Académique Documents

Professionnel Documents

Culture Documents

HEX Loop

Transféré par

cymyTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

HEX Loop

Transféré par

cymyDroits d'auteur :

Formats disponibles

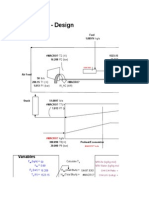

Steady-State Heat/Mass Balances

Hot PW stream Chilled Water stream Hot PW stream Chilled Water stream

Tin 85

o

C Tin 12

o

C Tin 80

o

C Tin 12

o

C

Tout 30

o

C Tout 19

o

C Tout 35

o

C Tout 19

o

C

q_hpw 5 m

3

/hr q_chw 39.3 m

3

/hr q_hpw 5 m

3

/hr q_chw 32.1 m

3

/hr

cp 4.00E+06 J/m

3

/K cp 4.00E+06 J/m

3

/K cp 4.00E+06 J/m

3

/K cp 4.00E+06 J/m

3

/K

Max Req'd Chilled Water Flow 40

m

3

/hr

Min Req'd Chilled Water Flow 33

m

3

/hr

This deisgn is approximate and will be used as a check against the supplier's unit (based on their estimates)

Heat Exchanger Design and Control Scheme

CHMR

CHMS

FO

M

PI

101

M

PI

101

TI

104

TI

103

TI

101

TI

102

FIT

101

FIC

101

LIT

101

LIC

101

TT

101

TIC

101

TK-101

PW Lift Tank To

TK-102/103/104

PW Storage Tanks

HEX-101

Cooler

LSLL

101

LALL

101

Chilled Water Return

(Medium Temperature)

Chilled Water Supply

(Medium Temperature)

PW from downstream

process at ~80-85

o

C

.

.

~12

o

C (Min.)

~19

o

C (Max.)

Upstream/Disposal Limit

~30-35

o

C

Plate-Frame HEX (Preliminary Design)

Fixed Design Parameters Read From Chart ~ 2000 Btu/hr/ft

2

/

o

F

Hot PW stream Chilled Water stream LMTD and NTU determination Heat transfer coefficients Assume MOC of HEX is SS316

Tin 85

o

C

Tin 12

o

C

LMTD 36.9

o

C h

hot

11360

W/m

2

/K k

SS316 15 W/m/K

Tout 30

o

C

Tout 19

o

C NTU

hot 1.49 h

cold

11360

W/m

2

/K

dx 0.0005 m plate thickness

Max. dP 50 kPa Max. dP 50 kPa NTU

cold 0.19 U

2707

W/m

2

/K

Heat Transfer Area Required

Based on "clean" heat transfer coefficient

A = Q/(U*LMTD) 3.1 m

2

10% heat transfer margin, i.e. SF = 1.1

Area required = 3.7 m

2

Simplifying assumptions:

1) Counterflow is assumed

2) SS 316 wetted thermal conductivity is given as above

3) Clean services for initial estimate

Approximate Cost of HEX

Factor of 1.5 account for supplier mark-up and

Factor of 2 is for on-site installation

C (USD) 7291

C(SGD) 11666

0

500

1000

1500

2000

2500

3000

3500

5 10 15 20 25 30

Pressure Drop (psig)

L

o

c

a

l

H

e

a

t

T

r

a

n

s

f

e

r

C

o

e

f

f

i

c

i

e

n

t

,

h

(

B

t

u

/

h

f

t

2

0

F

)

Heat Transfer Data for 0.25 < NTU < 2.0 for Plate and Frame Heat Exchangers, Water Based Properties

Pressure Drop (kPa)

Hot and cold sides are essentially

water, hence have same coefficients

Detailed HEX Sizing

Ch 5.56E+03 W/K (PW = Process Water = Fluid 1)

Assume: Cc 4.44E+04 W/K (CW = Chilled Water = Fluid 2)

1) Alfa-Laval P31 Plate is used.

2) Compressed gasket thickness = 2.9 mm Cmin 5555.556 W/K

3) Projected HT area per pate = 0.32 m

2

4) Effective diameter = 2 x gasket thickness = 5.8 mm NTU1 1.488762

R1 =C1/C2 1.25E-01

Cold side fluid : Hot water

G 9578.544 kg/m2/s 0.00116

viscosity 0.001 kg/m/s

De 0.0058 m

k 0.6 W/m/K

Re 55555.56

Pr 7.47

Nu 54.37637

hhot 5625.142 W/m2/K

Vous aimerez peut-être aussi

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- Bearing DesignDocument16 pagesBearing DesignOmar NajmPas encore d'évaluation

