Académique Documents

Professionnel Documents

Culture Documents

Defecte La Sudura

Transféré par

danut_horincas4988Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Defecte La Sudura

Transféré par

danut_horincas4988Droits d'auteur :

Formats disponibles

Welding defects

1

The purpose of this training material is to

tell about various welding defects and their

effects to the strength of metal construction,

and also how to avoid welding defects.

Welding defects

2

THE WELD : The weakest point of metal construction?

Reasons why the welded seam is weakest point of metal construction:

Welding defects

Wrong sequence of welding

Welding stresses

Welding deformation

Base material overheating

Characteristic of material variation

Damage usually starts from area of welded seam

Weakness of welding seam is a result of Welding defects

A weld which is made the correct way is as strong and as hard as other

parts of the metal product

F

F

Welding defects

3

How to eliminate welding seam faults?

Careful and faultless welding work

Correct filler material selection

Use the correct welding parameters and welding technique

Work according to the WPSs ( Welding Procedure Specification )

Follow the manufacturers instructions and recommendations

Follow the heat input recommendation

For impact ductility and strength

F

F

Welding defects

4

What is welding defect?

Discontinuity in the weld

Difference in the form of the weld

Welding defects are for example:

Cracks in the weld

Failure in penetration

Undercutting

Porosity in the weld

Lack of fusion

Spatter

Welding defect means: Deviation from perfect weld

Welding defects

5

Welding defects are grouped to the following six main groups:

Cracks Lack of fusion

Cavity Wrong shape

Solid inclusion Dimensional error

Welding defects can be divided roughly to the three groups:

Wrong shapes

Surface defects

Internal weld defects

Welding defects

6

Two-dimensional defects are flat surface and known also as crack

type defects

Two-dimensional defects are sharp-pointed:

Very dangerous for joint durability

Two-dimensional defects are:

Various cracks

Lack of fusion

Short joint penetration

Surface and internal weld defects are grouped to two and

three-dimensional:

Welding defects

7

Three-dimensional defect also known as volumetric, ball-shaped

defect or cylindrical without sharp pointed shape

Three-dimensional defects are:

Pores and other cavities

Inclusions, if they have not sharp-pointed shape

Undercuts, if they have round bottom

Welding defects

8

Micro crack

Longitudinal crack

In weld metal

On fusion line

On heat affected zone

In base material

Cross crack

In weld metal

On heat affected zone

In base material

Cracks on the welding area: ( Cooling down and strength causes these cracks )

Welding zone

Fusion zone

HAZ = Heat affectedzone

Heat affected area

Base material

Fusion line

Weld metal

Base material

HAZ

Welding defects

9

Radiation crack

In weld metal

On heat affected zone

In base material

Crater crack

To longitudinal direction

Across

Radially

Cracks on the welding area: ( Cooling down and strength?? causes these cracks )

Welding zone

Fusion zone

HAZ = Heat affectedzone

Heat affected area

Base material

Fusion line

Weld metal

Base material

HAZ

Welding defects

1

0

Crack group

In weld metal

In heat affected zone

In base material

Branch crack

In weld metal

In heat affected zone

In base material

Cracks on the welding area: ( Cooling down and strength causes these cracks )

Welding zone

Fusion zone

HAZ = Heat affectedzone

Heat affected area

Base material

Fusion line

Weld metal

Base material

HAZ

Welding defects

1

1

Some crack types which appear during or after welding

Hot cracks

Cold cracks

Hydrogen cracks

Seasoning crack

Cracks are most dangerous welding defects

A crack could be a signal of larger problems in welding

Wrong selection of base material

Failure in welding instructions

One welding seam can include one or several cracks

Welding defects

1

2

Hot cracks in the weld

Longitudinal solidified crack in weld metal

Often, on the center line of welded seam or on fusion line

Form in high temperature when weld pool starts to solidify

Can also appear on fusion line or as a cross crack in heat effected zone

Welding seam can be broken only from surface or through whole seam

Hot cracks in the heat effected zone

Hot cracks in heat effected zone are short, only 1 - 2 mm long

Can also be called by name melting cracks

Hot crack on center line Hot crack inside welding seam Hot crack on fusion line Hot cracks in heat effected zone

Welding defects

1

3

Metallurgic factors

The solidification area and its width

The chemical composition

The micro structure

Geometrical factors

The shape of welding groove ( length / width relationship )

