Académique Documents

Professionnel Documents

Culture Documents

Repair GI Coating

Transféré par

cashlover0 évaluation0% ont trouvé ce document utile (0 vote)

126 vues2 pagesProcedures to Repair GI Coating

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentProcedures to Repair GI Coating

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

126 vues2 pagesRepair GI Coating

Transféré par

cashloverProcedures to Repair GI Coating

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 2

REPAIR OF GALVANIZED COATINGS

When hot dip galvanized coatings are damaged by cutting or

welding, it is recommended that the uncoated areas are repaired.

There are a number of repair methods that are available and the

galvanizing industry has used and evaluated a wide range of products

for over 35 years.

There are a number of factors that have to be considered when

repairing hot dip galvanized coatings. These are:

the size of the area to be repaired

the ease of use of the repair material

the performance of the repair method with respect to the required

performance of the hot dip galvanized coating.

Blow-out from over lapping area on this fabrication

has caused a galvanized coating defect.

ZINC RICH PAINT REPAIR

Jotun Protective Coatings products are recommended by the

Industrial Galvanizers Australian Galvanizing Division.

For standard duty applications, Jotun Galvanite, a one-pack, airdrying zinc-rich primer can be used. The single pack system has good

adhesion to prepared surfaces and can be handled after 2 hours (at

20oC). Coating thickness per coat is typically 45 microns and two

coats are required to ensure compatible coating thickness to the hot

dip galvanized coatings.

Surface to be repaired is cleaned by wire brushing.

Jotuns Barrier two-pack epoxy zinc rich system is recommended for

heavy-duty applications and full coating reinstatement. The two-pack

system is touch dry in 15 minutes and hard dry in less than 2 hours at

20oC. Two coats at 45 microns each are recommended to provide

equivalent coatings thickness to hot dip galvanizing.

The recommended procedure for touch-up is as follows:

1. Power tool clean to Australian Standard 1627:2 Class 3 to remove

all welding scale, slag and corrosion products.

2. Degrease and remove all surface oil, grease or soil. (This step can

be omitted on new welds where no organic contamination of the

exposed steel has occurred.)

3. Apply two coats of Galvanite or Barrier to a minimum dry film

thickness of 85 microns.

4. Observe good painting practice with respect to weather condition

and application conditions. Ensure that the steel surface is above Dew

Point prior to application. If below the Dew Point, warm area to

ensure surface dryness

Approved epoxy-based zinc-rich paint is applied to

the uncoated area to at least equivalent thickness to

the galvanized coating.

5. Adhere to coating manufacturers product data sheets for safety,

mixing, pot life, application, overcoating and curing information.

6. If a close colour match is essential, apply a light coat of aluminium

paint over repair area after drying. Rub over aluminium paint with a

soft rag before drying to blend the repair into the surrounding

galvanized coating appearance. NOTE: The aluminium paint is NOT

an anti- corrosive coating and does not contribute to the performance

of the repair.

METALLIC REPAIR COATINGS

There are various types of metallic repair materials available in the

form of alloy `sticks which are applied by heating the area to be

repaired and melting the repair material onto the area. Early repair

sticks had a high lead content and did not reflect the characteristics of

a galvanized coating.

Cominco of Canada has developed its Galvaguard repair alloy that

has a high zinc content and is easier to use than previous repair

alloys.

These repair alloys are best used for repairing welds and similar

small areas on horizontal surfaces, that can be easily and quickly

heated . A higher level of operator skill is required to effect

successful repairs using Galvaguard or similar products. Some of

these products contain high levels of tin or lead. They are difficult to

apply in other than down-hand positions.

Zinc metal spray is an effective repair method for larger areas, as it

will apply a zinc coating of any required thickness. However,

successful application requires a high quality surface preparation

(Class 3) to ensure good adhesion. Specialised equipment and skilled

operators are required to apply zinc metal spray coatings, but they

provide a high quality repair solution where larger areas of the item

have not been galvanized due to design constraints.

