Académique Documents

Professionnel Documents

Culture Documents

Kara & Dundar - 2009 - Effect of Inertia and Deflection of A Reinforced Concrete Beam

Transféré par

Laila Monteiro A MeloDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Kara & Dundar - 2009 - Effect of Inertia and Deflection of A Reinforced Concrete Beam

Transféré par

Laila Monteiro A MeloDroits d'auteur :

Formats disponibles

Effect of loading types and reinforcement ratio on an effective moment

of inertia and deection of a reinforced concrete beam

Ilker Fatih Kara

a

, Cengiz Dundar

b,

*

a

Department of Civil Engineering, Nigde University, 51235 Nigde, Turkey

b

Department of Civil Engineering, Cukurova University, 01330 Adana, Turkey

a r t i c l e i n f o

Article history:

Received 4 August 2008

Received in revised form 23 December 2008

Accepted 24 January 2009

Available online 27 February 2009

Keywords:

Reinforced concrete

Effective moment of inertia

Effective shear modulus

Deections

Loads

a b s t r a c t

In the design of reinforced concrete structures, a designer must satisfy not only the strength require-

ments but also the serviceability requirements, and therefore the control of the deformation becomes

more important. To ensure serviceability criterion, it is necessary to accurately predict the cracking

and deection of reinforced concrete structures under service loads. For accurate determination of the

member deections, cracked members in the reinforced concrete structures need to be identied and

their effective exural and shear rigidities determined. The effect of concrete cracking on the stiffness

of a exural member is largely dependent on both the magnitude and shape of the moment diagram,

which is related to the type of applied loading. In the present study, the effects of the loading types

and the reinforcement ratio on the exural stiffness of beams has been investigated by using the com-

puter program developed for the analysis of reinforced concrete frames with members in cracked state.

In the program, the variation of the exural stiffness of a cracked member has been obtained by using ACI,

CEB and probability-based effective stiffness model. Shear deformation effect is also taken into account in

the analysis and the variation of shear stiffness in the cracked regions of members has been considered by

employing reduced shear stiffness model available in the literature. Comparisons of the different models

for the effective moment of inertia have been made with the reinforced concrete test beams. The effect of

shear deformation on the total deection of reinforced concrete beams has also been investigated, and

the contribution of shear deformation to the total deection of beam have been theoretically obtained

in the case of various loading case by using the developed computer program. The applicability of the

proposed analytical procedure to the beams under different loading conditions has been tested by a com-

parison of the analytical and experimental results, and the analytical results have been found in good

agreement with the test results.

2009 Elsevier Ltd. All rights reserved.

1. Introduction

Reinforced concrete members crack at relatively low load level

even with presence of reinforcement because of the very low ten-

sile strength of concrete. The crack initiation and propagation is

highly load dependent and have a signicant effect on the stiffness

and hence displacement of reinforced concrete structures. The ten-

sile cracking of concrete reduces the exural and shear stiffness of

members and thus results in an increase in the deection of rein-

forced concrete members.

In recent years, the serviceability of reinforced concrete struc-

tures has become a much more important design consideration

with the use of high strength steel and concrete coupled with more

accurate and efcient analytical procedures that enabled practicing

engineers to satisfy ultimate state requirements with more slender

but more highly stressed structural members. When designing

reinforced concrete structures, a designer must satisfy not only

the strength requirements but also the serviceability requirements,

and therefore the control of the deformation is important to ensure

serviceability criterion. For accurate determination of member

deection, the prediction of exural and shear stiffness of mem-

bers after cracking becomes important. Therefore, an analytical

model which can include the effects of nonlinearity due to the con-

crete cracking on the exural and shear stiffness of the members

and accurately assess the deections would be very useful.

Deections of reinforced concrete exural members have been

the focus of several research activities in the past decades, and as

a consequent, various methods have been developed for predicting

them under short-term deection [14]. For calculating the deec-

tion of reinforced concrete members under working load, an empir-

ical expression for the effective moment of inertia developed by

Branson [5] is perhaps the most widely used, and various form of

Branson formula can be found in the ACI [6] and AS 36001994 [7].

0965-9978/$ - see front matter 2009 Elsevier Ltd. All rights reserved.

doi:10.1016/j.advengsoft.2009.01.009

* Corresponding author. Tel.: +90 0322 3386762; fax: +90 322 3386702.

E-mail address: dundar@cu.edu.tr (C. Dundar).

Advances in Engineering Software 40 (2009) 836846

Contents lists available at ScienceDirect

Advances in Engineering Software

j our nal homepage: www. el sevi er . com/ l ocat e/ advengsof t

Several methods are available in the technical literature for com-

puting the deections in reinforced concrete structures, consider-

ing the nonlinear effects of concrete cracking [8,9]. These

methods take into account the constitutive relationships of both

steel and concrete together with the bondslip relationship. Due

to the complexities of the actual behavior of reinforced concrete

members and the cumbersome computations to be performed,

these procedures can not be easily adopted by the design engineers.

Cosenza [10] developed an analytical procedure for the nite

element analysis of reinforced concrete beams in a cracked state.

The momentcurvature relationship models, such as linear ten-

sion stiffening, constant tension stiffening, ACI [6] and CEB [11]

models, which include the contribution of tensile resistance of

concrete to exural rigidities, were considered in the analysis.

In obtaining the exibility inuence coefcients, simply sup-

ported beam elements with uniformly distributed load was used.

Also the variation of shear rigidity due to cracking was not con-

sidered in the formulation. However shear deformation can be

large and signicant after the development of cracks. Therefore,

reduction of shear rigidity due to cracking should be included

in the analysis for improving results of the analysis and obtaining

more accurate results.

A model for estimating the effective moment of inertia of

cracked member was developed to account for the load type by

considering the variation in the cracked length, dened as the

length of the beam segment over which working moment exceeds

the cracking moment [12]. This procedure forms the basis and a

rotational approach to take into account some variable affecting

the effective moment of inertia.

A probability-based effective stiffness model was also devel-

oped for predicting the effective stiffness of reinforced concrete

exural members under service load conditions [13,14]. The effects

of load types and reinforcement ratios on the exural stiffness

characteristics of the beams were investigated, but the compari-

sons of the experimental and theoretical deections of beams were

not included in the study. However shear deformation effect,

which can be large and signicant following crack developments

and therefore be of practical importance in the design, was not

considered in the analysis.

There are many factors affecting the short-term deection of a

reinforced concrete exural member. These factors involve the

span length, end constraints, material and sectional properties,

magnitude and distribution of loads, and the ratio of reinforce-

ment. The most signicant effect on the reduction of the exural

stiffness of members in the serviceability loading range is the load-

ing type effect, which is believed to be one of the dominant factors

controlling the cracking behavior.

In the present study, the effect of loading type and reinforce-

ment ratio on the exural stiffness of beams has been investigated

by using the computer program, based on the iterative analytical

procedure, developed for the analysis of reinforced concrete frames

with members in cracked state. In the program, the variation of the

exural stiffness of a cracked member has been evaluated by using

ACI, CEB and probability-based effective stiffness model. Shear

deformation effect is also taken into account in the analysis and

the variation of shear stiffness in the cracked regions of members

has been considered by employing reduced shear stiffness model

available in the literature. Comparisons of various models for the

effective moment of inertia have been made with the results of

the simply supported test beams. The effect of shear deformation

on the total deection of reinforced concrete beams has been

investigated, and the contribution of shear deformation to the total

deection of beam have been theoretically obtained in the case of

various loading case by using the developed computer program.

The inuence of reinforcement ratio on the exural stiffness of

beams has also been discussed in the present study. The numerical

solution of the analytical procedure is carried out by using the stiff-

ness matrix method, and the cracked member stiffness equation is

obtained, including the uniformly distributed and point loads on

the member. In the evaluation of the exibility inuence coef-

cient, a cantilever beam model is used which greatly simplies

the integral equation. Verication of the analytical procedure has

been presented by the experimental results of simply supported

beams subjected to various loading types, and the statically inde-

terminate beams.