Strength factors

The plate thickness

The steel construction and its stiffness

Depth

Width

Wrong depth / width relationship

Width

Depth

Correct depth / width relationship

The causes of hot cracking

Welding defects

1

4

Effect of weld profile to the cooling and appearance of hot cracks

Cooling direction

Crack

Wrong Pass form

Molten weld pool

Cooling direction

Correct Pass form

Molten weld pool

Welding defects

1

5

Prevention of hot cracking

Always select welding parameters so that depth / width ratio is >1

Surface of the weld joint must be cleaned from impurities

Welding with smaller parameters / penetration decrease the risk

Use a smaller air gap

Weld so that the welding stress is minimized

Weld so that the fillet weld becomes a little bit convex

Decrease the welding speed

Good pass form

Worse pass form

Depth / width ratio >1

Narrow and deep

Too fast welding speed

Correct welding speed

Weld pool Welding seam

Good pass form Worse pass form

Welding defects

1

6

Hydrogen creates cracks together with stresses to the area

of microstructure which is hardened

Hydrogen cracks appear under 150C temperature

Hydrogen cracks have various names like:

Cold cracking

Hardening cracking

Delayed cracking

Hydrogen cracks appear in the hardenable steels

If martensitic structure increases in the weld metal

Hydrogen crack

Welding defects

1

7

Hydrogen cracks appear in places, which are:

The heat effected zone of the base material

In longitudinal direction, under the welding seam

In the root, as a root crack

In the fusion line, beside welding seam

Across or longitudinal, in the heat effected zone or welding seam

Starts and stops of welding

Edge crack

Underbead crack

Root and longitudinal

crack

Cross crack Edge crack Underbead crack Root and longitudinal

crack

Cross crack

Welding defects

1

8

Reasons that can cause hydrogen cracking

High carbon or blend components content in base material

Too low or high welding energy / heat input

Large plate thickness or construction stiffness

Too low preheating or too low temperature between two

passes

Too much hydrogen in the weld metal or in filler material

A groove profile, which increases strength in root weld

Too rapid cooling speed of weld metal ( frost etc )

Impurities in the welding joint

Humidity or moisture in the weld seam

The wrong heat treatment

Edge crack

Underbead crack

Root and longitudinal

crack

Cross crack

Welding defects

1

9

Prevention of hydrogen cracking

Select base materials which have a low content of carbon or alloying

component

Use a welding process where the content of hydrogen is as low as possible

( MIG / MAG )

Take care of the filler material storing and re-drying

Clean the surfaces of welding joint before welding

Use sufficiently big heat input which is suitable for welding

requirements

Use preheating with thick base materials

Use post-heat treatment if possible

Welding defects

2

0

Content of hydrogen in various welding process

Filler material Very low Low

Medium Plenty

5 10 15 20 25 30

Hydrogen contest in weld metal HD ( ml / 100 g )

MMA rutile electrodes

FCW

SAW

MIG / MAG solid wire

MMA basic electrodes

Welding defects

2

1

Crater cracks

Longitudinal crater crack

Cross crater crack

Star form crater crack

Grain structure change creates of crater crack

Wrong ending technique of welding

Prevention of crater crack

Return movement in the end of welding and stop welding on the welding seam

Use the crater filling function of the welding machine

Decrease welding parameters / Energy with Minilogfunction

Fill the end crater by short spots during end of weld metal cooling time

Use ending plates which are cut away after welding

Crater crack

Welding defects

2

2

Cavity and porosity types

Single cavity

Ball-shaped gas cavity

Smooth porosity

Porosity group

Localized porosity

Formed group of various pores

Cavity and porosity inside the welded seam

Linear porosity

Longitudinal linear porosity in the weld

Elongated Porosity

Longitudinal big pore

Surface pore

Open to the surface of welded seam

Single crack

Smooth porosity

Localised porosity

Linear porosity

Welding defects

2

3

Reasons that can cause cavity and porosity

Gas pores inside welding seam, can come from:

Filler material moisture

Rust, oil and other impurities

Thick paint layer on the welding area

Poor gas shielding in the MIG / MAG welding

Wind in the welding environment

Too low shielding gas flow

Too big shielding gas flow

High shielding gas flow in start

Water or oxygen in the shielding gas

Too long welding arc or too high welding speed

Too large oscillation or too long stick out length

Too small welding power

Cavities insde of weld

Welding defects

2

4

Prevention of the cavity and porosity

Eliminate impurities from the base material surface

Eliminate wind from the welding area

Keep filler material dry from moisture and humidity

Clean and dry surfaces of the welding joint

Check the gas flow

Check the gas flow hoses and flow meter

Increase welding current sufficiently

Use correct the welding parameters ( U, I, Wfs )

Use correct the arc length and travel speed

Dont use too wide oscillation ( max gas nozzle diameter )

Use multi pass welding technique

Preheating eliminates risks with thick base materials

Weld seamwithout cavities

Welding defects

2

5

Reasons that can influence slag and oxide inclusions

Defective slag or oxide removal

Insufficient root opening of the welded root seam

Slag inclusions between two welding passes ( multi pass welding )

Incorrect welding technique

Slag is rolling to the front of weld pool during welding

Wrong welding parameters ( Current, Voltage, Wfs )

Too deep and narrow welding groove ( V- groove, X-groove, U-groove etc.)

Wrong weld profile ( need of grinding in intermediate passes )

Solid inclusions

Defective slag or oxide removal Slag inclusions between welding passes

Welding defects

2

6

Prevention of slag and oxide inclusions

Remove slag or oxide carefully from weld surface

Make the root opening with a grinding machine until the pure part of the weld

is visible

Weld seam so that the weld profile is not too high

Point the welding arc correctly in to the welding groove, to the edges

Make sure that the slag and weld metal are not mixed into the welding arc

Use the correct welding parameters

Use the correct travel speed

Wrong seamform

Critical point for slag inclusion

Smooth seamformdecrease risk of

slag inclusion in multi pass welding

Welding defects

2

7

Reasons that can influence Tungsten inclusions ( TIG )

Tungsten electrode touches the weld pool in the beginning or during TIG welding

Head of Tungsten electrode is melts ( too small Tungsten diameter )

Wrong type / alloy of Tungsten electrode

Melted part of electrode goes to the weld pool

Scratch ignition

Broken electrode head inside weld pool

Wrong shielding gas

Oxygenous shielding gas

Dirty base material

Rust, oil, paint, humidity

Air contamination of Tungsten electrode

Tungsten inclusion ( TIG )

Welding defects

2

8

Grain of crater crack

Part of copper contact tip is melted to the weld pool

Over heated contact tip ( Cooling disturbance )

Too small MIG gun ( >250 - 300 A use water cooled MIG gun )

Too short stick out length

Non original and Non genuine consumable parts

Prevention of copper inclusion

Use original consumable parts

With spray arc welding use M 8 thread current tips

Check the operation of water cooling

Increase stick out length ( max 25 mm )

Clean spatter carefully from welding head to eliminate arc inside gas nozzle

Too long contact tip can cause copper

inclusion if it touch to the weld pool

Copper inclusion ( MIG )

Welding defects

2

9

Incomplete joining between the weld metal and the base

material or between intermediate welding passes

J oint surface

Between welding passes in multi pass welding

Infusible root face in root seam ( lack of fusion in root pass )

Sometimes also called, lack of side weld fusion or lack of side wall fusion

Lack of fusion

Lack of fusion in a joint surface

Lack of fusion in a root pass

Lack of fusion between welding passes

Welding defects

3

0

Reasons that can cause lack of fusion

Molten weld metal rolls in front of the welding arc on the cold base material

Too low welding speed

Too high wire feed speed to the selected welding voltage

Too high welding current in relation to the welding speed

Faulty MIG gun / electrode angle

Too narrow groove angle

Spray arc welding out of position is forbidden

Too wide oscillation

Too small welding power

Too long arc length

Magnetic arc blow ( MMA )

Impurities in fusion face

Molten weld metal rolls to the front

of welding arc and cause lack of

fusion

Welding defects

3

1

Prevention of lack of fusion

Use correct welding technique

Welding parameters

Welding speed

MIG gun angle and stick out

Use correct recommended types and sizes of welding grooves

Use correct welding power

Use correct arc length

Use correct groove angles and openings

Change position of earth cable to the better place in work piece ( MMA )

