Académique Documents

Professionnel Documents

Culture Documents

Level of Schedule in Planning

Transféré par

Visas SivaCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Level of Schedule in Planning

Transféré par

Visas SivaDroits d'auteur :

Formats disponibles

Level of Schedule in Planning

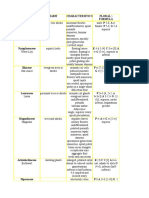

Level 3 schedules are the most used in planning. Level of schedule is usually

decomposed into 5. The intention of decomposing schedule level is to manage and control the

project or task to the manageable level.

Level 1 Schedule is the highest level, called overall project summary level.

It includes major milestones or achievements, highlights major activities and key

deliverables. Especially, it is also used in progress reporting.

Established by the client as an initial plan and can be integrated into level 2 and level 3

schedules which involved sub contractor and vendors in puts (commitments). Examples of

level 1 element are

(a) Engineering, Procurement and Construction (For Oil refinery plant expansion project )

(b) Engineering, Procurement and Construction (For Chemical Plant Shutdown Work)

Level 2 Schedule

is the area or system summary (roll up summary of level 3

schedule). It is also called major summary schedule. It is used to integrate into level 3 and

level 4 schedules which involved detail tasks. It can be used to report the project area or trade

progress status.

Examples of level 2 element are

(a) Utility Plant Modification Project, Hydro Cracker Revamp Work ( For Oil refinery plant

expansion project)

(b) Furnace Area, Compressor Area Shutdown Work (For Chemical Plant Shutdown Work)

Level 3 Schedule is a project coordinating and project reporting schedule. Roll up

summary of level 4 schedule. It is a primary tool for the project status tracking and manpower

loading analysis. It shows the summary of each discipline. For instance, piping engineering,

mechanical engineering, civil/structure engineering, process engineering and electrical and

instrumentation engineering are level 3 elements which are the disciplines of design

engineering. Normally developed and established by EPC (engineering, procurement and

construction) contractor. Used as a proposal schedule during the process of tendering. Also is

used as a guide line for subcontractors and vendors for their bid submissions. Applied critical

path method and used as monitoring schedule during the project execution phase. Normally,

level 3 schedule represents the area of responsible manager such as engineering schedule by

engineering manager, procurement by procurement manager and construction by construction

manager. Can be integrated into level 4 and level 5 schedule. The 3 month look-ahead

schedule is produced from this level and distribute to the responsible engineer or manager to

plan

ahead.

Level 4 Schedule is a low level schedule. It consists of the task or work categories

to be carried out. Level 3 schedule is further broken down into level 4 as an execution

schedule (working schedule). The detail task lists and work sequence are shown in this level.

Depending on the nature of project, the level 4 schedule may be level 1 schedule of

subcontractor (and/or) vendors. For example, we have a new project that required the new

pump no- P28 to be purchased and installed. Purchasing of pump materials and

manufacturing steps are apart of pump vendors level 4 element. When the pump vendors

schedule is roll-up into the highest level , the time frame from the purchased order issued date

to deliver date at site, is level 1 element of vendors schedule. That information becomes

main contractors level 4 schedule input. 6 week look-ahead schedule, 3 week look-ahead

schedule are frequently produced form this schedule by filtering the time frame, and

distribute the responsible engineer or manger to plan ahead before getting close to the

targeted

date.

Level 5 schedule is the lowest level of schedule. The task list and work sequence is

usually developed by the task supervisor or engineer and incorporated into level 4 schedule to

monitor day to day work.

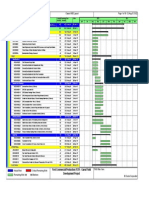

Schedule for Hot Tapping construction

Hot tapping work is a critical work especially in process industry such as pharmaceutical

plants, petrochemical plants, offshore platform and FPSO. Hot tapping work is the

connection of branch line piping to existing piping that contains live products such as gas or

oil under pressure. More information on hot tap operation and detail, refer to this site. In this

post, I would suggest the WBS and activities for a hot tap detail construction schedule.