2. Models used for the effective moment of inertia of a cracked

member

Different models for the effective moment of inertia which in-

clude the effect of cracking and participation of tensile concrete be-

tween cracks, called tension stiffening, have been proposed to

dene the effective exural behavior of reinforced concrete

cracked section. In the ACI model based on the Bronson studies

[1] the effective moment of inertia is given in the following form:

I

eff

M

cr

M

_ _

m

I

1

1

M

cr

M

_ _

m

_ _

I

2

; for M PM

cr

1a

I

eff

I

1

; for M < M

cr

1b

where m = 3. In the CEB model I

eff

is also dened as

I

eff

b

1

b

2

M

cr

M

_ _

2

1

I

1

1 b

1

b

2

M

cr

M

_ _

2

_ _

1

I

2

_ _

1

; for M PM

cr

2a

I

eff

I

1

; for M < M

cr

2b

in which b

1

is the coefcient representing the quality of the rein-

forcing bars; b

1

= 1 for high bond reinforcement and 0.5 for plain

bars. b

2

is the coefcient characterizing the inuence of the dura-

tion or repetition of loading; b

2

= 1 for the rst loading and 0.5 for

the loads applied in a sustained manner or in a large number of load

cycles [15].

In Eqs. (1) and (2), I

1

and I

2

are the moments of inertia of the

gross uncracked section which accounts for the reinforcing steel

to the stiffness, and the cracked transformed section, respectively,

M is the bending moment, M

cr

is the moment corresponding to

exural cracking considered. The cracking moment, M

cr

is com-

puted by the program using the following equation:

M

cr

f

r

r

v

I

1

y

t

3

where f

r

is the exural tensile strength of concrete, y

t

is the dis-

tance from centroid of gross section to extreme ber in tension

and r

v

is the axial compressive stress, especially for beam case

r

v

= 0.

In present study, the probability-based effective stiffness model

has also been considered for the effective moment of inertia of a

cracked member. In the probability-based effective stiffness model,

which considers the cracking of concrete with the stiffness reduc-

tion in the reinforced concrete exural members, the value of I

eff

is determined as the ratio of the area of moment diagram segment

over which the working moment exceeds the cracking moment M

cr

to the total area of moment diagram in the following form (Fig. 1).

A

uncr

A

4

A

5

A

6

A

7

_

Mx<Mcr

Mx

4a

A

cr

A

1

A

2

A

3

_

MxPMcr

Mx

4b

A A

cr

A

uncr

4c

I.F. Kara, C. Dundar / Advances in Engineering Software 40 (2009) 836846 837

P

uncr

Mx < M

cr

A

uncr

A

4d

P

cr

Mx PM

cr

A

cr

A

4e

I

eff

P

uncr

I

1

P

cr

I

2

4f

where A

cr

is the area of moment diagram segment over which the

working moment exceeds the cracking moment M

cr

and A is the to-

tal area of moment diagram. In the same equation, P

cr

and P

uncr

are

the probability of occurrence of cracked and uncracked sections,

respectively.

Comparisons of aforementioned models for the effective mo-

ment of inertia are presented in this study.

3. Model used for the reduced shear stiffness of a cracked

member

Shear deformation can be large and signicant especially after

the development of cracks and therefore be of practical importance

in the design of reinforced concrete members. The variation of the

effective shear modulus of concrete due to cracking is considered

by employing the model developed by Al-Mahaidi [16]. In this

model, Al-Mahaidi proposed the following hyperbolic expression

for the reduced shear stiffness G

c

to be employed in the constitu-

tive relation of cracked concrete

G

c

0:4G

c

e

1

=e

cr

; for e

1

Pe

cr

5

where G

c

is the elastic shear modulus of uncracked concrete, e

1

is

the principal tensile strain normal to the crack and e

cr

is the crack-

ing tensile strain.

In this study, since three-dimensional analysis is considered, I

eff

,

M

cr

, M, I

1

, I

2

, e

1

and e

cr

are the values related to the exure in local y

and z-directions.

4. Formulation of the analytical procedure

In the present study, the stiffness matrix method has been em-

ployed taking into account the cracking effect with the effective

stiffness model. The reduction of shear stiffness following the crack

development is also considered by employing the reduced shear

stiffness model available in the literature. The analytical procedure

does not increase the numbers of degrees of freedom with respect

to common procedure and, at the same time, is particularly useful

in the case of highly statically indeterminate structures [17]. The

formulation of the analytical procedure is obtained for the three

dimensional analysis of reinforced concrete frame.

In this part the exibility inuence coefcients of a member will

rst be evaluated and then the stiffness matrix and the load vector

of a member with some region in the cracked state will be obtained

by using compatibility conditions and equilibrium equations.

A typical three dimensional member subjected to a point and a

uniformly distributed load, and positive end forces with corre-

sponding displacements are also shown in Fig. 2. For calculating

the relations between nodal actions and basic deformation param-

eters of a general space element, a cantilever model is used (Fig. 3).

The basic deformation parameters of a general space element may

be established by applying unit loads in turn in the directions of 1

3 and 79. Then, the compatibility conditions give the following

equation in matrix form:

f

11

0 0 0 0 0

0 f

22

f

23

0 0 0

0 f

32

f

33

0 0 0

0 0 0 f

77

f

78

0

0 0 0 f

87

f

88

0

0 0 0 0 0 f

99

_

_

_

_

P

1

P

2

P

3

P

7

P

8

P

9

_

_

_

d

1

d

2

d

3

d

7

d

8

d

9

_

_

_

_

6

in which, f

ij

is the displacement in ith direction due to the applica-

tion of unit loads in jth direction, and can be obtained by means of

the principal of virtual work as follows:

f

ij

_

L

0

M

zi

M

zj

E

c

I

effz

M

yi

M

yj

E

c

I

effy

V

yi

V

yj

G

c

A

s

V

zi

V

zj

G

c

A

s

M

bi

M

bj

G

c

I

o

N

i

N

j

E

c

A

_ _

dx:

7

In Eq. (7), M

zi

, M

zj

, M

yi

, M

yj

, V

zi

, V

zj

, V

yi

, V

yj

, M

bi

, M

bj

, N

i

and N

j

are the

bending moments, shear forces, torsional moments and axial forces

due to the application of unit loads in ith and jth directions, respec-

tively, E

c

denotes the modulus of elasticity of concrete, s and A are

the shape factor and the cross sectional area, respectively.

M

i

M

j

M

cr

M

cr

M

cr M

cr

2

3

4 5

1, 3, 5 cracked regions

2, 4 uncracked regions

L

P q

j

i

A

1

A

2

A

3

A

4

A

5 A

6

A

7

1

Beam

1

=0

2

3

6

=1

Fig. 1. Cracked and uncracked regions of the simply supported beam element.

x

Z z

X

P

4

, d

4

P

1

, d

1

P

7

, d

7

P

2,

d

2

P

3

, d

3

P

10

, d

10

P

12

, d

12

P

5

, d

5

P

6

, d

6

a

P

P

9

, d

9

P

8

, d

8

P

11

,d

11

Y

y

L

q

Fig. 2. A typical three dimensional member subjected to a point and a uniformly

distributed loads.

8

3

1

9

2

7

y

z

x

Fig. 3. A cantilever model for calculating the relations between the nodal actions

and basic deformation parameters.

838 I.F. Kara, C. Dundar / Advances in Engineering Software 40 (2009) 836846

Stiffness matrix of space frame members is obtained by invert-

ing the exibility matrix in Eq. (6) and using the equilibrium

conditions.

