Académique Documents

Professionnel Documents

Culture Documents

ME401 - Assignment 4: October 21, 2014

Transféré par

Prakhar Gupta0 évaluation0% ont trouvé ce document utile (0 vote)

883 vues3 pagesThe document contains 9 problems related to axial and centrifugal compressor design and performance calculations. The problems involve calculating stage air angles, rotational speeds, mass flow rates, power requirements, pressure and temperature ratios, blade angles, and more based on given compressor specifications and operating conditions. A variety of compressor parameters, efficiencies, and flow properties are considered in the analysis.

Description originale:

assignment for turbomachinery

Titre original

Assignment 4

Copyright

© © All Rights Reserved

Formats disponibles

DOCX, PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentThe document contains 9 problems related to axial and centrifugal compressor design and performance calculations. The problems involve calculating stage air angles, rotational speeds, mass flow rates, power requirements, pressure and temperature ratios, blade angles, and more based on given compressor specifications and operating conditions. A variety of compressor parameters, efficiencies, and flow properties are considered in the analysis.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme DOCX, PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

883 vues3 pagesME401 - Assignment 4: October 21, 2014

Transféré par

Prakhar GuptaThe document contains 9 problems related to axial and centrifugal compressor design and performance calculations. The problems involve calculating stage air angles, rotational speeds, mass flow rates, power requirements, pressure and temperature ratios, blade angles, and more based on given compressor specifications and operating conditions. A variety of compressor parameters, efficiencies, and flow properties are considered in the analysis.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme DOCX, PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 3

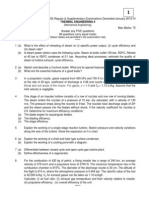

ME401 Assignment 4

October 21, 2014

1. An axial flow compressor stage has blade root, mean and tip velocities of 150, 200 and 250 m/s

respectively. The stage is to be designed for a stagnation temperature rise of 20

0

C and an axial

velocity of 150 m/s, both constant from root to tip. The work done factor is 0.93. Assuming 50%

reaction at mean radius, calculate the stage air angles at root, mean and tip and degree of

reaction at root and tip for a free vortex design.[45.71

0

, 16.95

0

, 13.78

0

, 39.40

0

, 54.87

0

, 40.21

0

,

67.995%, 22.23

0

, 53.86

0

, 30.597

0

, -20.27

0

, 11.099%]

2. A helicopter gas turbine requires an overall pressure ratio of 10:1. This is to be obtained using a

two-spool layout consisting of a four stage axial flow compressor followed by a single stage

centrifugal compressor. The polytropic efficiency of the axial flow compressor is 92 percent and

that of the centrifugal is 83 percent.

The axial compressor has stage temperature rise of 30

0

C, using symmetrical stages with a stator

outlet angle of 20

0

. If the mean diameter of each stage is 250 mm and each stage is identical,

calculate the required rotational speed. Assume a work done factor of 0.86 and a constant axial

velocity of 150 m/s.

Assuming an axial velocity at the eye of the impeller, an impeller diameter of 330 mm, a slip

factor of 0.90 and a power input factor of 1.04, calculate the rotational speed required for

centrifugal compressor. Ambient conditions are 1.01 bar and 288K.[Axial Compressor: 52.44

0

,

19070.399 rpm, 3.07; Centrifugal compressor: 27150.49 rpm]

3. Air at a temperature of 290 K enters a 10 stage axial flow compressor, at the rate of 2.8 kg/s.

The pressure ratio is 6.5 and the isentropic efficiency is 90 percent, the compression process

being adiabatic. The compression has symmetrical stages. The axial velocity of 110 m/s is

uniform across the stage and the mean blade speed of each stage is 180 m/s.

Determine the direction of air at entry to and exit from the rotor and the stator blades and also

the power given to the air. Cp=1.005kJ/kg and =1.4[22.81

0

C, 54.405

0

, 13.446

0

]

4. The first stage of an axial-flow compressor is designed on free vortex principle. The

rotational speed is 6000 rpm and stagnation temperature rise is 20 K. The hub- tip ratio is

0.60, the work done factor is 0.98 and the isentropic efficiency of the stage is 0.89.