Sample WBS are as follows;

1 Area

1.1 Work pack

1.1.1 Tie-in No

1.1.1.1 Off site Fabrication

1.1.1.2 Preliminary Activities

1.1.1.3 Execution

1.1.1.4 Post Activities

Activities such as fabrication of hot tap (split tee type or stub type), blasting and painting,

delivering to site are of off site fabrication WBS.The preliminary on site construction

activities before hot tap operation are as follows;

1.

2.

3.

4.

5.

6.

7.

Erect spark containment habitat (to avoid fire hazards)

Perform lamination check/UT test/MPI test (hot tap preparation work)

Perform ovality on hot tap location

Submitted UT test/MPI result to consultant/client for review

Approved to weld on hot tap location

Hydro test hot tap valve priority to drilling work

Remove walkway/support for hot tap machine access (this activity may or may not

exist, depends on nature of scope)

8. Hot work permit received

On site execution activities and work steps are as below;

1. Operation line check/gas test

2. Crane and welding machine into position (crane is not required if the hot tap size is

less than 6" and on above ground)

3. Clamp split tee for 14 hot tap

4. Check with operation on flow parameter

5. Fit-up/tack weld split tee on existing pipe

6. Fit-up inspection (contractor/consultant/client)

7. Welding (root run on branch section)

8. Welding (root run on longitudinal section)

9. NDT for both roots (MPT test)

10. Full fillet welding on circumstance existing pipe

11. Cap butt welds

12. Pneumatic test on comp pad

13. Install hot tap valve/blind for hydro test

14. Hydro test hot tap nozzle and valve

15. Inspect hot tap machine prior to drilling operation

16. Hot tap drilling by tapping contractor

17. Close hot tap valve

18. Depressurise and drain the tapping

19. Remove hot tap cutter

20. Install vented blind

Note : Welding type of activities 7,8 and 10 would be different if hot tap fitting is not a split

tee. In this post, Hot tap fitting is split tee type.

Post activities after drilling operation are

1. 1st PSSR by contractor/consultant/client clear punches items

2. Touch-up painting on hot tap nozzle

3. House keeping

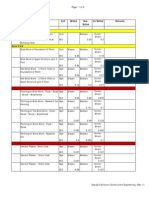

Sample hot tap construction schedule is shown as below.

You can also download this schedule

Vous aimerez peut-être aussi

- Complete Guide To Home CompostingDocument79 pagesComplete Guide To Home CompostingJoaquin Chila FPas encore d'évaluation

- ABC of DiabetesDocument111 pagesABC of DiabetesCandy E Ri ViPas encore d'évaluation

- Labour Productivity NormsDocument3 pagesLabour Productivity NormsSharad Kumar67% (6)

- Smoothies and BeyondDocument14 pagesSmoothies and BeyondWeldon Owen Publishing80% (5)

- Project Schedule Delay Log 1Document7 pagesProject Schedule Delay Log 1Hichem GuendouzPas encore d'évaluation

- Man Hour Calculation FormDocument152 pagesMan Hour Calculation Formمحمد شافق ابنو شافعتPas encore d'évaluation

- Project Control Stages A Complete Guide - 2019 EditionD'EverandProject Control Stages A Complete Guide - 2019 EditionPas encore d'évaluation

- Progress Tracking Sheet-Piping Touch Up PaintingDocument1 pageProgress Tracking Sheet-Piping Touch Up PaintingRedouane MerabtenePas encore d'évaluation

- Schedule LevelsDocument4 pagesSchedule Levelsferdie14Pas encore d'évaluation

- Construction Documentation TrackerDocument3 pagesConstruction Documentation TrackerTawfiq4444Pas encore d'évaluation

- 12-7-11 Daily Log Report (Reddick Construction) ASA BuildingDocument1 page12-7-11 Daily Log Report (Reddick Construction) ASA BuildingTimothy ReddickPas encore d'évaluation