The member xed-end forces for the case of a point and a uni-

formly distributed load can be obtained by using the compatibility

and equilibrium conditions as follows:

P

10

P

20

P

30

P

40

P

50

P

60

P

90

P

110

0: 8a

P

70

f

88

f

70

f

78

f

80

= f

77

f

88

f

78

f

87

8b

P

80

f

77

f

80

f

78

f

70

= f

77

f

88

f

78

f

87

8c

P

100

qL P P

70

8d

P

120

qL

2

=2 PL a P

70

L P

80

_ _

8e

where f

i0

(i = 7, 8) is the displacement in ith direction due to the

application of span loads which can be evaluated by means of the

principal of virtual work in the following form:

f

i0

_

L

0

M

yi

M

0

E

c

I

effy

V

zi

V

0

G

c

A

s

_ _

dx 9

where M

0

and V

0

are the bending moment in local y-direction and

shear force in local z-direction due to the span loads. Finally, the

member stiffness equation can be obtained as

kd P

0

P 10

where k (12 12) is the stiffness matrix, d (12 1) is the displace-

ment vector, P

0

(12 1) is the xed end force vector and P (12 1)

is the total end force vector of the member. Eq. (12) is given in the

member coordinate system (x, y, z). Hence it should be transformed

to the structure coordinate system (X, Y, Z).

The effect of cracking on the behavior of a exural member is

largely dependent on both the magnitude and shape of the mo-

ment diagram, which is related to the type of applied loading. In

general the member has three cracked and two uncracked region,

as seen in Fig. 1. The integral values in Eqs. (7) and (9) will there-

fore be carried out in these cracked and uncracked regions

individually.

The exibility inuence coefcient can now be obtained by

using Eqs. (7) and (9), with the following terms of moment

and shear forces expressed in terms of non-dimensional coordi-

nate n

M

2

n nL; V

2

n 1 11a

M

3

n 1; V

3

n 0 11b

M

7

n nL; V

7

n 1 11c

M

8

n 1; V

8

n 0 11d

M

9

n 1; V

9

n 0 11e

M

0

n

qnL

2

2

; 0 6 n 6 a=L

qnL

2

2

PnL a; a=L < n 6 1

_

_

_

_

_

_

11f

V

0

n

qnL; 0 6 n 6 a=L

qnL P; a=L < n 6 1

_ _

11g

where n = x/L. In general case, n

i

, i = 1, 2, . . . , 6 as seen in Fig. 1.

If ACI and CEB models are considered for the effective mo-

ment of inertia of the cracked members, the exibility inuence

coefcient can be evaluated using Eqs. (7), (9) and (11) as

follows

f

22

L

3

E

c

_

1

0

n

2

I

effz

dn

sL

A

_

1

0

1

Gc

dn 12a

f

23

L

2

E

c

_

1

0

n

I

effz

dn 12b

f

33

L

E

c

_

1

0

1

I

effz

dn 12c

f

77

L

3

E

c

_

1

0

n

2

I

effy

dn

sL

A

_

1

0

1

G

c

dn 12d

f

78

L

2

E

c

_

1

0

n

I

effy

dn 12e

f

88

L

E

c

_

1

0

1

I

effy

dn 12f

f

70

qL

4

2E

c

_

1

0

n

3

I

effy

dn

qsL

2

A

_

a=L

0

n

G

c

dn

PL

3

E

c

_

1

a=L

nn a=L

I

effy

dn

sL

A

_

1

a=L

P

G

c

dn 12g

f

80

qL

3

2E

c

_

1

0

n

2

I

effy

dn

PL

2

E

c

_

1

a=L

n a=L

I

effy

dn 12h

On the other hand, if the probability-based effective stiffness model

is used for the effective exural stiffness of the cracked members,

the exibility inuence coefcients can be obtained as

F

22

L

3

3E

c

I

effz

sL

A

_

1

0

1

Gc

dn 13a

f

23

L

2

2E

c

I

effz

13b

f

33

L

E

c

I

effz

13c

f

77

L

3

3E

c

I

effy

sL

A

_

1

0

1

G

c

dn 13d

f

78

L

2

2E

c

I

effy

13e

f

88

L

E

c

I

effy

13f

f

70

qL

4

8E

c

I

effy

qsL

2

A

_

a=L

0

n

G

c

dn

P

3E

c

I

effy

L

3

a

3

=2 3aL

2

=2

sL

A

_

1

a=L

P

G

c

dn 13g

f

80

qL

3

6E

c

I

effy

P

E

c

I

effy

L

2

=2 a

2

=2 aL

_ _

13h

In the cracked regions where the applied moment is greater than or

equal to the cracking moment, I

eff

and G

c

vary with M along the re-

gion. Therefore, the integral values in these regions should be calcu-

lated by a numerical integration technique. The stiffness of a

cracked member varies according to the amount of crack formation

occurring in the members. Changes in stiffness of the cracked mem-

ber leads to a certain transfer of the internal forces of these mem-

bers to the other uncracked member, thus causing the cracking of

some of the otherwise uncracked members. Since the analytical

procedure allows for changes in stiffness of members, the variation

of the effective moment of inertia and effective shear modulus of

concrete in the cracked regions necessitate the redistribution of

the internal moments and forces in the structure. Hence iterative

procedure should be applied to obtain the nal deections and

internal forces of the structure. This procedure is computationally

more efcient especially in the case of the large indeterminate rein-

forced concrete structures.

In the analytical procedure developed on the basis of stiffness

matrix method, member equations are rst obtained and then

the system stiffness matrix and system load vector are assembled

by considering the contributions which come from each element.

Finally, the system displacements and member end forces are

determined by solving the system equation. This procedure is re-

peated step by step in all iterations.

I.F. Kara, C. Dundar / Advances in Engineering Software 40 (2009) 836846 839

5. Computer program

A general purpose computer program developed for the three

dimensional analysis of reinforced concrete structures based on

the iterative procedure is coded in Fortran 77 language. The ow

chart of the solution procedure of the program is given in Fig. 4.

In the iterative procedure, over reduction of stiffness in some

members at one iteration may cause smaller redistributions of

internal forces for these members and therefore result in excessive

increase in the stiffness of these cracked members in the subse-

quent iteration. Increase of exural stiffness attracts the transfer

of more internal forces to these members, thus leading to over

reduction to occur again. The alternate increase and decrease in

the stiffness of members causes a generally non-convergent proce-

dure. Therefore, in the solution procedure, the member end forces

used at each iteration step are taken as the mean value of the end

forces of all previous iterations [10,17]. In the program,

P

n

i

P

n1

i

P

n

i

6 e 14

is used as convergence criterion. Here, n is the iteration number, e is

the convergence factor and P

n

i

(i = 1, 12) is the end forces of each

member of the structure for nth iteration.

6. Verication of theoretical results

In order to determine feasibility for applying the analytical pro-

cedure to the beams under different loading conditions and com-

pare the different models for the value of I

eff

, the reinforced

concrete test beams subjected to various loading congurations

are considered. For this purpose four examples are presented.

The rst three examples are the simply supported beams subjected

to different loading conditions. The fourth example is the applica-

tion of the proposed analytical method on the two span continuous

beams.

6.1. Example 1

In this example, the experimental results of the reinforced con-

crete beams tested by Ning [14] subjected to various loading types

are compared with the present computer program. The test beams

had the same dimensions of 300 450 mm cross-section with

simply supported clear span of 3000 mm. The reinforcing steel in

the beams, the span and the load are shown in Fig. 5. The geometric

properties of the test beams and the reinforcement arrangement

are also listed in Table 1.

Fig. 6 presents the comparisons of effective moment of inertia

obtained from the ACI, CEB and probability-based effective stiff-

ness models. The variation of the experimentally determined I

eff

is also shown in Fig. 6. In obtaining the the value of I

eff

by using

ACI and CEB models, maximum moment on a relevant exural

member is considered because ACI and CEB relationships are inde-

pendent of applied loading types. From Fig. 6 it is clearly indicated

that different forms of the applied loading gives different values of

I

eff

, which means different reductions in the exural stiffness of

cracked beams. The value of effective moment of inertia calculated

from mid-point loading case is much larger than other two forms

of loading for the same level of M

max

/M

cr

value. The reason is that

the area of A

cr

segment over which the working moment exceeds

the cracking moment for the mid-point loading case is less than

3000 mm

A

A

P

450 mm

300 mm

d'

A

s

'

A

s

A-A

Fig. 5. Simply supported beam with mid-span load tested by Ning [14].