Clean surfaces of welding joint and passes

Wire brush / Grinding machine

Grinding disc / Grinding machine

Welding defects

3

2

Separation between real and nominal penetration

Appears, when fusion face or faces are not melted

If requisite penetration is not reached

Incomplete penetration

Incomplete penetration in fillet weld

Requisite penetration

Incomplete penetration in V- groove root pass

Welding defects

3

3

Reasons that can cause incomplete penetration

Incorrect joint shape

Too high root face

Too small air gap

Too small groove angle

Wrong MIG gun / MMA electrode angle

Misalignment

Wrong MIG gun angle

Too small welding current / welding energy

Too thick filler material

Wrong location of the seams in butt joint welding

Especially when welded from both sides

Perpendicularity

Slag or oxide is rolling to the front of welding arc

Misalignment in the joint

Wrong location of the seams

Welding defects

3

4

Prevention of incomplete penetration

Correct joint type and size

Correct welding current / welding energy

Correct MIG gun / MMA electrode angle

Correct travel speed

Correct arc length and stick out

Use thinner filler material, especially in root pass

Correct location of the weld seams

Perpendicular

Correct welding technique

Use the correct oscillation amount

Use multi pass welding technique

Use pre heat with thicker base materials

No misalignment in the joint

Correct location of the seams

Welding defects

3

5

Incorrect shape of the weld seam

Means incorrect surface profile of welded seam ( top and root side )

Incomplete geometry of welded seam

Correct parameters, travel speed and welding technique together

with the correct weld groove dimensions guarantee good weld

results

Wrong weld shape and dimensions

h = 0,1 x b +1,5 ( mm )

h

1

= 0,1 x c +1,5 ( mm )

h

1

h

b

c

Welding defects

3

6

Appears in the base material, beside the welding seam

Longitudinal or discontinuous cavity, which the molten weld

metal has not filled

Different types of undercutting

Continuous undercut

Discontinuous undercut

Root side undercut

Undercut between welding passes

Local undercut

Continuous undercut

Continuous undercut

Discontinuous undercut

Undercut between welding passes

Undercut

Welding defects

3

7

Reasons that can cause undercut

Too high welding current / energy

Too high / low / variations in travel speed

Wrong electrode / MIG gun angle

Unstable welders hand

Tendency of welding arc

Welding arc is pointed to the vertical plate in fillet weld

Too large oscillation in fillet joint

Large fillet joints are recommended to weld with

multi pass technique with out oscillation

Opening between plates

Welder has no proper visual contact to weld seam

Too large oscillation

Tendency of welding arc

45

30

Welding defects

3

8

Prevention of undercut

Use correct welding current / energy

Use correct and constant stick out length

Use correct MIG gun / MMA electrode angle

Use correct arc length

Use correct and constant travel speed

Correct tendency of welding arc

Point arc to the lower plate in fillet weld

Use only small oscillation if its needed

Use multi pass technique in fillet joint

In case of openings dont try to fill large gaps with single pass

In large openings, fill gaps with root pass before top pass

Better welders location to improve visual contact

Correct tendency of welding arc

1.0 mmfromcorner of the fillet weld

1 - 2 mm

Welding defects

3

9

Unsymmetrical fillet weld

What is a unsymmetrical fillet weld

A fillet weld that has been welded uneven or irregularly to 1 plate

The welding seam lays too much on the lower plate side

Unsymmetrical weld causes typically undercut and lack of fusion to vertical plate

Reasons that cause unsymmetrical fillet weld

Wrong welding gun angle

Too high welding parameters

Too low travel speed

Prevention of unsymmetrical fillet weld

Use correct welding gun angle

Decrease productivity or increase welding speed

Correct profile

Unsymmetrical profile

Correct / Unsymmetrical

fillet weld profile

Welding defects

4

0

Appears in one side or on both side of root pass

Reasons that can cause undercut in root pass

High root face of the welding groove

Too small / large air gap

Too small / big welding current / energy

Wrong welding technique

High pressure of backing gas ( TIG )

Prevention

Use the correct size air gap and root face

Use the correct welding energy and backing gas pressure

Use the correct oscillation and delay time in both groove edges

Undercut in root of welding seam

Undercut on both side of root pass

Welding defects

4

1

Too much weld metal in a welding seam

Too high cap form in the welded seam

Reasons that can cause excess weld metal

Too slow welding speed compared to the productivity of filler material

Too low capacity of groove or joint without groove ( V,X and Y etc.)