Assuming an inlet velocity is 141 m/s and ambient conditions of 1.01 bar and 288K,

compute:

(i) The tip radius and corresponding rotor air angles, if the Mach number relative

to tip is limited to 0.95.[0.454m,

1

=63.85,

2

=56.23]

(ii) The mass flow rate entering the stage.[65kg/s]

(iii) The stagnation pressure-ratio and power required.[1.234,1306.9kW]

(iv) The rotor air angles at root section.[

1

=50.71,

2

=17.74]

5. An axial flow has overall pressure ratio of 4.0 and mass flow is 180 kg/minute. If the

polytrophic efficiency is 88% and stagnation temperature rise per stage must not exceed

to 25C, calculate no of stages required and the pressure ratio of the first stage and last

stages. Assume equal temperature rise in all stages. The absolute velocity approaching

the last rotor is 165m/s at an angle 20 from the axial direction, the work done factor is

0.83. The velocity diagram is symmetrical and means diameter of last rotor is 188mm,

compute rotational speed of the rotor in the last stage and length of the last stage rotor

blade at inlet to the rotor. Ambient conditions are 1.01bar and 288K.[7

Stages,1.265,24833rpm,13.37mm]

6. The following data refer to the eye of a single-sided impeller:

Inner diameter 130mm, outer diameter 300mm, speed 16000 rpm, Mass flow rate 9

kg/s , Ambient conditions 1.00bar and 288K.Assuming no pre-whirl and no loss in the

intake duct, compute the blade inlet angle at the root and tip of the eye and Mach

number at the tip of the eye.[

1(root)

=52.55,

1(tip)

=29.5,Mach#=0.865]

7. An aircraft engine is fitted with a single sided centrifugal compressor. The aircraft flies

with a speed of 850 km/h at an altitude where pressure is 0.23 bar and the temperature is

217 K. The inlet duct of the impeller eye contains fixed vanes which give the air pre-

whirl of 25 at all radii. The inner and outer diameters of the eye are 180 and 330 mm

respectively, the diameter of impeller tip is 540 mm and the rotational speed is 16000

rpm. Estimate the stagnation pressure at the compressor outlet when the mass flow is 216

kg per minute. Neglect the losses in the inlet duct and fixe vanes, and assume that the

isentropic efficiency of the compressor is 0.80. Take the slip factor as 0.9 and the power

input factor as 1.04. [1.63 bar]

8. Air from a practical quiescent atmosphere, pressure 1 bar and temperature 300 K, enters

axially a centrifugal compressor fitted with radial blades, and the air leaves the diffuser

with negligible velocity. The tip diameter of the impeller is 450 mm and the speed of

rotation is 18000 rpm. Neglecting all losses, calculate the temperature and the pressure of

the air as it leaves the compressor. Take =1.4, Cp=1.005 kJ/kg-K and =0.9. [461.08

K, 4.5 bar]

9. In the impeller of a centrifugal compressor the air enters the air without pre-whirl with a

velocity of 9.5 m/s. The relative air angle at the exit of the impeller is 65 with the

tangential direction, and the radial component of the velocity is 110 m/s and the tip speed

of the radial vanes is 500 m/s. The air flow rate is 2 kg/s and the mechanical efficiency is

96%. Calculate the power required to drive the compressor. If radius ratio of the impeller

eye is 0.3, calculate the suitable inlet diameter assuming the inlet flow is incompressible.

