Académique Documents

Professionnel Documents

Culture Documents

Activity Criticality Index Assessment Using Critical Path Segment Technique and Interactive Simulation

Transféré par

husktech0 évaluation0% ont trouvé ce document utile (0 vote)

71 vues10 pagesActivity Criticality Index Assessment Using Critical Path Segment Technique and Interactive Simulation

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentActivity Criticality Index Assessment Using Critical Path Segment Technique and Interactive Simulation

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

71 vues10 pagesActivity Criticality Index Assessment Using Critical Path Segment Technique and Interactive Simulation

Transféré par

husktechActivity Criticality Index Assessment Using Critical Path Segment Technique and Interactive Simulation

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 10

Activity Criticality Index Assessment Using Critical Path Segment Technique

and Interactive Simulation

Pei TANG

1

and Amlan MUKHERJEE

2

1

Ph.D. Candidate, Department of Civil and Environmental Engineering,

Michigan Technological University, Houghton, MI 49931, United States. E-mail:

ptang@mtu.edu.

2

Associate Professor, Department of Civil and Environmental Engineering,

Michigan Technological University, Houghton, MI 49931, United States. E-mail:

amlan@mtu.edu.

ABSTRACT

Critical Path Method (CPM) is the most widely used project scheduling tool. How-

ever, CPM tools are limited as a project management method as they cannot be used

to track and update the schedule as construction progresses. Often, during construc-

tion, activities are interrupted due to impacts of uncertain events like severe weather

and unforeseen harsh geological conditions, resulting in altered critical paths. From

a project management perspective, this means that given uncertain conditions, some

non-critical activities have a likelihood of becoming critical during the project execu-

tion and vice versa. Therefore, the objective of this paper is to identify the changes of

activities criticality during the construction process. It is assumed that an activitys

probability of being critical tends to be stable during the construction given a construc-

tion management strategy. The critical path segment (CPS) technique and interactive

simulation are coupled to capture the changes in an activitys criticality for a given

strategy. The research uses the CPS technique to schedule and simulate a highway

reconstruction project repeatedly using different strategies. For each simulation trial,

the changes in the critical path are recorded to identify the criticality of each segment.

The signicance of this research is that it applies the CPS technique within a dynam-

ic environment and presents a general method to predict the likelihood of an activity

becoming critical during the construction process.

INTRODUCTION

The construction industry has difculties with using Critical Path Method (CPM)

as a project control tool. Traditionally, an activity is identied as either critical or

non-critical only at the planning stage, which has limited the ability of CPM tools to

1094 Construction Research Congress 2012 ASCE 2012

control a project after it starts. After a project starts, activity progress may be interrupt-

ed by uncertain events like severe weather and unforeseen harsh geological conditions,

which change the constraint relationships between the activities. The changes some-

times force non-critical activities to become critical and vice versa. In addition, the

specic time in the schedule when the critical path changes can also signicantly im-

pact formulation of resource allocation plans. Therefore, the objective of this paper

is to identify a criticality index for each activity, at different construction stages for a

given construction decision-making strategy, and a given set of uncertain conditions.

This index is referred to as the Activity Criticality Index (ACI) and is dened as the

probability of an activity becoming critical.

The paper presents a general method to predict an activitys ACI during the con-

struction process given a construction decision-making strategy. A decision-making

strategy is dened as a guideline that provides a family of acceptable resource alloca-

tion decisions in order to achieve project goals (schedule, budget) while accounting for

impacts of uncertain events. Identifying the ACI of an activity can help construction

managers formulate resource allocation plans, and improve their construction manage-

ment strategies. Methodologically, the signicance of this research is that it applies

the CPS technique within a dynamic simulation environment and presents a general

method to support resource allocation decisions before the project starts.

BACKGROUND

The background literature discusses various methods that are relevant to calculat-

ing the ACI of an activity. One approach is to examine historical construction decision

data sets. Soibelman and Kim (2002) and Kim et al. (2008) use Knowledge Discovery

in Databases (KDD), a data analysis process, to identify main factors of construction

delays using statistical measurements and a decision tree based machine learning al-

gorithm. Other methods like regression models (Lucko and Mitchell 2010), pattern

analysis (Battikha 2008), and automatic hierarchical classication method (Caldas and

Soibelman 2003) have also been used to mine construction project documents with the

goal of identifying improved management strategies.

However, such methods allow only a partial observability of the success or failure

of a decision. Instead, this research adopts an interactive simulation method to ex-

amine the complete project outcomes given a construction management strategy. The

interactive simulation platform used is called Interactive Construction Decision Mak-

ing Aid (ICDMA), a continuous time advance simulator that simulates CPM scheduled

construction projects. It allows decision makers to respond to project contingencies by

(re)allocating resources during the simulation process to explore what-if scenarios and

multiple deviations from the as-planned project progress (Tang et al. 2010a; Tang et al.

2010b).

Therefore, for this research, the point of departure from the existing body of re-

search is that it uses a simulation based approach to explore alternative project real-

izations, and deviations from the intended critical path. Similar to previous effort-

s, the proposed method is based on an analysis of a completed construction project

schedule and documents. However, instead of statistically analyzing schedule perfor-

1095 Construction Research Congress 2012 ASCE 2012

mance across multiple projects that may or may not have shared similar circumstances,

the proposed method statistically analyzes multiple alternative realizations of a single

project within an uniformly simulated environment. The likely outcome of the pro-

posed method is to provide deeper insight on a project-by-project basis thus enhancing

project planning approaches.