Input structure and

material properties

Input external loads

Perform linear elastic

analysis of the structure

Determine cracked and uncracked

regions of the members of the structure

Determine member stiffness and load vector using

I

eff

and

c

G and assemble the system stiffness matrix

Compute displacements of joints

and member end forces

n

i

1 n

i

n

i

P

P P

Yes

No

Compute the mean

value of the end

forces of all the

previous iterations

Store/output

results

Fig. 4. Solution procedure of the program.

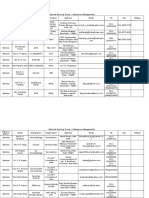

Table 1

Simply supported reinforced concrete beams tested by Ning [14].

Types of load Beam

type

Effective

depth

(d, mm)

Tensile

reinforcement

(A

s

)

Compressive

reinforcement

A

0

s

1. Mid-span load B16-1 400 3/16 2/12

B20-1 396 3/20 2/12

B25-1 393.5 3/25 2/12

2. Two-point load B16-2 400 3/16 2/12

B20-2 396 3/20 2/12

B25-2 393.5 3/25 2/12

U (uniformly

distributed load)

B16-U 400 3/16 2/12

B20-U 396 3/20 2/12

B25-U 393.5 3/25 2/12

840 I.F. Kara, C. Dundar / Advances in Engineering Software 40 (2009) 836846

that of other two forms of loading cases. ACI code relationship pre-

dicting the effective moment of inertia without the considering the

loading types, underestimates the value of I

eff

for the mid-point

loading case but overestimates for the other two cases. However

the results of the probability-based effective stiffness model are

in good agreement with the test results in all loading cases.

Fig. 7 compares the theoretical and experimental results of I

eff

for beams subjected to mid-point loading case for the three differ-

ent reinforcement ratios, which are equivalent to 0.15, 0.24, 0.39 of

q

b

, the steel ratio at balanced condition, when not considering the

reinforcement effect. This gure indicates that although there is

satisfactory agreement between the test and theoretical results

for B25-1, which the steel ratio equals to 0.39q

b

, signicant differ-

ences are obtained for B20-1 and B16-1 case, the steel ratios of

beams equal to 0.24q

b

, 0.15q

b

. To improve the prediction of the

effective moment of inertia of beams by using the probability-

based effective stiffness model, it is necessary to take into account

the reinforcement effect. Hence, to determine the interaction effect

between reinforcement and concrete P

q

was dened by Ning [14]

as

P

q

P

cr

a

15a

a

q

00

1

3

_

; when 0 6 q

00

6 1

q

00 3

p

0:46; when q

00

> 1

_ _

15b

q

A

s

bd

q

00

d

h

q 15c

and I

eff

was modied as the following equation:

I

eff

1 P

cr

P

q

_

I

uncr

P

cr

P

q

I

cr

16

Fig. 8 presents the variation of the effective moment of inertia con-

sidering the modication of the reinforcement effect in the analysis.

As seen from gure the analytical results show more accurate pre-

diction than those of values not considering the steel effect.

Figs. 9 and 10 show the comparisons of the value of I

eff

obtained

from experimental and analytical results without considering the

500

1000

1500

2000

2500

0 1 2 3 4 5 6

Probability-based effective stiffness model(B25-1)

Experimental(B25-1)

Probability-based effective stiffness model(B25-2)

Experimental(B25-2)

Probability-based effective stiffness model(B25-U)

Experimental(B25-U)

ACI

CEB

Ieff*10

6

mm

4

Mmax /Mcr

Fig. 6. Comparisons of the experimental and computed I

eff

values using different

models for B25 beams subjected to the three loading conditions.

0

500

1000

1500

2000

2500

0 1 2 3 4 5 6

B20-1(steel effect not considered)

B20-1(experimental results)

B16-1(steel effect not considered)

B16-1(experimental results)

B25-1(steel effect not considered)

B25-1(exprimental results)

Ieff *10

6

mm

4

Mmax/Mcr

Fig. 7. Comparisons of experimental I

eff

for beams subjected to mid-point loading

case with the theoretical results using probability-based effective stiffness model

(without considering the effects of reinforcement ratio).

0

500

1000

1500

2000

2500

0 1 2 3 4 5 6

Ieff *10

6

mm

4

Mmax/Mcr

B20-1(steel effect considered) B20-1(experimental results)

B16-1(steel effect considered) B16-1(experimental results)

B25-1(steel effect considered) B25-1(experimental results)

Fig. 8. Comparisons of the experimental I

eff

and analytical results for beams

subjected to mid-point loading case including the effects of reinforcement ratio.

0

500

1000

1500

2000

0 1 2 3 4 5

B25-U(steel effect not considered) B25-U (experimental results)

B16-U(steel effect not considered) B16-U(experimental results)

M

max

/M

cr

I

eff

*10

6

mm

4

Fig. 10. Comparisons of the experimental I

eff

and analytical results for beams

subjected to uniformly distributed loading case (without considering the effects of

reinforcement ratio).

0

500

1000

1500

2000

0 1 2 3 4 5

B20-2(steel effect not considered)

B20-2(experimental results)

B16-2(steel effect not considered)

B16-2(experimental results)

B25-2(steel effect not considered)

B25-2(experimental results)

I

eff

*10

6

mm

4

M

max

/M

cr

Fig. 9. Comparisons of experimental I

eff

for beams subjected to two point loading

case with the theoretical results using probability-based effective stiffness model

(without considering the effects of reinforcement ratio).

I.F. Kara, C. Dundar / Advances in Engineering Software 40 (2009) 836846 841

steel effect for the two point and uniformly distributed loading

cases. This gure indicates that it is not necessary to consider the

modication of the steel effect in the analysis for these loading

cases.

The comparison between the test and theoretical results for the

maximum vertical deection of beams is presented in Fig. 11

through Fig. 13. The numerical results obtained from the present

computer program by using the probability-based effective stiff-

ness model are in good agreement with the test results with max-

imum discrepancies of 9% in all loading cases. It can also be seen

from the gure that reinforcement ratio inuences signicantly

the deection of a cracked member in the serviceability loading

range (see Fig. 12).

Fig. 14 presents a comparison of the deections using the differ-

ent models for the effective moment of inertia of the cracked mem-

0

50

100

150

200

250

300

0 2 4 6 8 10

Displacement (mm)

P

(

k

N

)

B25-1(Probability-based effective stiffness model)

B25-1(experimental results)

B20-1(Probability-based effective stiffness model)

B20-1(experimental results)

B16-1(Probability-based effective stiffness model)

B16-1(experimental results)

Fig. 11. Comparison between experimental and analytical results of the deection

of beams under mid-point loading.

0

100

200

300

400

0 2 4 6 8 10 12

Displacement (mm)

P

(

T

o

t

a

l

l

o

a

d

,

k

N

)

B25-2(Probability-based effectie stiffness model)

B25-2(experimental results)

B20-2(Probability-based effective stiffness model)

B20-2(experimental results)

B16-2(Probability-based effective stiffness model)

B16-2(experimental results

Fig. 13. Comparison between experimental and predicted deection of beams

under two-point loading.

0 2 4 6 8 10

Displacement (mm)

0

100

200

300

400

500

P

(

T

o

t

a

l

l

o

a

d

,

k

N

)

B25-U(Probability-based effective stiffness model)

B25-U(experimental results)

B16-U(Probability-based effective stiffness model)

B16-U(experimental results)

Fig. 12. Comparisons of the analytical and experimental results of the deection of

beams under uniformly distributed loading.

0

100

200

300

400

500

0 2 4 6 8

Displacement (mm)

P

(

T

o

t

a

l

l

o

a

d

,

k

N

)

Probability-based effective stiffness model(B25-1)

ACI model(B25-1)

Probability-based effective stiffness model(B25-2)

ACI model(B25-2)

Probability-based effective stiffness model(B25-U)

ACI model(B25-U)

Fig. 14. Numerical comparison of the deection obtained by various models for the

effective exural stiffness.

