GOODS/CARGO

Module One Load And Unload Goods/Cargo

Page 23

1.6.1 SCHEDULING AND CONTINGENCY PLANNING

A planned schedule for loading and unloading goods/cargo is

a program of instructions and work activities to be carried out

within specific timelines. The schedule should include:

What items need to be loaded, e.g. pallets versus

individual items.

When items are to be loaded, e.g. the sequence

shown on the run sheet, a document outlining the

order in which the goods/cargo are to be

dropped/picked up.

Who carries out loading and unloading activities, e.g.

driver and co-driver, loaders.

How loading/unloading is carried out, e.g. use of

lifting appliances, forklifts, dunnage, or following a

distribution plan.

You need to monitor your work activities in line with

the planned schedule. When unplanned events occur,

however, you should follow the plans for dealing with

contingencies in your workplace.

TLID2004A LOAD AND UNLOAD GOODS/CARGO

Module One Load And Unload Goods/Cargo

Page 24

1.6.1.1 CONTINGENCY PLANS AND ACTIONS

A contingency is an event that may occur, but that is

not likely or intended. The possibility of contingencies

must, however be prepared for.

You need to implement contingency plans for

unexpected situations that may occur when loading

and unloading goods and cargo, for example:

A load is damaged during loading. A

replacement load is then required, meaning

delivery will be delayed.

The forklift breaks down during unloading and

the service technician is rostered off.

You may also need to modify your activities depending

on the differing environments, operational

contingencies and risk situations that arise during your

work.

Alternative procedures need to be identified that are

not part of your pre-planned work schedule.

If a situation arises, you may need to make a

judgement about the best, safest and most efficient

action to take. This could involve:

Sourcing another service technician to deal

with the forklift breakdown.

Hiring another vehicle or obtaining a trailer to

replace a vehicle that is delayed in loading.

TLID2004A LOAD AND UNLOAD GOODS/CARGO

Module One Load And Unload Goods/Cargo

Page 25

1.6.2 LOADING GOODS AND CARGO

Goods/cargo must be loaded safely, either manually or

with the aid of lifting equipment and appliances.

When loading goods/cargo you must follow relevant

OHS/WHS procedures, mass and loading regulations,

and workplace procedures.

1.6.2.1 LEGISLATION AND OHS/WHS PROCEDURES

You need to be aware of the legislative and OHS/WHS procedures and guidelines concerning the lifting

and movement of loads including:

Relevant Australian standards and regulations,

including state/territory mass and loading

regulations.

Codes of practice, e.g. the national standards

for manual handling, industry safety code.

National Load Restraint Guide.

Material safety data sheets.

Manufacturers specifications for lifting

equipment/appliances.

Ensure that you are familiar with the requirements contained in these documents, and can apply them to

your loading tasks.

TLID2004A LOAD AND UNLOAD GOODS/CARGO

Module One Load And Unload Goods/Cargo

Page 26

Harmonisation of Work Health & Safety Legislation

In response to industry calls for greater national consistency,

the Commonwealth, states and territories have agreed to

implement nationally harmonised Work Health & Safety

(WHS) legislation to commence on 1 January 2012.

While not all states and territories have actually implemented

the model WHS legislation as of the start of 2012, it is

important to be aware of these changes, as all states and

territories will eventually implement them.

Harmonisation aims to develop consistent, reasonable and effective safety standards and protections for

all Australian workers through uniform WHS laws, regulations and codes of practice.

TLID2004A LOAD AND UNLOAD GOODS/CARGO

Module One Load And Unload Goods/Cargo

Page 27

Key Elements Of The Work Health & Safety Legislation

The following key elements of the WHS legislation will impact the way you do your job, and the

responsibilities of your workplace:

The legislation also outlines requirements for:

The reporting requirements for notifiable incidents.

Licences, permits and registrations (e.g. for

persons engaged in high risk work or users of

certain plant or substances).

Provision for worker consultation, participation and

representation at the workplace.

Provision for the resolution of health and safety

issues.

Protection against discrimination.

Many specific details relating to WHS will be negotiated within the

workplace in accordance with the legislation.

It is important that you speak with your Health and Safety

Representative or supervisor for more information on how these

elements will effect your day-to-day operations, or if you have any

concerns relating to health and safety.

A list of common WHS terms and their definitions can be found in

Appendix 1A.

TLID2004A LOAD AND UNLOAD GOODS/CARGO

Module One Load And Unload Goods/Cargo

Page 28

1.6.2.2 MASS AND LOADING REGULATIONS

Mass is a measure of the amount of matter in an

object, and is commonly measured to in kilograms (kg)

or tonnes (t).