Determine the overall stagnation pressure ratio of the compressor when the isentropic

efficiency is 80%, assuming the velocity at the exit from the diffuser is negligible. Take

R=287 J/kg-K, =1.4, Cp=1.005 kJ/kg-K, stagnation temperature and stagnation pressure

at the compressor entry as 288 K and 1.013 bar respectively. [467.4 kW, 155mm,

5.4124]

Vous aimerez peut-être aussi

- HTFS Presentation 2 Heat ExchangerDocument57 pagesHTFS Presentation 2 Heat ExchangerSuphi YükselPas encore d'évaluation

- Sam G. Dukelow The Control of BoilersDocument414 pagesSam G. Dukelow The Control of Boilerskanbouch75% (4)

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGD'EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGPas encore d'évaluation

- An Evaluation of Critical Multiphase Flow Performance Through Wellhead ChokesDocument8 pagesAn Evaluation of Critical Multiphase Flow Performance Through Wellhead ChokesAhmed Khalil JaberPas encore d'évaluation

- Axial and Radial Flow Turbines Solved Problems RagazaDocument4 pagesAxial and Radial Flow Turbines Solved Problems RagazaAnonymous 1VhXp1Pas encore d'évaluation

- TMP - 10995-ME PREBOARD - PIPE-1801710724Document10 pagesTMP - 10995-ME PREBOARD - PIPE-1801710724rex tanongPas encore d'évaluation

- 1 - Energy and Energy BalancesDocument135 pages1 - Energy and Energy BalancesHabib Al-Aziz100% (2)

- Axial Flow CompressorDocument22 pagesAxial Flow CompressorJohn67% (3)

- 4 Performance of A Centrifugal FanDocument7 pages4 Performance of A Centrifugal Fanfinix33Pas encore d'évaluation

- Otto DixDocument13 pagesOtto DixPrakhar GuptaPas encore d'évaluation

- Numericals On Centrifugal and Axial CompressorsDocument2 pagesNumericals On Centrifugal and Axial CompressorsMoiz Tinwala33% (3)

- PSet03 TurboB2020Document2 pagesPSet03 TurboB2020Kyillos SaaidPas encore d'évaluation

- Sheet 2Document2 pagesSheet 2Medo NassarPas encore d'évaluation

- COMPSDocument2 pagesCOMPSHarsh NklkPas encore d'évaluation

- Applied Thermal Engineering - II (MEC 316) Unit - 2 Gas Turbines Tutorial SheetDocument4 pagesApplied Thermal Engineering - II (MEC 316) Unit - 2 Gas Turbines Tutorial SheetShashi Kant KhalkhoPas encore d'évaluation

- Assignments of Turbo MachineryDocument8 pagesAssignments of Turbo Machinerysohaib310% (1)

- Assignment 04Document16 pagesAssignment 04Pritam SahPas encore d'évaluation

- Axial Flow Compressors and Fans - DixDocument4 pagesAxial Flow Compressors and Fans - DixYanganani SindeloPas encore d'évaluation

- Axial Flow CompressorDocument22 pagesAxial Flow CompressorRonnyPas encore d'évaluation

- AE321-Tutorial 7Document3 pagesAE321-Tutorial 7Hritik singh parmarPas encore d'évaluation

- Centrifugal CompresserDocument13 pagesCentrifugal CompresserSaurabhMehraPas encore d'évaluation

- Centrifugal CompressorDocument2 pagesCentrifugal CompressorAyman EsaPas encore d'évaluation

- Axial Compressor SHEETDocument2 pagesAxial Compressor SHEETpaulaPas encore d'évaluation

- Centrifugal CompressorDocument2 pagesCentrifugal CompressorHassan KamilPas encore d'évaluation

- TM 7me4a Question Bank Mid Term IDocument1 pageTM 7me4a Question Bank Mid Term IVijay SharmaPas encore d'évaluation

- Turbomachinery Problem Sheet 1: General Electric J85-GE-17A Turbojet EngineDocument4 pagesTurbomachinery Problem Sheet 1: General Electric J85-GE-17A Turbojet EngineEchebiri Collins100% (1)

- شيتات تربوDocument15 pagesشيتات تربومحمد عفيفىPas encore d'évaluation

- Assignment FD Compressors and BlowersDocument2 pagesAssignment FD Compressors and BlowersXheikhKaleemPas encore d'évaluation