METHODOLOGY

The proposed methodology applies the Critical Path Segment (CPS) technique

(Hegazy and Menesi 2010) for representing schedule information, within an interac-

tive simulation environment, ICDMA, to experimentally explore possible deviations

from the as-planned critical path. The motivation for using the CPS method is that it

allows the representation of an activity at a ner level of granularity. Different from

traditional representation of an activity as a solid bar that spans a given duration, the

CPS technique decomposes the duration of each activity into a number of separate, but

connected time segments that add up to the total duration of the activity. For example,

if the scheduled duration for paving concrete is 30 days, 30 time segments are used to

represent it. Hence, this representation makes it possible to represent any logical re-

lationship (nish-to-start, nish-to-nish, start-to-nish, and nish-to-nish) and lags

by only nish-to-start relationship. It also allows scheduling activities with not only

time-based, but also production-based methods. When the CPS technique is used in

conjunction with ICDMA, it allows for a closer examination of each activity segments

criticality by performing multiple simulation trials. The as-planned and as-built sched-

ules from a real life highway construction project are used so that the simulation results

can be checked for validity against the actual project outcome.

The general method presented in this paper consists of the following steps:

Identify project constraints and uncertainty information from the construction

project being studied. Sometimes the constraints may be in space and/or driven

by safety requirements. All such constraints are converted to equivalent tem-

poral constraints.

Develop time-based and production-based as-planned schedules using the CPS

technique.

Set up project simulation environment in ICDMA using the as-planned sched-

ules and project constraints identied in the previous steps.

Design the simulation experiment using ICDMA and conduct simulation ex-

periments for alternative decision-making strategies.

Analyze simulation outcomes and calculate the ACI for each activity segment.

The rest of the paper discusses each of the above steps in the context of a case study

project.

IMPLEMENTATION

The case study is a ten-mile concrete pavement re-construction project in southeast

Michigan. This research studied the reconstruction of the east bound section. The east

bound section consisted of fourteen major activities (Table 1). The activities and dura-

tions were obtained from the as-planned schedule and the progress schedule (MDOT

1096 Construction Research Congress 2012 ASCE 2012

TABLE 1. Activity Duration and Technical Precedence

.

Activity Duration Precedence

activities

1 Strip topsoil 10 days N/A

2 Remove concrete pavement 30 days 1

3 Grade subbase 26 days 2

4 Install drainage 18 days 2,3

5 Place open-graded drainage course (OGDC) mainline 18 days 2,3,4

6 Pave east bound (E.B.) mainline 32 days 5

7 Place OGDC ramps and gaps 8 days 4,5,6

8 Pave E.B. gaps and ramps 9 days 7

9 Place gravel shoulder 4 days 6,8

10 Slope grading and restoration E.B. 26 days 8

11 Stripe to open pavement E.B. 3 days 10

12 Relocate barrier wall 10 days 11

13 Re-stripe west bound 3 days 12

14 All lanes open 1 days 9,10,13

Form 1130) provided by the contractor. The project was scheduled to be completed in

106 working days and was actually completed in 129 working days.

Step 1: Activity Constraints and Uncertainty Information

In a construction project, activities are related by constraint relationships. Be-

sides the precedence determined by technical constraints, safety constraints between

the processes should be considered as well. The safety distances are determined on the

assumption that two activities cannot occupy the same working spot. For two activities

i and j (assuming that Activity i precedes Activity j), the minimum distance between

them at the beginning of Activity i is dened as:

D

i j

max{t

L

T

j

, (1

T

i

T

j

) L} (1)

where D

i j

represents distance between Activity i and Activity j, L represents the length

of the project, t is the buffer time between the activities, and T

i

and T

j

represent the

duration of Activities i and j respectively. Buffer time is subject to technical constraint

and is determined by the schedulers experience. As CPM uses temporal relationships

to relate activities, the minimum distances between them are converted into temporal

constraints. For two activities i and j (assuming that Activity i precedes Activity j),

if the safety distance is D

i j

, the time that Activity j should start later than Activity

i is determined by T

i j

1

T

i

D

i j

, where T

i j

represents the temporal constraint that is

equivalent to distance constraint D

i j

.

For this case, the distance constraints identied by the contractor were: one mile

between Activities 1 and 2, two miles between Activities 2 and 3, three miles between

Activities 3 and 4, four miles between Activities 4 and 5, six miles between Activities

5 and 6, seven miles between Activities 6 and 7, three miles between Activities 8 and 9,

1097 Construction Research Congress 2012 ASCE 2012

and one mile between Activities 10 and 11. Using the distance and temporal constraint

conversion equation, the temporal constraints between activities were: (1) Activity 2

started one day after the beginning of Activity 1, (2) Activity 3 started six days after the

beginning of Activity 2, (3) Activity 4 started eight days after the beginning of Activity

3, (4) Activity 5 started six days after the beginning of Activity 4, (5) Activity 6 started

eleven days after the beginning of Activity 5, (6) Activity 7 started twenty-ve days

after the beginning of Activity 6 and zero days after completion of Activity 5, (7) Ac-

tivity 8 started zero days after the completion of Activity 7, (8) Activity 9 started three

days after the beginning of Activity 8 and zero days after the completion of Activity

6, (9) Activity 10 started zero days after the completion of activity 8, (10) Activity 11

started two days after the beginning of activity 10, (11) Activity 12 started zero days

after the completion of Activity 11, (12) Activity 13 started zero days after the com-

pletion of Activity 12, and (13) Activity 14 started zero days after the completion of

Activity 9, Activity 13 and Activity 10.

During the construction, uncertain events usually occur and interrupt the project

activities. To observe the changes in critical paths, the following event-consequence-

probability tuples were considered: (1) bad weather, reducing productivity to half on

all activities, occurrence probability of 20%, (2) equipment failure or worker sickness,

occurrence probability of 12%, (3) concrete testing failure, resulting in stoppage of

paving east bound mainline or paving east bound gaps and ramps for one day, occur-

rence probability of 5%, and (4) high water table, causing stoppage on grading subbase

for one day waiting to change new subbase material, occurrence probability of 10%.

The events, consequences and probabilities were obtained from directly mining the

as-built project records and documents that were directly collected with the help of

project site inspectors (Cass et al. 2011).