You need to load goods/cargo in accordance with the

relevant mass and loading regulations, as well as your

workplace procedures.

Mass and loading regulations require that:

A load on a vehicle must not be placed in a

way that makes the vehicle unstable or

unsafe.

A load on a vehicle must be secured so that it

is unlikely to fall or be dislodged from the

vehicle.

An appropriate method must be used to

restrain the load on a vehicle.

Application of mass and loading regulations means

that:

A loaded vehicle must not exceed the

manufacturers tyre and axle load capacity,

the Gross Vehicle Mass (GVM) or Aggregate

Trailer Mass (ATM) and, where applicable,

Gross Combination Mass (GCM).

The carrying capacity of a vehicle (or trailer)

is its GVM (or ATM) less its Tare mass.

The legal mass limits as required by federal,

state and local government jurisdictions must

not be exceeded.

TLID2004A LOAD AND UNLOAD GOODS/CARGO

Module One Load And Unload Goods/Cargo

Page 29

1.6.2.3 LOADING AND CENTRE OF MASS

A load should be positioned so that its centre of mass is as low as possible and not offset to one side of the

vehicle. Positioning the load in this way will reduce the vehicles tendency to overturn when cornering.

This can be achieved by loading heavy objects first and placing them close to the centre-line of the vehicle.

TLID2004A LOAD AND UNLOAD GOODS/CARGO

Module One Load And Unload Goods/Cargo

Page 30

1.6.3 PROBLEMS WHEN LOADING

Problems that may arise when loading goods and cargo may include:

Problems that may relate to regulatory requirements

and workplace procedures could include:

Load position.

Load stability, i.e. unstable loads.

Use of dunnage.

Requirements for safe transport of

dangerous goods.

Requirements for restraint.

TLID2004A LOAD AND UNLOAD GOODS/CARGO

Module One Load And Unload Goods/Cargo

Page 31

1.6.3.1 RESOLVING PROBLEMS

Action that can be taken to prevent or resolve problems with

loading may include:

Making sure that a vehicles load space and loading

deck are suitable for the type and size of the load.

Checking the weight of the load to be carried.

Checking the positioning of the load within the

vehicle.

Considering the positioning of the load after partially

loading or unloading the vehicle.

Positioning the load evenly across the vehicle.

Providing extra restraints for tall loads.

You need to promptly report and/or rectify any identified problems that may arise when loading and

unloading goods and cargo, in accordance with regulatory requirements and workplace procedures. This

may involve:

Reporting to a supplier, client, management staff, the driver, freight company or government

regulatory authorities.

Rectifying the situation by accessing special equipment, e.g. forklift, better arranging of the load,

or using alternative restraint methods.

TLID2004A LOAD AND UNLOAD GOODS/CARGO

Module One Load And Unload Goods/Cargo

Page 32

1.6.4 RISK MANAGEMENT IN LOADING OR UNLOADING

Risk management is the process of reducing or managing the risks

when working with a hazard or in a hazardous situation and should

take into consideration the context of the organisation and worksite.

Risk management must be conducted in accordance with:

Legislative, organisational and site

requirements/procedures, including OHS/WHS.

Australian Standards (AS/NZS ISO 31000:2009).

Codes of Practice.

Employment and workplace relations legislation.

Equal employment opportunity and disability legislation.

Risk management is made up of the following stages:

Consultation and communicating with others and monitoring and review should be planned for and carried

out at every stage of the risk management process.

TLID2004A LOAD AND UNLOAD GOODS/CARGO

Module One Load And Unload Goods/Cargo

Page 33

A RISK is the chance of a hazard hurting you or

somebody else or causing some damage.

A HAZARD is the thing or situation that causes injury,

harm or damage.

If you can remove or at least control a HAZARD you can

reduce the RISK involved.

Part of your job is to look around to see if you can identify any

hazards and risks before you start loading and unloading

goods/cargo.

Hazards in the work area may include:

Exposure to chemicals, dangerous or hazardous

substances.

Movements of equipment, goods and materials.

Condition of restraints, e.g. stretched, broken.

Risks when loading and unloading goods/cargo can

involve:

Load position, e.g. shifted in transit, too tall.

Restraints, e.g. not working, missing parts,

worn out.

Load items, e.g. damaged due to weather,

accident.

Transit route taken, e.g. rain, hail, humidity

affecting the load.

TLID2004A LOAD AND UNLOAD GOODS/CARGO

Module One Load And Unload Goods/Cargo

Page 34

The load should always be packed, located and

restrained in a way that allows its safe loading and

unloading.

You will therefore need to apply precautions and other

required actions to minimise, control or eliminate any

hazards and risks that may exist during the loading

and unloading of goods and cargo.