- WSchedule Levels 1 To 5Document4 pagesWSchedule Levels 1 To 5KenmillicanPas encore d'évaluation

- Sample WeightageDocument3 pagesSample WeightageAbdul Nafeeq AliPas encore d'évaluation

- Fidic Conditions of ContractDocument57 pagesFidic Conditions of ContractalokPas encore d'évaluation

- Flower ArrangementDocument39 pagesFlower ArrangementJun Rey M. Gubaton100% (1)

- Resources Histogram, Planned VS ActualDocument6 pagesResources Histogram, Planned VS ActualburereyPas encore d'évaluation

- BCRUA Construction Progam Report Feb10Document19 pagesBCRUA Construction Progam Report Feb10OvidiuPas encore d'évaluation

- Site Weekly Report: ProjectDocument3 pagesSite Weekly Report: ProjectAhmad AliPas encore d'évaluation

- Pt. Duta Utama Tehnik Abadi: Daily ReportDocument45 pagesPt. Duta Utama Tehnik Abadi: Daily ReportMa'rifatullahPas encore d'évaluation

- 2.0 Alexis GPS Construction Schedule - 0BDocument1 page2.0 Alexis GPS Construction Schedule - 0BSyer Khomainie Mohamad Yakop100% (1)

- Tank Erection ProcedureDocument29 pagesTank Erection ProcedureVisas Siva100% (3)

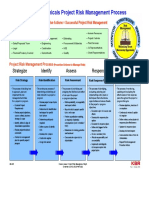

- Energy & Chemicals Project Risk Management ProcessDocument2 pagesEnergy & Chemicals Project Risk Management ProcessnbnbPas encore d'évaluation

- EVM GeneralUsing The Earned Value Method To Calculate Project Delays in Terms of TimeDocument29 pagesEVM GeneralUsing The Earned Value Method To Calculate Project Delays in Terms of TimeAhmed Elsayed100% (1)

- Construction Planning and SchedulingDocument11 pagesConstruction Planning and SchedulingAWAKSEORANGPas encore d'évaluation

- Procurement Process in Larsen & Toubro Epc: by Deepak Bhatt 063015Document14 pagesProcurement Process in Larsen & Toubro Epc: by Deepak Bhatt 063015Deepak BhattPas encore d'évaluation

- Material List (Sultaco)Document2 pagesMaterial List (Sultaco)sui1981Pas encore d'évaluation

- wdd-7 0-1 0Document1 pagewdd-7 0-1 0Kevin DomunPas encore d'évaluation

- Biomes of The Earth-TaigaDocument241 pagesBiomes of The Earth-TaigaTurcanu Liliana100% (1)

- 6.290 Project Handover Plan TempateDocument6 pages6.290 Project Handover Plan Tempatetuanthanh16Pas encore d'évaluation

- Al Ramah Residental C Al Ramah Residental Complexes (Infrastructure)Document5 pagesAl Ramah Residental C Al Ramah Residental Complexes (Infrastructure)anoopvvvPas encore d'évaluation

- Jeffrey Hamelman's Foreword To Home Baked by Hanne RisgaardDocument3 pagesJeffrey Hamelman's Foreword To Home Baked by Hanne RisgaardChelsea Green Publishing25% (4)

- Unit Rates & Cost Establishment For SSIP AGPDocument65 pagesUnit Rates & Cost Establishment For SSIP AGPketemaPas encore d'évaluation

- Planning EngineersDocument4 pagesPlanning EngineersAnonymous E2oSW7Pas encore d'évaluation

- Change Management ProcedureDocument5 pagesChange Management Procedureautocad abdelmjidPas encore d'évaluation

- 01 Intro Theory GT r03 PDFDocument118 pages01 Intro Theory GT r03 PDFThanapaet RittirutPas encore d'évaluation

- Tank ErectionDocument13 pagesTank Erectionsajay2010Pas encore d'évaluation

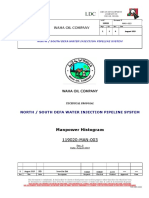

- 119020-MAN-003 Manpower HistogramDocument3 pages119020-MAN-003 Manpower HistogramMoaatazz Nouisri0% (1)