Step 2: Develop CPS Time-based and Production-based Scheduling

Different from traditional CPM scheduling, the CPS technique uses only nish-to-

start relationship to represent all constraint relationships between activities. The activ-

ities, associated durations, and constraints between them were used to create critical

path diagrams. Figure 5 shows the critical path diagram using time-based scheduling

method. The constraints were set only between the beginning of each activity. For ex-

ample, Activity 3 was scheduled to start six days after Activity 2 began. Therefore, the

rst segment of Activity 3 started after the completion of the rst segment of Activity 2,

whose duration was six days. As a result, the total duration was 101 days and the crit-

ical activities were identied in dark color. For production-based scheduling method

(Figure 5), the constraints were set between the segments of activities. In addition to

the rst segment of Activity 3 starting after the completion of the rst segment of Ac-

tivity 2, constraints were also set between the end of the second, third, fourth, and sixth

segments of Activity 2 and the beginning of the second, fourth, fth, and seventh seg-

ments of Activity 3. The scheduled duration was 111 days, which was 10 days longer

than scheduled with time-based method. In addition, the critical activities identied in

two methods were different.

1098 Construction Research Congress 2012 ASCE 2012

Early Start Duration Early Finish

Late Start Late Finish

Task Name

62 8 70

62 70

7

m

49 3 52

49 52

11

i

j

Activity j starts m days after the

beginning of activity i.

Activity j starts m days after the

beginning of activity i.

j

Activity j is

critical.

Activity j is

critical.

76 3 79

84 87

84

89 3 92

97 100

13

100 1 101

100 101

14

0 1 1

0 1

1-a

32 11 43

32 43

6-a

35 6 41

51 57

5-d

32 1 33

50 51

5-c

21 4 25

39 43

4-c

20 1 21

20 21

4-b

15 5 20

15 20

4-a

27 5 32

27 32

5-b

64 1 65

64 65

7-b

31 2 33

47 49

3-h

27 4 31

43 47

3-g

23 4 27

39 43

3-f

17 5 22

33 38

3-d

15 2 17

31 33

3-c

12 3 15

12 15

3-b

7 5 12

7 12

3-a

30 1 31

42 43

2-f

25 5 30

37 42

2-e

19 6 25

31 37

2-d

13 6 19

25 31

2-c

7 6 13

19 25

2-b

1 6 7

1 7

2-a

1 9 10

33 42

1-b

33 2 35

49 51

4-f

27 4 31

45 49

4-e

25 2 27

43 45

4-d

71 3 74

71 74

8-c

68 3 71

68 71

8-b

65 3 68

65 68

8-a

70 2 72

98 100

9-c

69 1 70

97 98

9-b

68 1 69

96 97

9-a

21 6 27

21 27

5-a

74 2 76

74 76

10-a

57 7 64

57 64

7-a

76 24 100

76 100

10-b

57 7 64

89 96

6-c

43 14 57

43 57

6-b

79 10 89

87 97

12

22 1 23

38 39

3-e

FIG. 1. Time-based Critical Path Scheduling

Early Start Duration Early Finish

Late Start Late Finish

Task Name

62 8 70

62 70

7

m

49 3 52

49 52

11

i

j

Activity j starts m days after the

beginning of activity i.

37 4 41

41 45

4-e

86 3 89

94 97

11

99 3 102

107 110

13

110 1 111

110 111

14

0 1 1

0 1

1-a

42 11 53

42 53

6-a

43 6 49

47 53

5-d

42 1 43

46 47

5-c

27 4 31

31 35

4-c

26 1 27

30 31

4-b

16 5 21

25 30

4-a

37 5 42

37 42

5-b

74 1 75

74 75

7-b

35 2 37

43 45

3-h

31 4 35

31 35

3-g

26 4 30

27 31

3-f

25 1 26

26 27

3-e

19 5 24

21 26

3-d

16 2 18

19 21

3-c

13 3 16

16 19

3-b

7 5 12

11 16

3-a

30 1 31

30 31

2-f

25 5 30

25 30

2-e

19 6 25

19 6 25

2-d

13 6 19

13 19

2-c

7 6 13

7 13

2-b

1 6 7

1 7

2-a

1 9 10

21 30

1-b

41 2 43

45 47

4-f

35 2 37

35 37

4-d

81 3 84

81 84

8-c

78 3 81

78 81

8-b

75 3 78

75 78

8-a

84 2 86

108 110

9-c

81 1 82

107 108

9-b

78 1 79

106 107

9-a

27 6 33

31 37

5-a

84 2 86

84 86

10-a

67 7 74

67 74

7-a

86 24 110

86 110

10-b

67 7 74

67 74

6-c

53 14 67

53 67

6-b

89 10 99

97 107

12

j

Activity j is

critical.

Activity j is

critical.

FIG. 2. Production-based Critical Path Scheduling

Step 3: ICDMA Simulation Setup

ICDMA simulates a construction project based on its resource-loaded as-planned

(RLAP) schedule and its project environment. The RLAP schedule of the highway

reconstruction project consisted of: (1) activities to complete the project and the esti-

mated durations; (2) material, labor, and equipment usages for each activity; (3) unit

price of labor, equipment, and material along with unit space occupied by each materi-

al; (4) as-planned schedule (Figures 5 and 5). The activity information is summarized

in Table 1. The process of obtaining the second and third data sets can be found in

co-authors previous work (Cass et al. 2011). All the information was input into a

database to complete the project set up process.

Step 4: Experimental Design

After the set up of simulated project, experiments were conducted in a situation

where the uncertain events were turned off to verify the simulation results. The sim-

ulated as-built results from time-based schedule and production-based schedule were

exactly the same as scheduled, which veried that the simulation platform produced

the correct intended results.

As it assumes that criticality alternations are stable given a construction manage-

1099 Construction Research Congress 2012 ASCE 2012

ment strategy, two decision strategies were designed. Control Strategy manages the

schedule by taking the minimum number of actions in dealing with interruptions,

which was implemented to compare the abilities of the time-based method and the

production-based method in representing activity criticality. Catch Up Strategy, aim-

ing at completing the project on time, was implemented on production-based schedule

to estimate ACIs of each activity. Details about the strategy denition and establish-

ment can be found in authors previous work (Tang et al. 2010a; Tang et al. 2010b).