Some appropriate precautions could include:

Releasing the tension in lashings, e.g. be

careful of any sudden uncontrolled

movement of handles, sharp steel strapping

and hooks on lashings and elastic straps.

Conducting a visual check of the load before

working with it.

Communicating with the driver, client,

supplier as per their observations.

Reviewing your workplace chemical handling

procedures before handling dangerous

goods.

Opening doors, gates, sides and side

curtains and when removing lashings and

tarpaulins, e.g. take care of loads that may

have shifted during a journey which can

dislodge and cause injury.

Reading and interpreting signs, symbols,

documentation.

TLID2004A LOAD AND UNLOAD GOODS/CARGO

Module One Load And Unload Goods/Cargo

Page 35

1.6.4.1 LOAD AND SUPPLY CHAIN SECURITY

Supply chain security refers to efforts to enhance the security of the transport and logistics systems for

cargo. You need to be aware of security requirements when loading and unloading vehicles and in

particular the recognition, isolation and reporting of suspicious cargo and goods.

TLID2004A LOAD AND UNLOAD GOODS/CARGO

Module One Load And Unload Goods/Cargo

Page 36

Suspicious cargo can be recognised by many factors

including:

Paperwork is missing, unsigned, or incomplete.

The load contains unidentified items, more

items than those listed on the manifest or other

paperwork, or items are heavier than the

recorded weight.

Load security tags are missing, doors are

unlocked, container numbers are mismatched,

or tamper-proof seals are broken.

If suspicious cargo is identified, you need to follow

security requirements for the situation, which may

include the following actions:

Isolate the vehicle and/or load.

Inspect the load.

Confirm the credentials of the driver/operator.

Validate the contents of the cargo being

shipped.

Complete a report with evidence.

Report your findings to your supervisor, the

client/supplier, and appropriate authorities.

Loading operations may be carried out manually or with the aid of lifting equipment and/or appliances.

TLID2004A LOAD AND UNLOAD GOODS/CARGO

Module One Load And Unload Goods/Cargo

Page 37

1.7 LOAD WITH LIFTING AIDS AND APPLIANCES

Lifting aids and appliances can assist with the safe loading of a vehicle or trailer. Your selection and use of

this equipment must comply with workplace procedures and OHS/WHS legislation. This includes wearing

PPE as required by industry and OHS/WHS standards.

Selecting a lifting aid involves:

Assessing the situation, including the weight, shape and size of the vehicle and the load.

Choosing the most appropriate aid for the load, e.g. forklift, vehicle-mounted crane, skip container

with a lift arm, or cargo nets.

TLID2004A LOAD AND UNLOAD GOODS/CARGO

Module One Load And Unload Goods/Cargo

Page 38

Using a lifting aid involves:

While carrying out your work activities you may need to operate and adapt to differences in cargo, load

types, restraining devices, equipment and appliances.

You should always follow standard operating

procedures when adapting your technique or

approach to certain tasks, such as:

Handling cargo of different types and

substances use guidelines for touching

infectious substances.

Using equipment of different makes and

models operate an unfamiliar forklift as per

the manufacturers handbook.

You will also need to consider safe and efficient

methods of unloading goods and cargo.

TLID2004A LOAD AND UNLOAD GOODS/CARGO

Module One Load And Unload Goods/Cargo

Page 39

1.8 UNLOAD SAFELY AND EFFICIENTLY

When unloading a vehicle you must always think of safety.

If the vehicle has travelled any distance with the load you may find that it is not as secure as when you last

checked it and some items might have shifted.

You need to conduct unloading activities in a safe and efficient manner, taking into account suitable

locations, stowage, safe use of equipment and the balance of the remaining load.

TLID2004A LOAD AND UNLOAD GOODS/CARGO

Module One Load And Unload Goods/Cargo

Page 40

1.8.1 PLACES FOR UNLOADING

You should find a suitable place for unloading. Locations

can range from designated and controlled areas with

bays, to open areas with unsealed surfaces, and public

roads. You will need to assess each individual situation.

Ideally you want a level site that is clear of other freight

and debris.

It should be well lit, ventilated and away from traffic and

pedestrians.

You should also have enough room to walk around and

manoeuvre loads and equipment.

In some situations, such as stopping on a slope, you

may need chock the wheels, turn the steering wheel to

full lock and barricade off the unloading area.

1.8.2 PREPARING TO UNLOAD

When you are ready to unload, start by walking around

the vehicle and checking the load for any signs of

movement or change.

You should slowly open doors and/or remove restraints

and continue to watch for any movement in the load.