Vous aimerez peut-être aussi

- Weld Like a Pro: Beginning to Advanced TechniquesD'EverandWeld Like a Pro: Beginning to Advanced TechniquesÉvaluation : 4.5 sur 5 étoiles4.5/5 (6)

- Water-Based Paint Formulations, Vol. 3D'EverandWater-Based Paint Formulations, Vol. 3Évaluation : 4.5 sur 5 étoiles4.5/5 (6)

- Repairing Damaged Hot-Dip Galvanized Steel With Zinc-Rich Paint, Zinc MetallDocument4 pagesRepairing Damaged Hot-Dip Galvanized Steel With Zinc-Rich Paint, Zinc MetallMJK008100% (1)

- Your Home Inspected: An Addendum for Residential Home Inspection ReportsD'EverandYour Home Inspected: An Addendum for Residential Home Inspection ReportsPas encore d'évaluation

- Paint Guide For GI SteelDocument12 pagesPaint Guide For GI SteelDiLungBanPas encore d'évaluation

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionD'EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionPas encore d'évaluation

- Astm A780Document4 pagesAstm A780Raúl Venegas Munita100% (5)

- Distillation Column ReportDocument81 pagesDistillation Column ReportJaspreet Singh67% (9)

- Astm A860Document5 pagesAstm A860Marcelo ColomboPas encore d'évaluation

- The Haram Emulsifier CodeDocument18 pagesThe Haram Emulsifier Codelarnz81% (21)

- GEOMETDocument4 pagesGEOMETtoyota952Pas encore d'évaluation

- Surface Prepairation STD For PC ASTM D6386Document4 pagesSurface Prepairation STD For PC ASTM D6386Rohit SangwanPas encore d'évaluation

- Four Key Characteristics of Coatings for Exposed Structural SteelDocument4 pagesFour Key Characteristics of Coatings for Exposed Structural SteelUsama Awad100% (1)

- ASTM A780A780M - 09 (Reapproved 2015) Standard Practice For Repair of Damaged and Uncoated Areas of Hot-Dip Galvanized Coatings1Document4 pagesASTM A780A780M - 09 (Reapproved 2015) Standard Practice For Repair of Damaged and Uncoated Areas of Hot-Dip Galvanized Coatings1Thomas Farfan100% (2)

- Hot Dip Galvanized CoatingDocument28 pagesHot Dip Galvanized CoatingOci Rizal100% (6)

- Corrosion Testing for Metal Finishing: Institute of Metal FinishingD'EverandCorrosion Testing for Metal Finishing: Institute of Metal FinishingPas encore d'évaluation

- Military Plating Spec-1Document11 pagesMilitary Plating Spec-1Durbha RaviPas encore d'évaluation

- Corrosion Swimming)Document6 pagesCorrosion Swimming)skenny1Pas encore d'évaluation

- PaintingSpecifications T 8567 PDFDocument7 pagesPaintingSpecifications T 8567 PDFRaed ThakurPas encore d'évaluation

- Interzinc 52: Epoxy Zinc-RichDocument4 pagesInterzinc 52: Epoxy Zinc-RichKrishna VachaPas encore d'évaluation

- How to use hydrogen peroxide to prevent root rot and overwatering in hydroponics and soil gardensDocument9 pagesHow to use hydrogen peroxide to prevent root rot and overwatering in hydroponics and soil gardensgennoxydPas encore d'évaluation

- Types & Procedures: Internal Tank Linings & CoatingsDocument22 pagesTypes & Procedures: Internal Tank Linings & CoatingsAhmed100% (1)

- Repair of Damages in Zinc LayersDocument4 pagesRepair of Damages in Zinc LayersBobPas encore d'évaluation