Each strategy was implemented for forty runs to meet the minimum requirement of sta-

tistical analysis. For the sake of uniformity, a single decision maker (the author in this

case) ran all the simulations. The changes of critical paths were recorded for analysis.

Control Strategy: It manages the schedule by taking the minimum number of

actions in dealing with interruptions. The implementation is reected by the

following resource allocation policies: (a) labor crew policy: no extra workers

are replaced in any case; (b) equipment policy: equipment is not xed on the

same day in any case; (c) space policy: space is allocated rst to the critical

activities; (d) no actions are taken when the project is falling behind.

Catch Up Strategy: It manages the project schedule passively. The implemen-

tation is reected by the following resource allocation policies: (a) labor policy:

extra workers are hired and replaced in cases of illnesses; (b) equipment poli-

cy: equipment is xed by the mechanics immediately; (c) space policy: space

is allocated rst to the critical activities; (d) actions are taken to catch up the

schedule every time the project is three days behind the as-planned schedule.

Step 5: Critical Path Analysis

A total of 80 instances of the project realization with simulated as-built project pro-

cess were collected when implementing Control Strategy to time-based and production-

based schedules. Another 40 instances were collected when applying Crash Strategy

to the production-based schedule. The average simulated as-built completion durations

for three cases were 125.7, 139.1, and 112.6 working days, which were comparable to

the as-built completion duration (129 working days).

Table 2 shows the average ACIs for each activity segment, where:

ACI =

Days being critical

Simulated as-built duration

(2)

The second and fourth columns shows the as-planned critical activities in Figures 5

and 5, represented by X. The third and fth columns have the ACIs (range from 0 to

1) for each activity. The higher the value of ACI, the higher the probability that the

activity segment will be critical when performed. Table 2 shows that some of ACIs in

the fth column were between 0 and 1, indicating production-based scheduling method

was more capable to capture activities criticality changes.

Figure 5 summarizes the average ACIs for each activity segment when applying

Crash Strategy. The x-axis represents the activity progress and y-axis represents prob-

ability of being critical (ACIs). For example, the rst 10% of the activity of stripping

topsoil had a 100% chance of being critical. It indicated that more emphasis should be

1100 Construction Research Congress 2012 ASCE 2012

TABLE 2. Scheduled and as-built Critical Activities

Time-based Production-based

Critical ACI Critical ACI

1 Strip Topsoil(a) X 1.00 X 1.00

1 Strip Topsoil(b) 0.00 0.00

2 Remove Concrete Pavement(a) X 1.00 X 1.00

2 Remove Concrete Pavement(b) 0.00 X 1.00

2 Remove Concrete Pavement(c) 0.00 X 1.00

2 Remove Concrete Pavement(d) 0.00 X 0.99

2 Remove Concrete Pavement(e) 0.00 X 0.92

2 Remove Concrete Pavement(f) 0.00 X 0.89

3 Grade Subbase(a) X 1.00 0.00

3 Grade Subbase(b) X 1.00 0.00

3 Grade Subbase(c) 0.00 0.00

3 Grade Subbase(d) 0.00 0.07

3 Grade Subbase(e) 0.00 0.23

3 Grade Subbase(f) 0.00 0.43

3 Grade Subbase(g) 0.00 X 1.00

3 Grade Subbase(h) 0.00 0.00

4 Install Drainage(a) X 1.00 0.00

4 Install Drainage(b) X 1.00 0.00

4 Install Drainage(c) 0.00 0.00

4 Install Drainage(d) 0.00 X 1.00

4 Install Drainage(e) 0.00 0.00

4 Install Drainage(f) 0.00 0.00

5 Place OGDC Mainline(a) X 1.00 0.00

5 Place OGDC Mainline(b) X 1.00 X 1.00

5 Place OGDC Mainline(c) 0.00 0.00

5 Place OGDC Mainline(d) 0.00 0.00

6 Pave E.B. Mainline(a) X 1.00 X 1.00

6 Pave E.B. Mainline(b) X 1.00 X 1.00

6 Pave E.B. Mainline(c) 0.00 X 0.87

7 Place OGDC Ramps and Gaps(a) X 1.00 X 0.85

7 Place OGDC Ramps and Gaps(b) X 1.00 X 1.00

8 Pave E.B. Gaps and Ramps(a) X 1.00 X 1.00

8 Pave E.B. Gaps and Ramps(b) X 1.00 X 1.00

8 Pave E.B. Gaps and Ramps(c) X 1.00 X 1.00

9 Place Gravel Shoulder(a) 0.00 0.00

9 Place Gravel Shoulder(b) 0.00 0.00

9 Place Gravel Shoulder(c) 0.00 0.00

10 Slope Grading and Restoration E.B. (a) X 1.00 X 1.00

10 Slope Grading and Restoration E.B. (b) X 1.00 X 1.00

11 Stripe to Open Pavement E.B. 0.00 0.00

12 Relocate Barrier Wall 0.00 0.00

13 Re-stripe W.B. 0.00 0.00

14 All Lanes Open X 1.00 X 1.00

placed on the rst 10% of Activity 1 because any interruption in the rst 10% of the

activity will result in project delays. For Activity 3, identied critical segment (Fig-

ure 5) was 3-g (between 72% and 92% of the activity). However, simulation results

showed that if applying Crash Strategy, there was still a chance to be critical for the

segments of Activity 3 between 19% and 72%. For Activities 9 and 11, there was no

chance of being critical.