0

50

100

150

200

250

300

0 1 2 3 4 5 6 7 8

Displacement (mm)

P

(

k

N

)

B25-1(shear deformation considered)

B25-1(shear deformation not considered)

B20-1(shear deformation considered)

B20-1(shear deformation not considered)

Fig. 15. Theoretical inuence of shear deformation on the deection of beam under

mid-point concentrated loading.

0

100

200

300

400

0 2 4 6 8

Displacement (mm)

P

(

T

o

t

a

l

l

o

a

d

,

k

N

)

B25-2(shear deformation considered)

B25-2(shear deformation not considered)

B20-2(shear deformation considered)

B20-2(sher deformation not considered)

Fig. 16. Effect of shear deformation on the deection of beam under two-point

concentrated loading.

842 I.F. Kara, C. Dundar / Advances in Engineering Software 40 (2009) 836846

bers. As seen from the gure, there is satisfactory agreement be-

tween ACI and probability-based effective stiffness model for

beams subjected to mid-point loading case. Although the differ-

ences between the computed deections obtained by the different

effective exural stiffness models are found at the initial stage of

applied loading for beams subjected to two-point and uniformly

distributed loads, the results are close to one another with increas-

ing the vertical loads.

Fig. 15 through Fig. 17 shows the inuence of shear deformation

on the maximum total deection of the reinforced concrete beams.

It can be seen that the contribution of the shear deformation to the

total vertical deection of the beams increase with increasing ver-

tical loads in all loading cases. The results also indicate that the

percentage of shear deformation in the total deection of beams

is approximately 11% (see Fig. 16).

6.2. Example 2

The accuracy of the proposed analytical procedure has also been

investigated using other test results available in the literature [12].

Comparisons have been made with the results reported of three

beams with rectangular sections under different loading condi-

tions. The test beams had the same 200 mm square cross section

with simply supported clear span of 2500 mm and same tensile

reinforcement arrangement, two 16 mm diameter deformed steel

bars. The reinforcing steel in the beams and the types of load are

listed in Table 2. Three different types of loading were applied,

Table 2

Simply supported beams tested by Al-Shaikh and Al-Zaid [12].

Types of load Beam

type

Tensile

reinforcement

Compressive

reinforcement

C (mid-span load) B3-C 2/16 /10

T (third-point load) B5-T 2/16 /10

U (uniformly distributed

load)

B1-U 2/16 /10

0

100

200

300

400

500

0 2 4 6 8 10

Displacement (mm)

P

(

T

o

t

a

l

l

o

a

d

,

k

N

)

B25-U(shear deformation considered)

B25-U(shear deformation not considered)

B16-U(shear deformation considered)

B16-U(shear deformation not considered)

Fig. 17. Theoretical inuence of shear deformation on the deection of beam under

uniformly distributed loading.

0

20

40

60

80

100

120

0 1 2 3 4 5

B1-U(Probability based effective stiffness model)

B1-U(experimental results)

B3-C(Probability based effective stiffness model)

B3-C(experimental results)

B5-T(Probability based effective stiffness model)

B5-T(experimental results)

ACI model

CEB model

Ieff*10

6

mm

4

M

max

/M

cr

Fig. 18. Comparisons of the experimental and computed I

eff

values using different

models for beams subjected to the three loading conditions.

0

10

20

30

40

50

60

0 2 4 6 8 10 12

Displacement (mm)

P

(

T

o

t

a

l

l

o

a

d

,

k

N

)

Probability-based effective stiffness model(B1-U)

Experimental (B1-U)

Probability-based effective stiffness model(B3-C)

Experimental (B3-C)

Fig. 19. Comparison between experimental and predicted deection of beams

under the different loading conditions.

2500

A

A

P

240

200

188

10

A

s

A-A

Fig. 20. Simply supported beam with mid-span load tested by Al-Shaikh and Al-

Zaid [18] (dimensions in mm).

Probability-based effective stiffness model(BL-11,p=0.8%)

Experimental(BL-11,p=0.8%)

Probability-based effective stiffness model(BN-12,p=1.4%)

Experimental(BN-12,p=1.4%)

Probability-based effective stiffness model(BH-13,p=2%)

Experimental(BH-13,p=2%)

I

eff

*10

6

mm

4

M

max

/M

cr

0

50

100

150

200

250

0 1 2 3 4 5 6

Fig. 21. Comparisons of experimental I

eff

with the theoretical results using

probability-based effective stiffness model (without considering the effects of

reinforcement ratio).

I.F. Kara, C. Dundar / Advances in Engineering Software 40 (2009) 836846 843

which included mid-span concentrated load; third-point concen-

trated load and uniformly distributed load.

Fig. 18 shows the comparisons of experimentally determined I

eff

for beams under different loading conditions. The variation of the

effective moment of inertia obtained from the probability-based

effective stiffness model, and ACI and CEB predictions at different

moment levels are also presented in Fig. 18. As seen from the g-

ure, similar results are obtained for the variation in the effective

moment of inertia as the previous example. The comparison be-

tween test and theoretical results indicate that probability-based

effective stiffness model are in good agreement with the test re-

sults more satisfactorily in all loading cases than the ACI and CEB

models.

The comparison between the test and theoretical results for the

maximum deection of beams obtained by the developed com-

puter program is presented in Fig. 19. It can be seen from gure

that the numerical results agree well with the test results with

maximumdiscrepancies of 6%. This analytical method also predicts

the deection with a high degree of accuracy in the serviceability

loading range.

6.3. Example 3

In this example, comparisons of different models for the effec-

tive moment of inertia obtained by the present computer program

have been made with the results of simply supported test beams,

having three different reinforcement ratios under the mid-span

load case [18]. The section dimensions of beams were 200 mm

wide and 240 mm deep. The reinforcing steel in the beams, the

span and the load are shown in Fig. 20.

Fig. 21 compares the experimental and theoretical values of I

eff

for beams with 0.8%, 1.4% and 2% steel ratio which are equivalent

to 2.2, 0.4 and 0.55q

b

when not considered the reinforcement ef-

fect in the analysis. As seen from the gure signicant differences

are found between test and theoretical results. In order to obtain

more accurate results and improve this prediction of effective mo-

ment of inertia of beams, it is necessary to consider the effect of

reinforcement ratio by using Eqs. (15) and (16) for this loading case

as the rst example. Fig. 22 shows the variation of the effective

0

50

100

150

200

250

0 1 2 3 4 5 6

Probability-based effective stiffness model(BL-11,p=0.8%)

Experimental(BL-11,p=0.8%)

Probability-based effective stiffness model(BN-12,p=1.4%)

Experimental(BN-12,p=1.4%)

Probability-based effective stiffness model(BH-13,p=2%)

Experimental(BH-13,p=2%)

I

eff

*10

6

mm

4

M

max

/M

cr

Fig. 22. Comparisons of the experimental I

eff

and analytical results including the

effects of reinforcement ratio.

(a) Two span continuous beams with uniformly distributed load

Negative Moment

Region

Positive Moment

Region

Beam b

(mm)

h

(mm)

q

(kN/mm)

L

(mm)

A

s

A

s

' A

s

A

s

'

X1,X4 152.4 203.2 2.77 12192 684 600 400 400

X2,X5 152.4 203.2 2.77 12192 684 600 400 200

X3,X6 152.4 203.2 2.77 12192 684 600 400 -

Y1,Y4 304.8 127 2.13 12679.7 1000 1000 516 516

Y2,Y5 304.8 127 2.13 12679.7 1000 1000 516 258

Y3,Y6 304.8 127 2.13 12679.7 1000 1000 516 -

Z1,Z4 304.8 76.2 0.99 10668 516 645 284 284

Z2,Z5 304.8 76.2 0.99 10668 516 645 284 142

Z3,Z6 304.8 76.2 0.99 10668 516 645 284 -

b (dimensions of beams)

Section A-A

h

b

w

A

s

A

s

'

L

2

3 4 5 6 1 7

A

A

0.21 L 0.165 L 0.125 L 0.125 L 0.165 L 0.21 L

q

Fig. 23. Two span continuous beams tested by Washa and Flock [19].

