Académique Documents

Professionnel Documents

Culture Documents

Executive Shirt Working

Transféré par

Abhishek KumarCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Executive Shirt Working

Transféré par

Abhishek KumarDroits d'auteur :

Formats disponibles

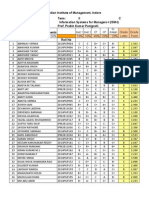

Type of Operation Number of workers

Number of

Machines

Average WIP

(number of 60-

shirt batches

Cutting 4 1 16

Sewing 48 48 144

Inspection 4 12

Ironing 4 4 12

Packaging 4 12

64 196

Operation

Regular Shirts

Laber Content

(Minutes per shirt)

Number of

Workers

Capacity (No. of

shirts/day)

Cycle

Time

Cutting 30.00 4

Setup for Cutting 1.50 4 1920 0.250

1. Make Collar 3.90 8 985 0.488

2. Make cuffs 2.00 4 960 0.500

3. Make sleeves 0.65 2 1477 0.325

4. Make front 2.50 6 1152 0.417

5. Make back 1.70 4 1129 0.425

6. Join shoulders 0.66 2 1455 0.330

7. Attach collar 1.65 4 1164 0.413

8. Attach sleeves 1.55 4 1239 0.388

9. Stitch down sleeves 0.65 2 1477 0.325

10. Sew side seam 1.80 4 1067 0.450

11. Attach cuffs 1.55 4 1239 0.388

12. Hem bottom 1.70 4 1129 0.425

13. Inspect 1.50 4 1280 0.375

14.Iron 1.95 4 985 0.488

15. Fold, Package 1.75 4 1097 0.438

26.51 64.00

Labor Content for Cutting 1

Current Process Regular

Actual Cycle Time(min./shirt)* 0.60

WIP Inventory(shirts) 11760

Manufacturing Lead Time(days) 14.7

Production Capacity(shirts/day)** 960

Capacity Utilization 83.33

Direct Labor Content Req.(min./shirt) 26.51

Direct Labor Content Available(min/shirt) 38.4

Direct Labor Utilization 69.0

Direct Labor Cost($/shirt) 3.84

Exhibit 3 :Current production of Regular Shirts at ESC,Inc.

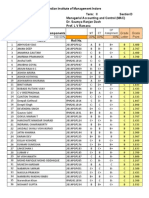

Exhibit 5 Mike's plan for Regular and Custom Shirts

Type of Operation

Number of

Workers

Number of

machines

Average

WIP (in

batches of 5

shirts each)

Cutting 5 2 36

Sewing 48 48 288

Inspection 4 24

Ironing 4 4 24

Packaging 4 24

65 396

Operation

Regular Shirts

Laber Content

(Minutes per

shirt)

Number of

Workers

Cutting 30.00 4

Setup for Cutting 1.50 4

Cutting(Custom shirts) 2.50 1

1. Make Collar 3.90 8

2. Make cuffs 2.00 4

3. Make sleeves 0.65 2

4. Make front 2.50 6

5. Make back 1.70 4

6. Join shoulders 0.66 2

7. Attach collar 1.65 4

8. Attach sleeves 1.55 4

9. Stitch down sleeves 0.65 2

10. Sew side seam 1.80 4

11. Attach cuffs 1.55 4

12. Hem bottom 1.70 4

13. Inspect 1.50 4

14.Iron 1.95 4

15. Fold, Package 1.75 4

25.51

Mike's Plan Regular&Custom

Actual Cycle Time(min./shirt)* 0.53

WIP Inventory(shirts) 1980

Manufacturing Lead Time(days) 2.2

Production Capacity(shirts/day)** 960

Capacity Utilization 93.75

Direct Labor Content required (min./shirt) 26.45 For Regular Shirt 26.51 For Custom Shirt

Direct Labor Content Available(min/shirt) 34.67

Direct Labor Utilization 76.31

Direct Labor Cost($/shirt) 3.467

For Custom Shirt 26.01

Exhibit 6 Ike's Plan for Regular and Custom Shirts

Type of Operation

Number of

workers

Number of

machines

Average WIP

(number of 60-

shirt batches)

Cutting 4 1 16

Sewing 36 36 108

Inspection 3 9

Ironing 3 3 9

Packaging 3 9

49 151

Operation

Regular Shirts

Laber Content

(Minutes per

shirt)

Number of

Workers for

Reg. shirts

Individual

Capacity (Reg.

shirts/day)

Number of

Workers for

Cust. shirts

Cutting 30.00 4

Setup for Cutting 1.50 4 1920

Cutting(Custom shirts) 2.50 1 960 1

1. Make Collar 3.90 7 862 1

2. Make cuffs 2.00 3 720 1

3. Make sleeves 0.65 1 738 1

4. Make front 2.50 5 960 1

5. Make back 1.70 3 847 1

6. Join shoulders 0.66 1 727 1

7. Attach collar 1.65 3 873 1

8. Attach sleeves 1.55 3 929 1

9. Stitch down sleeves 0.65 1 738 1

10. Sew side seam 1.80 3 800 1

11. Attach cuffs 1.55 3 929 1

12. Hem bottom 1.70 3 847 1

13. Inspect 1.50 3 960 1

14.Iron 1.95 3 738 1

15. Fold, Package 1.75 3 823 1

25.51 49 16

Ike's Plan Regular Custom

Actual Cycle Time(min./shirt)*

WIP Inventory(shirts)