1101 Construction Research Congress 2012 ASCE 2012

0.0

0.2

0.4

0.6

0.8

1.0

1.2

0% 10% 100%

Predicted

Scheduled

1_StripTopsoil

ACI

Progress

0.0

0.2

0.4

0.6

0.8

1.0

1.2

0 20% 40% 60% 80% 97% 100%

Predicted

Scheduled

2_RemoveConcretePavement

ACI

Progress

0.0

0.2

0.4

0.6

0.8

1.0

1.2

0% 19% 31% 38% 58% 62% 77% 92% 100%

Predicted

Scheduled

ACI

Progress

3_GradeSubbase

0.0

0.2

0.4

0.6

0.8

1.0

1.2

0% 28% 33% 56% 67% 89% 100%

Predicted

Scheduled

ACI

Progress

4_InstallDrainage

0.0

0.2

0.4

0.6

0.8

1.0

1.2

0% 33% 61% 67% 100%

Predicted

Scheduled

ACI

Progress

5_PlaceOGDCMainline

0.0

0.2

0.4

0.6

0.8

1.0

1.2

0% 34% 78% 100%

Predicted

Scheduled

ACI

Progress

6_PaveE.B.Mainline

0.0

0.2

0.4

0.6

0.8

1.0

1.2

0% 47% 100%

Predicted

Scheduled

ACI

Progress

7_PlaceOGDCRampsandGaps

0.0

0.2

0.4

0.6

0.8

1.0

1.2

0% 33% 67% 100%

Predicted

Scheduled

ACI

Progress

8_Pave E.B. GapsandRamps

0.0

0.2

0.4

0.6

0.8

1.0

1.2

0% 25% 50% 100%

Predicted

Scheduled

ACI

Progress

9_PlaceGravelShoulder

0.0

0.2

0.4

0.6

0.8

1.0

1.2

0% 8% 100%

Predicted

Scheduled

ACI

Progress

10_SlopeGradingandRestorationE.B.

0.0

0.2

0.4

0.6

0.8

1.0

1.2

0% 100%

Predicted

Scheduled

ACI

Progress

11_StripetoOpenPavementE.B.

0.0

0.2

0.4

0.6

0.8

1.0

1.2

0% 100%

Predicted

Scheduled

ACI

Progress

12_RelocateBarrierWall

0.0

0.2

0.4

0.6

0.8

1.0

1.2

0% 100%

Predicted

Scheduled

ACI

Progress

13_RestripeWestBound

0.0

0.2

0.4

0.6

0.8

1.0

1.2

0% 100%

Predicted

Scheduled

ACI

Progress

14_AllLanesOpen

FIG. 3. Activity Criticality Index (ACI) Prediction for Each Activity

CONCLUSION

This paper proposes a method that combines the CPS technique and interactive

simulation to predict activities criticality in their construction phases. By compar-

ing the scheduled and simulated critical activities, the production-based scheduling

method was proven to be more capable to capture the criticality changes than time-

based scheduling method. Given a Catch Up Strategy, activities criticality in a high-

way reconstruction project was calculated (Figure 5).

1102 Construction Research Congress 2012 ASCE 2012

This paper presents a preliminary work to identify the activities criticality in their

construction life given a construction management strategy. The signicance of the

work lies in connecting ACIs with the construction progress of each activity. The esti-

mated ACIs for each activity can be used to formulate contingency plans for resource

allocation. The long term goal is to improve resource allocation strategies through

predicting activities criticality before the project starts. Given a construction project,

it is expected that construction managers can test different construction managemen-

t strategies and examine the ACIs outcomes to formulate the best contingency plans

for resource allocation. To achieve the long term objective, challenges still need to

be addressed in: 1) how to use predicted ACIs to improve construction management

strategies, 2) examining the sensitivities of ACIs to different strategies and uncertain

project construction environments, 3) investigating the impacts of using ACIs on cost

or schedule management, and 4) validating the research results with the real project.

REFERENCES

Battikha, M. G. (2008). Reasoning mechanismfor construction nonconformance root-

cause analysis. Journal of Construction Engineering and Management, 134(4),

280288.

Caldas, C. and Soibelman, L. (2003). Automating hierarchical document classica-

tion for construction management information systems. Automation in Construc-

tion, 12(4), 395406.

Cass, D., Tang, P., and Mukherjee, A. (2011). Managing construction operations to

minimize greenhouse gas emissions. The 2nd International Conference on Trans-

portation Construction Management, February 7-10, Orlando, FL, USA.

Hegazy, T. and Menesi, W. (2010). Critical Path Segments Scheduling Technique.

Journal of Construction Engineering and Management, 136(10), 10781085.

Kim, H., Soibelman, L., and Grobler, F. (2008). Factor selection for delay analysis

using Knowledge Discovery in Databases. Automation in Construction, 17(5), 550

560.

Lucko, G. and Mitchell, Jr., Z. W. (2010). Quantitative Research: Preparation of In-

congruous Economic Data Sets for Archival Data Analysis. Journal of Construction

Engineering and Management, 136(1), 4957.

Soibelman, L. and Kim, H. (2002). Data preparation process for construction knowl-

edge generation through knowledge discovery in databases. Journal of Computing

in Civil Engineering, 16(1), 3948.

Tang, P., Mukherjee, A., and Onder, N. (2010a). Strategy optimization and generation

for construction project management using an interactive simulation. Proceedings

of the 2010 Winter Simulation Conference, B. Johansson, S. Jain, J. Montoya-Torres,

J. Hugan, and E. Y ucesan, eds., Piscataway, New Jersey. Institute of Electrical and

Electronics Engineers, Inc., 3088 3099.

Tang, P., Mukherjee, A., and Onder, N. (2010b). Studying dynamic decision-making

in construction management using adaptive interactive simulations. Construction

Research Congress 2010: Innovation for Reshaping Construction Practice, Pro-

ceedings of the 2010 Construction Research Congress. 37938.