- 7ADC8292A41A4EB196A3FFDEE99589FDDocument4 pages7ADC8292A41A4EB196A3FFDEE99589FDyashvantPas encore d'évaluation

- Assignment 5Document2 pagesAssignment 5Swapnil SumanPas encore d'évaluation

- Assignment 6Document3 pagesAssignment 6Muhammad Jawad IsmaeelPas encore d'évaluation

- Propulsion 1 Unit-V Question Bank (Compressors)Document4 pagesPropulsion 1 Unit-V Question Bank (Compressors)kevintsubasa0% (2)

- TurbomachinesDocument2 pagesTurbomachinesThesinghPas encore d'évaluation

- Class: B.E. 4/4 Mech-1 Sub: TTM: MVSR Engineering College, Nadergul Department of Mechanical Engineering Assignment-2Document2 pagesClass: B.E. 4/4 Mech-1 Sub: TTM: MVSR Engineering College, Nadergul Department of Mechanical Engineering Assignment-2santhosh bandariPas encore d'évaluation

- Page 1 of 3Document3 pagesPage 1 of 3yashvantPas encore d'évaluation

- Assignment and WorksheetDocument2 pagesAssignment and WorksheetAbebe AyingdaPas encore d'évaluation

- Propulsion Ii Question BankDocument13 pagesPropulsion Ii Question BankSathya NarayananPas encore d'évaluation

- Qip JP ProblemsDocument9 pagesQip JP Problemsmurad_ashourPas encore d'évaluation

- Assignment I 3rd RegularDocument2 pagesAssignment I 3rd RegularRoha EngineeringPas encore d'évaluation

- Tutorial 3Document4 pagesTutorial 3Ngudo Ewart NephawePas encore d'évaluation

- Assignment - 2 TE-1-1Document1 pageAssignment - 2 TE-1-1Lalith SunkojuPas encore d'évaluation

- TutorialDocument2 pagesTutorialKenneth ChawPas encore d'évaluation

- Turbo MachinesDocument2 pagesTurbo MachinesDarani PriyaPas encore d'évaluation

- Co1 Practice QuestionsDocument1 pageCo1 Practice QuestionsramsastryPas encore d'évaluation

- Channabasaveshwara Institute of Technology: (NAAC Accredited & An ISO 9001:2015 Certified Institution)Document2 pagesChannabasaveshwara Institute of Technology: (NAAC Accredited & An ISO 9001:2015 Certified Institution)cenu 1999Pas encore d'évaluation

- Thermal Questions KonguDocument9 pagesThermal Questions Konguabu19870% (1)

- Assignment 2Document3 pagesAssignment 2Ziyad AwaliPas encore d'évaluation

- Assignment 2 Gas Turbine Cycles For Aircraft EnginesDocument3 pagesAssignment 2 Gas Turbine Cycles For Aircraft EnginesŤhåŕüñ Kūmæř GøwđPas encore d'évaluation

- Mechanical Power Department 4 Year Turbo-Machinery II Centrifugal CompressorDocument5 pagesMechanical Power Department 4 Year Turbo-Machinery II Centrifugal Compressorاحمد تاشهاويPas encore d'évaluation

- 9A03501 Thermal Engineering IIDocument4 pages9A03501 Thermal Engineering IIsivabharathamurthyPas encore d'évaluation

- Assignment 1 ATDDocument4 pagesAssignment 1 ATDPrashant Singh0% (1)

- r05312105 Aerospace Propulsion IDocument8 pagesr05312105 Aerospace Propulsion ISrinivasa Rao GPas encore d'évaluation

- 2 CalculationsDocument11 pages2 CalculationsThiện KhiêmPas encore d'évaluation

- Tutorial Gas Turbine CyclesDocument6 pagesTutorial Gas Turbine CyclesPranav MishraPas encore d'évaluation