Manufacturing Lead Time(days)

Production Capacity(shirts/day)**

Capacity Utilization

Direct Labor Content(min./shirt)

Direct Labor Content Available(min/shirt)

Direct Labor Utilization

Direct Labor Cost($/shirt)

Overtime (mins)

Regular Shirts

Individual

Capacity (cust.

shirts/day)

960

123

240

738

192

282

727

291

310

738

267

310

282

320

246

274

Exhibit 4 : Cost Structure for a Standard-Sized Shirt (current production process)

cost in $

Raw Materials 7.00

Total Labor(Direct + Indirect

*

) 4.50

Other Indirect Costs 4.50

Total Manufacturing Cost 16.00

Wholesale Price 25.00

Retail Price 50.00

* Indirect labor costs include costs of material handling and supervisory labor.

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Invoice OD109172599294660000Document2 pagesInvoice OD109172599294660000Abhishek KumarPas encore d'évaluation

- Antecedent Verification ProcessDocument4 pagesAntecedent Verification ProcessAbhishek KumarPas encore d'évaluation

- Active Portfolio ManagementDocument7 pagesActive Portfolio ManagementAbhishek KumarPas encore d'évaluation

- Financial Modeling Case StudyDocument7 pagesFinancial Modeling Case StudyAbhishek KumarPas encore d'évaluation

- An Example of Attribute Based MDS Using Discriminant AnalysisDocument17 pagesAn Example of Attribute Based MDS Using Discriminant AnalysisAbhishek KumarPas encore d'évaluation

- Marketing of ServicesDocument6 pagesMarketing of ServicesAbhishek KumarPas encore d'évaluation

- Chapter 10 Regression SlidesDocument46 pagesChapter 10 Regression SlidesAbhishek KumarPas encore d'évaluation

- An Example of Attribute Based MDS Using Discriminant AnalysisDocument17 pagesAn Example of Attribute Based MDS Using Discriminant AnalysisAbhishek KumarPas encore d'évaluation

- Chapter12 SlidesDocument15 pagesChapter12 SlidesParth Rajesh ShethPas encore d'évaluation

- Anova and The Design of Experiments: Welcome To Powerpoint Slides ForDocument22 pagesAnova and The Design of Experiments: Welcome To Powerpoint Slides ForAbhishek KumarPas encore d'évaluation

- XOLO-Snapdeal - Marketer of The YearDocument3 pagesXOLO-Snapdeal - Marketer of The YearAbhishek KumarPas encore d'évaluation

- Agency 1 IndiaHike Detailed ScheduleDocument9 pagesAgency 1 IndiaHike Detailed ScheduleAbhishek KumarPas encore d'évaluation

- Q3fy15 Result ConcallDocument1 pageQ3fy15 Result ConcallAbhishek KumarPas encore d'évaluation

- Candidates Interning BFSI DomainDocument2 pagesCandidates Interning BFSI DomainAbhishek KumarPas encore d'évaluation

- ISM-I Sec CDocument2 pagesISM-I Sec CAbhishek KumarPas encore d'évaluation

- Nifty: Trading StrategiesDocument2 pagesNifty: Trading StrategiesAbhishek KumarPas encore d'évaluation

- Indian Institute of Management Indore: MT ET CP AssignmentDocument2 pagesIndian Institute of Management Indore: MT ET CP AssignmentAbhishek KumarPas encore d'évaluation

- Nifty: Trading StrategiesDocument2 pagesNifty: Trading StrategiesAbhishek KumarPas encore d'évaluation

- Indian Institute of Management Indore: MT ET CP AssignmentDocument2 pagesIndian Institute of Management Indore: MT ET CP AssignmentAbhishek KumarPas encore d'évaluation

- Absence Record PGP-1 Term IIIDocument87 pagesAbsence Record PGP-1 Term IIIAbhishek KumarPas encore d'évaluation

- Support Service PDF PackDocument15 pagesSupport Service PDF PackAnderson CostaPas encore d'évaluation

- Absence Record PGP-1 Term IIIDocument87 pagesAbsence Record PGP-1 Term IIIAbhishek KumarPas encore d'évaluation

- SHRMDocument13 pagesSHRMRachit Pradhan100% (1)

- INOX Leisure Ltd. Location Listing with Over 40 LocationsDocument2 pagesINOX Leisure Ltd. Location Listing with Over 40 LocationsAbhishek KumarPas encore d'évaluation

- Overview of HR FunctionsDocument24 pagesOverview of HR FunctionsAbhishek KumarPas encore d'évaluation

- Qt-Iii - 2012-14Document71 pagesQt-Iii - 2012-14Abhishek KumarPas encore d'évaluation