1103 Construction Research Congress 2012 ASCE 2012

Vous aimerez peut-être aussi

- Minute Math 2Document112 pagesMinute Math 2Lidia Dicu100% (3)

- 2 Forex Game TheoryDocument36 pages2 Forex Game TheoryKareem El Malki100% (1)

- Construction Claims A Short Guide For Contractors PDFDocument233 pagesConstruction Claims A Short Guide For Contractors PDFhusktech100% (30)

- Martin Caon - Examination Questions and Answers in Basic Anatomy and Physiology 2000 Multiple Choice Questions-Springer (2020)Document746 pagesMartin Caon - Examination Questions and Answers in Basic Anatomy and Physiology 2000 Multiple Choice Questions-Springer (2020)Charles santos da costa100% (6)

- Substantiation and Assessment of Claims For Extensions of TimeDocument12 pagesSubstantiation and Assessment of Claims For Extensions of Timeegglestona100% (2)

- Chess Architecture PDFDocument36 pagesChess Architecture PDFRahul Peddi100% (2)

- Construction Supervision Qc + Hse Management in Practice: Quality Control, Ohs, and Environmental Performance Reference GuideD'EverandConstruction Supervision Qc + Hse Management in Practice: Quality Control, Ohs, and Environmental Performance Reference GuideÉvaluation : 5 sur 5 étoiles5/5 (2)

- OOPS PythonDocument99 pagesOOPS PythonramPas encore d'évaluation

- The Law of SchedulesDocument15 pagesThe Law of ScheduleshusktechPas encore d'évaluation

- Substation Construction MethodologyDocument23 pagesSubstation Construction Methodologyhusktech67% (15)

- Career Change From Real Estate to Oil and Gas ProjectsD'EverandCareer Change From Real Estate to Oil and Gas ProjectsÉvaluation : 5 sur 5 étoiles5/5 (1)

- HSE Communication ProcedureDocument7 pagesHSE Communication ProcedureWanda QurniaPas encore d'évaluation

- Chapter 6 - SchedulingDocument21 pagesChapter 6 - SchedulingjohnPas encore d'évaluation

- Progress MonitoringDocument7 pagesProgress MonitoringGihanEdiriPas encore d'évaluation

- Dr. Adel El Shabrawy & Dr. Tarek Sakr: PRMG 10:planning & ControlDocument49 pagesDr. Adel El Shabrawy & Dr. Tarek Sakr: PRMG 10:planning & ControlMohamed SamirPas encore d'évaluation

- Cha, H. S., & Kim, C. K. (2011), "Quantitative Approach For Project Performance Measurement On Building Construction in South Korea PDFDocument2 pagesCha, H. S., & Kim, C. K. (2011), "Quantitative Approach For Project Performance Measurement On Building Construction in South Korea PDFDavid SabaflyPas encore d'évaluation

- Construction Planning ReviewDocument25 pagesConstruction Planning ReviewRic S. MalongaPas encore d'évaluation

- Perception of Coc Pup Students For Twitter As A Source of InformationDocument28 pagesPerception of Coc Pup Students For Twitter As A Source of Informationmark aljon fajardoPas encore d'évaluation

- Crashing Time Scheduling ProblemDocument9 pagesCrashing Time Scheduling ProblemeragornPas encore d'évaluation

- Judgement and PripositionsDocument7 pagesJudgement and Pripositionschememartinez29Pas encore d'évaluation

- Chapter 6 - SchedulingDocument21 pagesChapter 6 - Schedulingmuliye tarekegnPas encore d'évaluation

- Population, Sample and Sampling TechniquesDocument8 pagesPopulation, Sample and Sampling TechniquesMuhammad TalhaPas encore d'évaluation

- NZBERS-2014 Proc FP Zaeri-FDocument19 pagesNZBERS-2014 Proc FP Zaeri-Ftekalegn barekuPas encore d'évaluation

- Clemente and Cachadinha 2013 - BIM-Lean Synergies in The Management On MEP Works in Public Facilities of Intensive Use - A Case Study PDFDocument10 pagesClemente and Cachadinha 2013 - BIM-Lean Synergies in The Management On MEP Works in Public Facilities of Intensive Use - A Case Study PDFJuanka QNPas encore d'évaluation

- Construction Scheduling Using Constraint Satisfaction Problem MethodDocument23 pagesConstruction Scheduling Using Constraint Satisfaction Problem MethodRaneesh MohamedPas encore d'évaluation

- Presentation SME4823 (Space KL) Engineering Management & Safety (Lecturer: Asc Prof DR Mohd Zamani)Document12 pagesPresentation SME4823 (Space KL) Engineering Management & Safety (Lecturer: Asc Prof DR Mohd Zamani)Charles MeadowsPas encore d'évaluation

- Activity Overlapping Technique For Early Completion of Construction ProjectDocument11 pagesActivity Overlapping Technique For Early Completion of Construction ProjectIJRASETPublicationsPas encore d'évaluation

- Impact of Project Briefing Clarity On Construction Project PerformanceDocument14 pagesImpact of Project Briefing Clarity On Construction Project PerformanceshajbabyPas encore d'évaluation

- CPM Analysis of Rolai-Rinjlai Road Construction: Res. J. Mathematical & Statistical SciDocument9 pagesCPM Analysis of Rolai-Rinjlai Road Construction: Res. J. Mathematical & Statistical SciizhharkamaluddinPas encore d'évaluation

- Literature Review (CPM)Document3 pagesLiterature Review (CPM)SyEd Amir Syahmi100% (1)

- Ijer 2014 309Document6 pagesIjer 2014 309Innovative Research PublicationsPas encore d'évaluation

- Removing Constraints To Make Task Ready in Weekly Work PlanningDocument7 pagesRemoving Constraints To Make Task Ready in Weekly Work PlanningarraffiyPas encore d'évaluation

- 1.1 General: Chapter 1: IntroductionDocument4 pages1.1 General: Chapter 1: IntroductionSanjay TiwariPas encore d'évaluation

- Automated Schedule Updates Using As-Built Data and A 4D Building Information ModelDocument16 pagesAutomated Schedule Updates Using As-Built Data and A 4D Building Information ModelPHILBIN M PHILIP M.Tech SECM 2019-2021Pas encore d'évaluation

- 09 - EARNED VALUE METHOD - Nengah Putra Apriyanto - INDODocument18 pages09 - EARNED VALUE METHOD - Nengah Putra Apriyanto - INDOJoel Jeffery SarkarPas encore d'évaluation