Too thick diameter of filler material ( TIG welding )

Prevention

Correct welding parameters

Correct groove type and size

Correct filler material diameter

Correct welding technique

Less full weld groove before top pass

Too high cap formin fillet weld

Too high cap formin butt weld

Welding defects

4

2

Too much weld metal in a welding seam

Too high cap form in the welded seam

Reasons that can cause excess weld metal

Too slow welding speed compared to the welding productivity

Too high filling or too small grinding of the filling pass

Too thick diameter of the filler material ( MMA / TIG welding )

Too short delay times in the weld edges

Prevention

Correct welding parameters

Correct groove type / size and grinding

Correct filler material diameter ( MMA / TIG )

Correct welding technique ( oscillation / delay time )

For top pass in MIG must

leave space 1,0 - 2,0 mm

Welding defects

4

3

Excessive root profile

Protrusion of root is too large from the base material

surface

Also known with the name excessive penetration

Various types of excessive root profile

Local high root reinforcement

Constant high root reinforcement

Through excessive penetration

Excessive root profile

High root reinforcement

Welding defects

4

4

Reasons that can cause excessive root profile

Too large air gap

Too small root face

Wrong welding parameters

Too short arc length

Too low welding speed

Too big MIG wire / MMA electrode diameter

Prevention

Correct the air gap and root face

Correct the welding speed and energy

Correct the oscillation movement

Correct the stick out length

More delay time in the weld edges

0 - 4 mm

min 60

2 - 6 mm

> 10 mm

Welding defects

4

5

Root concavity

What is a root concavity?

Groove in a root cap which is created contraction and the root edges are melted

Reasons that can cause root concavity

Too large root face in a welding groove

Too small air gap or variations of air gap

Too high welding speed

Too small welding energy

If backing gas pressure is too high ( TIG )

Prevention of root concavity

Use the correct size of root face and air gap

Use the correct welding energy

Decrease the pressure of the backing gas ( TIG )

Root concavity in root cap

Welding defects

4

6

Steep joining of the welded seam means

J oint between the welding seam and the base material is too steep

Steep joining

Steep joining in the edge of welding seam

Welding defects

4

7

Steep joining on a weld edge

Appears on the edge of a welded seam

Weld metal has flowed to the surface of base material with out fusion

On the top of welding seam or on root side

Is normally caused by too high wire feed speed

Wrong use of backing bars cause steep joining on root side

Wrong MIG gun angle

Too low arc Voltage ( MIG )

Excessive penetration on root side

Excessive penetration on the top of welding seam

Welding defects

4

8

What is welding spatter

Molten drops which fly out from the welding arc or molten weld pool and stick

to the surface of base material

Reasons that can cause spatter

Wrong welding parameters

Voltage, wire feed speed and arc length are not in balance

Too low or too high welding power

Variations of stick out length

Wrong MIG gun angle

Changes in openings between base materials

Impurities on base material surface

paint, rust, oil and humidity

Often steel spatter starts corrosion on the base material ( thin paint layer )

Welding spatter

Welding defects

4

9

Welding spatter

Prevention of welding spatter

Use the correct welding parameters for each welding case

J oint type ( butt joint, V-groove, X- groove etc. )

Out of position welding ( horizontal, vertical up / down , over head )

Use the correct welding power for each welding case

Keep stick out length constant

Weld with the correct MIG gun angle

Remove impurities from the base material surface

Use anti spatter spray ( MIG )

Keep the MIG gun welding head and liner clean

Use the correct size MIG gun

Argon based mix gases produce less spatter than CO2

Use correct current in MMA welding

Welding defects

5

0

Spatter removal

Sand or glass ball blasting

Manual or machine wire brushing

Grinding with discs or with special grinding wheels

Mechanical cleaning with a file / chisel

Minimizing spatter

Thin primary paint decreases sticking of spatter to base material ( FCW )

Anti spatter spray layer over base material decreases the spatter sticking

Spray arc welding with Ar +CO2 decreases spatter

Use of FCW wire decrease spatter

Use of Synergic Pulse-MIG decrease spatter

Mechanized welding decrease spatter

Cleaning of spatter

Vous aimerez peut-être aussi

- ASM Handbook of Case Histories in Failure Analysis, Vol 3, 2019Document709 pagesASM Handbook of Case Histories in Failure Analysis, Vol 3, 2019Tony Rizzo100% (10)