- BC Sec CDocument2 pagesBC Sec CAbhishek KumarPas encore d'évaluation

- Absence Record PGP-1 Term IIIDocument123 pagesAbsence Record PGP-1 Term IIIAbhishek KumarPas encore d'évaluation

- FORT FrameworkDocument7 pagesFORT FrameworkAbhishek KumarPas encore d'évaluation

- Pharmacy Service Improvement atDocument5 pagesPharmacy Service Improvement atAbhishek KumarPas encore d'évaluation

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Ti e Protegol 130 HT Nov 07Document3 pagesTi e Protegol 130 HT Nov 07A MahmoodPas encore d'évaluation

- Stainless Steel 304 PipesDocument6 pagesStainless Steel 304 PipesVikas ShahPas encore d'évaluation

- 8rxCMPCAT-En Rexnord Conveyor Components CatalogDocument126 pages8rxCMPCAT-En Rexnord Conveyor Components CatalogIndraPas encore d'évaluation

- Fashionablyin VirtualDocument12 pagesFashionablyin VirtualTarun ThadaniPas encore d'évaluation

- Metallographic Sample Preparation and Microstructure ObservationDocument11 pagesMetallographic Sample Preparation and Microstructure Observationafnanhanany50% (2)

- Australia Oil & Gas Project Summary and Engineering RolesDocument6 pagesAustralia Oil & Gas Project Summary and Engineering RolesPeter CollierPas encore d'évaluation

- MCQ 1Document90 pagesMCQ 1alfred basilyPas encore d'évaluation

- Karla Melissa Martinez Medina. Vanessa Margarita Duran Aguilera. Leticia Serrano Wong. Dariela Zuñiga TreviñoDocument12 pagesKarla Melissa Martinez Medina. Vanessa Margarita Duran Aguilera. Leticia Serrano Wong. Dariela Zuñiga TreviñoKarla Martinez100% (1)

- Highway and Transportation EngineeringDocument12 pagesHighway and Transportation EngineeringkirannrgPas encore d'évaluation

- Surface Vehicle Recommended Practice: Rev. FEB2001Document10 pagesSurface Vehicle Recommended Practice: Rev. FEB2001san moedanoPas encore d'évaluation

- False ceiling materials and usesDocument17 pagesFalse ceiling materials and usesAshuthosh MurulyaPas encore d'évaluation

- Effective Control of Warping During Injection Molding: Ming-Shyan Huang, Shih-Chih Nian, and Chih-Yang WuDocument4 pagesEffective Control of Warping During Injection Molding: Ming-Shyan Huang, Shih-Chih Nian, and Chih-Yang WuPrabhath SanjayaPas encore d'évaluation

- Waukesha Bearings Corporation BrochureDocument8 pagesWaukesha Bearings Corporation BrochureMrr AfrasiabiPas encore d'évaluation

- API Airtech Aluminum Heat ExchangersDocument8 pagesAPI Airtech Aluminum Heat ExchangerscarlosPas encore d'évaluation

- Production Theory & EstimationDocument26 pagesProduction Theory & EstimationMelyan LhyandPas encore d'évaluation

- QA PLAN FOR UPVC PIPESDocument3 pagesQA PLAN FOR UPVC PIPESAnonymous ciKyr0t33% (3)

- Supply Chain Management - Wal-Mart CaseDocument18 pagesSupply Chain Management - Wal-Mart CaseBinay Pradhan50% (4)

- Sludge Thickening: Design of Gravitational ThickeningDocument8 pagesSludge Thickening: Design of Gravitational ThickeningugurPas encore d'évaluation

- Sca-Pca RCC Design SeminarDocument40 pagesSca-Pca RCC Design Seminarintimate4lifePas encore d'évaluation

- Peri Komponentu Katalogas Klojiniams 2015 enDocument948 pagesPeri Komponentu Katalogas Klojiniams 2015 enLuôn HồPas encore d'évaluation

- Muscat OverseasDocument5 pagesMuscat Overseasamjath584Pas encore d'évaluation

- Delhi-Mumbai Industrial Corridor Project OverviewDocument11 pagesDelhi-Mumbai Industrial Corridor Project Overviewer_ankurpareekPas encore d'évaluation

- Supply Chain ScienceDocument157 pagesSupply Chain ScienceSrinivas Kumar100% (1)

- Cartridge Case Manufacture PDFDocument7 pagesCartridge Case Manufacture PDFcbr6000100% (2)

- 07910Document3 pages07910sethu1091Pas encore d'évaluation

- Cat. Durochem Bbas. DDocument5 pagesCat. Durochem Bbas. DDavid ManzanoPas encore d'évaluation

- W CompositeDocument1 pageW CompositeSudhakar KarnanPas encore d'évaluation

- DCSP Tig Welding of Aa2219 Aluminum AlloyDocument14 pagesDCSP Tig Welding of Aa2219 Aluminum AlloySgk ManikandanPas encore d'évaluation

- Crane Wheel Heat Treating MethodsDocument20 pagesCrane Wheel Heat Treating Methodsgmurdzhev67% (3)

- Ammonia Paper Little TheoryDocument59 pagesAmmonia Paper Little TheoryThabangPas encore d'évaluation