- SherardizingDocument2 pagesSherardizingRichard HockleyPas encore d'évaluation

- Additional Information On SWEEP Sandblast Cleaning - For-Galvanized Steel - INDUSTRIALDocument3 pagesAdditional Information On SWEEP Sandblast Cleaning - For-Galvanized Steel - INDUSTRIALro snPas encore d'évaluation

- Interzinc 52Document4 pagesInterzinc 52mirzaaliPas encore d'évaluation

- Renovate Galvanized SteelDocument1 pageRenovate Galvanized SteelSam SamuelsonPas encore d'évaluation

- ASTM A780 v1Document1 pageASTM A780 v1Enzo GacitúaPas encore d'évaluation

- Zinc Rich PrimerDocument2 pagesZinc Rich PrimerAhmad ElghazolyPas encore d'évaluation

- T Crib 0063 WDocument3 pagesT Crib 0063 WHytam carPas encore d'évaluation

- A 780Document3 pagesA 780Gustavo SuarezPas encore d'évaluation

- Interzinc 22 Series: Rapid Re-Coat Zinc Silicate TechnologyDocument2 pagesInterzinc 22 Series: Rapid Re-Coat Zinc Silicate TechnologyAnindya Aulia PratiwiPas encore d'évaluation

- Barrier 77: Technical Data Sheet Application GuideDocument8 pagesBarrier 77: Technical Data Sheet Application GuideNurmalinda SihombingPas encore d'évaluation

- Barrier 65: Technical Data Sheet Application GuideDocument8 pagesBarrier 65: Technical Data Sheet Application Guidesabari ramasamyPas encore d'évaluation

- Technical Data Sheet Application GuideDocument8 pagesTechnical Data Sheet Application GuideAyman JadPas encore d'évaluation

- Application Jotamastic 90 AlDocument13 pagesApplication Jotamastic 90 Aladitya kristantoPas encore d'évaluation

- Screenshot 2023-05-20 at 14.51.58Document8 pagesScreenshot 2023-05-20 at 14.51.58morisPas encore d'évaluation

- COLD GALVANISING Spray - GBDocument2 pagesCOLD GALVANISING Spray - GBANIL PLAMOOTTILPas encore d'évaluation

- 3M2216Document8 pages3M2216pat_kunal1601Pas encore d'évaluation

- CH 01.07 Galvin SteelDocument5 pagesCH 01.07 Galvin Steelkhairul ardyPas encore d'évaluation

- GalvInfoNote - 2 - 1 The Continuous Hot-Dip Coating Process For Steel Sheet ProductsDocument4 pagesGalvInfoNote - 2 - 1 The Continuous Hot-Dip Coating Process For Steel Sheet ProductsKYAW SOEPas encore d'évaluation

- Motor PaintingDocument6 pagesMotor PaintingImran BagwanPas encore d'évaluation

- Barrier: Technical Data Sheet Application GuideDocument8 pagesBarrier: Technical Data Sheet Application GuideNurmalinda SihombingPas encore d'évaluation

- Standard Specification For Hot Dip GalvanizingDocument4 pagesStandard Specification For Hot Dip GalvanizingNuzul Furqony100% (1)

- Information On GI PaintingDocument5 pagesInformation On GI PaintingPavan SharmaPas encore d'évaluation

- Barrier 77 PDFDocument8 pagesBarrier 77 PDFRizki AhmadPas encore d'évaluation

- Barrier Smart Pack: Technical Data Sheet Application GuideDocument9 pagesBarrier Smart Pack: Technical Data Sheet Application GuideLia Susanti MciPas encore d'évaluation

- Tankguard PlusDocument11 pagesTankguard PlusAbrar HussainPas encore d'évaluation

- B_Introduction to Coating_2023_Period 6Document61 pagesB_Introduction to Coating_2023_Period 6asePas encore d'évaluation

- Zinc Rich Paints Manufacturers in Vadodara Gujarat IndiaDocument2 pagesZinc Rich Paints Manufacturers in Vadodara Gujarat IndiaRudra ShivaPas encore d'évaluation