- Welding Module #2 PDFDocument112 pagesWelding Module #2 PDFHARSH SHARMAPas encore d'évaluation

- Connectors in FPDDocument64 pagesConnectors in FPDDrkvpratheep Pratheep94% (16)

- Welding Interview Questions and Answers PDFDocument11 pagesWelding Interview Questions and Answers PDFMOHANPas encore d'évaluation

- Welding Imperfection and Material InspectionDocument62 pagesWelding Imperfection and Material Inspectionintfarha10Pas encore d'évaluation

- Shielded Metal Arc WeldingDocument33 pagesShielded Metal Arc WeldingAit Biñan100% (3)

- Welding Positions - 4 Main Types - Weld GuruDocument19 pagesWelding Positions - 4 Main Types - Weld GuruFarid Ahmed Khwaja100% (1)

- Welding PositionDocument27 pagesWelding Positionsgt estreroPas encore d'évaluation

- Introduction To Arc WeldingDocument36 pagesIntroduction To Arc WeldingJo ShPas encore d'évaluation

- SMAW Basci Concept DoxDocument30 pagesSMAW Basci Concept DoxAmrut KajvePas encore d'évaluation

- Welding BasicDocument88 pagesWelding BasicMoneragala WorkshopPas encore d'évaluation

- Electric WeldingDocument28 pagesElectric WeldingmayankPas encore d'évaluation

- Shielded Metal Arc WeldingDocument4 pagesShielded Metal Arc WeldingLloyd AlmontePas encore d'évaluation

- Manual Metal Arc Welding (MMAW)Document20 pagesManual Metal Arc Welding (MMAW)Akmal Bin Saipul AnuarPas encore d'évaluation

- Welding Defects PDFDocument50 pagesWelding Defects PDFJohn Dare100% (4)

- ME 328.3 E5 - Welding MetallurgyDocument41 pagesME 328.3 E5 - Welding MetallurgyDEEPAKPas encore d'évaluation

- ME 328.3 E5 - Welding MetallurgyDocument41 pagesME 328.3 E5 - Welding Metallurgytbmari100% (1)

- Metallurgy of WeldingDocument40 pagesMetallurgy of Weldingquiron2010100% (1)

- Welding Defects: Their Causes and PreventionDocument18 pagesWelding Defects: Their Causes and PreventionsanjaykumarmauryaPas encore d'évaluation

- Welding Defects: Ganesan V Assistant Manager-TSD D&H Secheron Electrodes PVT - LTDDocument49 pagesWelding Defects: Ganesan V Assistant Manager-TSD D&H Secheron Electrodes PVT - LTDPrakash RajPas encore d'évaluation

- Piping Inspections: For BeginnersDocument38 pagesPiping Inspections: For BeginnersKamal UddinPas encore d'évaluation

- Defects in WeldsDocument6 pagesDefects in WeldsSaran KumarPas encore d'évaluation

- Welding Defects and AcceptanceDocument76 pagesWelding Defects and Acceptancearavindan100% (1)

- Welding DefectsDocument47 pagesWelding Defects0502raviPas encore d'évaluation

- Types of Welding Defects PDFDocument12 pagesTypes of Welding Defects PDFDhiab Mohamed AliPas encore d'évaluation

- WeldingDocument41 pagesWeldinggigiphiPas encore d'évaluation

- Questions Related To WeldingDocument12 pagesQuestions Related To WeldingpremPas encore d'évaluation

- Defects in MaterialsDocument89 pagesDefects in MaterialsSumedh Singh67% (3)

- Unit 2 Welding III HazDocument9 pagesUnit 2 Welding III HazHada NanuPas encore d'évaluation

- Defects in MetallurgyDocument49 pagesDefects in Metallurgyraghavendrajoshi870% (1)

- Shielded Metal Arc Welding (Smaw) 1. Electric Arc Welding DefectsDocument3 pagesShielded Metal Arc Welding (Smaw) 1. Electric Arc Welding DefectsLawrence PicardalPas encore d'évaluation

- 5 Classification of DiscontinuitiesDocument29 pages5 Classification of Discontinuitiesjose_sebastian_2Pas encore d'évaluation

- Microstructure Study of Welded JointDocument17 pagesMicrostructure Study of Welded JointRatul Islam Antor100% (1)