TLID2004A LOAD AND UNLOAD GOODS/CARGO

Module One Load And Unload Goods/Cargo

Page 41

As a general rule you should plan to unload from

the right side of the vehicle first as the camber of

the road tends to make freight shift slightly to the

left.

Unloading attachments and equipment need to be

in good working order and you must use any

necessary PPE, e.g. gloves, as required.

1.8.3 UNLOADING

When unloading you need to do so in a timely

fashion, keep to your schedule and be courteous to

other drivers or personnel/workers who may be

waiting to use the area.

If you are removing part of the load, you will need to

rearrange the remaining items to ensure the load is

balanced, stowed correctly and complies with

regulations.

Covers and restraints need to be reapplied and

unloading equipment put away.

When loading and unloading goods/cargo, be aware that some items may require special handling and/or

documentation.

TLID2004A LOAD AND UNLOAD GOODS/CARGO

Module One Load And Unload Goods/Cargo

Page 42

1.9 IDENTIFY GOODS REQUIRING SPECIAL

HANDLING

You need to identify any goods requiring special handling and/or documentation and follow the appropriate

procedures. These goods may include:

Appropriate procedures for dealing with special goods may

involve the following:

Use of technology, e.g. bar code/chip scanners,

metal detectors, X-ray/photographic devices.

Use of specialised equipment, e.g. roll on/roll off

ramps, conveyer belts for loading/unloading,

tarpaulins.

Implementation of a cold-chain, i.e. whereby the

load is kept continuously in cold temperatures.

Administration of paperwork, e.g. livestock

declarations, permits.

A further consideration for loading and unloading

goods/cargo is making sure that any relocated material is

appropriately restacked.

TLID2004A LOAD AND UNLOAD GOODS/CARGO

Module One Load And Unload Goods/Cargo

Page 43

1.10 RESTACK RELOCATED MATERIAL

Material or goods that have been loaded or unloaded will need to be restacked in the new location in

readiness for further handling or transport.

TLID2004A LOAD AND UNLOAD GOODS/CARGO

Module One Load And Unload Goods/Cargo

Page 44

When restacking goods/cargo, you need to consider the

characteristics and any special requirements of the load.

Restacking should account for the size and weight of

the goods/cargo, remembering that small or crushable

goods will need careful placement.

In addition, the stack must be a safe height and

appropriate for the method of transport being used.

You also need to ensure that you carry out the

restacking in accordance with national standards, safety

codes and site operating procedures.

Methods used to restack cargo may involve:

Arrangements for multiple layers, stacks of

material or bundles of individual lengths.

The segregation of dangerous goods and

hazardous substances.

The use of refrigeration or freezer areas for

perishables.

Arrangements for bulk loads.

The use of pallets as a portable platform for

lifting bulk quantities.

TLID2004A LOAD AND UNLOAD GOODS/CARGO

Module One Load And Unload Goods/Cargo

Page 45

APPENDIX 1A WORK HEALTH & SAFETY

COMMON TERMS AND DEFINITIONS

Person

Conducting a

Business or

Undertaking

(PCBU)

A person conducting a business or undertaking (PCBU) replaces the term employer. A

PCBU includes all employers, sole traders, principal contractors, unincorporated

associations, partnerships and franchisees. Volunteer organisations that also employ

people will be PCBUs.

A PCBUs primary duty of care is to ensure the health and safety of everyone in the

workplace, so far as is reasonably practicable.

Officers An Officer is a person who makes, or participates in making, decisions that affect the

whole or a substantial part of a corporation. This includes Health and Safety

Representatives (HSR).

Workers Worker replaces the term employee. It is defined broadly to mean a person who carries

out work in any capacity for a PCBU.

A worker covers employees, contractors, sub-contractors (and their employees), labour

hire employees, outworkers, apprentices, trainees, work experience students and

volunteers.

Reasonably

Practicable

Reasonably Practicable is defined as action that is, or was at a particular time,

reasonably able to be done to help ensure health and safety based on the following

factors:

a) Chances of the hazard or risk occurring (likelihood).

b) The degree of harm (consequence).

c) The knowledge of persons involved in the situation relating to the hazard or risk

and methods of eliminating or controlling it.

d) The availability and suitability of ways to eliminate or control the hazard or risk.

e) The costs involved in taking action to eliminate or control the hazard or risk

including consideration of whether the cost involved is inconsistent to the level of

risk.

Due

Diligence

The Work Health and Safety Act 2011 (the WHS Act 2011) imposes a specific duty on

officers of corporations to exercise due diligence to ensure that the corporation meets its

work health and safety obligations. In short, they have a responsibility to ensure that the

PCBU is doing everything it should to ensure health and safety.

