Académique Documents

Professionnel Documents

Culture Documents

Diferenciacion Periodica Del Limite de Coordenadas Del Monkey Island

Transféré par

IceMAtluckyTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Diferenciacion Periodica Del Limite de Coordenadas Del Monkey Island

Transféré par

IceMAtluckyDroits d'auteur :

Formats disponibles

Fault Finding

25

1. A quick check is to blank off the rear of the generator and to

let it reach its pre-set pressure. All of the LEDs on the bar-

graph display should go out if the generator itself is gas

tight.

2. Gas demand exceeds the output capacity of the generator.

Reduce demand until the preset pressure can be maintained

3. Leak in external gas line. Check all joints and fittings. Seal

all leaks no matter how small they may be.

4. Check silica gel cartridge especially if it has been replaced.

If the advice below and none of the above points resolve the

problem, contact Peak Scientific Instruments Ltd for further

advice.

AUTO SHUTDOWN LED flashing.

Refer to the notes below for further

Advice and information.

1. No water in the external supply. Refill and retry.

2. Blocked or twisted water supply line. Trace blockage and

rectify.

LOW WATER LED flashing.

1. Internal leak inside generator. Contact Peak Scientific

Instruments Ltd for further advice.

2. Large change in pre-set pressure. Switch the generator off

and back on again, reset pressure and do not adjust during

check.

3. Reduced efficiency due to poor water quality. Contact Peak

Scientific for further advice.

SYSTEM CHECK LED flashing.

1. Ribbon connector has become dislodged inside. Contact

Peak Scientific Instruments Ltd for further advice.

2. Generator pressure has gone above the maximum

permissible pressure. Check if there is any other high-

pressure gas supply on the same If not, contact Peak

Scientific Ltd.

Fans rotates but no display

1. Check power supply and secure connection.

2. Check mains fuse and replace with T10 amp fuse if

required.

Nothing happens at switch ON

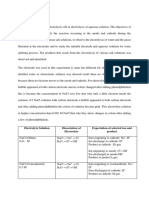

Possible Causes and Action Required Symptom

User Manual - Revision 4

Fault Finding

Further Advice and Notes on Fault Finding

Installing the generator to supply gas through long and/or large bore tubing.

Long gas lines and large bore tubing can have a large internal volume. This means

that it may take some time for the generator to pressurise the gas line to the set

point pressure. In certain cases, the set point pressure may not be reached within

the 20 minute time limit before the capacity excess alarm sounds resulting in the

Generator shutting down.

To overcome this problem, please do the following:

1. Close off all of the gas consuming applications. This will allow the generator to

initially pressurise the gas lines.

2. Set the delivery pressure at 1 Bar/14.5 psi and let the generator pressurise the

tubing.

3. Once this pressure has been reached, increase the delivery pressure in 1 Bar/14.5

psi increments.

4. Keep increasing the set pressure until the desired pressure has been reached.

5. Gradually turn on one application at a time and allow the pressure to stabilise with

each application.

Using the bar-graph display as a diagnostic tool

The bar-graph indicates how much gas the generator is producing. For example, a

CFH600 will generate a maximum of 600 cc/min, so each of the 10 LEDs on the

bar-graph represents 60 cc/min. If the consuming application is known to use 180

cc/min, then we should expect 3 LEDs to be lit. If this is the case, then the

generator and the gas lines are gas tight. If we have more than 3 LEDs lit, then we

know there is a leak somewhere. By closing the outlet of the generator we can

determine if the problem is with the generator or with the gas lines

26

User Manual - Revision 4

27

Maintenance Log.

Work Done Remarks Date Name

User Manual - Revision 4

28

Notes

.

User Manual - Revision 4

Vous aimerez peut-être aussi

- Una Determinacion Libre para e Contagio Del EbolaDocument4 pagesUna Determinacion Libre para e Contagio Del EbolaIceMAtluckyPas encore d'évaluation

- Internation Limit Asocicated DefenceDocument4 pagesInternation Limit Asocicated DefenceIceMAtluckyPas encore d'évaluation

- Manual Micro GCDocument196 pagesManual Micro GCIceMAtluckyPas encore d'évaluation

- BalaSum PDFDocument4 pagesBalaSum PDFIceMAtluckyPas encore d'évaluation

- BalaSum PDFDocument4 pagesBalaSum PDFIceMAtluckyPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Junction boxes gas group IIC selectionDocument16 pagesJunction boxes gas group IIC selectionkskadryPas encore d'évaluation