- Welding - Processes, Metallurgy and Defects: Summer 2010Document25 pagesWelding - Processes, Metallurgy and Defects: Summer 2010daemsalPas encore d'évaluation

- Casting 119 - EndDocument39 pagesCasting 119 - EndVarun AgrawalPas encore d'évaluation

- عيوب اللحامDocument20 pagesعيوب اللحامابو حيدرا الخزعليPas encore d'évaluation

- Material Processing DefectsDocument52 pagesMaterial Processing DefectsAmeem TariqPas encore d'évaluation

- Piping Welding Notes For Beginners Piping and Welding QAQCDocument38 pagesPiping Welding Notes For Beginners Piping and Welding QAQCيوسف عادل حسانين100% (2)

- Piping & Welding Notes For Beginners Piping and Welding Qaqc PDFDocument38 pagesPiping & Welding Notes For Beginners Piping and Welding Qaqc PDFbhinta ramadha100% (2)

- Ultrasonic Testing HandbookDocument29 pagesUltrasonic Testing HandbookRafael HernandezPas encore d'évaluation

- NDT Discontinuities - World of NDTDocument51 pagesNDT Discontinuities - World of NDTHòa NguyễnPas encore d'évaluation

- Welding Processes: EN358 - Ship StructuresDocument27 pagesWelding Processes: EN358 - Ship StructuresMayur PatelPas encore d'évaluation

- Soldering, Brazing and Braze Welding: Ag Metals I Welding Principles & ApplicationsDocument51 pagesSoldering, Brazing and Braze Welding: Ag Metals I Welding Principles & ApplicationsAd Man GeTigPas encore d'évaluation

- Introduction To Welding Technology: The WeldnetDocument67 pagesIntroduction To Welding Technology: The WeldnetThulasi RamPas encore d'évaluation

- InspectionDocument17 pagesInspectionRishu GuptaPas encore d'évaluation

- Repair Welds: Mark/Locate Weld: DefectsDocument23 pagesRepair Welds: Mark/Locate Weld: DefectsJhultran KatipunanPas encore d'évaluation

- Properties of Fusion Welds: EF420 Lecture 4 John TaylorDocument34 pagesProperties of Fusion Welds: EF420 Lecture 4 John TaylorBakheit LayliPas encore d'évaluation

- To Assure Quality of Weld Workmanship The Welds Are Examined With The Factors Listed Above in MindDocument30 pagesTo Assure Quality of Weld Workmanship The Welds Are Examined With The Factors Listed Above in MindNidhi SharmaPas encore d'évaluation

- Familiarization With Metal Welding II: Module Name: ME2024 Semester: 3Document11 pagesFamiliarization With Metal Welding II: Module Name: ME2024 Semester: 3Awishka EashanPas encore d'évaluation

- Solidification (Hot) Cracking Define Hot/Solidification CrackingDocument1 pageSolidification (Hot) Cracking Define Hot/Solidification CrackingrcpretoriusPas encore d'évaluation

- Lecture 7 - Manufacturing Processes - Metal and Sheet Forming, Bulk Deformation Processes - DR Bilal Ahmad PDFDocument62 pagesLecture 7 - Manufacturing Processes - Metal and Sheet Forming, Bulk Deformation Processes - DR Bilal Ahmad PDFjawad khalidPas encore d'évaluation

- DefectologyDocument91 pagesDefectologySivasankaran Raju100% (6)

- Welding DefectDocument33 pagesWelding DefectabdoPas encore d'évaluation

- VISUALDocument57 pagesVISUALasma100% (2)

- Casting DefectsDocument35 pagesCasting DefectsYaser Mohamed AbasPas encore d'évaluation

- Learning ObjectivesDocument19 pagesLearning Objectivesfred gallardoPas encore d'évaluation

- Welding 1Document61 pagesWelding 1عبدالرحمن سيدPas encore d'évaluation

- Materials, Processes and DefectsDocument28 pagesMaterials, Processes and DefectsmangsureshPas encore d'évaluation

- Welding DefectsDocument13 pagesWelding DefectsVinay Kumar SharmaPas encore d'évaluation

- QC General NotesDocument21 pagesQC General NotesBilly Kurniawan100% (2)

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonD'EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonPas encore d'évaluation