- Chapter 6 - SchedulingDocument21 pagesChapter 6 - SchedulingAiden SolomonBrPas encore d'évaluation

- Sustainability 11 01613Document19 pagesSustainability 11 01613Islam Fath El BaBPas encore d'évaluation

- Ijtimes ShashankDocument3 pagesIjtimes Shashanksakit786Pas encore d'évaluation

- Optimum Activity Overlapping Strategy For Construction Management Using Analytical ApproachDocument9 pagesOptimum Activity Overlapping Strategy For Construction Management Using Analytical ApproachIJRASETPublicationsPas encore d'évaluation

- 5-20103 Window MethodsDocument7 pages5-20103 Window MethodsPavanKumarPas encore d'évaluation

- Integrated Design Process For Modular Construction Projects To Reduce ReworkDocument19 pagesIntegrated Design Process For Modular Construction Projects To Reduce ReworkbuddhikaPas encore d'évaluation

- Development of A Model For Predicting ProbabilistiDocument18 pagesDevelopment of A Model For Predicting ProbabilistimohdkhidirPas encore d'évaluation

- 622-Article Text-1063-1-10-20230101Document10 pages622-Article Text-1063-1-10-20230101K. Mohammed NowfalPas encore d'évaluation

- 3D Geological Modelling For The Design of Complex Underground WorksDocument10 pages3D Geological Modelling For The Design of Complex Underground WorksHichemPas encore d'évaluation

- Simple Method Proposal For Cost Estimation From Work Breakdown StructureDocument8 pagesSimple Method Proposal For Cost Estimation From Work Breakdown StructureRizwan IshaqPas encore d'évaluation

- SSC JE Study Materials Civil ESTIMATING COSTING and VALUATIONDocument20 pagesSSC JE Study Materials Civil ESTIMATING COSTING and VALUATIONArindam Patra100% (1)

- Benchmarking of Project PlanningDocument2 pagesBenchmarking of Project PlanningEhab ShataPas encore d'évaluation

- RIEJ - Volume 6 - Issue 4 - Pages 283-292Document10 pagesRIEJ - Volume 6 - Issue 4 - Pages 283-292Michelle AngelPas encore d'évaluation

- Evaluating Construction Project Success With Use of The M-Topsis MethodDocument8 pagesEvaluating Construction Project Success With Use of The M-Topsis MethodMagno A. GonzPas encore d'évaluation

- Project IT Project Management 3 (HIPM300-1) 23Document4 pagesProject IT Project Management 3 (HIPM300-1) 23Musa ZvinowandaPas encore d'évaluation

- Construction Planning: 9.1 Basic Concepts in The Development of Construction PlansDocument32 pagesConstruction Planning: 9.1 Basic Concepts in The Development of Construction PlansjananiPas encore d'évaluation

- 01 - Introduction To Project Planning, MonitoringDocument20 pages01 - Introduction To Project Planning, MonitoringWanie MahirPas encore d'évaluation

- Tugas MPI UASDocument23 pagesTugas MPI UASdilaPas encore d'évaluation

- Project Management Scheduling Expedited PDFDocument8 pagesProject Management Scheduling Expedited PDFsai vardhanPas encore d'évaluation

- Construction PlanningDocument32 pagesConstruction PlanningTewodros TadessePas encore d'évaluation

- The Use of The Critical Path and Critical Chain Methods in The South African Construction IndustryDocument23 pagesThe Use of The Critical Path and Critical Chain Methods in The South African Construction IndustryGeorgette BalcitaPas encore d'évaluation

- Optimization Model For Resource Assignment Problems of Linear Construction ProjectsDocument14 pagesOptimization Model For Resource Assignment Problems of Linear Construction ProjectsDarko TešićPas encore d'évaluation

- 16234-Article Text-60126-3-10-20220221Document16 pages16234-Article Text-60126-3-10-20220221dupe2010Pas encore d'évaluation

- Construction PlanningDocument17 pagesConstruction PlanningLyka TanPas encore d'évaluation

- Dynamic Planning and ControlDocument2 pagesDynamic Planning and ControlHarry BasadaPas encore d'évaluation

- 1.0 Construction Project PlanningDocument22 pages1.0 Construction Project PlanningsyafiqahanidaPas encore d'évaluation

- 1.construction PlanningDocument33 pages1.construction PlanningSundara LingamPas encore d'évaluation

- Modul 12 - Latihan CrashingDocument10 pagesModul 12 - Latihan CrashingMTS8REG1 TEKNIK SIPIL 8Pas encore d'évaluation

- Construction PlanningDocument30 pagesConstruction PlanningUjang BOP EngineerPas encore d'évaluation

- Estimate at CompletionDocument3 pagesEstimate at Completionc6nysf9jm6Pas encore d'évaluation

- Applied SciencesDocument18 pagesApplied SciencesefePas encore d'évaluation

- Construction Planning: 9.1 Basic Concepts in The Development of Construction PlansDocument199 pagesConstruction Planning: 9.1 Basic Concepts in The Development of Construction PlansootPas encore d'évaluation

- Construction ManagementDocument184 pagesConstruction Managementkarthikeyan PPas encore d'évaluation

- Determine The Overall Project Duration and The Activities' Float Times. Such Data Provide ImportantDocument1 pageDetermine The Overall Project Duration and The Activities' Float Times. Such Data Provide ImportantSanjay TiwariPas encore d'évaluation

- 10.1515 - Eng 2019 0020Document10 pages10.1515 - Eng 2019 0020Shafira AmalinaPas encore d'évaluation

- ICCP Industry Insights - Programmes & Planning Full PaperDocument3 pagesICCP Industry Insights - Programmes & Planning Full PaperhusktechPas encore d'évaluation

- Dcma Schedule Analyzer Forproject: Simple, Streamlined Dcma 14 Point Analysis For Microsoft® Office ProjectDocument2 pagesDcma Schedule Analyzer Forproject: Simple, Streamlined Dcma 14 Point Analysis For Microsoft® Office Projecthusktech100% (1)