- Properties of MatterDocument117 pagesProperties of MatterKarren Ferrer-Mora Handayan100% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Tensile TestDocument12 pagesTensile Testmeysam1215100% (3)

- 12 MEPL P 1019 0 (Pipeline Calculation Book)Document40 pages12 MEPL P 1019 0 (Pipeline Calculation Book)Ibad Alam100% (4)

- Syllabus - Vishwakarma Institute of TechnologyDocument211 pagesSyllabus - Vishwakarma Institute of TechnologyAditya PophalePas encore d'évaluation

- Reservoir Rock PropertiesDocument148 pagesReservoir Rock Propertiesiscribdusername100% (7)

- LDD 30502 Ship Resistance and Ship Resistance and Propulsion TOPIC 1: Total Hull ResistanceDocument9 pagesLDD 30502 Ship Resistance and Ship Resistance and Propulsion TOPIC 1: Total Hull ResistanceIkram NajihuddinPas encore d'évaluation

- Material TestingDocument20 pagesMaterial TestingMohd Afandy100% (1)

- CO2 CorrosionDocument18 pagesCO2 CorrosionShie OthongPas encore d'évaluation

- Knopf: Ammonia Process FlowsheetDocument1 pageKnopf: Ammonia Process FlowsheetcymyPas encore d'évaluation

- Installed Flow CharacteristicsDocument4 pagesInstalled Flow CharacteristicscymyPas encore d'évaluation

- Live Solution Tank ExampleDocument6 pagesLive Solution Tank ExamplecymyPas encore d'évaluation

- Counter Current Heat Exchanger CarnahanDocument4 pagesCounter Current Heat Exchanger CarnahancymyPas encore d'évaluation

- Air Standard Cycle - Off Design 2: W - AC (KJ/S)Document8 pagesAir Standard Cycle - Off Design 2: W - AC (KJ/S)cymyPas encore d'évaluation

- Problem 8.6 L (160.67F)Document3 pagesProblem 8.6 L (160.67F)cymyPas encore d'évaluation

- Combustion Equilibrium Calculations: A1 A2 A3 A4Document6 pagesCombustion Equilibrium Calculations: A1 A2 A3 A4cymyPas encore d'évaluation

- Nox Kinetics Calculations - : Cvode Starts at Line 100 On Excel SheetDocument13 pagesNox Kinetics Calculations - : Cvode Starts at Line 100 On Excel SheetcymyPas encore d'évaluation

- Air Standard Cycle - Design Conditions: W - AC (KJ/S)Document6 pagesAir Standard Cycle - Design Conditions: W - AC (KJ/S)cymyPas encore d'évaluation

- Problem 10.9bDocument2 pagesProblem 10.9bcymyPas encore d'évaluation

- SI - Real Gas - Design: VariablesDocument9 pagesSI - Real Gas - Design: VariablescymyPas encore d'évaluation

- Air Standard Cycle With HRSG Supplemental Firing: Overall Energy Balance MethodDocument6 pagesAir Standard Cycle With HRSG Supplemental Firing: Overall Energy Balance MethodcymyPas encore d'évaluation

- Linear Data Reconciliation: Narasimhan and Jordache (2000)Document1 pageLinear Data Reconciliation: Narasimhan and Jordache (2000)cymyPas encore d'évaluation

- Mass Flowrates and Weight %: Styrene FlowsheetDocument1 pageMass Flowrates and Weight %: Styrene FlowsheetcymyPas encore d'évaluation

- Example 6.16aDocument1 pageExample 6.16acymyPas encore d'évaluation

- Example 5.6aDocument1 pageExample 5.6acymyPas encore d'évaluation

- 0.25 Reaction N + 3H NH: Ammonia Material Balance Using Gauss Jordan Elimination and Newton RaphsonDocument1 page0.25 Reaction N + 3H NH: Ammonia Material Balance Using Gauss Jordan Elimination and Newton RaphsoncymyPas encore d'évaluation

- Feed Reactor in Reactor Out Product Vapor Out Recycle Purge RHSDocument1 pageFeed Reactor in Reactor Out Product Vapor Out Recycle Purge RHScymyPas encore d'évaluation

- Problem 5.6a Ammonia Process - Energy Balance For Mixer Into R2Document1 pageProblem 5.6a Ammonia Process - Energy Balance For Mixer Into R2cymyPas encore d'évaluation

- X (0) X (1) X (2) RHS X X X: Newton-Raphson Method All VBA CodeDocument1 pageX (0) X (1) X (2) RHS X X X: Newton-Raphson Method All VBA CodecymyPas encore d'évaluation