- Weekly Progress Report - No. 06: Sai Gon Binh An Urban AreaDocument15 pagesWeekly Progress Report - No. 06: Sai Gon Binh An Urban AreaMinh Thuận100% (1)

- Sample CV - Project PlannerDocument3 pagesSample CV - Project PlannermeshahanPas encore d'évaluation

- Piping Insulation Project Planned Schedule-Rev2Document1 pagePiping Insulation Project Planned Schedule-Rev2Anene EmmanuelPas encore d'évaluation

- Planning Engineer Interview QuestionsDocument14 pagesPlanning Engineer Interview QuestionsShreyasPas encore d'évaluation

- Module 11 Biointensive GardeningDocument22 pagesModule 11 Biointensive GardeningMeliktePas encore d'évaluation

- MPR Month YearDocument58 pagesMPR Month YearSanthosh PalaniappanPas encore d'évaluation

- (Books in Soils, Plants, and The Environment) Arie Altman-Agricultural Biotechnology (Books in Soils, Plants, and The Environment) - CRC Press (1997)Document792 pages(Books in Soils, Plants, and The Environment) Arie Altman-Agricultural Biotechnology (Books in Soils, Plants, and The Environment) - CRC Press (1997)Cesar Diaz Barrios100% (1)

- Serpentine Soils PDFDocument36 pagesSerpentine Soils PDFHery LapuimakuniPas encore d'évaluation

- Template and Example For Baseline Schedule NarrativeDocument25 pagesTemplate and Example For Baseline Schedule NarrativeMukul Bahuguna67% (3)

- Monthly Progress Review Report (MPRR) Page - 01 1. GeneralDocument21 pagesMonthly Progress Review Report (MPRR) Page - 01 1. Generalලහිරු විතානාච්චිPas encore d'évaluation

- Resume For The Post of Project, Planning EngineerDocument5 pagesResume For The Post of Project, Planning Engineerssbapi33% (3)

- Proj Desc 1768 29may2018 PDFDocument31 pagesProj Desc 1768 29may2018 PDFKungu Teddy NjorogePas encore d'évaluation

- 02DEC2022 Progress MeasurementDocument83 pages02DEC2022 Progress Measurementjing aytonaPas encore d'évaluation

- Key Points: EPC4 Weekly Report 22 February 2011 Teamwork at Its HighestDocument7 pagesKey Points: EPC4 Weekly Report 22 February 2011 Teamwork at Its HighestMarkyPas encore d'évaluation

- Commissioning and Start-UpDocument1 pageCommissioning and Start-UpLuciano GaglianoPas encore d'évaluation

- Garraf FCP DD ScheduleDocument19 pagesGarraf FCP DD ScheduleSalman HussainPas encore d'évaluation

- Interface Engineer: Position Title Reports To DurationDocument1 pageInterface Engineer: Position Title Reports To DurationAnonymous ygQUvDKPas encore d'évaluation

- How Much How Many 36876Document2 pagesHow Much How Many 36876Orlando Mota100% (2)

- CRSE-SA-T-775 Monthly Quality Management Report For The Month of July 2020Document65 pagesCRSE-SA-T-775 Monthly Quality Management Report For The Month of July 2020Ahmad Assad mrednPas encore d'évaluation

- Project Management Plan TemplateDocument9 pagesProject Management Plan TemplateAsmaaPas encore d'évaluation

- PGPM 31 Nicmar AssignmentsDocument29 pagesPGPM 31 Nicmar Assignmentsvjrana2003Pas encore d'évaluation

- Baseline Schedule Review Check List - Control DivisionDocument2 pagesBaseline Schedule Review Check List - Control DivisionMaulik RavalPas encore d'évaluation

- Quantity Surveyor Job DescriptionDocument1 pageQuantity Surveyor Job DescriptionfreannPas encore d'évaluation