- AG 2521 Barrier Euk GBDocument9 pagesAG 2521 Barrier Euk GBDoni RandanuPas encore d'évaluation

- Barrier: Technical Data Sheet Application GuideDocument8 pagesBarrier: Technical Data Sheet Application GuideANIBALLOPEZVEGAPas encore d'évaluation

- Aliphatic Acrylic Polyurethane Finish CoatDocument4 pagesAliphatic Acrylic Polyurethane Finish CoatDexter R. RoquePas encore d'évaluation

- Penguard Express Application GuideDocument10 pagesPenguard Express Application GuidenizamuddinPas encore d'évaluation

- Investigate Surface Treatments Early for Optimal DesignDocument5 pagesInvestigate Surface Treatments Early for Optimal Designraghukk1988Pas encore d'évaluation

- Penguard Mio Application GuideDocument9 pagesPenguard Mio Application Guidenachi100Pas encore d'évaluation

- Fire Sprinkler Pipe Painting GuideDocument5 pagesFire Sprinkler Pipe Painting Guideareef007Pas encore d'évaluation

- Galvanizing Fundamentals and ProcessDocument95 pagesGalvanizing Fundamentals and Processazerai2000Pas encore d'évaluation

- Weicon Zinc Spray - Bright Grade TDSDocument2 pagesWeicon Zinc Spray - Bright Grade TDSshoaib1985Pas encore d'évaluation

- Surface Protection External Coating of Claas ProductsDocument1 pageSurface Protection External Coating of Claas ProductsTomaszPas encore d'évaluation

- Interzinc 22: Inorganic Zinc-Rich SilicateDocument4 pagesInterzinc 22: Inorganic Zinc-Rich SilicateKristi FoxPas encore d'évaluation

- The Art of Lead Burning: A practical treatise explaining the apparatus and processesD'EverandThe Art of Lead Burning: A practical treatise explaining the apparatus and processesPas encore d'évaluation

- The Saudi-UAE Alliance Turns Sour: Fraught HistoryDocument5 pagesThe Saudi-UAE Alliance Turns Sour: Fraught HistorycashloverPas encore d'évaluation

- What's at Stake in Cuba's Protests: Depends On Foreign PatronsDocument6 pagesWhat's at Stake in Cuba's Protests: Depends On Foreign PatronscashloverPas encore d'évaluation

- The Trouble With China's Tech Titans: Slapped DownDocument4 pagesThe Trouble With China's Tech Titans: Slapped DowncashloverPas encore d'évaluation

- A New Reality Emerges in Afghanistan Geopoliticalfutures ComDocument6 pagesA New Reality Emerges in Afghanistan Geopoliticalfutures ComcashloverPas encore d'évaluation

- Killer Facebook: by George Friedman - July 21, 2021Document5 pagesKiller Facebook: by George Friedman - July 21, 2021cashloverPas encore d'évaluation

- Facing Reality A New American Strategy Geopoliticalfutures ComDocument15 pagesFacing Reality A New American Strategy Geopoliticalfutures ComcashloverPas encore d'évaluation

- The Nagging Question in The Indo-Pacific: A Festering WoundDocument6 pagesThe Nagging Question in The Indo-Pacific: A Festering WoundyerytPas encore d'évaluation

- COVID and CarsDocument3 pagesCOVID and CarscashloverPas encore d'évaluation

- The Next Israel-Hezbollah War - Geopolitical FuturesDocument6 pagesThe Next Israel-Hezbollah War - Geopolitical FuturescashloverPas encore d'évaluation

- David, Goliath and Modern Warfare: The Life Cycle of Weapons SystemsDocument4 pagesDavid, Goliath and Modern Warfare: The Life Cycle of Weapons SystemscashloverPas encore d'évaluation