- Turbine Combustion Kinetics PSR-1 : CVODE Starts at Line 100 On EXCEL SheetDocument14 pagesTurbine Combustion Kinetics PSR-1 : CVODE Starts at Line 100 On EXCEL SheetcymyPas encore d'évaluation

- CGAM Problem - Ideal Gas: Variables PhysicalDocument6 pagesCGAM Problem - Ideal Gas: Variables PhysicalcymyPas encore d'évaluation

- Trigger 0 (Either 0 To Reset or 1 To Iterate) Iterations 0.00000000 Reaction Iteration Count X 10Document1 pageTrigger 0 (Either 0 To Reset or 1 To Iterate) Iterations 0.00000000 Reaction Iteration Count X 10cymyPas encore d'évaluation

- Multiple Unit Operations: Linear Data ReconciliationDocument1 pageMultiple Unit Operations: Linear Data ReconciliationcymyPas encore d'évaluation

- Cvode: Initial y ComponentsDocument1 pageCvode: Initial y ComponentscymyPas encore d'évaluation

- Turbine Combustion Kinetics PFR-1 : CVODE Starts at Line 100 On EXCEL SheetDocument14 pagesTurbine Combustion Kinetics PFR-1 : CVODE Starts at Line 100 On EXCEL SheetcymyPas encore d'évaluation

- Problem 5.5dDocument16 pagesProblem 5.5dcymyPas encore d'évaluation

- Example 3.10Document1 pageExample 3.10cymyPas encore d'évaluation

- Brosur Pompa DS Dan DVSDocument4 pagesBrosur Pompa DS Dan DVSBilly Christovel100% (1)

- Parker Sizing of ValvesDocument8 pagesParker Sizing of ValvesAlberto Corticelli100% (1)

- Wier On Permeable FoundationDocument34 pagesWier On Permeable FoundationMahmoud I. MahmoudPas encore d'évaluation

- MP Priority Valve - 301-P-900002-EnDocument3 pagesMP Priority Valve - 301-P-900002-EnCésaire Aimé NdjemPas encore d'évaluation

- Stress Analysis of A Bicycle SpannerDocument3 pagesStress Analysis of A Bicycle SpannerkramanPas encore d'évaluation

- Biofuel 200W TEGDocument3 pagesBiofuel 200W TEGCătălin TrandafirPas encore d'évaluation

- Lecture 1 (Introduction-1)Document8 pagesLecture 1 (Introduction-1)Muhannad MohammedPas encore d'évaluation

- CH 1Document49 pagesCH 1Arbanah Muhammad0% (1)

- Numerical Analytic Approach To A Calculation of A Thermal Stress State of Shell and Tube Heat ExchangersDocument5 pagesNumerical Analytic Approach To A Calculation of A Thermal Stress State of Shell and Tube Heat Exchangerssagar1503Pas encore d'évaluation

- M 110yDocument2 pagesM 110yjawadPas encore d'évaluation

- Microsoft Word Water PumpsDocument2 pagesMicrosoft Word Water PumpsJosh Vincent Ranque0% (1)

- Hs Hhs Ms Pump Performance SheetDocument1 pageHs Hhs Ms Pump Performance SheetsunbopumpPas encore d'évaluation

- 3c Zeroth Law of ThermodynamicsDocument5 pages3c Zeroth Law of ThermodynamicsSamuel BoujeePas encore d'évaluation

- 2005 084Document5 pages2005 084Anonymous v1blzDsEWAPas encore d'évaluation

- Charles - LawDocument19 pagesCharles - Lawshort bondpaperPas encore d'évaluation

- Me6502 HMT Mech Vs Au Unit VDocument12 pagesMe6502 HMT Mech Vs Au Unit VnahlashkeifePas encore d'évaluation

- Editorial Shift To Compact Heat Exchangersppi00413en PDFDocument10 pagesEditorial Shift To Compact Heat Exchangersppi00413en PDFAnkit LonarePas encore d'évaluation

- The Second Law of Thermodynamics (Continued) (Lecture 05) : - Prashant Uday ManoharDocument28 pagesThe Second Law of Thermodynamics (Continued) (Lecture 05) : - Prashant Uday ManoharHRIDAY MAHESHWARIPas encore d'évaluation

- 3 - CEM - Testing of Mechanical Properties PDFDocument11 pages3 - CEM - Testing of Mechanical Properties PDFSmit GandhiPas encore d'évaluation

- Presion Capilary Historia de La SaturacionDocument16 pagesPresion Capilary Historia de La SaturacionJhonny Vacaflores JimenezPas encore d'évaluation