The duty requires officers to be proactive in ensuring that the corporation complies with

its duty.

Due diligence may be demonstrated through the following courses of action:

1. Acquiring knowledge of health and safety issues.

2. Understanding operations and associated hazards and risks.

3. Ensuring that appropriate resources and processes are used to eliminate or

minimise risks to health and safety.

4. Implementing processes for receiving and responding to information about

incidents, hazards and risks.

5. Establishing and maintaining compliance processes.

6. Verifying the provision and use of the resources mentioned in 1-5.

Vous aimerez peut-être aussi

- First Aid - Learner GuideDocument144 pagesFirst Aid - Learner GuideLachlan CliffordPas encore d'évaluation

- Notice of Disclaimer and Limitation of LiabilityDocument85 pagesNotice of Disclaimer and Limitation of LiabilityCaleb CameroPas encore d'évaluation

- XDM-1000 IMM ETSI A08 8.1 enDocument508 pagesXDM-1000 IMM ETSI A08 8.1 enVossKarr100% (1)

- HTTP WWW - Nema.org Download - CFM Docid 4054&filename PB 1 2006 WebDocument36 pagesHTTP WWW - Nema.org Download - CFM Docid 4054&filename PB 1 2006 WebJesus ContrerasPas encore d'évaluation

- MIKE 321 FM Scientific Doc PDFDocument64 pagesMIKE 321 FM Scientific Doc PDFahmad azwarPas encore d'évaluation

- Siteminder Ps Install Enu PDFDocument465 pagesSiteminder Ps Install Enu PDFharshad27Pas encore d'évaluation

- CA Plex Tutorial System ENUDocument110 pagesCA Plex Tutorial System ENUxavier bouPas encore d'évaluation

- 2017-02 TIA Working DictionaryDocument91 pages2017-02 TIA Working DictionaryNguyễn Văn CườngPas encore d'évaluation

- JoompayDocument43 pagesJoompayRisma Bin Mat RosPas encore d'évaluation

- Fastiron 08090 DhcpguideDocument129 pagesFastiron 08090 DhcpguideMochammad Yoga KhulaifiPas encore d'évaluation

- Fastiron 09010 TrafficguideDocument67 pagesFastiron 09010 Trafficguideyanceyleo22Pas encore d'évaluation

- BroadGate BG 20 Installation Operation ADocument206 pagesBroadGate BG 20 Installation Operation ANguyen Le PhuongPas encore d'évaluation

- Cabi Release EnuDocument30 pagesCabi Release EnuManaliSharmaPas encore d'évaluation

- NEMA ABP 1 Selective CoordinationDocument47 pagesNEMA ABP 1 Selective Coordinationtaner56Pas encore d'évaluation

- Espec Tecn XDM-500Document242 pagesEspec Tecn XDM-500Jose JaramilloPas encore d'évaluation

- Fastiron 08061 DhcpguideDocument99 pagesFastiron 08061 DhcpguideSuresh VNPas encore d'évaluation

- Nema PB 2 - 2006 SwitchboardDocument36 pagesNema PB 2 - 2006 SwitchboardAlejandro SantillanPas encore d'évaluation

- Fastiron 08090 CommandrefDocument2 967 pagesFastiron 08090 CommandrefMochammad Yoga KhulaifiPas encore d'évaluation

- Fastiron 08090 L3guideDocument426 pagesFastiron 08090 L3guidePeace SukprapaipatPas encore d'évaluation

- Fastiron 08070 Ipmulticastguide PDFDocument207 pagesFastiron 08070 Ipmulticastguide PDFChamuelDiazPas encore d'évaluation

- Fastiron 08070 DhcpguideDocument103 pagesFastiron 08070 DhcpguideSuresh VNPas encore d'évaluation

- Fastiron 08070 UpgradeguideDocument59 pagesFastiron 08070 UpgradeguideDaniel MontesPas encore d'évaluation

- Fastiron 08050 CommandrefDocument2 435 pagesFastiron 08050 CommandrefVenkata SureshPas encore d'évaluation

- Blackberry Enterprise Server Release Notes 1557778 0414043117 001 1.0 USDocument9 pagesBlackberry Enterprise Server Release Notes 1557778 0414043117 001 1.0 USAnderson HaasPas encore d'évaluation

- Spectrum Web Api PDFDocument73 pagesSpectrum Web Api PDFrupinder_gujral5102Pas encore d'évaluation

- MigrationDocument44 pagesMigrationRohit SharmaPas encore d'évaluation

- NEMA Application Guide For AC VAriable Speed Drive SystemsDocument89 pagesNEMA Application Guide For AC VAriable Speed Drive Systemsssmanian68100% (1)