- Construction Planning & ManagementDocument39 pagesConstruction Planning & ManagementAnkur SrivastavaPas encore d'évaluation

- Sample CloseoutDocument6 pagesSample CloseoutArpita GuptaPas encore d'évaluation

- Itp - Rebar & Concrete-UploadDocument4 pagesItp - Rebar & Concrete-UploadMohammad Arif RasheedPas encore d'évaluation

- MTU-DRL-CON-011-2018: Project: Client: ContractorDocument3 pagesMTU-DRL-CON-011-2018: Project: Client: ContractorSaddem HadfiPas encore d'évaluation

- What Is The Best Way To Adjust or Get Rid of Negative Float in Primavera P6Document2 pagesWhat Is The Best Way To Adjust or Get Rid of Negative Float in Primavera P6Mohammed AmjadPas encore d'évaluation

- Supplier RegisterDocument12 pagesSupplier RegisterBeauty MurewaPas encore d'évaluation

- A. Gis and SWGR: 1. Precast Beam and Wall Panel Erection GIS 2. Hollow Core Slab InstallationDocument4 pagesA. Gis and SWGR: 1. Precast Beam and Wall Panel Erection GIS 2. Hollow Core Slab InstallationSyed Munawar Ali100% (1)

- Revised Standard Data For ElectrificationDocument120 pagesRevised Standard Data For Electrificationsrikanth0483287Pas encore d'évaluation

- Construction Phase Progress: Progrees Status Report As of 28Th January 2018Document2 pagesConstruction Phase Progress: Progrees Status Report As of 28Th January 2018Athambawa RameesPas encore d'évaluation

- Free Change Log Template ProjectManager WLNKDocument8 pagesFree Change Log Template ProjectManager WLNKbtbowmanPas encore d'évaluation

- Mep Planning Engineer TCR - JDDocument4 pagesMep Planning Engineer TCR - JDclaudelgoPas encore d'évaluation

- CV of Haseeb (Quantity Surveyor or Estimator)Document4 pagesCV of Haseeb (Quantity Surveyor or Estimator)Amzal Ahamed100% (1)

- 7 - SBI BC ManualDocument24 pages7 - SBI BC ManualVisas SivaPas encore d'évaluation

- Proposal and Questionnaire For Contractor'sDocument6 pagesProposal and Questionnaire For Contractor'sVisas SivaPas encore d'évaluation

- Proposal For Contractor'S Plant & Machinery InsuranceDocument5 pagesProposal For Contractor'S Plant & Machinery InsuranceVisas SivaPas encore d'évaluation

- ContractorDocument6 pagesContractorVisas SivaPas encore d'évaluation

- Conditional FormattingDocument5 pagesConditional FormattingVisas SivaPas encore d'évaluation

- PilDocument2 pagesPilVisas SivaPas encore d'évaluation

- Proposal and Questionnaire For Erection All Risks/Marine-Cum-Erection InsuranceDocument5 pagesProposal and Questionnaire For Erection All Risks/Marine-Cum-Erection InsuranceVisas SivaPas encore d'évaluation

- EmployeeDocument4 pagesEmployeeVisas SivaPas encore d'évaluation

- PliDocument2 pagesPliVisas SivaPas encore d'évaluation

- Proposal For Standard Fire & Special Perils PolicyDocument6 pagesProposal For Standard Fire & Special Perils PolicyVisas SivaPas encore d'évaluation

- WCPDocument4 pagesWCPVisas SivaPas encore d'évaluation

- Proposal For Contractor'S Plant & Machinery InsuranceDocument5 pagesProposal For Contractor'S Plant & Machinery InsuranceVisas SivaPas encore d'évaluation

- 5-Project Summary and Description TemplateDocument23 pages5-Project Summary and Description TemplateVisas SivaPas encore d'évaluation

- Weight CalculatorDocument6 pagesWeight CalculatorSaurabhPas encore d'évaluation