- Forecasting and Living: The Storm Before The CalmDocument3 pagesForecasting and Living: The Storm Before The CalmcashloverPas encore d'évaluation

- Why Australia Spurned France: by George Friedman - September 20, 2021Document3 pagesWhy Australia Spurned France: by George Friedman - September 20, 2021cashloverPas encore d'évaluation

- China Faces A Divided Front in EuropeDocument10 pagesChina Faces A Divided Front in EuropecashloverPas encore d'évaluation

- Jordans Perennial Quest For Survival Geopoliticalfutures ComDocument4 pagesJordans Perennial Quest For Survival Geopoliticalfutures ComcashloverPas encore d'évaluation

- David, Goliath and Modern Warfare: The Life Cycle of Weapons SystemsDocument4 pagesDavid, Goliath and Modern Warfare: The Life Cycle of Weapons SystemscashloverPas encore d'évaluation

- Jordans Perennial Quest For Survival Geopoliticalfutures ComDocument4 pagesJordans Perennial Quest For Survival Geopoliticalfutures ComcashloverPas encore d'évaluation

- Control of InfrastructureDocument3 pagesControl of InfrastructurecashloverPas encore d'évaluation

- Brazil - A Bad Year Could Get WorseDocument8 pagesBrazil - A Bad Year Could Get WorsecashloverPas encore d'évaluation

- The Geopolitics of Heartbreak Geopoliticalfutures ComDocument3 pagesThe Geopolitics of Heartbreak Geopoliticalfutures ComcashloverPas encore d'évaluation

- COVID and CarsDocument3 pagesCOVID and CarscashloverPas encore d'évaluation

- COVID and CarsDocument3 pagesCOVID and CarscashloverPas encore d'évaluation

- Identification, Traceability and Preservation of Material, Equipment and WorkDocument5 pagesIdentification, Traceability and Preservation of Material, Equipment and WorkcashloverPas encore d'évaluation

- Inspection and Testing: Working ProcedureDocument4 pagesInspection and Testing: Working ProcedurecashloverPas encore d'évaluation

- COVID and CarsDocument3 pagesCOVID and CarscashloverPas encore d'évaluation

- The Geopolitics of Heartbreak Geopoliticalfutures ComDocument3 pagesThe Geopolitics of Heartbreak Geopoliticalfutures ComcashloverPas encore d'évaluation

- Control of Nonconformities: Working ProcedureDocument4 pagesControl of Nonconformities: Working ProcedurecashloverPas encore d'évaluation

- Us Withdrawal From The Middle East Geopoliticalfutures ComDocument4 pagesUs Withdrawal From The Middle East Geopoliticalfutures ComcashloverPas encore d'évaluation

- 3 2 3Document62 pages3 2 3AlexanderLinaresPas encore d'évaluation

- IIHF Ice Rink Guide Web PDFDocument108 pagesIIHF Ice Rink Guide Web PDFVlad BalanPas encore d'évaluation

- Typ-Sand-Base-Rink DWG-PKG PDFDocument96 pagesTyp-Sand-Base-Rink DWG-PKG PDFcashloverPas encore d'évaluation

- RSC Advances: ReviewDocument20 pagesRSC Advances: ReviewGabrielPas encore d'évaluation

- Analisis Lemak & Minyak: By. Mulono ApriyantoDocument47 pagesAnalisis Lemak & Minyak: By. Mulono ApriyantoSalsabila NurPas encore d'évaluation

- Electrochemistry: 0 8 0 79 0 34 2 37 Ag / Ag - HG / HG - Cu / Cu - MG / MGDocument11 pagesElectrochemistry: 0 8 0 79 0 34 2 37 Ag / Ag - HG / HG - Cu / Cu - MG / MGAnikin Skywalker100% (1)

- Chemical Composition of Callisia Fragrans Juice 1. Phenolic CompoundsDocument2 pagesChemical Composition of Callisia Fragrans Juice 1. Phenolic CompoundsLeTienDungPas encore d'évaluation