- Ae2255 QB 2014Document8 pagesAe2255 QB 2014vicky CJPas encore d'évaluation

- Axial Compressor SheetDocument1 pageAxial Compressor SheetAyman AbazaPas encore d'évaluation

- Me0302 Assn Tutorial QDocument4 pagesMe0302 Assn Tutorial QVijay Pal Singh0% (1)

- Centrifugal CompressorsDocument48 pagesCentrifugal CompressorsSyedahmedkabir IjazfazilPas encore d'évaluation

- Thermal EnggDocument9 pagesThermal Enggmadhume01Pas encore d'évaluation

- Practice Midterm ProblemsDocument4 pagesPractice Midterm ProblemsAnonymous Ms8nYcbxY2Pas encore d'évaluation

- Take Home Exam v2Document3 pagesTake Home Exam v2AliPas encore d'évaluation

- Magtulis, Kate Anne M. Problem Set #2 Che 124 - Chemical Engineering Thermodynamics 2 July 22, 2015Document7 pagesMagtulis, Kate Anne M. Problem Set #2 Che 124 - Chemical Engineering Thermodynamics 2 July 22, 2015Lucienne IrianaPas encore d'évaluation

- Consolated Tut Sheet For VARIOUS FIELDSDocument3 pagesConsolated Tut Sheet For VARIOUS FIELDSvysnktPas encore d'évaluation

- 3-QUESTION PAPER TEE 2020 Model PaperDocument2 pages3-QUESTION PAPER TEE 2020 Model PapermvzhvschdbsKPas encore d'évaluation

- Zabbix DocumentationDocument1 pageZabbix DocumentationPrakhar GuptaPas encore d'évaluation

- CreditsDocument1 pageCreditsPrakhar GuptaPas encore d'évaluation

- Testing Workflow: Objective: Test If All Services Are Working (For A Given Request, Endpoints ReturnDocument1 pageTesting Workflow: Objective: Test If All Services Are Working (For A Given Request, Endpoints ReturnPrakhar GuptaPas encore d'évaluation

- JEE 2011 ReportDocument66 pagesJEE 2011 ReportPrakhar GuptaPas encore d'évaluation

- 15-458 Local Government Apps Report-Proof3Document4 pages15-458 Local Government Apps Report-Proof3Prakhar GuptaPas encore d'évaluation

- Vai S5203Document60 pagesVai S5203Muthukumaran Chandrasekaran0% (1)

- Modern Art Reference BookDocument2 pagesModern Art Reference BookPrakhar GuptaPas encore d'évaluation

- Barron's Japanese Grammar PDFDocument246 pagesBarron's Japanese Grammar PDFAmykkaPas encore d'évaluation

- Joint Entrance Examination (JEE) - 2011Document1 pageJoint Entrance Examination (JEE) - 2011Prakhar GuptaPas encore d'évaluation

- Me770, Me770a - Course OutlineDocument3 pagesMe770, Me770a - Course OutlinePrakhar GuptaPas encore d'évaluation

- NilihanthDocument14 pagesNilihanthPrakhar GuptaPas encore d'évaluation

- Maa ChudhaoDocument2 pagesMaa ChudhaoPrakhar GuptaPas encore d'évaluation

- CIMA Qualification and SyllabusDocument50 pagesCIMA Qualification and SyllabusMoyce M MotlhabanePas encore d'évaluation

- Stress Predictions at Elbow Ends Under Internal Pressure and System MomentsDocument9 pagesStress Predictions at Elbow Ends Under Internal Pressure and System MomentsGaurav BedsePas encore d'évaluation

- Compressibility of NGDocument15 pagesCompressibility of NGmark_fish22Pas encore d'évaluation

- Low Speed Aerodynamics ASE 320: Lecture 5: Fluid StaticsDocument15 pagesLow Speed Aerodynamics ASE 320: Lecture 5: Fluid StaticsMert BağrıyanıkPas encore d'évaluation