844 I.F. Kara, C. Dundar / Advances in Engineering Software 40 (2009) 836846

moment of inertia taking into account the modication of rein-

forcement effect in the analysis. It can be seen from gure that

the results show more accurate prediction than those of values

not considering the reinforcement effect. Hence it is important to

consider the effect of reinforcement in the analysis for beams un-

der the mid-point loading case in order to obtain more accurate

results.

6.4. Example 4

In the last example, two span continuous beam tested by Washa

and Flock [19] is taken into account. The continuous beam

subjected to uniformly distributed loads is modeled by six beam

elements as seen in Fig. 23. The dimensions of the beam, the spans

and the loads are also shown in the gure. For calculating the

exural tensile strength and modulus of elasticity of concrete the

following equations (ACI Code Eq. [20]) are also used.

E

c

4730

f

c

_

N=mm

2

17a

f

r

0:62

f

c

_

N=mm

2

17b

in which, f

c

is the compressive strength of concrete.

The comparison between experimental and theoretical deec-

tion of joint 2 obtained from the present study using the different

models for the effective moment of inertia are given in Table 3. As

seen in Table 3 the results of the theoretical deections determined

from present computer program agree well with the experimental

results. It can also be seen that different models provide similar

results.

In this example, almost the same results are also obtained

whether the steel effect is considered or not considered in the anal-

ysis. Therefore the same conclusion is reached for the case of the

two-span continuous beam as for the simple beam examples.

7. Conclusions

The work described in this paper is concerned with the effect of

the loading types and reinforcement ratios on the stiffness and

deection of reinforced concrete beams. For this purpose, an itera-

tive analytical procedure, which considers the cracking effect with

the effective stiffness model in the reinforced concrete structures

under different loading conditions, has been presented. The feasi-

bility for applying the proposed procedure to the beams subjected

to different loading congurations has also been tested by a com-

parison between experimental and numerical results.

In the analytical procedure, the variation of the exural stiffness

of a cracked member has been evaluated by using ACI, CEB and

probability-based effective stiffness model. Shear deformation ef-

fect, which can be large following crack developments and thus

be practical importance in design, is also taken into account in

the analysis, and the variation of shear stiffness in the cracked re-

gions of members has been considered by employing reduced

shear stiffness model available in the literature.

Comparisons of various models for the effective moment of

inertia have been made with the reinforced concrete test beams.

The probability-based effective stiffness model predicts effective

stiffness of members more accurately than the either ACI or CEB

relationships. The results also indicate that different forms of the

applied loading give different values of the effective moment of

inertia, which implies different reductions in the exural stiffness

of cracked beams.

The numerical results of the analytical procedure indicate that

the effect of reinforcement ratio on the effective moment of inertia

has a signicant factor on the beams under mid-point loading case,

while it has less signicant effect on the beams under the two-

point and uniformly distributed loading cases. Therefore it is nec-

essary to consider the effect of reinforcement ratio for the mid-

point loading case.

The feasibility and the reliability of the proposed analytical pro-

cedure have been tested by means of comparisons with the theo-

retical and experimental results of the deection of reinforced

concrete beams. The numerical results have been found to be in

good agreement with the test results. The analytical procedure also

predicts the deections with a high degree of accuracy in the ser-

viceability loading range.

The theoretical deection of beams has also been obtained with

the different effective exural stiffness models. There is satisfac-

tory agreement between ACI and probability-based effective stiff-

ness models for beams subjected to mid-point loading case.

Although the differences between the deections obtained by the

different effective exural stiffness models are found at the initial

stage of applied loading for beams subjected to two-point and uni-

formly distributed loads, the results are close to one another with

increasing the vertical loads.

Stiffness matrix method has been applied to obtain the numer-

ical solutions of the proposed analytical procedure. The major

advantage of this procedure is that it is efcient from the view-

points of computational effort and convergence rate to analyze

the statically indeterminate structures with members in cracked

state.

The numerical results of the analytical procedure indicate that

contribution of the shear deformation to the total defection of

the reinforced concrete beams increases with increasing loads. It

is therefore important to consider the variation of shear rigidity

in the cracked regions of members for obtaining more accurate

results.

References

[1] Cauvin A. Inuence of tension stiffening on behavior of structures. In:

Proceedings of the IABSE colloquium, international association of bridge and

structural engineers, Zurich; 1991. p. 1538.

Table 3

Comparison of experimental [19] and predicted deections at joint 2.

Beam type Deection at joint 2 (mm) Ratio

Experimental (A) Present study (probability-based eff. stiff. mod. (B) Present study (ACI mod.) (C) Cosenza [6] (D) B/A C/A D/A

X1, X4 14.2 14.6 13.4 16 1.03 0.94 1.13

X2, X5 14.4 14.9 13.8 16.3 1.03 0.96 1.13

X3, X6 13.2 15.3 14.3 16.6 1.16 1.08 1.26

Y1, Y4 22.6 23.5 21.7 25.1 1.04 0.96 1.11

Y2, Y5 23.6 24.1 22.4 25.7 1.02 0.95 1.09

Y3, Y6 25.4 24.8 23.3 26.2 0.98 0.92 1.03

Z1, Z4 26.4 28.6 26 32.3 1.08 0.98 1.22

Z2, Z5 28.7 29.3 26.8 32.6 1.02 0.93 1.13

Z3, Z6 30.5 30 27.7 33 0.98 0.91 1.08

Mean ratio 1.03 0.96 1.13

I.F. Kara, C. Dundar / Advances in Engineering Software 40 (2009) 836846 845

[2] Massicotte B, Elwi AE, MacGregor JG. Tension-stiffening model for planar

reinforced concrete members. J Struct Eng ASCE 1990;116(11):303958.

[3] Polak MA, Vecchio FJ. Nonlinear analysis of reinforced concrete shells. J Struct

Eng ASCE 1993;119(12):343962.

[4] Sakai K, Kakuta Y. Momentcurvature relationship of reinforced concrete

members subjected to combined bending and axial force. ACI J

1980;77:18994.

[5] Branson DE. Instantaneous and time-dependent deections of simple and

continuous reinforced concrete beams. HPR, Alabama Highway Department/

US Bureau of Public Roads, Report no. 7, vol. 1; 1963. p. 78.

[6] ACI Committee 435. Deection of reinforced concrete exural members. ACI J

1966;63:63774.

[7] Standarts Association of Australia (SAA). SAA concrete structures code. AS

3600-1994, Sydney, Australia; 1994.

[8] Ngo D, Scordelis AC. Finite element analysis of reinforced concrete beams. ACI J

1967;64(3):15263.

[9] Channakeshava C, Sundara Raja Iyengar KT. Elasto-plastic cracking analysis of

reinforced concrete. J Struct Eng ASCE 1988;114:242138.

[10] Cosenza E. Finite element analysis of reinforced concrete elements in a cracked

state. Comput Struct 1990;36(1):719.

[11] Comite Euro-International du Beton. Manual on cracking and deformation,

Bulletin dInformation; 1985. p. 158-E.

[12] Al-Zaid RZ, Al-Shaikh AH, Abu-Hussein MM. Effect of loading type on the

effective moment of inertia of reinforced concrete beams. ACI Struct J

1991;88(2):18490.

[13] Ning F, Mickleborough NC, Chan CM. Service loads response prediction of

reinforced concrete exural members. Struct Eng Mech 2001;12(1):116.

[14] Ning F. Lateral stiffness characteristics of tall reinforced concrete buildings.

PhD dissertation, Department of Civil Engineering, Hong Kong University

Science and Technology, Hong Kong; 1998.

[15] Ghali A, Favre R. Concrete structures: stresses and deformations. NY: Chapman

and Hall; 1986.