- ESAB 308L, 316L & 309L Plus Stainless Steel ElectrodesDocument1 pageESAB 308L, 316L & 309L Plus Stainless Steel Electrodesanupmenon menonPas encore d'évaluation

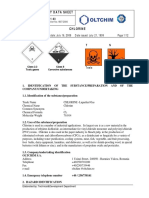

- Msds Cl2Document12 pagesMsds Cl2Ganjar Tri Gita AzhariPas encore d'évaluation

- Experiment 4Document12 pagesExperiment 4Doğukan Aybars ÖztürkPas encore d'évaluation

- Bai Tap Chuong EquilibriumDocument3 pagesBai Tap Chuong EquilibriumHUY NGUYỄN PHƯƠNG PHÚC100% (1)

- Fabrication (Metal Joining) : Ravishankar M D 17EME14 Elements of Mechanical EngineeringDocument18 pagesFabrication (Metal Joining) : Ravishankar M D 17EME14 Elements of Mechanical EngineeringSatish HSPas encore d'évaluation

- 677 Aluminium Products Brochure E4Document2 pages677 Aluminium Products Brochure E4MeteusPas encore d'évaluation

- Astm B488 (23.10.2019)Document8 pagesAstm B488 (23.10.2019)CK TehPas encore d'évaluation

- 3Cps5Nos13 17Document59 pages3Cps5Nos13 17Rafael DirainPas encore d'évaluation

- Chromite Mineral DataDocument20 pagesChromite Mineral DatamodikiritPas encore d'évaluation

- Important Points About Introduction of Analytical ChemistryDocument9 pagesImportant Points About Introduction of Analytical ChemistryMohammed AlherbawiPas encore d'évaluation

- 5 Centrifuge Tubes Evaporating Dish Test Tube Holder Crucible Tongs Two Droppers Latex Gloves LabelsDocument16 pages5 Centrifuge Tubes Evaporating Dish Test Tube Holder Crucible Tongs Two Droppers Latex Gloves LabelsMatti MendozaPas encore d'évaluation

- Final Touch (RCC Do / Die Questions) Chapter: S-BlockDocument13 pagesFinal Touch (RCC Do / Die Questions) Chapter: S-Blockharita shindePas encore d'évaluation

- Acids 1Document22 pagesAcids 1Pratima JainPas encore d'évaluation

- PGDIRI Syllabus PDFDocument11 pagesPGDIRI Syllabus PDFVinod KumarPas encore d'évaluation

- Report MIG WeldingDocument12 pagesReport MIG Weldingyuwaraja0% (2)

- Activity 4 - Flame Test For Metal - CRUZ ARJAYDocument5 pagesActivity 4 - Flame Test For Metal - CRUZ ARJAYArjay Francisco CruzPas encore d'évaluation

- Standard Specification For: ScopeDocument2 pagesStandard Specification For: Scopedong ganPas encore d'évaluation

- DDS Plus Railroad Engine Oils: Tier IV - 11BNDocument2 pagesDDS Plus Railroad Engine Oils: Tier IV - 11BNMarcelo ViscardiPas encore d'évaluation

- Anaerobic Digestion of Wastewater Sludge: (Nazaroff & Alvarez-Cohen, Section 6.E.3)Document7 pagesAnaerobic Digestion of Wastewater Sludge: (Nazaroff & Alvarez-Cohen, Section 6.E.3)syafiqzainordinPas encore d'évaluation

- Chemistry Investigatory Project - KaranDocument10 pagesChemistry Investigatory Project - KaranKaran RathorePas encore d'évaluation

- Classification and Nomenclature of Organic CompoundsDocument15 pagesClassification and Nomenclature of Organic CompoundsМария МановаPas encore d'évaluation

- Ficha Tecnica NordelDocument2 pagesFicha Tecnica NordelStephany HernándezPas encore d'évaluation