- Astm D 2170 - 07Document10 pagesAstm D 2170 - 07m_seyedPas encore d'évaluation

- Exam 1 Properties of Fluids UploadDocument2 pagesExam 1 Properties of Fluids UploadJoryPas encore d'évaluation

- Correlation of JKR Probe With Undrained Shear StreDocument6 pagesCorrelation of JKR Probe With Undrained Shear StreKS LeePas encore d'évaluation

- jspd170003 1494449798282Document13 pagesjspd170003 1494449798282Biplab DasPas encore d'évaluation

- Irrigation Engineering 4 (3+1) : 11.1 Open ChannelsDocument2 pagesIrrigation Engineering 4 (3+1) : 11.1 Open Channelssaurabh singhPas encore d'évaluation

- Spin Orientation During Acrylic Fiber FormationDocument20 pagesSpin Orientation During Acrylic Fiber FormationGurjinder SinghPas encore d'évaluation

- Engineering Materials 18-20 100922-150922Document33 pagesEngineering Materials 18-20 100922-150922Sanu SouravPas encore d'évaluation

- Review of P-Y Relationships in Cohesionless SoilDocument33 pagesReview of P-Y Relationships in Cohesionless SoilMalik RizwanPas encore d'évaluation

- Sheet 4 - ME 211TDocument3 pagesSheet 4 - ME 211Tsophia haniPas encore d'évaluation

- AnnieDocument6 pagesAnnieAnnie Glorina LumauigPas encore d'évaluation

- 6.1. PurlinsDocument29 pages6.1. PurlinsCherry Amor AbalosPas encore d'évaluation

- Circular Slabs - PpsDocument19 pagesCircular Slabs - PpssrivaruniPas encore d'évaluation

- Ce6303 Mechanics of Fluids Unit 4 NotesDocument18 pagesCe6303 Mechanics of Fluids Unit 4 NotesnkchandruPas encore d'évaluation

- Solubility and Diffusion of Hydrogen in Pure Metals and AlloysDocument10 pagesSolubility and Diffusion of Hydrogen in Pure Metals and AlloysBalló NorbertPas encore d'évaluation

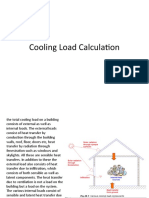

- Cooling Load CalculationDocument22 pagesCooling Load CalculationAniket MitraPas encore d'évaluation

- Engineering Structures: Qiang Han, Yulong Zhou, Yuchen Ou, Xiuli DuDocument12 pagesEngineering Structures: Qiang Han, Yulong Zhou, Yuchen Ou, Xiuli Duserkanozen80Pas encore d'évaluation

- Stress Strain RelationDocument5 pagesStress Strain RelationAditya AgrawalPas encore d'évaluation

- Friction Factor ArticleDocument10 pagesFriction Factor ArticleLim BrandonPas encore d'évaluation

- Isobaric Vapor Liquid Equilibrium For Binary Systems of Cyclohexanone + Benzene, Cyclohexanone + Toluene, and Cyclohexanone + P Xylene at 101.3 KpaDocument7 pagesIsobaric Vapor Liquid Equilibrium For Binary Systems of Cyclohexanone + Benzene, Cyclohexanone + Toluene, and Cyclohexanone + P Xylene at 101.3 KpaAyush DeorePas encore d'évaluation

- Hydraulic Schematic 430, 440 Skid Steer and 440Ct Compact Track LoaderDocument1 pageHydraulic Schematic 430, 440 Skid Steer and 440Ct Compact Track LoaderRicardo BilbaoPas encore d'évaluation

- Cement: Concrete CompositesDocument9 pagesCement: Concrete CompositesAdi PrasetyoPas encore d'évaluation

- Designing Barriers in Nile River For Controlling Water Hyacinth From Reaching To Cairo GovernerateDocument25 pagesDesigning Barriers in Nile River For Controlling Water Hyacinth From Reaching To Cairo GoverneratecrassipesEPas encore d'évaluation