[16] Al-Mahaidi RSH. Nonlinear nite element analysis of reinforced concrete deep

members. Department of Structural Engineering, Cornell University, Report no.

79, vol. 1; 1978. p. 357.

[17] Dundar C, Kara IF. Three dimensional analysis of reinforced concrete frames

with cracked beam and column elements. Eng Struct 2007;29(9):226273.

[18] Al-Shaikh AH, Al-Zaid RZ. Effect of reinforcement ratio on the effective

moment of inertia of reinforced concrete beams. ACI Struct J 1993;90:1449.

[19] Washa GW, Fluck PH. Plastic ow (creep) of reinforced concrete continuous

beams. ACI J 1956;52:54961.

[20] ACI-318-95. Building code requirements for reinforced concrete, Michigan;

1995.

846 I.F. Kara, C. Dundar / Advances in Engineering Software 40 (2009) 836846

Vous aimerez peut-être aussi

- Lateral Stiffness Characteristics of Tall PDFDocument19 pagesLateral Stiffness Characteristics of Tall PDFLaila Monteiro A MeloPas encore d'évaluation

- Effectof Cyclic Loadingsonthe Shear StrengthandDocument14 pagesEffectof Cyclic Loadingsonthe Shear StrengthandAbel MulugetaPas encore d'évaluation

- CDP For Shear WallsDocument19 pagesCDP For Shear WallsLaxmith ShettyPas encore d'évaluation

- Effect of Material Properties On Behavior of Over-Reinforced Concrete BeamsDocument10 pagesEffect of Material Properties On Behavior of Over-Reinforced Concrete BeamssanjusamsonPas encore d'évaluation

- Importance of Shear Assessment of Concrete Structures Detailed To Different Capacity Design RequirementsDocument15 pagesImportance of Shear Assessment of Concrete Structures Detailed To Different Capacity Design RequirementsbenzentenPas encore d'évaluation

- EFFECT OF CONFINEMENT ON CURVATURE DUCTILITY OF REINFORCED CONCRETE BEAMS Ijariie20729Document10 pagesEFFECT OF CONFINEMENT ON CURVATURE DUCTILITY OF REINFORCED CONCRETE BEAMS Ijariie20729chaitanya krishnaPas encore d'évaluation

- Effects of Inclined Shear Reinforcement in Reinforced Concrete BeamDocument12 pagesEffects of Inclined Shear Reinforcement in Reinforced Concrete BeamvivekPas encore d'évaluation

- Behavior of Steel-Concrete Composite Beams Under Fatigue LoadsDocument11 pagesBehavior of Steel-Concrete Composite Beams Under Fatigue LoadsSourav ceePas encore d'évaluation

- Affecting Aspects On The Behaviour of Frame Joints: HBRC JournalDocument16 pagesAffecting Aspects On The Behaviour of Frame Joints: HBRC JournalVennela VasupilliPas encore d'évaluation

- Nonlinear Analysis of Prestressed Concrete Structures Considering Slip Behavior of TendonsDocument22 pagesNonlinear Analysis of Prestressed Concrete Structures Considering Slip Behavior of TendonsAdam AhmadPas encore d'évaluation

- Engineering Structures: Mohammad M. Kashani, Laura N. Lowes, Adam J. Crewe, Nicholas A. AlexanderDocument13 pagesEngineering Structures: Mohammad M. Kashani, Laura N. Lowes, Adam J. Crewe, Nicholas A. AlexanderRaja ShekarPas encore d'évaluation

- Mos Innovative Project 183&161Document22 pagesMos Innovative Project 183&1612K20-ME-161 Mridul AnandPas encore d'évaluation

- tmpC1DB TMPDocument12 pagestmpC1DB TMPFrontiersPas encore d'évaluation

- Application of Nonlinear Concrete Model PDFDocument7 pagesApplication of Nonlinear Concrete Model PDFOat GTPas encore d'évaluation

- PHD Thesis VGribniak 2009Document216 pagesPHD Thesis VGribniak 2009aecom2009Pas encore d'évaluation

- Analysis of Flectural Stiffness of Composite BeamsDocument22 pagesAnalysis of Flectural Stiffness of Composite BeamsVictorPas encore d'évaluation

- Son Vu Et Al - EngStruct - 2014 PDFDocument12 pagesSon Vu Et Al - EngStruct - 2014 PDFsarain_alvarezPas encore d'évaluation

- Anchor Stiffness FormulaDocument24 pagesAnchor Stiffness FormulaAhsan SattarPas encore d'évaluation

- AulaDocument45 pagesAulajorge mathaeusPas encore d'évaluation

- Efecto de La Flexibilidad en Los Nodos en El Desempeño de Estructuras de ConcretoDocument10 pagesEfecto de La Flexibilidad en Los Nodos en El Desempeño de Estructuras de ConcretoNataly RamírezPas encore d'évaluation

- Pull-Out Test For Studying Bond Strength inDocument14 pagesPull-Out Test For Studying Bond Strength inحسام رسميPas encore d'évaluation

- Reinforced Concrete Buildings: Behavior and DesignD'EverandReinforced Concrete Buildings: Behavior and DesignÉvaluation : 5 sur 5 étoiles5/5 (1)

- Analytical Stress-Strain Model and Damage Index FoDocument11 pagesAnalytical Stress-Strain Model and Damage Index Fomhmdwalid95Pas encore d'évaluation

- Research Activities - Tokyo Metropolitan UniDocument31 pagesResearch Activities - Tokyo Metropolitan UniCPas encore d'évaluation

- Predicting Nonlinear Behavior and Stress-Strain Relationship of Rectangular Confined Reinforced Concrete Columns With ANSYSDocument9 pagesPredicting Nonlinear Behavior and Stress-Strain Relationship of Rectangular Confined Reinforced Concrete Columns With ANSYSraunak upadhyayaPas encore d'évaluation

- Experimental Study On The Influence of Support andDocument13 pagesExperimental Study On The Influence of Support andsamPas encore d'évaluation

- Abaqus - Nonlinear Analysis of Reinforced Concrete Beam Experimentation2015Document5 pagesAbaqus - Nonlinear Analysis of Reinforced Concrete Beam Experimentation2015oioPas encore d'évaluation

- JTS 8Document10 pagesJTS 8Bob VandinnoPas encore d'évaluation

- Analytical Approach of Tension Stiffening Contribution of GFRP-MembersDocument8 pagesAnalytical Approach of Tension Stiffening Contribution of GFRP-MembersTigon Vo NgocPas encore d'évaluation

- Materials 13 05804 v2Document16 pagesMaterials 13 05804 v2deviationzPas encore d'évaluation

- Analytical Approach of Anchor Rod Stiffness and Steel-Sap2000Document24 pagesAnalytical Approach of Anchor Rod Stiffness and Steel-Sap2000Vladimir GuamanPas encore d'évaluation

- Literature ReviewDocument28 pagesLiterature Reviewபுருஷோத்தமன் சரவணன்100% (2)

- Construction Stages of Cable-Stayed Brid PDFDocument14 pagesConstruction Stages of Cable-Stayed Brid PDFnelsoncaicedoPas encore d'évaluation

- Gunes Lau Tuakta Ob CBMDocument11 pagesGunes Lau Tuakta Ob CBMAidil FitrianshahPas encore d'évaluation

- RC T Beams Strengthened To Shear With Carbon Fiber CompositesDocument12 pagesRC T Beams Strengthened To Shear With Carbon Fiber CompositesJackson Oliveira Dos SantosPas encore d'évaluation

- Predicting The Deflection of Concrete Structures in PracticeDocument10 pagesPredicting The Deflection of Concrete Structures in Practicehayder1974Pas encore d'évaluation

- Literature Review: 2.1 PreambleDocument26 pagesLiterature Review: 2.1 PreambleamokePas encore d'évaluation

- Building Frame Bridge Bent Structural WallDocument9 pagesBuilding Frame Bridge Bent Structural WallpmergosPas encore d'évaluation