- OTM 6.4.3 Security Guide PDFDocument146 pagesOTM 6.4.3 Security Guide PDFvikramdasPas encore d'évaluation

- Safety1 - Guidelines For The Use of Personal Protective Equipment in Thermal SprayingDocument33 pagesSafety1 - Guidelines For The Use of Personal Protective Equipment in Thermal SprayingArlen NurlanPas encore d'évaluation

- GL Hardware Software Service Level Agreement SLADocument23 pagesGL Hardware Software Service Level Agreement SLAJoel ManuelPas encore d'évaluation

- Ics 5 2000 R2005 R2010Document156 pagesIcs 5 2000 R2005 R2010Jesus Salazar50% (2)

- CA Deliver - Ref - ENUDocument365 pagesCA Deliver - Ref - ENUBurhan MalikPas encore d'évaluation

- TI-89 / TI-92 Plus / Voyage™ 200 Statistics With List EditorDocument200 pagesTI-89 / TI-92 Plus / Voyage™ 200 Statistics With List EditorKyukyu96Pas encore d'évaluation

- Business Strategy Enabled by Cloud Master Usage Model Rev 1.0Document39 pagesBusiness Strategy Enabled by Cloud Master Usage Model Rev 1.0OscarPas encore d'évaluation

- Plex Tutorial Windows ENUDocument148 pagesPlex Tutorial Windows ENUSamuel PilayPas encore d'évaluation

- Nema ABP 1-2010 Selective CoordinationDocument47 pagesNema ABP 1-2010 Selective CoordinationAdam AbrahamPas encore d'évaluation

- User's Manual: Volume 1 and 2Document103 pagesUser's Manual: Volume 1 and 2Putu SuarmaPas encore d'évaluation

- User Guide PDFDocument2 011 pagesUser Guide PDFSonny Jason APas encore d'évaluation

- SprinkCalc TutorialsDocument170 pagesSprinkCalc Tutorialsmancas500% (1)

- Nema PB2.2-1999Document41 pagesNema PB2.2-1999fernandoPas encore d'évaluation

- HAC - Onshore Seismic OperationsDocument92 pagesHAC - Onshore Seismic OperationsPablo Sánchez100% (1)

- Ruckus WI FIDocument202 pagesRuckus WI FIThalesPas encore d'évaluation

- TTPLPDocument348 pagesTTPLPerrr33Pas encore d'évaluation

- Frequency Response Calculator and Mooring Analysis: MIKE 21 MaritimeDocument32 pagesFrequency Response Calculator and Mooring Analysis: MIKE 21 Maritimekhanh locPas encore d'évaluation

- Oracle® Real-Time Decisions: Decision Center User GuideDocument38 pagesOracle® Real-Time Decisions: Decision Center User GuideishtiaqisPas encore d'évaluation

- CA Workload Automation CA 7® Edition - Messages PDFDocument1 845 pagesCA Workload Automation CA 7® Edition - Messages PDFAravind RaviPas encore d'évaluation

- UCA 2013 IEC61850 IOP Report 18042014Document246 pagesUCA 2013 IEC61850 IOP Report 18042014Sheik HussainPas encore d'évaluation

- Lakes Wrplot View User GuideDocument110 pagesLakes Wrplot View User Guidebrayan stiven sanchez moraPas encore d'évaluation

- LightSOFT V14.2 Fault Management and Performance Monitoring GuideDocument140 pagesLightSOFT V14.2 Fault Management and Performance Monitoring GuideRenato TrinoPas encore d'évaluation

- NEMA ICS 1-2000 (R2005, R2008) - Industrial Control and Systems - General Requirements - 98pDocument98 pagesNEMA ICS 1-2000 (R2005, R2008) - Industrial Control and Systems - General Requirements - 98pjosemrondon99100% (1)

- Dhis2 Implementation Guide enDocument76 pagesDhis2 Implementation Guide enNasir Khan SaikatPas encore d'évaluation

- CA Easytrieve® - 11.6 - ENU - 20180723Document1 108 pagesCA Easytrieve® - 11.6 - ENU - 20180723stnlyc0% (1)

- Wireline Operations DACC IRP 13Document74 pagesWireline Operations DACC IRP 13AkashPas encore d'évaluation

- XDM-1000 Product Line RM ETSI B01 8.2.3-8.2.4 enDocument688 pagesXDM-1000 Product Line RM ETSI B01 8.2.3-8.2.4 enIvan M.Pas encore d'évaluation

- Cisco FireAmp User GuideDocument187 pagesCisco FireAmp User GuideMorionPas encore d'évaluation