- Topic 4 - Chemical Kinetics 4b - Half LifeDocument20 pagesTopic 4 - Chemical Kinetics 4b - Half LifeJoshua LaBordePas encore d'évaluation

- Synopsis On Cyber Cafe Management SystemDocument22 pagesSynopsis On Cyber Cafe Management Systemyadavdhaval9Pas encore d'évaluation

- Reinforcement Detailing in BeamsDocument9 pagesReinforcement Detailing in Beamssaheed tijaniPas encore d'évaluation

- Air Suspension Benefits Over Steel SpringsDocument3 pagesAir Suspension Benefits Over Steel SpringsBejoy G NairPas encore d'évaluation

- Lab 5-Activity DiagramDocument19 pagesLab 5-Activity Diagramsayed omranPas encore d'évaluation

- Scan Path DesignDocument54 pagesScan Path DesignGowtham HariPas encore d'évaluation

- Honeywell VisionPro 8000 Install Manual 69-1706Document20 pagesHoneywell VisionPro 8000 Install Manual 69-1706electrician 15Pas encore d'évaluation

- NX Advanced Simulation坐标系Document12 pagesNX Advanced Simulation坐标系jingyong123Pas encore d'évaluation

- Basic Symbols and Fundamental Elements of Technical Drawing 1Document26 pagesBasic Symbols and Fundamental Elements of Technical Drawing 1seanmatthewferrerPas encore d'évaluation

- SERIES-90 180cc SERVICE BLN-2-41695 1997-05Document52 pagesSERIES-90 180cc SERVICE BLN-2-41695 1997-05thailanPas encore d'évaluation

- Openscape Business V2: How To Configure Sip Trunk For Netfone HungaryDocument14 pagesOpenscape Business V2: How To Configure Sip Trunk For Netfone HungaryBelahreche MohamedPas encore d'évaluation

- Experiment List (FEE)Document5 pagesExperiment List (FEE)bpkelePas encore d'évaluation

- Geometri Ruang File 1Document4 pagesGeometri Ruang File 1Muhammad Isna SumaatmajaPas encore d'évaluation

- Experiment03 PCM-DecodingDocument10 pagesExperiment03 PCM-DecodingMary Rose P Delos SantosPas encore d'évaluation

- LED Linear Highbay LightingDocument7 pagesLED Linear Highbay LightingMohammed YasarPas encore d'évaluation

- Carbon FibreDocument25 pagesCarbon Fibrejagadish.kvPas encore d'évaluation

- Water Quality Study of Kallai RiverDocument43 pagesWater Quality Study of Kallai Riverpratheesh thekedanPas encore d'évaluation

- Image ReconstructionDocument28 pagesImage ReconstructionRahul PaulPas encore d'évaluation

- Sandvik DL311Document4 pagesSandvik DL311Anonymous Dm7iMmtPas encore d'évaluation

- tc107 Research PaperDocument6 pagestc107 Research PaperAtharva BhidePas encore d'évaluation

- Grundfosliterature 5439390Document108 pagesGrundfosliterature 5439390ptlPas encore d'évaluation

- Discussion Exp 2 Chm674Document4 pagesDiscussion Exp 2 Chm674Eva Lizwina MatinPas encore d'évaluation

- Basic Research Approaches and Designs - An Overview - Amoud - 2020Document18 pagesBasic Research Approaches and Designs - An Overview - Amoud - 2020Haaji CommandoPas encore d'évaluation

- Flex-Shaft Attachment Instructions Model 225: WarningDocument1 pageFlex-Shaft Attachment Instructions Model 225: WarningFernando Lopez Lago100% (1)

- Instantaneous Waterhammer EquationDocument10 pagesInstantaneous Waterhammer EquationkiranPas encore d'évaluation

- Cot 2018-2019Document11 pagesCot 2018-2019Crush Na Crush KitaPas encore d'évaluation

- CB Climbing Bracket PERIDocument52 pagesCB Climbing Bracket PERINathan FryerPas encore d'évaluation

- MetaLINK Info r456Document5 pagesMetaLINK Info r456Milan AntovicPas encore d'évaluation

- Altera - ENDocument8 pagesAltera - ENDoanh NguyenPas encore d'évaluation