- BurglaryDocument5 pagesBurglaryVisas SivaPas encore d'évaluation

- Car 1Document6 pagesCar 1Visas SivaPas encore d'évaluation

- Two Year Calendar 2014 2015 Landscape in ColorDocument1 pageTwo Year Calendar 2014 2015 Landscape in ColorVisas SivaPas encore d'évaluation

- Comment Resolution SheetDocument1 pageComment Resolution SheetVisas SivaPas encore d'évaluation

- CRNDocument6 pagesCRNVisas SivaPas encore d'évaluation

- Meeting AgendaDocument3 pagesMeeting AgendaVisas SivaPas encore d'évaluation

- MD PV ASME v0.1Document35 pagesMD PV ASME v0.1Visas SivaPas encore d'évaluation

- Carbon Steel Storage TanksDocument1 pageCarbon Steel Storage TanksVisas SivaPas encore d'évaluation

- Comment Resolution SheetDocument1 pageComment Resolution SheetVisas SivaPas encore d'évaluation

- 5-Project Summary and Description TemplateDocument23 pages5-Project Summary and Description TemplateVisas SivaPas encore d'évaluation

- PlanningDocument67 pagesPlanningVisas SivaPas encore d'évaluation

- Herbal Medicines Compendium - Pelargonium Sidoides Root - 2013-07-26Document3 pagesHerbal Medicines Compendium - Pelargonium Sidoides Root - 2013-07-26xumbalPas encore d'évaluation

- Webquest - Genetics AnswersDocument2 pagesWebquest - Genetics AnswersSomeonePas encore d'évaluation

- Growing Temperate Fruit Trees in KenyaDocument138 pagesGrowing Temperate Fruit Trees in KenyanonimugoPas encore d'évaluation

- Workbook AnswersDocument16 pagesWorkbook AnswersNoelia UnamunoPas encore d'évaluation

- Elementary Statistics 9th Edition Weiss Solutions ManualDocument24 pagesElementary Statistics 9th Edition Weiss Solutions ManualDustinMahoneyidbj100% (27)

- FAMILY Amborellaceae AmborellaDocument4 pagesFAMILY Amborellaceae AmborellabibohkidPas encore d'évaluation

- Open LetterDocument24 pagesOpen LetterN D Senthil RamPas encore d'évaluation

- Bamboo Bending - Types and TechniquesDocument14 pagesBamboo Bending - Types and TechniquesM Sachet KiranPas encore d'évaluation

- Statistics Assignment - 2-3Document7 pagesStatistics Assignment - 2-3NavinPas encore d'évaluation

- Presentation EIL Project by JMV LPSDocument59 pagesPresentation EIL Project by JMV LPSMahesh Chandra ManavPas encore d'évaluation

- Objective Type Questions For Power System Operation and Control Final YearDocument110 pagesObjective Type Questions For Power System Operation and Control Final YearSree LekhaPas encore d'évaluation

- PD 953Document4 pagesPD 953Lloyl MonteroPas encore d'évaluation

- Etiología Del Chile HabaneroDocument12 pagesEtiología Del Chile Habaneronadia landeroPas encore d'évaluation

- Adulteration and Evaluation of Crude DrugsDocument48 pagesAdulteration and Evaluation of Crude DrugsVikash KushwahaPas encore d'évaluation

- Dynamech Quotation 100 KG - HR Potato Chips Plant Full AutoDocument12 pagesDynamech Quotation 100 KG - HR Potato Chips Plant Full AutoDhivyanthPas encore d'évaluation

- ReferanceDocument5 pagesReferanceRukshana Amin SonetPas encore d'évaluation

- Flora &faunaDocument2 pagesFlora &faunarajesh0005Pas encore d'évaluation

- William Knight 1897Document20 pagesWilliam Knight 1897Norman MaiPas encore d'évaluation

- Fourth Periodic Test English Grade 7Document4 pagesFourth Periodic Test English Grade 7Gemma BanggocPas encore d'évaluation

- Sri LankaDocument68 pagesSri Lankancaluhewa100% (2)