- Oracle Bills of Material 12.2Document364 pagesOracle Bills of Material 12.2Quang Hung NguyenPas encore d'évaluation

- Aztech Wl558usb User Manual v1.0Document47 pagesAztech Wl558usb User Manual v1.0Serkan KahramanPas encore d'évaluation

- Implementing Zero Trust Architecture: An Enterprise GuideD'EverandImplementing Zero Trust Architecture: An Enterprise GuideÉvaluation : 5 sur 5 étoiles5/5 (1)

- Corporate AgentsDocument1 023 pagesCorporate AgentsVivek Thota0% (1)

- Section A: Demographic Profile: (PMKVY 2.0/fee based/DDUGKY/NULM/NAPS/CTS/ ATS Etc.)Document9 pagesSection A: Demographic Profile: (PMKVY 2.0/fee based/DDUGKY/NULM/NAPS/CTS/ ATS Etc.)satish vermaPas encore d'évaluation

- Training Advisory Board - PTODocument2 pagesTraining Advisory Board - PTOsatish vermaPas encore d'évaluation

- MpcDocument1 pageMpcsatish vermaPas encore d'évaluation

- Ra List ReportDocument218 pagesRa List Reportsatish vermaPas encore d'évaluation

- Sl. No. Name of The Department Head of Department of District DDO CodeDocument54 pagesSl. No. Name of The Department Head of Department of District DDO Codesatish vermaPas encore d'évaluation

- Permanent Affiliation (Govt. Institution) : SL Name of The Institute Code Address, Website, E-Mail Telephone SessionDocument7 pagesPermanent Affiliation (Govt. Institution) : SL Name of The Institute Code Address, Website, E-Mail Telephone Sessionsatish vermaPas encore d'évaluation

- 2005 Member DirectoryDocument2 pages2005 Member Directorysatish vermaPas encore d'évaluation

- List of Nstis/Nsti (W)Document5 pagesList of Nstis/Nsti (W)satish vermaPas encore d'évaluation

- Applied Mycology and Plant Pathology: M. Sc. BOTANY (MSCBOT-12/13/16) Second Year, Examination, 2017Document6 pagesApplied Mycology and Plant Pathology: M. Sc. BOTANY (MSCBOT-12/13/16) Second Year, Examination, 2017satish vermaPas encore d'évaluation

- LinkedIn GroupsDocument4 pagesLinkedIn Groupssatish vermaPas encore d'évaluation

- SampleDocument11 pagesSamplesatish vermaPas encore d'évaluation

- Training Advisory Board / Committee: Dr.B.MuthukumarDocument2 pagesTraining Advisory Board / Committee: Dr.B.Muthukumarsatish vermaPas encore d'évaluation

- 2018 NJAASC Member RosterDocument15 pages2018 NJAASC Member Rostersatish vermaPas encore d'évaluation

- Cpa DirectoryDocument11 pagesCpa Directorysatish vermaPas encore d'évaluation

- List of ExhibitorsDocument201 pagesList of Exhibitorssatish verma100% (1)

- List of Importers in Brazil For Products CodedDocument162 pagesList of Importers in Brazil For Products Codedsatish verma100% (1)

- Master TrainerDocument19 pagesMaster Trainersatish vermaPas encore d'évaluation

- Delegate List For 2017 HR and LDDocument4 pagesDelegate List For 2017 HR and LDsatish vermaPas encore d'évaluation

- Peenya RtiDocument25 pagesPeenya Rtisatish vermaPas encore d'évaluation

- Employee DirectoryDocument13 pagesEmployee Directorysatish vermaPas encore d'évaluation

- Police Directory TeliphoneDocument78 pagesPolice Directory TeliphoneAmitDigambari62% (29)

- Ukd PolDocument2 pagesUkd Polsatish vermaPas encore d'évaluation

- S.No Name Course/Package Address Contact DetailsDocument11 pagesS.No Name Course/Package Address Contact Detailssatish verma100% (1)

- Respiratory Disease Anatomy and Phys Sheridan CollegeDocument7 pagesRespiratory Disease Anatomy and Phys Sheridan CollegeAudrey AndinoPas encore d'évaluation

- Ventricular ArrhythmiaDocument37 pagesVentricular Arrhythmiaelhassia elhassiaPas encore d'évaluation

- Pemeriksaan Kualitas Udara Ruang Yang Berhubungan Dengan Angka Kuman Di Ruang Operasi Rumah Sakit Sumber Hidup Di Kota Ambon 2020Document9 pagesPemeriksaan Kualitas Udara Ruang Yang Berhubungan Dengan Angka Kuman Di Ruang Operasi Rumah Sakit Sumber Hidup Di Kota Ambon 2020tedilevinrarianPas encore d'évaluation