- Astm A-572Document5 pagesAstm A-572Wanderley CardosoPas encore d'évaluation

- Internship Report ISGEC PDFDocument31 pagesInternship Report ISGEC PDFManu BhaRdWaJPas encore d'évaluation

- Astm 182Document15 pagesAstm 182ISABELPas encore d'évaluation

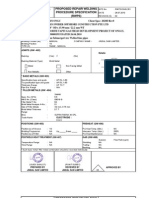

- Rev 2 - Proposed Repair WPSDocument2 pagesRev 2 - Proposed Repair WPSRakesh Patel75% (4)

- Hy19569 R05Document7 pagesHy19569 R05veeru22099Pas encore d'évaluation

- Mil STD 1907Document19 pagesMil STD 1907Mario100% (2)

- 2 Engineering MaterialsDocument14 pages2 Engineering MaterialsPRASAD326100% (1)

- Hard Gold Plating For Edge ConnectorsDocument12 pagesHard Gold Plating For Edge ConnectorsjackPas encore d'évaluation

- Assignment#1: Water Engineering CEE-307Document7 pagesAssignment#1: Water Engineering CEE-307Muhammad ShahzaibPas encore d'évaluation

- B477-1997 (2008)Document3 pagesB477-1997 (2008)Srinivasan KrishnamoorthyPas encore d'évaluation

- Rusting and Corrosion: Conditions For Iron To RustDocument3 pagesRusting and Corrosion: Conditions For Iron To Rusthussein hajiPas encore d'évaluation

- Quenching ProcessDocument14 pagesQuenching ProcessSandeep KumarPas encore d'évaluation

- Literature Review On Metal FabricationDocument4 pagesLiterature Review On Metal Fabricationc5t0jsyn100% (1)

- 4 Extraction of Iron in A Blast Furnace PDFDocument1 page4 Extraction of Iron in A Blast Furnace PDFShashank pandeyPas encore d'évaluation

- Specification For Structural Steel (Materials, Fabrication, Erection)Document24 pagesSpecification For Structural Steel (Materials, Fabrication, Erection)sivagnanam sPas encore d'évaluation

- Selective Hardening MethodsDocument47 pagesSelective Hardening MethodsvishnuPas encore d'évaluation

- Alternatives To Hard Chromium Plating On Piston RodsDocument59 pagesAlternatives To Hard Chromium Plating On Piston Rodsserkan_apayPas encore d'évaluation

- Msts Study Guide Asme Pcc-2Document40 pagesMsts Study Guide Asme Pcc-2jpwhyteincPas encore d'évaluation

- En10028 2Document12 pagesEn10028 2Patilea Daniela100% (1)

- CEN ISO TR 17844 (2004) (E) CodifiedDocument7 pagesCEN ISO TR 17844 (2004) (E) CodifiedOerroc Oohay0% (1)

- Nimblewill Nomad's Wood Burning Stove With Optional FrontDocument7 pagesNimblewill Nomad's Wood Burning Stove With Optional FrontAlan DemarcosPas encore d'évaluation

- Alcoa Innovation Welding Workshop: Kyle Williams - Alcoa Technical CenterDocument53 pagesAlcoa Innovation Welding Workshop: Kyle Williams - Alcoa Technical CenterspiritveluPas encore d'évaluation

- Anticorrosion - Technical Data Sheet - Materials 15022017 PolandDocument1 pageAnticorrosion - Technical Data Sheet - Materials 15022017 PolandRajesh MotgharePas encore d'évaluation

- Making Tongs For Blacksmithing: Register For Our ClassDocument14 pagesMaking Tongs For Blacksmithing: Register For Our ClassTemesgen HenokPas encore d'évaluation

- Astm A510 PDFDocument7 pagesAstm A510 PDFMann Gurpreet100% (4)

- 4B Drop Forged Chain CatalogDocument7 pages4B Drop Forged Chain CatalogCarlos CatalánPas encore d'évaluation

- Reinforcing Steel Bars Price List: Structural (Astm Grade 33)Document1 pageReinforcing Steel Bars Price List: Structural (Astm Grade 33)Emileandro Perito QuindiaganPas encore d'évaluation

- BusbarDocument119 pagesBusbarGabriel IrimiaPas encore d'évaluation

- Improved Technology of Scandium Recovery...Document7 pagesImproved Technology of Scandium Recovery...Balakrushna PadhiPas encore d'évaluation