- Wei Liu, Ya-Ping PENG, Xin-Sheng XUDocument6 pagesWei Liu, Ya-Ping PENG, Xin-Sheng XUSA023Pas encore d'évaluation

- Design of Anchor Plates Based On The Component Method Rybinski & KulhmannDocument12 pagesDesign of Anchor Plates Based On The Component Method Rybinski & KulhmannvcKampPas encore d'évaluation

- 10 5923 J Cmaterials 20120203 02Document10 pages10 5923 J Cmaterials 20120203 02ashenafiPas encore d'évaluation

- 99-s38 - On Evaluation of Rotation Capacity For Reinforced Concrete BeamsDocument9 pages99-s38 - On Evaluation of Rotation Capacity For Reinforced Concrete BeamsbllldPas encore d'évaluation

- Testing and Numerical Modelling of Steel-Concrete - Steel With Stud Bolts ConnectorsDocument22 pagesTesting and Numerical Modelling of Steel-Concrete - Steel With Stud Bolts ConnectorsGogyPas encore d'évaluation

- Analysis and Design of Prestressed Precast Hollow Core Slabs Using Strut and Tie Method PDFDocument12 pagesAnalysis and Design of Prestressed Precast Hollow Core Slabs Using Strut and Tie Method PDFZarko LazicPas encore d'évaluation

- Nonlinear Analysis of RC Beams Based On Moment-Curvature RelationDocument14 pagesNonlinear Analysis of RC Beams Based On Moment-Curvature RelationSamia ChowdhuryPas encore d'évaluation

- Journal of Constructional Steel Research: Binglin Lai, J.Y. Richard LiewDocument20 pagesJournal of Constructional Steel Research: Binglin Lai, J.Y. Richard LiewNlieshPas encore d'évaluation

- Analytical Approach of Anchor Rod Stiffness and Steel Base-Plate Calculation Under TensionDocument24 pagesAnalytical Approach of Anchor Rod Stiffness and Steel Base-Plate Calculation Under TensionAmin AskariPas encore d'évaluation

- Elmatzoglou 2017Document10 pagesElmatzoglou 2017Nefeli ChatzatoglouPas encore d'évaluation

- Seismic Behavior of Beam Column Joints in Reinforced Concrete Moment Resisting Frames 2Document36 pagesSeismic Behavior of Beam Column Joints in Reinforced Concrete Moment Resisting Frames 2m7j7a7Pas encore d'évaluation

- A Strain Based Non-Linear Finite Element Analysis of The Exterior Beam Column JointDocument15 pagesA Strain Based Non-Linear Finite Element Analysis of The Exterior Beam Column JointNiamul IslamPas encore d'évaluation

- EESD Hsiao Etal 2012Document18 pagesEESD Hsiao Etal 2012faisaladePas encore d'évaluation

- Aslani2012 Bond SCCDocument20 pagesAslani2012 Bond SCCEslam Abd El-Latif SolimanPas encore d'évaluation

- Structural Behavior of Steel-Concrete Composite BeamDocument12 pagesStructural Behavior of Steel-Concrete Composite BeamJaime Morales BazalduaPas encore d'évaluation

- 34Document8 pages34sahmeduPas encore d'évaluation

- Computation: Numerical Modelling of Double-Steel Plate Composite Shear WallsDocument30 pagesComputation: Numerical Modelling of Double-Steel Plate Composite Shear WallsNasarKhanPas encore d'évaluation

- Copy First Phase Report MSDocument39 pagesCopy First Phase Report MSSREEKUMARA GANAPATHY V S stellamaryscoe.edu.inPas encore d'évaluation

- 1 s2.0 S2214509522001644 MainDocument12 pages1 s2.0 S2214509522001644 Mainadnan-651358Pas encore d'évaluation

- Finite Element Analysis and Design of Steel and Steel–Concrete Composite BridgesD'EverandFinite Element Analysis and Design of Steel and Steel–Concrete Composite BridgesÉvaluation : 4.5 sur 5 étoiles4.5/5 (16)

- Seminarski RadDocument32 pagesSeminarski RadAdmir KlinčevićPas encore d'évaluation

- Course Recorder (Paperless) MDR290Document4 pagesCourse Recorder (Paperless) MDR290Jay SanchaniyaPas encore d'évaluation

- Riviera Sponsorship LetterDocument7 pagesRiviera Sponsorship LetterAnirudh Reddy YalalaPas encore d'évaluation

- Workshop Manual Group 21-26 - 7745282 PDFDocument228 pagesWorkshop Manual Group 21-26 - 7745282 PDFabdelhadi houssinPas encore d'évaluation

- HIDROMONTAŽA - We Change EverythingDocument1 pageHIDROMONTAŽA - We Change EverythingsamccoPas encore d'évaluation

- Desktop 10 QA Exam Prep Guide PDFDocument16 pagesDesktop 10 QA Exam Prep Guide PDFShiva RungtaPas encore d'évaluation

- L5 - Dipl in Computing International StudentsDocument6 pagesL5 - Dipl in Computing International StudentscuriousEnginePas encore d'évaluation

- Non Domestic Building Services Compliance GuideDocument76 pagesNon Domestic Building Services Compliance GuideZoe MarinescuPas encore d'évaluation

- Operating System ComponentsDocument59 pagesOperating System ComponentsJikku VarUghesePas encore d'évaluation

- Operations Management: William J. StevensonDocument36 pagesOperations Management: William J. StevensonRubel Barua100% (4)

- Economics Case StudyDocument28 pagesEconomics Case StudyZehra KHanPas encore d'évaluation

- Is Standard ListDocument11 pagesIs Standard ListSunil PulikkalPas encore d'évaluation

- Hydraulic Backhoe MachineDocument57 pagesHydraulic Backhoe MachineLokesh SrivastavaPas encore d'évaluation

- Lecture02 WindLoadingDocument53 pagesLecture02 WindLoadingMongkol JirawacharadetPas encore d'évaluation

- NGO-CSR Internship Report TemplateDocument4 pagesNGO-CSR Internship Report TemplatePriyanka Singh100% (1)

- NASM3Document4 pagesNASM3GFS ConsultoriaPas encore d'évaluation

- Strategic Management MBA (GTU)Document639 pagesStrategic Management MBA (GTU)keyur0% (2)

- 50rhe PDDocument40 pages50rhe PDm_moreira1974Pas encore d'évaluation

- 7GCBC PohDocument75 pages7GCBC PohEyal Nevo100% (1)

- SDLCDocument2 pagesSDLCTahseef RezaPas encore d'évaluation

- Volvo InstructionsDocument4 pagesVolvo InstructionsRonaldo Adriano WojcikiPas encore d'évaluation

- Real Time Blood Type Determination by Gel Test Method On An Embedded SystemDocument4 pagesReal Time Blood Type Determination by Gel Test Method On An Embedded Systemngocbienk56Pas encore d'évaluation

- Statement of Purpose China PDFDocument2 pagesStatement of Purpose China PDFShannon RutanPas encore d'évaluation

- Competitive Products Cross-Reference GuideDocument30 pagesCompetitive Products Cross-Reference GuideJeremias UtreraPas encore d'évaluation

- Trasdata HelpDocument4 852 pagesTrasdata HelpPaul Galwez75% (4)

- 563000-1 Web Chapter 4Document22 pages563000-1 Web Chapter 4Engr Ahmad MarwatPas encore d'évaluation

- AGC IPC Slash Sheet ReferenceDocument4 pagesAGC IPC Slash Sheet ReferenceSelvakumar NatarajanPas encore d'évaluation

- Contact List For All NWGDocument22 pagesContact List For All NWGKarthickPas encore d'évaluation

- XLPE-AL 33 KV Single Core Cable - Hoja de Datos - NKT CablesDocument2 pagesXLPE-AL 33 KV Single Core Cable - Hoja de Datos - NKT CableskjkljkljlkjljlkPas encore d'évaluation

- Usability Engineering (Human Computer Intreraction)Document31 pagesUsability Engineering (Human Computer Intreraction)Muhammad Usama NadeemPas encore d'évaluation