- A Study Guide For Modern Epidemiology 3rd Edition - Basic ConceptsDocument5 pagesA Study Guide For Modern Epidemiology 3rd Edition - Basic ConceptsGenevieve Magpayo NangitPas encore d'évaluation

- Graduate School, Chulalongkorn University Application Form For Combined Scholarship For International Graduate Students For Academic Year, SemesterDocument4 pagesGraduate School, Chulalongkorn University Application Form For Combined Scholarship For International Graduate Students For Academic Year, SemesterHiếu Nguyễn MinhPas encore d'évaluation

- Problem Statement 1 (Autosaved) Real DimpyDocument8 pagesProblem Statement 1 (Autosaved) Real Dimpycharanjit kaurPas encore d'évaluation

- Individual Development Plan: Department of EducationDocument4 pagesIndividual Development Plan: Department of Educationjessemar waoPas encore d'évaluation

- Ardrox 8501 Aerosol SDS 2016Document5 pagesArdrox 8501 Aerosol SDS 2016Ken SidhartaPas encore d'évaluation

- Ballista Spring - Palatally Impac CanineDocument5 pagesBallista Spring - Palatally Impac CanineThendral DevanathanPas encore d'évaluation

- ReadingDocument1 pageReadingCongreso IIG BIIMASPas encore d'évaluation

- Cordially Invite You To: The Tamilnadu DR.M.G.R Medical UniversityDocument4 pagesCordially Invite You To: The Tamilnadu DR.M.G.R Medical UniversityDamothara MuthuPas encore d'évaluation

- Chapter 1group 5stem 12 Inventiveness1Document15 pagesChapter 1group 5stem 12 Inventiveness1John Aerol Allosada - DignityPas encore d'évaluation

- Howlett and Ramesh Educational Policy ModelDocument11 pagesHowlett and Ramesh Educational Policy ModelJaquelyn Montales100% (1)

- Vinci X 2 User ManualDocument1 pageVinci X 2 User ManualRizkyPas encore d'évaluation

- Gajanan CirtificateDocument1 pageGajanan CirtificateLearn easy By Gajanan topalePas encore d'évaluation

- Analyctical 3Document22 pagesAnalyctical 3Bunda LembayungPas encore d'évaluation

- David Moises Memorial High SchoolDocument8 pagesDavid Moises Memorial High SchoolRonald ArtilleroPas encore d'évaluation

- F-08-65 Stainless Steel Alloys Eu MDR Statement On CMR and Endocrine Disrupting SubstancesDocument3 pagesF-08-65 Stainless Steel Alloys Eu MDR Statement On CMR and Endocrine Disrupting SubstancesMubeenPas encore d'évaluation

- Education: Professional ProfileDocument3 pagesEducation: Professional ProfileAbed AlhaleemPas encore d'évaluation

- Rev B S10 AutosamplerDocument90 pagesRev B S10 AutosamplerevalenciaPas encore d'évaluation

- Medical Clinic Standards v.1Document13 pagesMedical Clinic Standards v.1ummuawisyPas encore d'évaluation

- Petro Canada Duron HP - 15w-40 PDFDocument10 pagesPetro Canada Duron HP - 15w-40 PDFPubcrawl100% (1)

- MSDS B362 BensolDocument5 pagesMSDS B362 Bensolレテイ サマ ヒルカPas encore d'évaluation

- Scrap Material Handling & Loading Jha - 1Document2 pagesScrap Material Handling & Loading Jha - 1Dwitikrushna Rout100% (1)

- Jurisprudance DI Questions Paper BPSC 2023 PharmapediaDocument9 pagesJurisprudance DI Questions Paper BPSC 2023 Pharmapediakrishnamahalle12Pas encore d'évaluation

- HR4202 ReassessmentDocument7 pagesHR4202 ReassessmentBhavya Charitha Madduri AnandaPas encore d'évaluation

- British Women Surgeons and Their Patients 1860 1918 PDFDocument318 pagesBritish Women Surgeons and Their Patients 1860 1918 PDFAndra DoniPas encore d'évaluation

- Disability and PovertyDocument65 pagesDisability and PovertyRahul ChinthakayalaPas encore d'évaluation

- GMRS Distal Femur: Global Modular Replacement SystemDocument48 pagesGMRS Distal Femur: Global Modular Replacement SystemSomPas encore d'évaluation

- The State of Course Learning Outcomes at Leading UniversitiesDocument14 pagesThe State of Course Learning Outcomes at Leading Universitiessandra milena bernal rubioPas encore d'évaluation