- Using Schedule Simulation Approaches To Reduce Greenhouse Gas Emissions in Highway Construction ProjectDocument11 pagesUsing Schedule Simulation Approaches To Reduce Greenhouse Gas Emissions in Highway Construction ProjecthusktechPas encore d'évaluation

- Managing Construction Operations To Minimize Greenhouse Gas EmissionsDocument10 pagesManaging Construction Operations To Minimize Greenhouse Gas EmissionshusktechPas encore d'évaluation

- Investigating The Effect of Construction Management Strategies On Project Greenhouse Gas Emissions Using Interactive SimulationDocument11 pagesInvestigating The Effect of Construction Management Strategies On Project Greenhouse Gas Emissions Using Interactive SimulationhusktechPas encore d'évaluation

- Studying Dynamic Decision Making in Construction Management Using Adaptive Interactive Simulations.Document10 pagesStudying Dynamic Decision Making in Construction Management Using Adaptive Interactive Simulations.husktechPas encore d'évaluation

- IdentificatiIdentification of Key Liability Risks of Supervision Engineers in Chinaon of Key Liability Risks of Supervision Engineers in ChinaDocument18 pagesIdentificatiIdentification of Key Liability Risks of Supervision Engineers in Chinaon of Key Liability Risks of Supervision Engineers in ChinahusktechPas encore d'évaluation

- Construction Schedule Simulation For Improved Project Planning Activity Criticality Index AssessmentDocument12 pagesConstruction Schedule Simulation For Improved Project Planning Activity Criticality Index AssessmenthusktechPas encore d'évaluation

- Using An Interactive Schedule Simulation Platform To Assess and Improve Contingency Management StrategiesDocument10 pagesUsing An Interactive Schedule Simulation Platform To Assess and Improve Contingency Management StrategieshusktechPas encore d'évaluation

- Construction Management Applications - Challenges in Developing Execution Control PlansDocument4 pagesConstruction Management Applications - Challenges in Developing Execution Control PlanshusktechPas encore d'évaluation

- Strategy Optimization and Generation For Construction Project Management Using An Interactive SimulationDocument12 pagesStrategy Optimization and Generation For Construction Project Management Using An Interactive SimulationhusktechPas encore d'évaluation

- Unit 4 Review Worksheet APDocument12 pagesUnit 4 Review Worksheet APphantomofthekeysPas encore d'évaluation

- Gas Laws Physics Lab ReportDocument10 pagesGas Laws Physics Lab Reportشاہ سعودPas encore d'évaluation

- PGBM03 LC MayDocument3 pagesPGBM03 LC MayWaqas CheemaPas encore d'évaluation

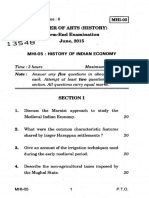

- Mhi 05 12Document6 pagesMhi 05 12aravPas encore d'évaluation

- Converting .Mp4 Movies With VLCDocument5 pagesConverting .Mp4 Movies With VLCrazvan_nPas encore d'évaluation

- Thermal KPN PDFDocument160 pagesThermal KPN PDFRithish BarathPas encore d'évaluation

- 12 General - Unit 5 - Lessons 5 - 6 - InnovationDocument40 pages12 General - Unit 5 - Lessons 5 - 6 - Innovationshahadjuma801Pas encore d'évaluation

- E3 - Identify Purpose of Components and Build CircuitsDocument2 pagesE3 - Identify Purpose of Components and Build Circuitsapi-316704749Pas encore d'évaluation

- Rename Quick Access FolderDocument13 pagesRename Quick Access FolderSango HanPas encore d'évaluation

- Annotated BibliographyDocument17 pagesAnnotated Bibliographyapi-2531405230% (1)

- Of James Prescott Joule: BiographyDocument6 pagesOf James Prescott Joule: BiographyJhanbert GalinadaPas encore d'évaluation

- Lesson Plan Civic Form 3Document1 pageLesson Plan Civic Form 3Nurul Liyana Abdullah100% (2)

- Back To Basics - The Fundamentals of 4-20 MA Current Loops - Precision DigitalDocument5 pagesBack To Basics - The Fundamentals of 4-20 MA Current Loops - Precision DigitalJason FloydPas encore d'évaluation

- Specific Volume, M /KG Internal Energy, KJ/KG Temp. Press. Sat. Liquid Evap. Sat. Vapor Sat. Liquid Evap. Sat. Vapor (C) (Kpa)Document6 pagesSpecific Volume, M /KG Internal Energy, KJ/KG Temp. Press. Sat. Liquid Evap. Sat. Vapor Sat. Liquid Evap. Sat. Vapor (C) (Kpa)sidhartha dasPas encore d'évaluation

- Automatic Selection by Penalized Asymmetric L - Norm in An High-Dimensional Model With Grouped VariablesDocument39 pagesAutomatic Selection by Penalized Asymmetric L - Norm in An High-Dimensional Model With Grouped VariablesMarcelo Marcy Majstruk CimilloPas encore d'évaluation

- Psych ReviewerDocument4 pagesPsych ReviewerAudrey AngPas encore d'évaluation

- Environment Setup - User Manual PDFDocument38 pagesEnvironment Setup - User Manual PDFambrishPas encore d'évaluation

- Zhejiang TelecomDocument4 pagesZhejiang TelecomShariffah Rekha Syed SalimPas encore d'évaluation

- Multiple Routes Routing in Computer Networks Remote DistanceDocument3 pagesMultiple Routes Routing in Computer Networks Remote DistanceerpublicationPas encore d'évaluation

- NCHE Guide Lines For Programme DevelopmentDocument3 pagesNCHE Guide Lines For Programme DevelopmentSamuel MushakaPas encore d'évaluation

- Volt White DocumentationDocument2 pagesVolt White DocumentationSantiago Rodriguez ArenasPas encore d'évaluation